Colorful LED-UV glass coating and preparation method thereof

A technology of LED-UV and glass coatings, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc. Focus on problems such as strength, to achieve the effect of resistance to organic solvents, high adhesion, and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

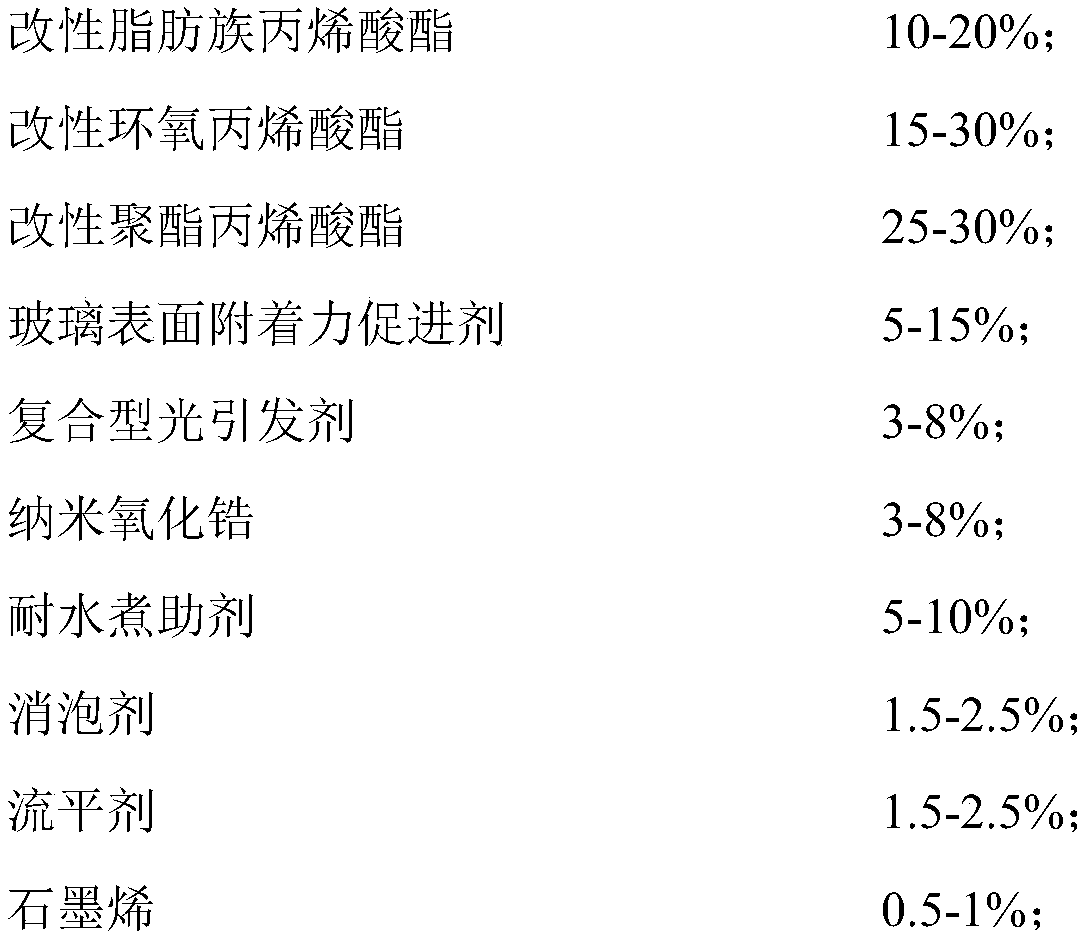

[0040] A kind of colored LED-UV glass paint, is made up of adding pigment and thinner by the raw material of following percentage by weight:

[0041]

[0042]

[0043] Among them, the composite photoinitiator is a mixture of photoinitiator 819, photoinitiator 907 and photoinitiator ITX, with a mass ratio of 1:1:1.

