A wave-absorbing and heat-generating coating for melting ice of wind power blades and its preparation method

A technology for wind power blades and ice melting, applied in coatings, wind power generation, coatings that absorb radiation, etc., can solve the problems of destroying blade surface streamlines, inability to actively remove ice, and high cost of deicing, and achieve strong microwave absorption and adhesion. Strong focus and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

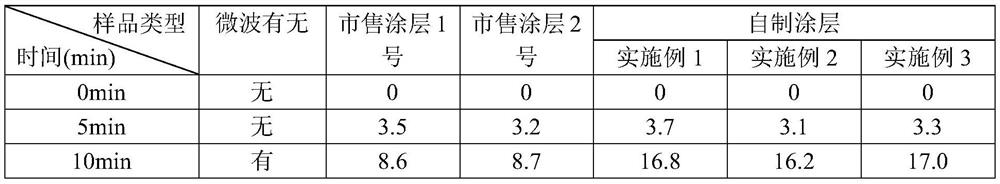

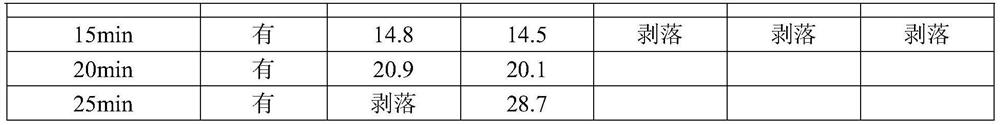

Examples

preparation example Construction

[0028] The preparation method of above-mentioned surface coating is:

[0029] The preparation method of the coating bottom layer is to mix and stir methylphenyl silicone resin, epoxy modified silicone resin, titanium dioxide and bentonite, and use colloid to grind to a particle size of ≤ 40 μm to obtain component A; mix component A and After the B-component curing agent is mixed and stirred, the bottom coating can be obtained, which can be used. When using, spray the bottom coating onto the pre-treated substrate, repair and polish it after curing.

[0030] The preparation method of the coating surface layer is to mix and heat 60-80 parts of diphenol-based epoxy resin and 16-22 parts of polyisocyanate-based polyurethane prepolymer to prepare polyurethane modified epoxy resin; Epoxy resin, 3 to 4 parts of diluent, 0.5 to 1 part of filler, 3 to 8 parts of ferrocerium alloy nano powder and 8 to 12 parts of curing agent are mixed evenly, then add polyurethane modified epoxy resin, ...

Embodiment 1

[0046] Step 1, in parts by mass, after mixing and stirring 30 parts of methylphenyl silicone resin, 30 parts of epoxy-modified silicone, 12 parts of titanium dioxide and 13 parts of bentonite, use colloidal grinding to grind to a particle size ≤ 40 μm , to obtain component A; mix component A and 650# polyamide resin to obtain the bottom coating, spray the bottom coating on the substrate, repair and polish it after curing, and obtain the bottom layer; the thickness of the bottom layer is 300 μm.

[0047] Step 2, in parts by mass, 72 parts of E-51 and 20 parts of polyisocyanate-based polyurethane prepolymers are mixed and heated to obtain polyurethane modified epoxy resin; 13 parts of E-51, 3 parts of propylene oxide butyl Ether, 0.8 parts of glass powder, 6 parts of cerium-iron alloy nano powder and 10 parts of curing agent are mixed evenly and added to polyurethane modified epoxy resin, then 4 parts of silicon carbide particles and 0.3 part of dispersant are added, and after stir...

Embodiment 2

[0054] Step 1, in parts by mass, after mixing and stirring 25 parts of methylphenyl silicone resin, 28 parts of epoxy-modified silicone, 11 parts of titanium dioxide and 8 parts of bentonite, use colloidal grinding to grind to a particle size ≤ 40 μm , to obtain component A; mix component A and 650# polyamide resin to obtain the bottom coating, spray the bottom coating on the substrate, repair and polish it after curing, and obtain the bottom layer; the thickness of the bottom layer is 200 μm.

[0055] Step 2, in parts by mass, 94 parts of E44 and 19 parts of polyisocyanate-based polyurethane prepolymers are mixed and heated to obtain polyurethane modified epoxy resin; 12 parts of E-51, 4 parts of propylene oxide butyl ether, Mix 0.9 parts of glass powder, 3 parts of cerium-iron alloy nanopowder and 8 parts of curing agent evenly and add them to the polyurethane modified epoxy resin, then add 5 parts of silicon carbide particles and 0.2 parts of dispersant, and stir evenly to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com