Sloping diamond synthesis block

A diamond and synthetic block technology, applied in the field of italic diamond synthetic blocks, can solve the problems of crack hammer accident, accelerated thermal fatigue of non-heated top hammer, and cracking of non-heated top hammer, so as to reduce the number of crack hammers, reduce the occurrence of accidents, The effect of reducing thermal fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

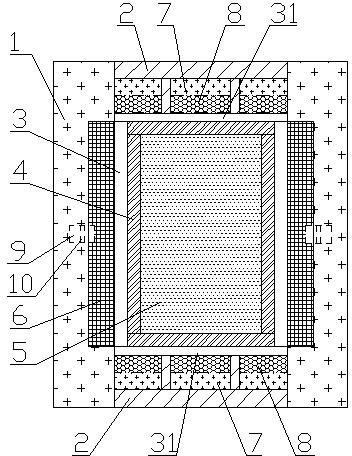

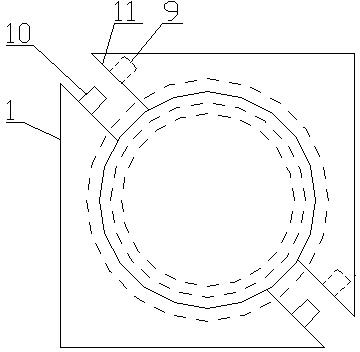

[0022] Embodiment 1: as figure 1 , figure 2 The italic diamond composite block shown includes graphite column 5, conductive steel ring 2 at both ends of graphite column 5, and pyrophyllite block on the periphery of graphite column 5 and conductive steel ring 2, and graphite column 5 is formed by pressing graphite and catalyst powder , the conductive steel ring 2 is filled with pyrophyllite ring 7 and dolomite ring 8, the conductive steel ring 2 is arranged at both ends of the graphite column 5, and the pyrophyllite block is arranged at the periphery of the graphite column 5 and the conductive steel ring 2. The pyrophyllite block is composed of two half blocks 1 that are fastened to each other, and the middle part of the two fastened half blocks 1 forms a graphite column cavity for installing a graphite column 5 . In order to improve the stability and firmness of the pyrophyllite block, on the fastening surface 11 of each half block 1, there are grooves 9 and bumps 10 that co...

Embodiment 2

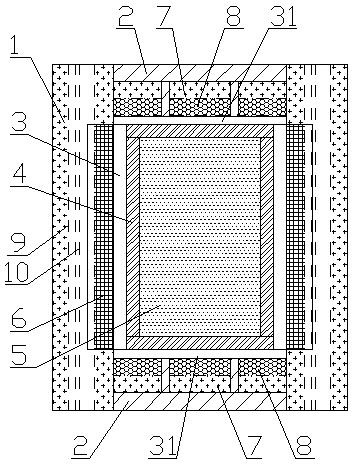

[0025] Embodiment 2: as image 3 , Figure 4 The italic diamond composite block shown includes graphite column 5, conductive steel ring 2 at both ends of graphite column 5, and pyrophyllite block on the periphery of graphite column 5 and conductive steel ring 2, and graphite column 5 is formed by pressing graphite and catalyst powder , the conductive steel ring 2 is filled with pyrophyllite ring 7 and dolomite ring 8, the conductive steel ring 2 is arranged at both ends of the graphite column 5, and the pyrophyllite block is arranged at the periphery of the graphite column 5 and the conductive steel ring 2. The pyrophyllite block is composed of two half blocks 1 that are fastened to each other, and the middle part of the two fastened half blocks 1 forms a graphite column cavity for installing the graphite column 5; in order to improve the stability and firmness of the pyrophyllite block, each half The shape of the block 1 is a triangular prism, and on the fastening surfaces 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com