Yellowing-resistance nitrolacquer

A nitro paint, yellowing resistance technology, applied in coatings, polyester coatings, etc., can solve the problems of harmful gas volatilization pollution, easy damage, poor weather resistance and yellowing resistance, etc., to achieve good compatibility and good The effect of transparency, overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

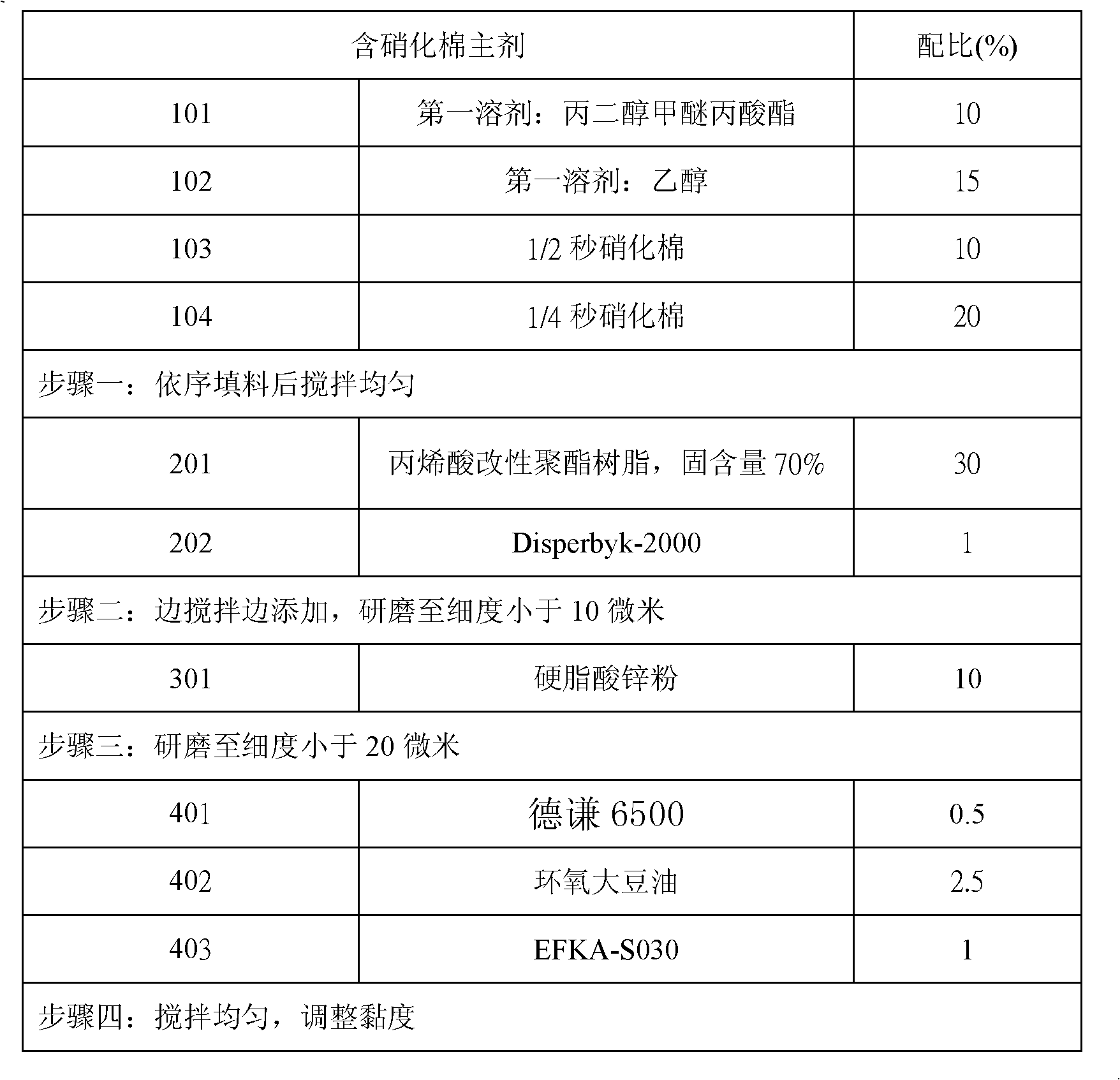

[0034] Example 1 Anti-yellowing nitrocellulose primer: containing nitrocellulose main agent 70%; diluent 30%.

