Preparation method of acrylic-resin-modified water-based nitrocellulose emulsion for paint

A technology of acrylic resin and nitrocellulose, applied in the direction of coating, can solve the problems of low flexibility, low fullness and poor stability of the coating film, and achieve the effects of good flexibility, simple preparation process and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

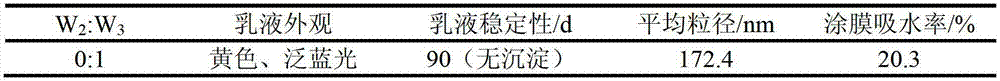

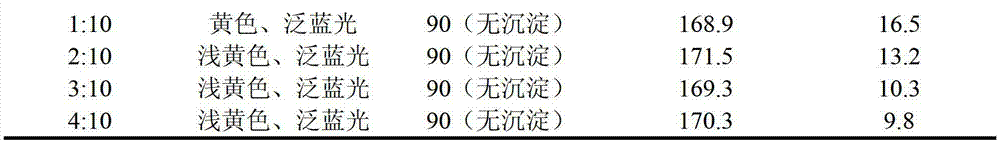

Examples

Embodiment 1

[0024] 1) Synthesis of nitrocellulose emulsion:

[0025] 1.1) Under nitrogen protection, 0.05g of dehydrated dibutyltin dilaurate, 4.48g of isophorone diisocyanate (IPDI) trimer, and 3.33g of N-methylpyrrolidone were dissolved in 2.01g of dimethylolpropane Add acid (DMPA) into a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser to obtain a reaction system; among them, the dehydrated dibutyltin dilaurate is obtained by dehydrating dibutyltin dilaurate with 4A molecular sieve for 1 day ;

[0026] 1.2) React the reaction system at a constant temperature of 40°C for 1 hour, then raise the temperature to 72°C, add a butanone solution of nitrocellulose with a mass concentration of 25%, and keep the reaction for 2 hours to obtain a reaction solution; wherein, the added nitrocellulose butanone The nitrocellulose in the ketone solution is 7.0g;

[0027] 1.3) Cool the reaction solution to 40°C, add triethylamine to adjust the pH of the reaction solution ...

Embodiment 2

[0031] 1) Synthesis of nitrocellulose emulsion:

[0032] 1.1) Under nitrogen protection, 0.05g of dehydrated dibutyltin dilaurate, 4.68g of isophorone diisocyanate (IPDI) trimer, and 3.33g of N-methylpyrrolidone were dissolved in 2.11g of dimethylolpropane Add acid (DMPA) into a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser to obtain a reaction system; among them, the dehydrated dibutyltin dilaurate is obtained by dehydrating dibutyltin dilaurate with 4A molecular sieve for 1 day ;

[0033] 1.2) React the reaction system at a constant temperature of 45°C for 1 hour, then raise the temperature to 72°C, add a butanone solution of nitrocellulose with a mass concentration of 27%, and keep the reaction for 2 hours to obtain a reaction solution; wherein, the added nitrocellulose butanone The nitrocellulose in the ketone solution is 7.2g;

[0034] 1.3) Cool the reaction solution to 40°C, add triethylamine to adjust the pH of the reaction solution ...

Embodiment 3

[0038] 1) Synthesis of nitrocellulose emulsion:

[0039] 1.1) Under nitrogen protection, 0.05g of dehydrated dibutyltin dilaurate, 4.98g of isophorone diisocyanate (IPDI) trimer, and 3.33g of N-methylpyrrolidone were dissolved in 2.21g of dimethylol Add propionic acid (DMPA) into a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser to obtain a reaction system; among them, the dehydrated dibutyltin dilaurate is obtained by dehydrating dibutyltin dilaurate with 4A molecular sieve for 1 day of;

[0040] 1.2) React the reaction system at a constant temperature of 45°C for 1 hour, then raise the temperature to 72°C, add a butanone solution of nitrocellulose with a mass concentration of 28%, and keep the reaction for 2 hours to obtain a reaction solution; wherein, the added nitrocellulose butanone The nitrocellulose in the ketone solution is 7.3g;

[0041] 1.3) Cool the reaction solution to 40°C, add triethylamine to adjust the pH of the reaction solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com