Optically transparent glue composition with organic silicone liquid and method for preparing optically transparent glue composition

An optically transparent and silicone technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of large shrinkage rate of optically transparent glue, easy to corrode ITO, and light spots, etc., to shorten the production process and manufacturing time, reduce production costs, and increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

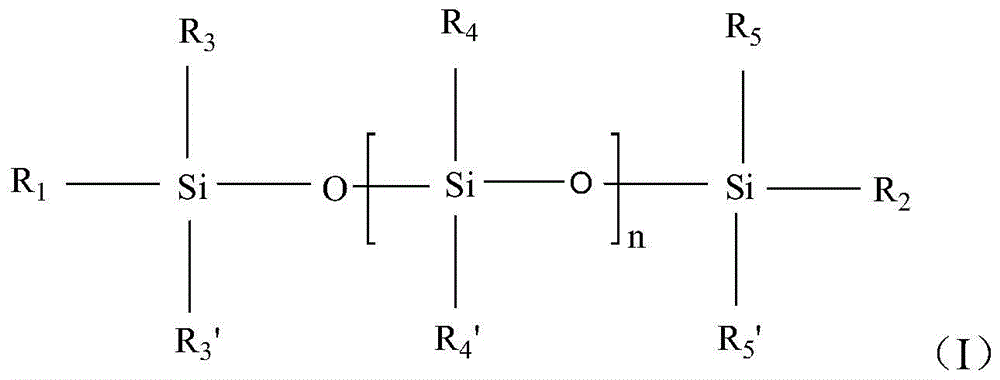

Method used

Image

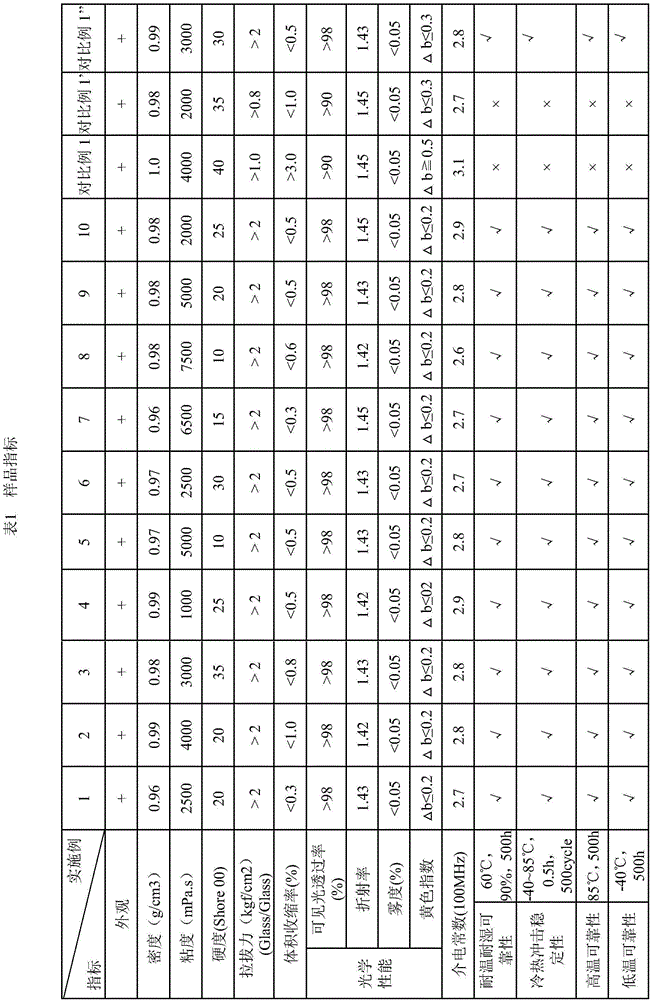

Examples

Embodiment 1

[0043] Weigh acrylate-terminated vinyl silicone oil, vinyl MQ silicone resin, hydrogen-containing silicone oil, 2-hydroxy-2-phenylacetophenone, and γ-methacryloxypropyltrimethoxysilane in the following proportions , 1,4-butynediol and karstedt platinum catalyst were added to the dynamic mixer respectively, stirred at a speed of 500r / min for 1h under a vacuum of -0.04MPa and a temperature of 35°C, and the obtained product was filtered , and packed into designated containers, and finally degassed by a high-speed degassing machine at a speed of 2500r / min, and finally packaged through a sealed pipe to obtain a silicone liquid optically transparent glue.

[0044] components

Embodiment 2

[0056] Weigh acrylate-terminated vinyl silicone oil, vinyl MQ silicone resin, vinyl MDT silicone oil, hydrogen-containing silicone oil, 2-hydroxy-2-phenylacetophenone, 1,4-butynediol and karstedt according to the ratios in the table below Platinum catalyst, and respectively added to the dynamic mixer, under the environment of vacuum degree of -0.04MPa, temperature of 35 ℃, stirring at the speed of 500r / min for 1h, the obtained product was filtered, and packed into the designated container, finally It is degassed by a high-speed degassing machine at a speed of 2500r / min, and finally packaged through a sealed pipe to obtain a silicone liquid optically transparent glue.

[0057]

[0058]

Embodiment 3

[0060] Weigh acrylate-terminated vinyl silicone oil, vinyl MQ silicone resin, vinyl MDT silicone oil, hydrogen-containing silicone oil, 2-hydroxy-2-phenylacetophenone, 1,4-butynediol, γ-Methacryloyloxypropyltrimethoxysilane and Karstedt platinum catalyst were added to the dynamic mixer respectively, and stirred at a speed of 500r / min for 1h at a vacuum degree of -0.04MPa and a temperature of 35°C , the obtained product is filtered and packed into designated containers, and finally degassed by a high-speed degassing machine at a speed of 2500r / min, and finally packaged through a sealed pipe to obtain a silicone liquid optically transparent glue.

[0061] components

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com