Fire retardant coating with photocatalytic performance and preparation method thereof

A technology of fire retardant coating and photocatalysis, applied in the direction of fire retardant coating and coating, can solve the problems of high electron-hole recombination rate, low utilization rate of visible light, low photocatalytic activity, etc. The ability of light to absorb visible light and the effect of improving anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

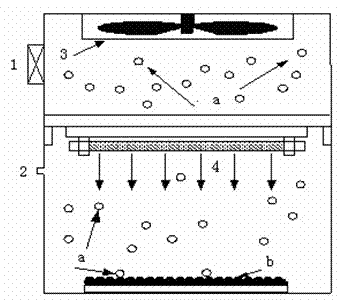

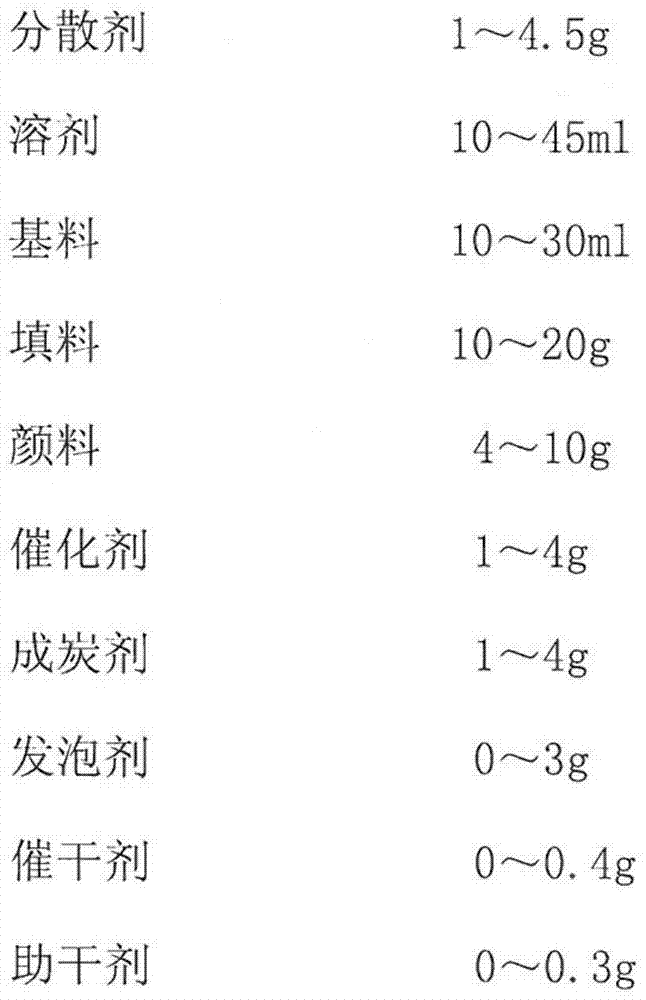

[0050] A preparation method of a fireproof coating with photocatalytic performance, comprising the steps of:

[0051] (1) Add 45ml of water to 4.5g of BYK180 polymer dispersant, stir for 7min in a stirring plate at a rotation speed of 1500 rpm; then add 10ml of aluminum dihydrogen phosphate and 10g of aluminum 2 / Kg ultrafine slag powder, stir for 7min; then add 4g Cu-Ce / TiO 2 , and then stirred for 7min;

[0052] (2) Reduce the rotating speed of the stirring plate to 1000 rpm, add 1g of ammonium polyphosphate, 1g of pentaerythritol and 2g of melamine, stir for 35min, and prepare the fireproof white paste;

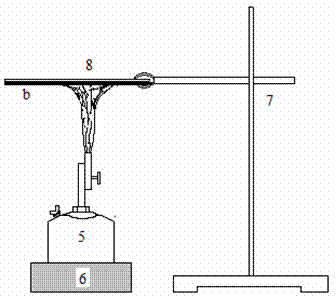

[0053] (3) join the fireproof white slurry prepared by step (2) in the paint mixing tank, adjust the rotating speed of the stirring plate to be 500 rpm, then add 0.15g lead oxide, 0.25g zinc powder, 1ml nanometer mother liquor, stir for 25min, A fireproof coating with photocatalytic properties is obtained as the final target product.

Embodiment 2

[0055] A preparation method of a fireproof coating with photocatalytic performance, comprising the steps of:

[0056] (1) Add 35ml of water to 3.5g of BYK180 polymer dispersant, and stir for 6min in a stirring plate at a rotation speed of 1500 rpm; then add 20ml of aluminum dihydrogen phosphate and 16g of aluminum dihydrogen phosphate in turn with a specific surface area of 681m 2 / Kg ultrafine slag powder, stir for 6min; then add 6g Cu-Ce / TiO 2 , and then stirred for 6min;

[0057] (2) Reduce the rotating speed of the stirring plate to 1000 rpm, add 2g ammonium polyphosphate, 2g pentaerythritol and 3g melamine, stir for 32min, and prepare the fireproof white paste;

[0058] (3) join the fireproof white slurry prepared by step (2) in the paint mixing tank, adjust the rotating speed of the stirring plate to be 500 rpm, then add 0.2g lead oxide, 0.1g zinc powder, 7ml nanometer mother liquor, stir for 22min, A fireproof coating with photocatalytic properties is obtained as th...

Embodiment 3

[0060] A preparation method of a fireproof coating with photocatalytic performance, comprising the steps of:

[0061] (1) Add 25ml of water to 2.5g of BYK180 polymer dispersant, stir for 5min in a stirring plate at a speed of 1500 rpm; then add 15ml of aluminum dihydrogen phosphate and 14g of aluminum dihydrogen phosphate 2 / Kg ultrafine slag powder, stir for 5min; then add 8g Cu-Ce / TiO 2 , and then stirred for 5min;

[0062] (2) Reduce the rotating speed of the stirring plate to 1000 rpm, add 2g of ammonium polyphosphate, 2g of pentaerythritol and 1g of melamine, stir for 30min, and prepare the fireproof white paste;

[0063] (3) join the fireproof white slurry prepared by step (2) in the paint mixing tank, adjust the rotating speed of the stirring plate to be 500 rpm, then add 0.3g lead oxide, 0.2g zinc powder, 5ml nanometer mother liquor, stir 20min, A fireproof coating with photocatalytic properties is obtained as the final target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com