Pre-pressurized hydraulic drive with variable speed pump

A driving device, variable speed technology, used in fluid pressure actuating devices, presses, servo motors, etc., can solve the problems of reducing the economy of hydraulic driving devices, not being widely accepted, etc., to achieve energy saving, short time period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

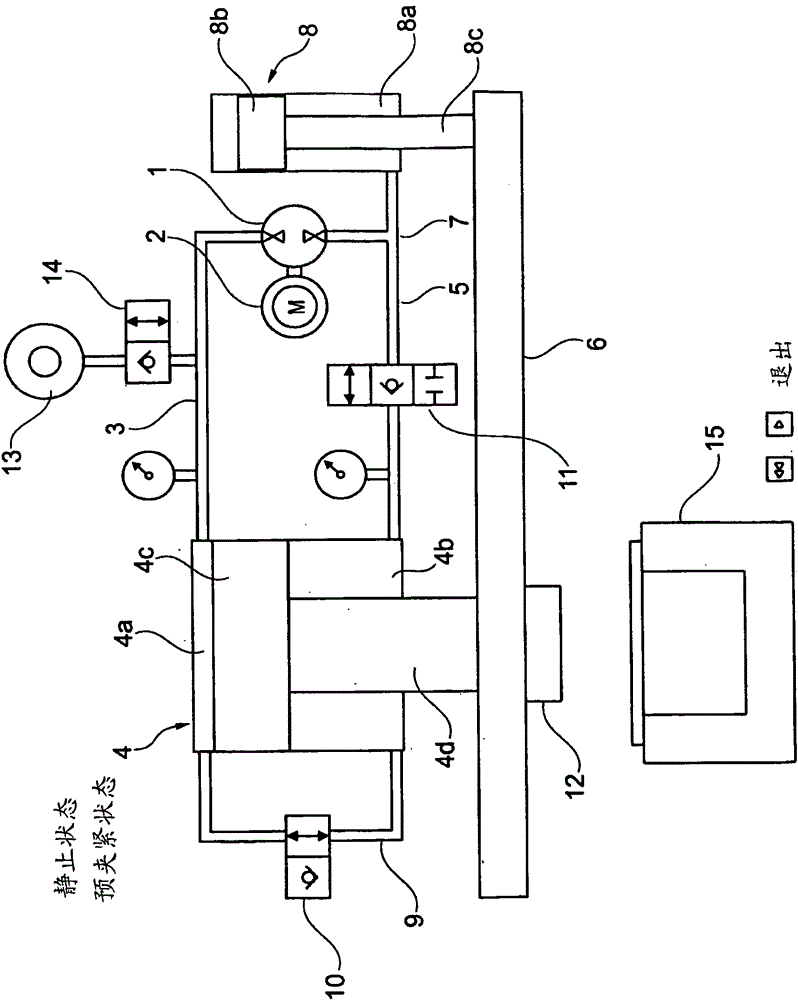

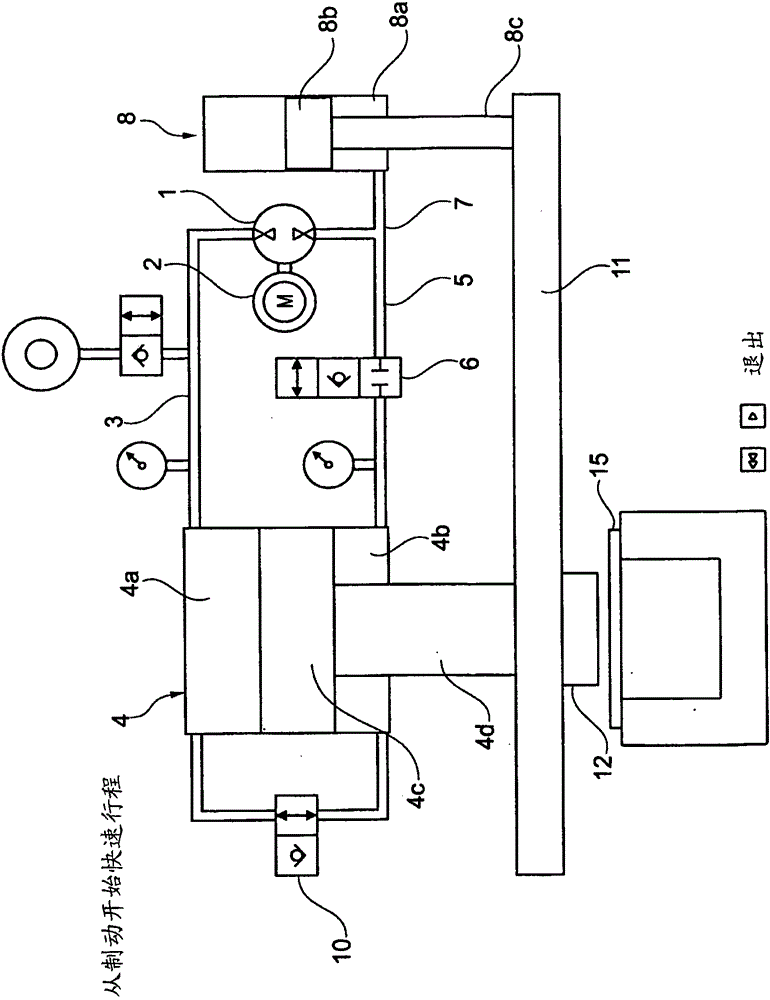

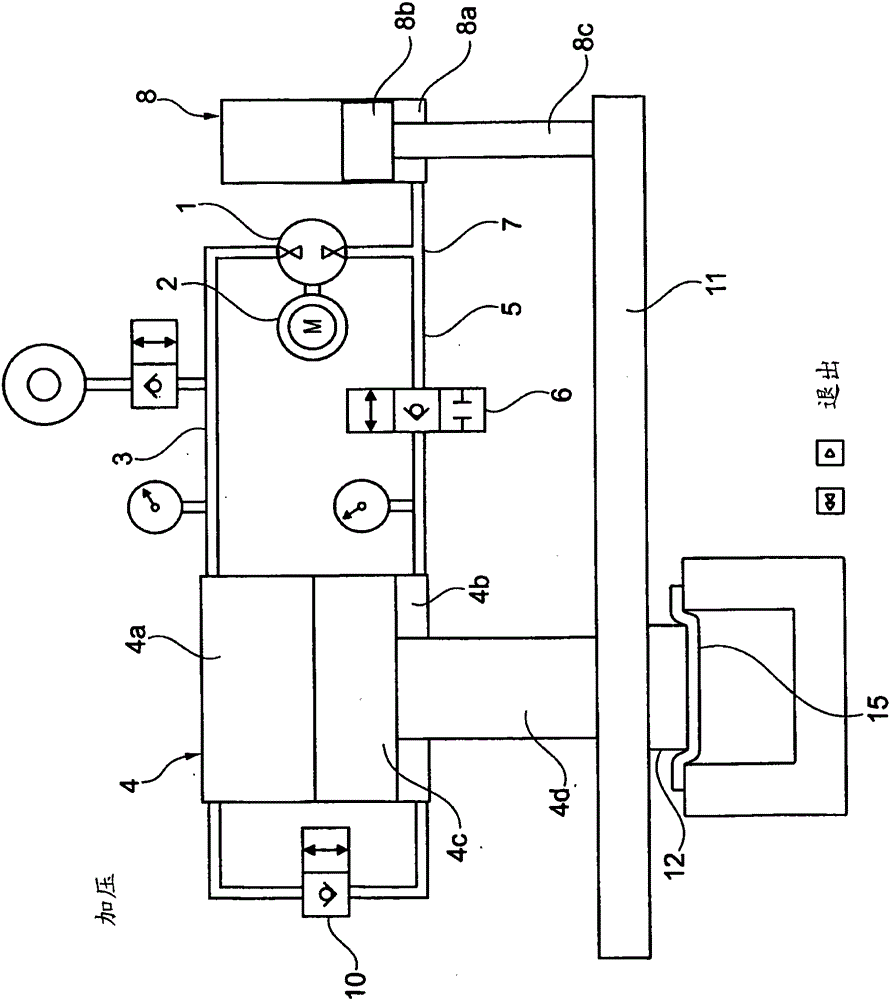

[0017] As can be seen from all the figures, the hydraulic drive according to the invention has a pressure medium source in the form of a variable-speed driven hydraulic machine 1 as a pump, which is mechanically connected to an electric motor 2 for this purpose. The hydraulic machine 1 is connected at its two pressure connections to a pressure piping system forming a closed-loop hydraulic circuit.

[0018] Specifically, a first connecting line 3 is connected to a first pressure connection of the hydraulic machine 1 , said first connecting line leading directly to the piston-side pressure chamber 4 a of the master cylinder 4 . A second line 5 is connected to a second pressure connection of the hydraulic machine 1 , said second line being connected via a valve 6 to a pressure chamber 4 b on the piston rod side of the master cylinder 4 (hereinafter referred to as annular chamber). The valve 6 is currently designed as a directional control valve, in particular as a 3 / 2-way switchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com