Internal-pressure automatic forming device and method for large-diameter cylindrical part

A technology for automatic forming and cylindrical parts, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of difficult control of internal pressure changes, steep pressure change gradients, large consumption of hydraulic media, etc., to reduce the compression volume , enrich the forming method, save the effect of hydraulic medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

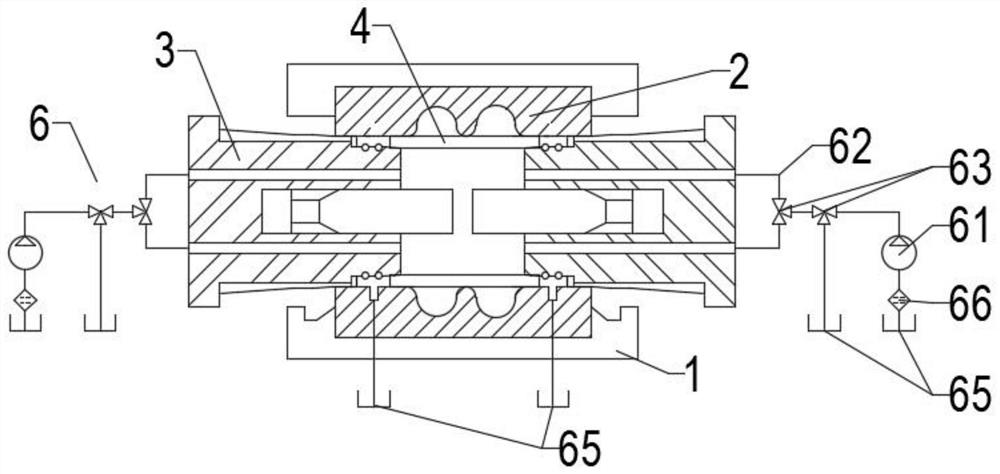

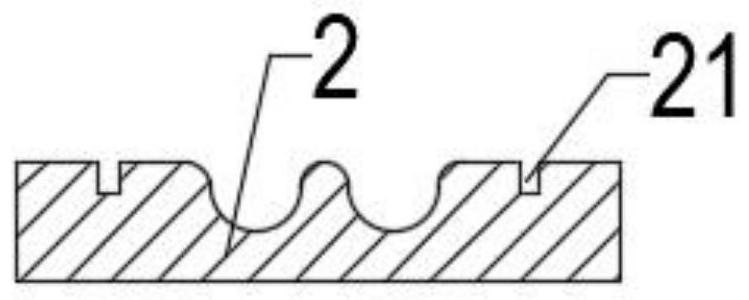

[0067] An automatic internal pressure forming device for large-diameter cylindrical parts, including a hydraulic system 6, a platform 1, a mold 2 installed on the platform 1, and punches 3 arranged at both ends of the mold 2, and the punch 3 includes:

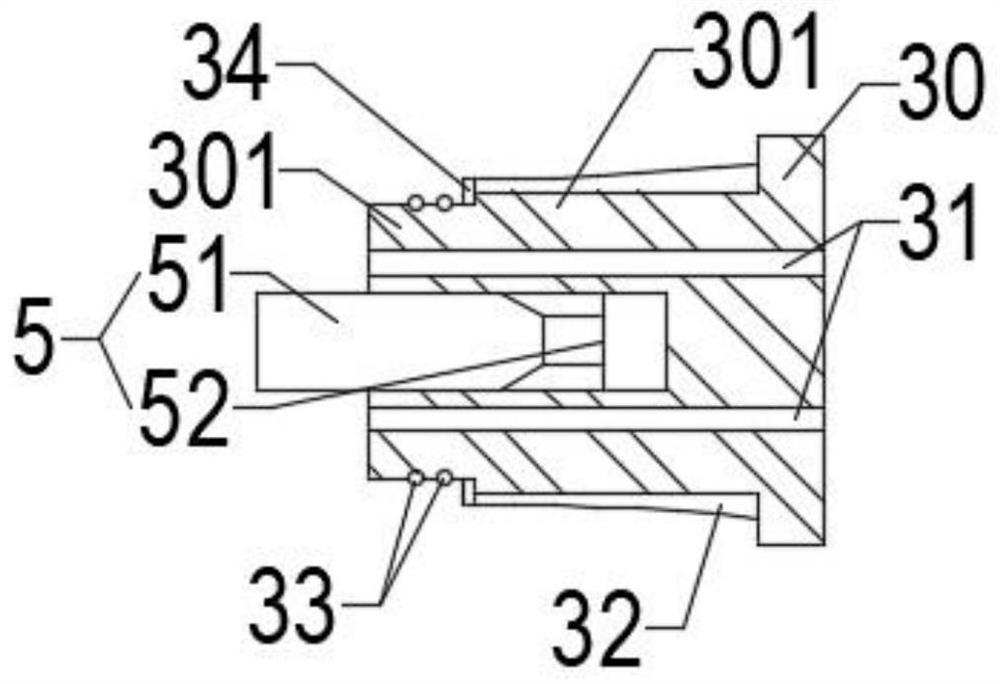

[0068] The punch body 30 is a multi-layer circular frustum structure, and the multi-layer circular frustum structure includes an integrally formed first circular table 301 and a second circular table 302; the end of the punch body 30 away from the mold 2 is fixedly connected to the axial push rod ;

[0069] The first round platform 301 is in sealing and sliding connection with the inner wall of one end of the tube blank 4;

[0070] The second round table 302 is in a sealing and sliding connection with one end of the mold 2 and exerts an axial side thrust on the cylindrical member;

[0071] The telescopic shaft 5 is arranged on the end face of the first circular platform 301 near the end of the tube blank 4 , and the outer diam...

Embodiment 2

[0100] A method for automatic internal pressure forming of large-diameter cylindrical parts, which is applied to the above-mentioned device, includes the following steps:

[0101] Step 1, prepare the automatic forming device, put the tube blank 4 into the corresponding mold 2, then use the leak detection lamp to check the state of the sealing ring 33 on the punch 3, and then check the state of the sealing table 32; then according to the tube blank 4 Different from mold 2, set different pressure curves and axial feed force curves of the control module;

[0102] Step 2, control the axial push rod to push the punch 3 to the initial position, so that the first round table 301 is sealed with the inner wall of the tube blank 4, the end surface of the second round table 302 is in contact with the tube blank 4, and then the telescopic shaft 5 is controlled to extend, so that The telescopic shafts 5 of the punches 3 at both ends are in contact, and then the hydraulic system 6 is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com