[0044] Its preparation method is:

[0045] Modified aliphatic acrylate, modified epoxy acrylate, modified polyester acrylate, glass surface adhesion promoter, composite photoinitiator, graphene, nano-zirconia, pigment, water boiling additive, dilution Put the agent, defoamer and leveling agent into the container in turn, stir and grind to get the colored LED-UV glass coating.

Embodiment 2

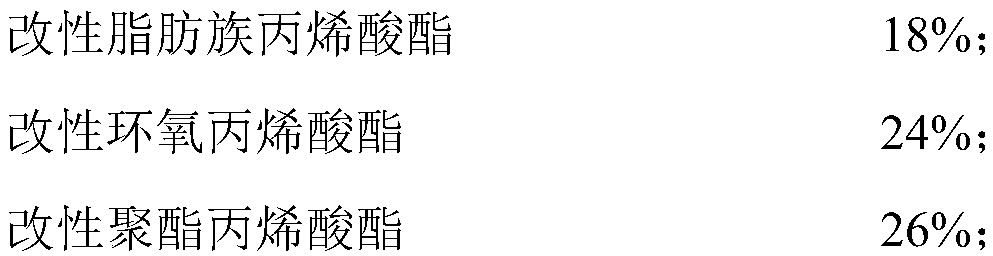

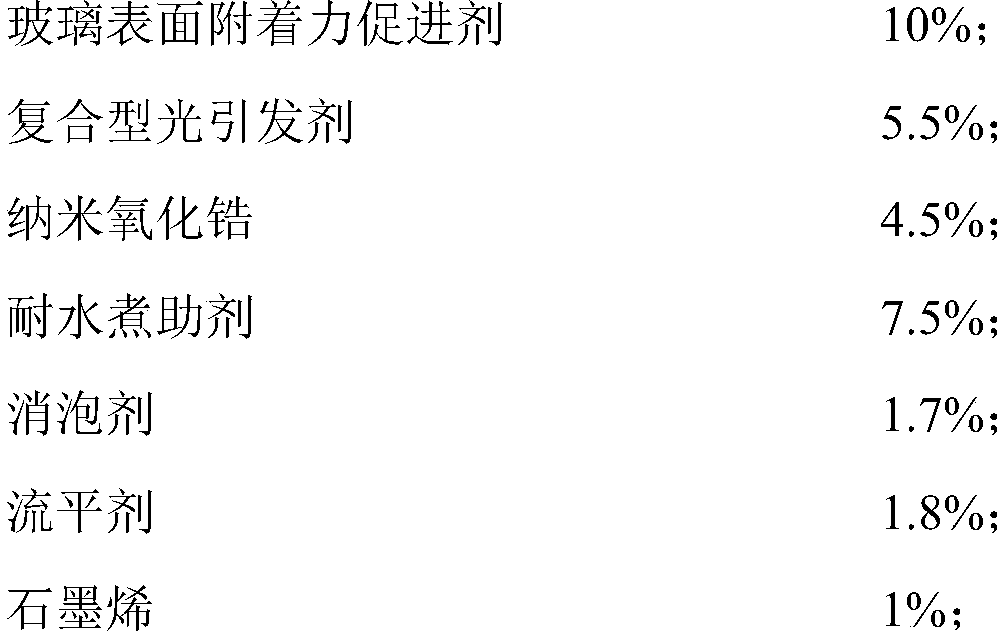

[0047] A kind of colored LED-UV glass paint, is made up of adding pigment and thinner by the raw material of following percentage by weight:

[0048]

[0049] Among them, the composite photoinitiator is a mixture of photoinitiator 819, photoinitiator 907, photoinitiator ITX and photoinitiator 369, with a mass ratio of 1:2:2:1.

[0050] Its preparation method is with embodiment 1.

Embodiment 3

[0052] A kind of colored LED-UV glass paint, is made up of adding pigment and thinner by the raw material of following percentage by weight:

[0053]

[0054] Among them, the composite photoinitiator is a mixture of photoinitiator 819, photoinitiator 907, photoinitiator ITX, photoinitiator 369, photoinitiator BDK and photoinitiator TPO, with a mass ratio of 1:3:2:2: 1:3.

[0055] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com