Waterproof moisture-permeable waterborne polyurethane fabric coating material and preparation method thereof

A water-based polyurethane, waterproof and moisture-permeable technology, applied in the field of preparation of waterproof and moisture-permeable fabric coating agents, can solve problems such as unsatisfactory improvement in mechanical properties, and achieve improved moisture permeability and mechanical properties, improved waterproof performance, and improved operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

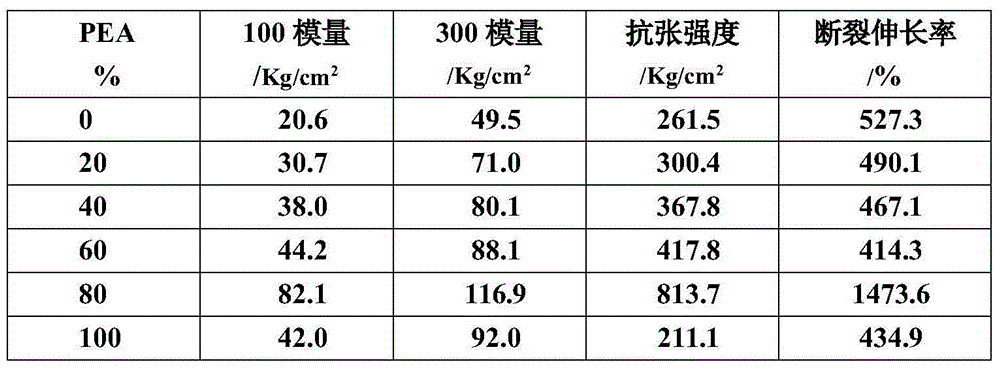

Embodiment 1

[0023] 1. Polymer diol: the molecular weight of polytetrahydrofuran ether (PTMG) and polyethylene adipate glycol (PEA) is 1000, the total mass of mixed polymer diol is 114.2g, and the content of polyester diol is 0 respectively %, 20%, 40%, 60%, 80%, 100%;

[0024] 2. Diisocyanate: 70.0g of isophorone diisocyanate;

[0025] 3. Hydrophilic monomer: dimethylol butyric acid 10.8g;

[0026] 4. Small molecule diol: 4.9g of 1,4-butanediol;

[0027] 5. Chain extender: ethylenediamine 2.6g;

[0028] 6. Neutralizer: 7.4g of triethylamine;

[0029] 7. Solvent: butanone 120.0g (for adjusting the viscosity of the reaction system); deionized water 466.7g (for adjusting the solid content of the product).

[0030] The concrete steps of synthetic method are:

[0031] Room temperature, N 2 Under the atmosphere, put the polymer diol into the reaction kettle, raise the temperature to 105°C, vacuum dehydrate for 3 hours, then cool down to 40°C, add diisocyanate, dimethylol butyric acid, 1,4...

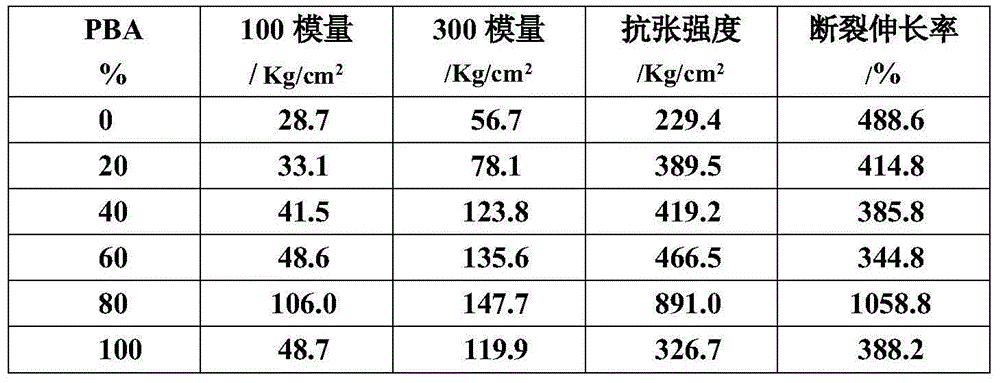

Embodiment 2

[0035] 1. Polymer diol: polytetrahydrofuran ether, polybutylene adipate (PBA) with a molecular weight of 1000,

[0036] The total mass of mixed polymer diol is 117.4g, and the contents of polyester diol are 0%, 20%, 40%, respectively.

[0037] 60%, 80%, 100%;

[0038] 2. Diisocyanate: 70.0g of isophorone diisocyanate;

[0039] 3. Hydrophilic monomer: dimethylol butyric acid 10.8g;

[0040] 4. Small molecule diol: 1.8g of 1,4-butanediol;

[0041] 5. Chain extender: ethylenediamine 3.8g;

[0042] 6. Neutralizer: 7.4g of triethylamine;

[0043] 7. Solvent: butanone 120.0g (for adjusting the viscosity of the reaction system); deionized water 466.7g (for adjusting the solid content of the product).

[0044] The concrete steps of synthetic method are:

[0045] Room temperature, N 2 Under the atmosphere, put the polymer diol into the reaction kettle, raise the temperature to 110°C, vacuum dehydrate for 3 hours, then cool down to 45°C, add diisocyanate, dimethylol butyric acid,...

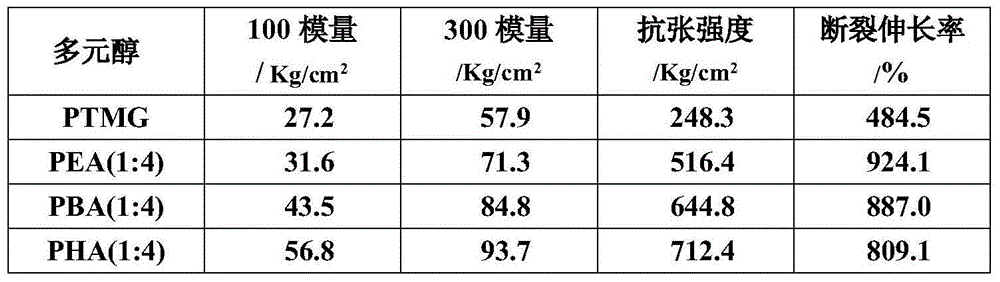

Embodiment 3

[0049] 1. Polymer diol: the molecular weight of polytetrahydrofuran ether, polyethylene adipate glycol, polybutylene adipate, polyhexamethylene adipate (PHA) is 1000, and the mixed polymer diol The total mass is 117.4g, and the mass ratio of polyether to polyester diol is 1:4;

[0050] 2. Diisocyanate: 70.0g of isophorone diisocyanate;

[0051] 3. Hydrophilic monomer: dimethylol butyric acid 10.8g;

[0052] 4. Small molecule diol: 5.8g of 1,4-butanediol;

[0053] 5. Chain extender: ethylenediamine 4.3g;

[0054] 6. Neutralizer: 7.4g of triethylamine;

[0055] 7. Solvent: butanone 120.0g (for adjusting the viscosity of the reaction system); deionized water 466.7g (for adjusting the solid content of the product).

[0056] The concrete steps of synthetic method are:

[0057] Room temperature, N 2 Under the atmosphere, put the polymer diol into the reaction kettle, raise the temperature to 115°C, vacuum dehydrate for 3h, then cool down to 50°C, add diisocyanate, dimethylol b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com