Special chilled cast iron roller for wire rod bar finishing mill rack and production process thereof

A chilled cast iron and roll technology is applied in the field of chilled cast iron rolls and its production technology, which can solve the problems of difficult machining pass, high heat treatment requirements, complex production processes, etc., and achieves resistance to thermal fatigue oxidative cracks and low heat treatment requirements. , the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

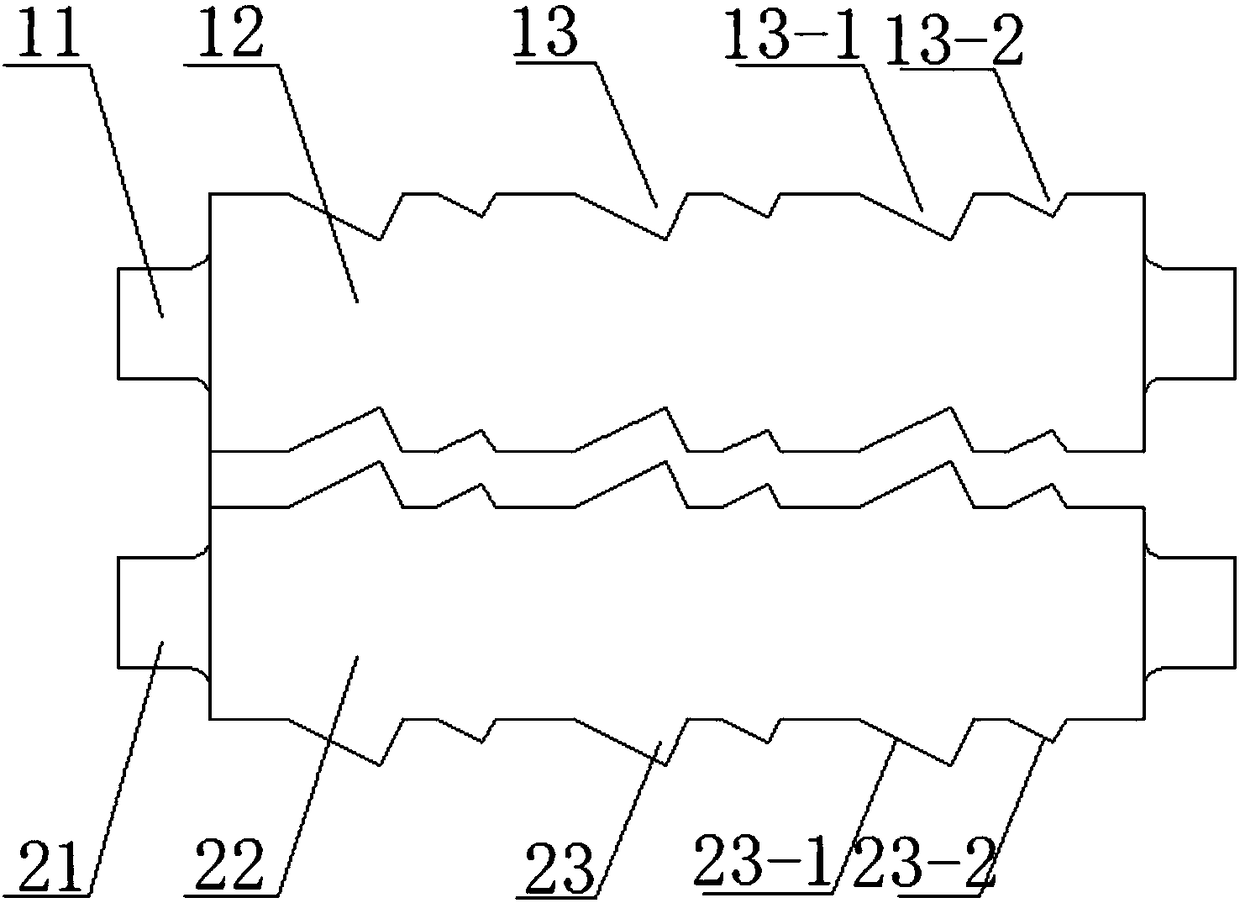

Image

Examples

Embodiment 1

[0031] The present invention is a chilled cast iron roll specially used for a wire and bar finishing stand. The chemical composition of the chilled cast iron roll specially used for a wire and bar finishing stand is configured in two parts: an outer layer and a core, wherein the chemical composition of the outer layer is For: C: 3.0%; Si: 0.4%; Mn: 0.4%; P: 0.03%; S: 0.025%; Cr: 1.25%; Mo: 0.5%; Ni: 3.0%; V: 0.1%; Re: 0.07 %; Nb: 0.2%; core chemical composition: C: 3.1%; Si: 2.2%; Mn: 0.45%; P: 0.025%; S: 0.015%; Cu: 0.85%; It is Fe and a small amount of residual elements.

[0032] The present invention is specially used for the chilled cast iron roll outer layer matrix structure of wire bar finishing stand is VC, Mo 2 C6, NbC granular alloy carbide + bainite + a small amount of martensite; the core structure is: spherical graphite + 20-25% ferrite + pearlite. The design value of roll surface hardness is 75-85HSD, and the measured value in this example is 76.5HSD; the design...

Embodiment 2

[0042] The present invention is a chilled cast iron roll specially used for a wire and bar finishing stand. The chemical composition of the chilled cast iron roll specially used for a wire and bar finishing stand is configured in two parts: an outer layer and a core, wherein the chemical composition of the outer layer is For: C: 3.1%; Si: 0.5%; Mn: 0.3%; P: 0.025%; S: 0.025%; Cr: 1.35%; Mo: 0.3%; Ni: 3.3%; V: 0.2%; %; Nb: 0.3%; core chemical composition: C: 3.3%; Si: 2.4%; Mn: 0.50%; P: 0.025%; S: 0.025%; Cu: 1.0%; It is Fe and a small amount of residual elements.

[0043] The present invention is specially used for the chilled cast iron roll outer layer matrix structure of wire bar finishing stand is VC, Mo 2 C6, NbC granular alloy carbide + bainite + a small amount of martensite; the core structure is: spherical graphite + 20-25% ferrite + pearlite. The design value of roll surface hardness is 75-85HSD, and the measured value in this example is 82HSD; the design value of t...

Embodiment 3

[0051] The present invention is a chilled cast iron roll specially used for a wire and bar finishing stand. The chemical composition of the chilled cast iron roll specially used for a wire and bar finishing stand is configured in two parts: an outer layer and a core, wherein the chemical composition of the outer layer is For: C: 3.2%; Si: 0.6%; Mn: 0.5%; P: 0.015%; S: 0.015%; Cr: 1.45%; Mo: 0.5%; Ni: 3.5%; V: 0.3%; %; Nb: 0.4%; core chemical composition: C: 3.5%; Si: 2.6%; Mn: 0.60%; P: 0.015%; S: 0.015%; Cu: 1.2%; Mg: 0.1%; It is Fe and a small amount of residual elements.

[0052] The present invention is specially used for the chilled cast iron roll outer layer matrix structure of wire bar finishing stand is VC, Mo 2 C6, NbC granular alloy carbide + bainite + a small amount of martensite; the core structure is: spherical graphite + 20-25% ferrite + pearlite. The design value of roll surface hardness is 75-85HSD, and the measured value in this example is 85HSD; the design ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com