Multi-layer special-material integrated pipe and manufacturing technique thereof

A manufacturing process and integrated tube technology, which is applied to the multi-layer dissimilar material integrated integrated tube and its manufacturing process field, can solve the problems of high manufacturing difficulty, low temperature difference environment function, large traffic resistance, etc., and achieves easy integrated manufacturing and simple product structure. , The effect of convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

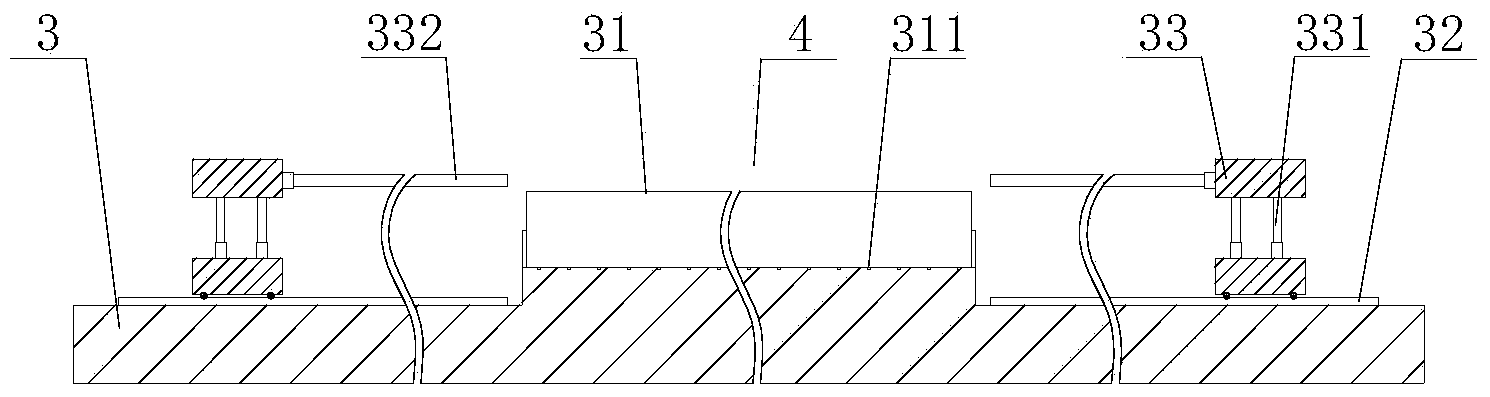

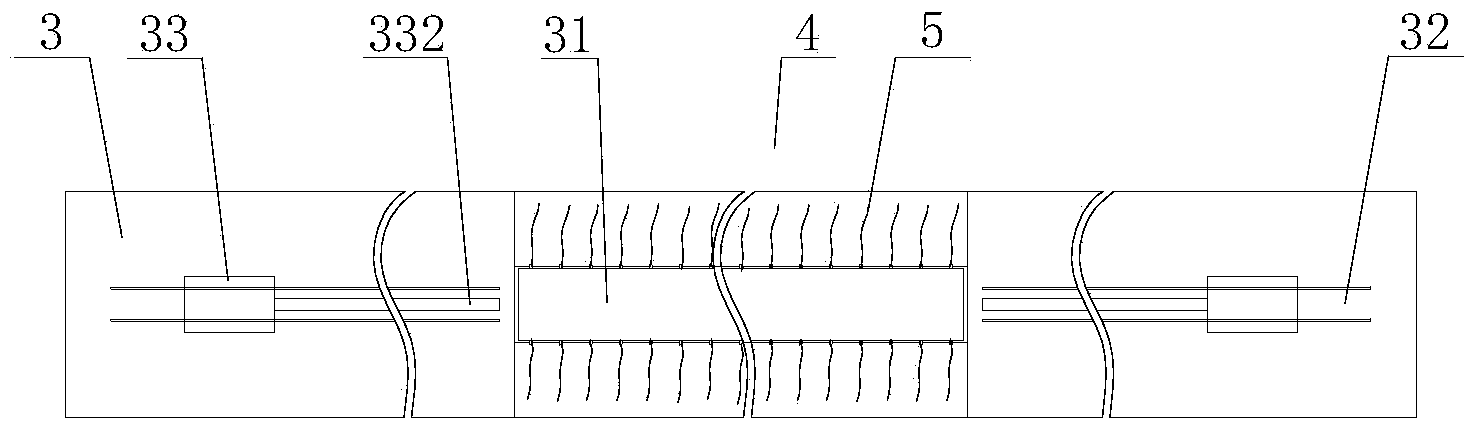

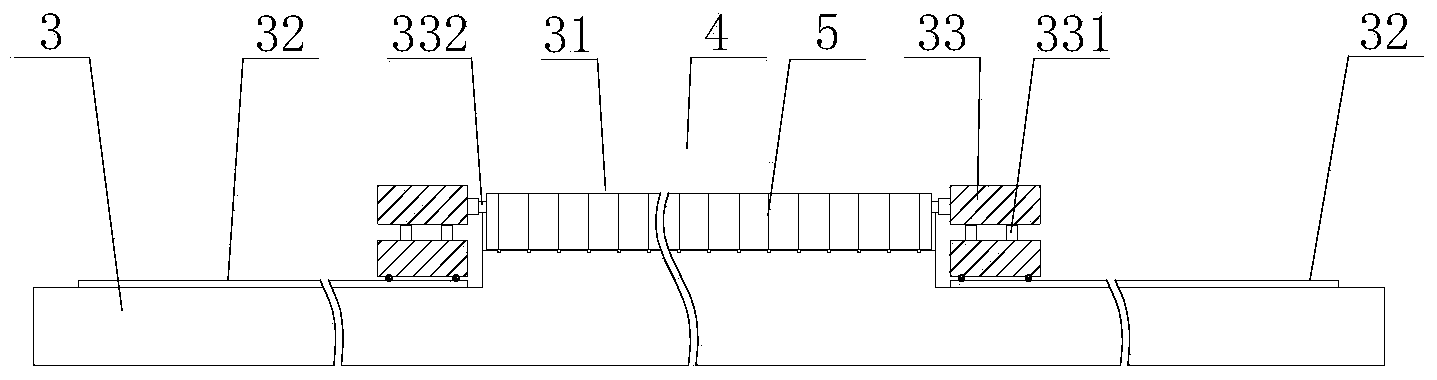

[0081] In conjunction with the accompanying drawings, a multi-layer heterogeneous material integrated integrated pipe, which includes an outer layer mother pipe 1 and an inner layer son pipe 2, the mother pipe 1 is made online or prefabricated, and the daughter pipe 2 is first fabricated on-line A layer of green body 23, the green body 23 is inserted into the inner cavity of the heating mother pipe 1 after being deformed to form a whole. The main online production process is as follows:

[0082] A. Sub-pipe online production

[0083] (1) Sub-pipe-on-line billet making

[0084] ①, solid rubber particles, plastic resin blending and mixing-drying and mixing equipment;

[0085] ②, double-layer co-extrusion-extrusion and co-extrusion molds and equipment;

[0086] ③. Vacuum sizing dn tolerance control - sizing mold, vacuum equipment;

[0087] ④, cooling - spray equipment;

[0088] ⑤ Traction-traction equipment;

[0089] ⑥, fixed-length cutting-cutting equipment;

[0090] ⑦. Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com