Device for spraying adhesive to shoe vamp

A technology of spraying glue and shoe upper, which is applied in the directions of footwear, bonding shoe parts, shoe-making machinery, etc., can solve the problems of high cost, low production efficiency, and easy curing of glue, and achieves low cost, high production efficiency, and difficult The effect of curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

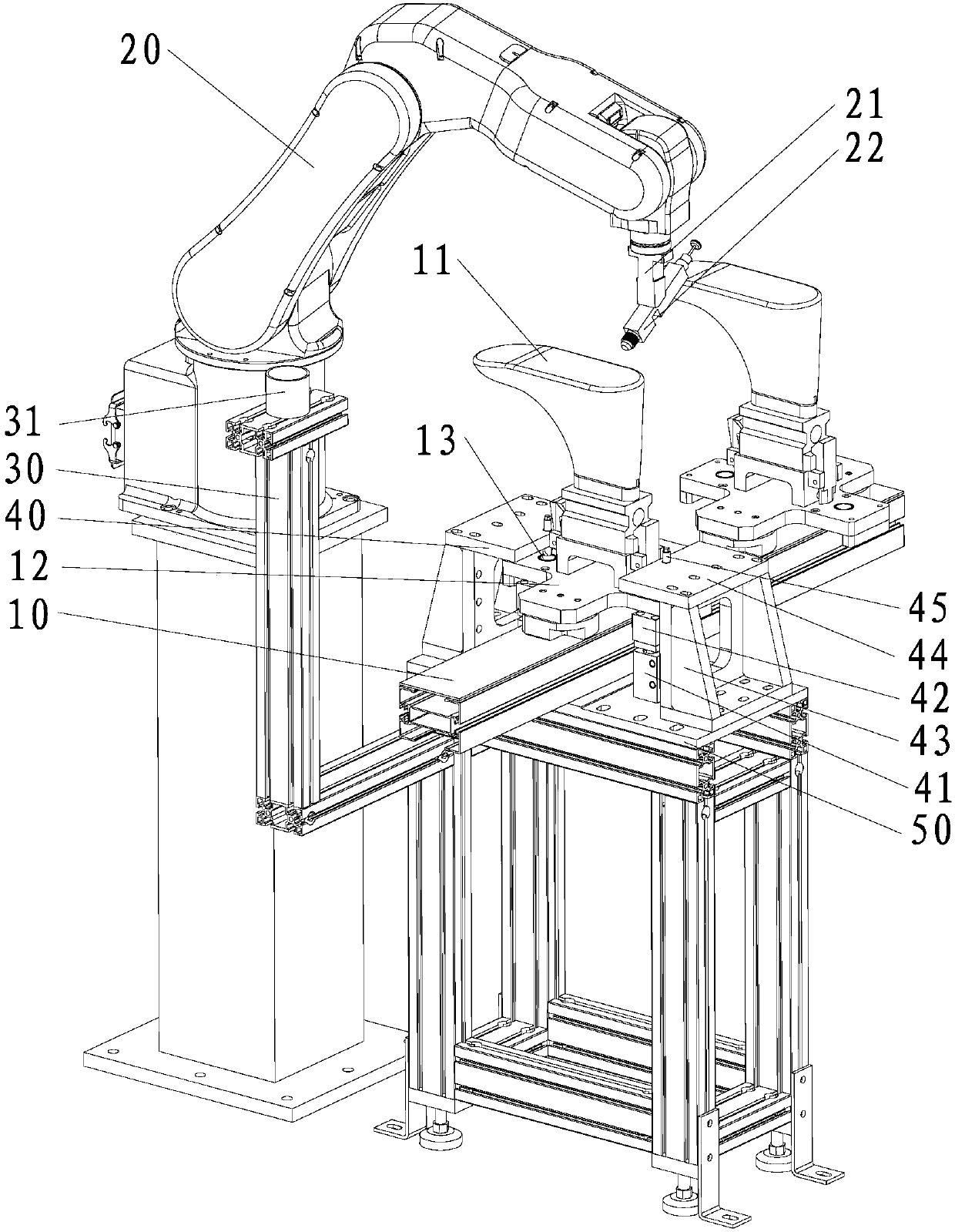

[0025] Such as figure 1 As shown, the vamp spraying device provided in this embodiment includes a conveyor 10 and a multi-joint manipulator 20 and a support 30 positioned beside the conveyor 10, wherein the conveyor 10 and the multi-joint manipulator 20 can be purchased directly from the market The obtained equipment will not be described in detail here.

[0026] The terminal joint of multi-joint manipulator 20 is fixedly connected with spray gun frame 21, and spray gun 22 is installed on the spray gun frame 21, and the angle of the included angle between this spray gun 22 and the end joint of multi-joint manipulator 20 is 45 °, and this spray gun 22 is most It is better to be on a different plane than other joints on the multi-joint manipulator 20 except the end joints. It should be noted that the above-mentioned angles may allow a certain d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com