Full-automatic watering vehicle

A fully automatic, wheel-based technology, applied to watering devices, gardening, botanical equipment and methods, etc., can solve the problems of time-consuming, labor-intensive watering vehicles, water consumption, etc., and achieve convenient operation, complete functions, and energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

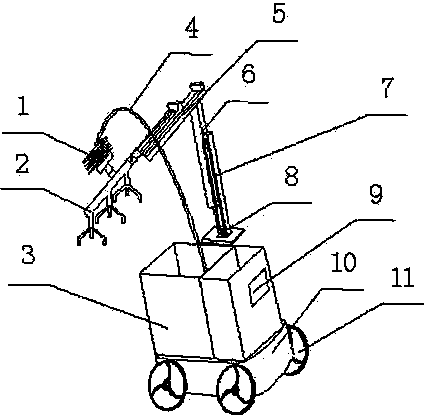

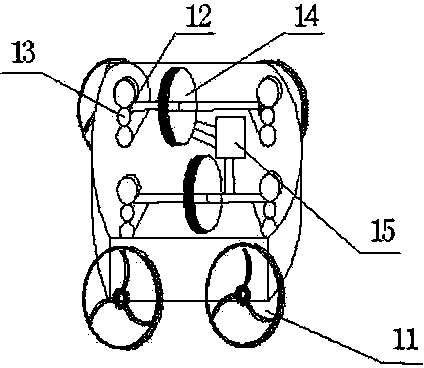

[0018] Further illustrate the present invention below in conjunction with accompanying drawing.

[0019] A fully automatic watering vehicle, characterized in that a water storage tank 3 and a locker are arranged above the lower body 10, the water storage tank 3 and the locker are arranged side by side, and a controller 9 is arranged on the locker, and the controller 9 is connected with the locker respectively. The horizontal telescopic assembly 5, the vertical telescopic assembly 6 and the presser 1 are connected, the vertical telescopic assembly 6 is arranged on the side of the water storage tank 3, a chain 7 is installed on the telescopic rod of the vertical telescopic assembly 6, and the chain 7 is driven by a motor 8, The motor 8 can carry out positive and negative rotation, and drives the chain 7 to perform positive and negative rotation, so as to realize the vertical expansion and contraction of the vertical telescopic assembly 6. The horizontal expansion assembly 5 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com