[0035]

[0036]

[0037]

[0038] The above-mentioned high-performance low-temperature curing polyurethane topcoat is used in conjunction with the primer. The actual test data is as follows:

[0039]

Embodiment 2

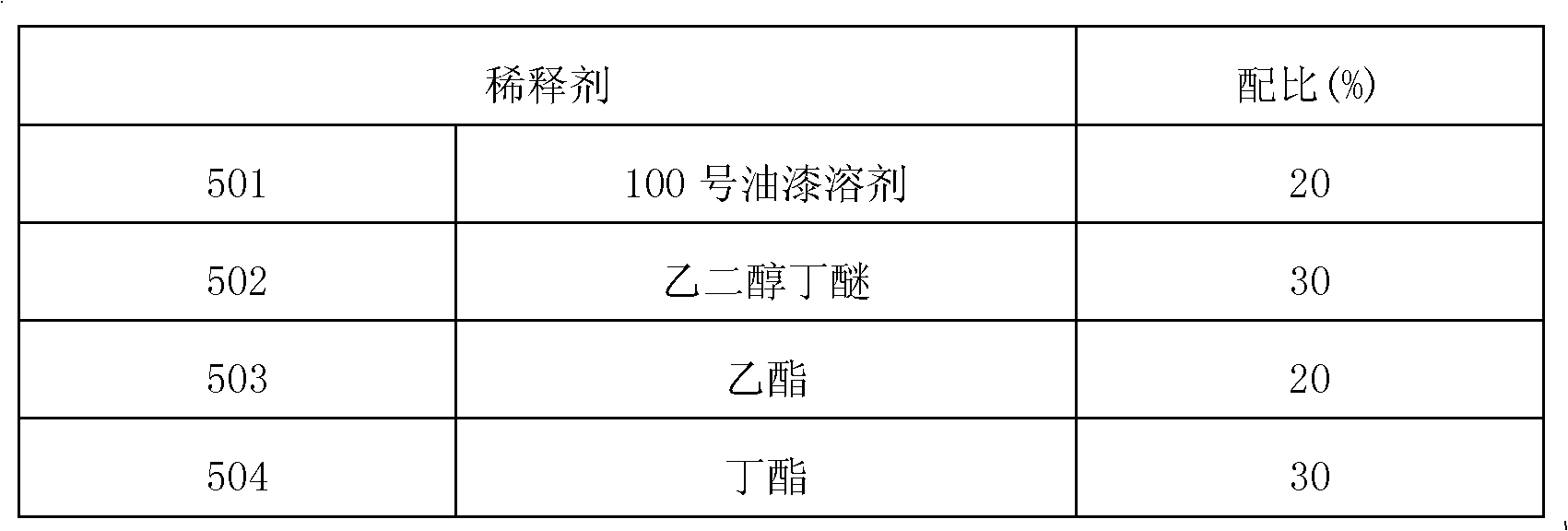

[0040] Example 2 Anti-yellowing nitro white topcoat: containing nitrocellulose main agent 62%; diluent 38%.

[0041]

[0042]

[0043]

[0044] When in use, mix the main agent containing nitrocellulose with the diluent, stir well and adjust to an appropriate viscosity.

[0045] The above-mentioned high-performance low-temperature curing all-whitening polyurethane topcoat is used in conjunction with the primer. The actual test data is as follows:

[0046]

Embodiment 3

[0047] Embodiment 3 anti-yellowing nitro transparent topcoat: containing nitrocellulose main agent 65%; diluent 35%.

[0048]

[0049]

[0050] When in use, mix the main agent containing nitrocellulose with the diluent, stir well and adjust to an appropriate viscosity.

[0051] The above-mentioned high-performance low-temperature curing polyurethane primer, the actual test data is as follows:

[0052]

[0053] In the above examples, the UV resistance test can show that the present invention has the advantage of yellowing resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com