Copper composite conductive powder with grapheme structure and wrapped by carbon layer and preparation method thereof

A technology of composite conductive powder and graphene, which is applied in the direction of metal/alloy conductors, cable/conductor manufacturing, circuits, etc., can solve the problems of high resistivity, copper powder is easy to be oxidized, etc., to prevent oxidation, prevent particle agglomeration, and resist Effect of Oxidation Performance Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

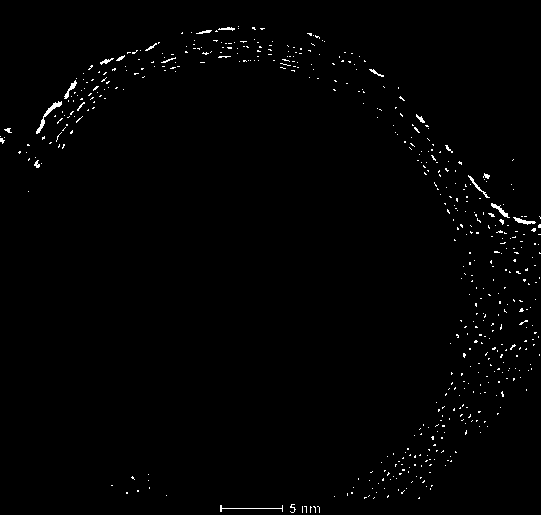

Image

Examples

Embodiment 1

[0060] 8.0g LPAN solution (molecular weight 4000, mass percentage 80%) was stirred at 120°C for 60 hours to form a microcyclized LPAN solution, and the microcyclized LPAN solution was heat-treated at 220°C for 8 hours to form a Thermally oxidized polyacrylonitrile oligomer (OPAN) solid, then add 7.5g of copper oxide powder, 30ml of solvent (water), and use a planetary ball mill to mill the sample, the ball-to-material ratio is 15:1, the speed is 400rad / min, and the ball mill is 10 h, after discharging, dry in an oven at 220°C for 3 hours to obtain a thermally oxidized precursor (that is, a low-temperature carbonized precursor-coated copper compound). Put the thermal oxidation precursor in a porcelain boat, under the protection of an inert atmosphere, the gas flow rate is 250ml / min, the selected temperature is 1000°C for calcination, the holding time is 6 h, and then cooled to room temperature to obtain a carbon layer coating with a graphene structure Copper composite conductiv...

Embodiment 2

[0062] 10.0g LPAN solution (molecular weight 2500, mass percentage 50%) was stirred at 80°C for 72 hours to form a microcyclized LPAN solution, and the microcyclized LPAN solution was heat-treated at 200°C for 10 hours to form a Thermally oxidized polyacrylonitrile oligomer (OPAN) solid, then add 4.0g of copper oxide powder, 15ml of solvent (methanol), and use a planetary ball mill to mill the sample with a ball-to-material ratio of 15:1, a speed of 400rad / min, and ball mill for 10 h, after discharging, dry in an oven at 180°C for 10 hours to obtain a thermally oxidized precursor (that is, a low-temperature carbonized precursor-coated copper compound). Put the thermal oxidation precursor in a porcelain boat, under the protection of an inert atmosphere, the gas flow rate is 10ml / min, the selected temperature is 1800°C for calcination, the holding time is 15h, and then cooled to room temperature to obtain a graphene-structured carbon layer-coated Copper composite conductive powd...

Embodiment 3

[0064] 10.0g LPAN solution (molecular weight 150, mass percentage 20%) was stirred at 300°C for 8 hours to form a microcyclized LPAN solution, and the microcyclized LPAN solution was heat-treated at 300°C for 1 hour to form a Thermally oxidized polyacrylonitrile oligomer (OPAN) solid, then add 4.0g of copper oxide powder, 20ml of solvent (ethanol), and use a planetary ball mill to grind the sample, the ball-to-material ratio is 15:1, the speed is 400rad / min, and the ball mill is 10 h, after discharging, dry in an oven at 250°C for 1 hour to obtain a thermally oxidized precursor (that is, a low-temperature carbonized precursor-coated copper compound). Put the thermal oxidation precursor in a porcelain boat, under the protection of an inert atmosphere, the gas flow rate is 500ml / min, the selected temperature is 1300°C for calcination, the holding time is 24 h, and then cooled to room temperature to obtain a carbon layer coating with a graphene structure Copper composite conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com