Patents

Literature

74results about How to "Meet sealing needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature sealing gum, and preparation method and application thereof

InactiveCN108219681AEvenly dispersedImprove adhesionNon-macromolecular adhesive additivesPretreated surfacesRoom temperatureThermal expansion

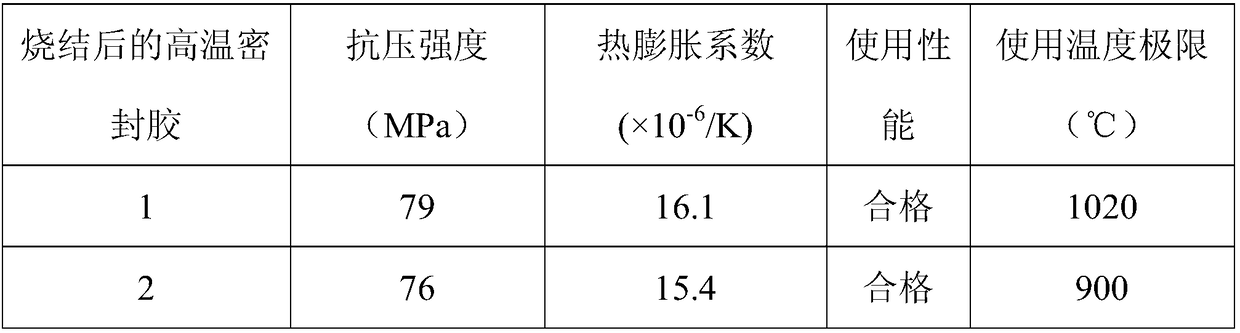

The invention relates to high-temperature sealing gum, which includes, by weight, 50-80 parts of glass powder, 5-40 parts of Ag / Cu alloy powder and 10-20 parts of a dispersant. The glass powder is prepared by crushing SiO2 glass and / or boron oxide glass. By adding the Ag / Cu alloy powder and the dispersant to the glass powder, the high-temperature sealing gum can seal or connect metal materials, ceramic materials or both, has excellent chemical stability and thermal stability, can effectively seal the material from room temperature to 1000 DEG C; meanwhile, after the high-temperature sealing gum is cured, thermal-expansion coefficient can be adjusted according to the content of oxides in the glass powder, ratio of silver in the Ag / Cu alloy powder and addition amount of the Ag / Cu alloy powder and can be changed optionally in the range of 7.3*10<-6> - 16.1*10<-6> / K, thus satisfying sealing demand on materials in different thermal-expansion coefficients.

Owner:上海穗杉实业股份有限公司

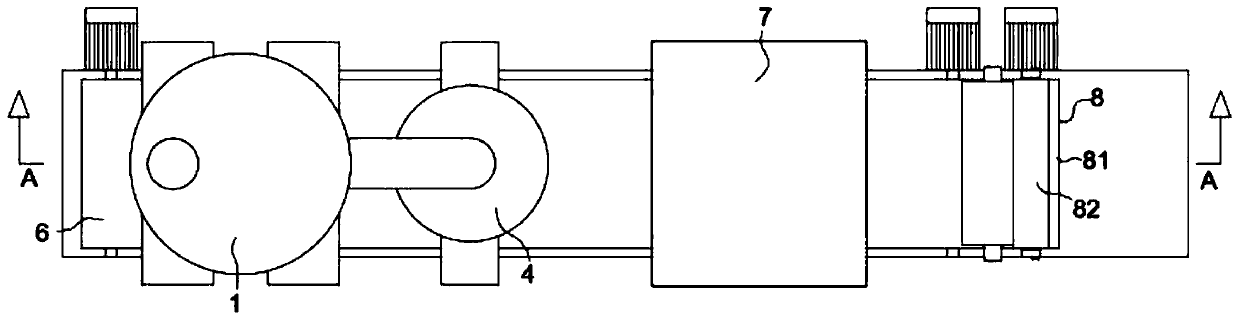

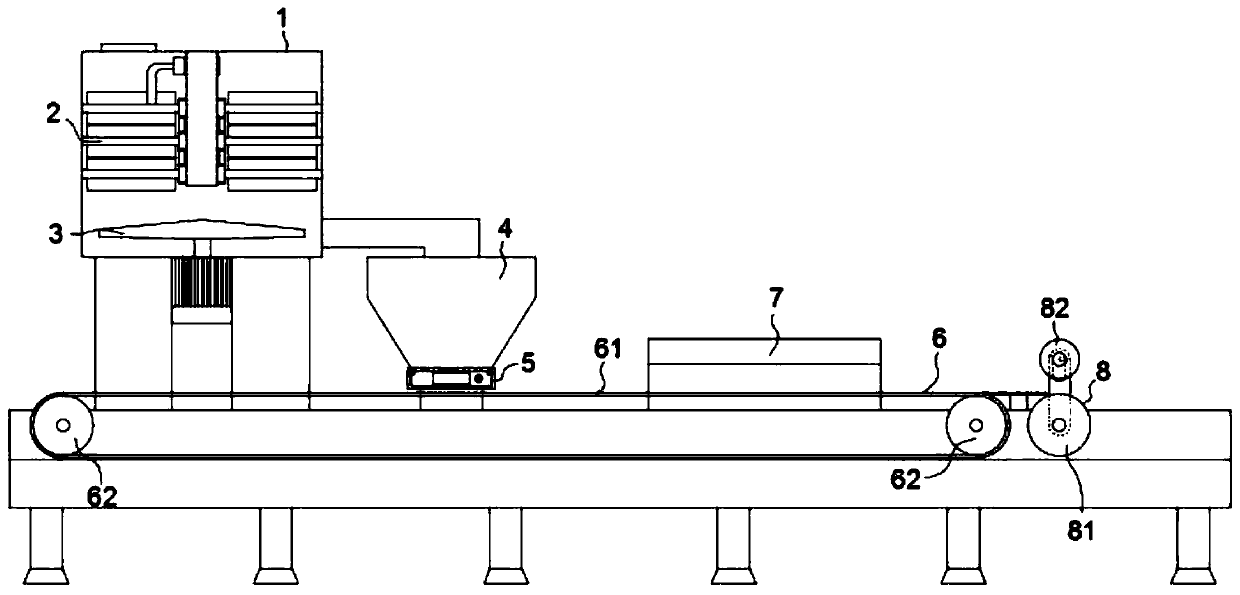

Particle material packaging machine

ActiveCN104760717AOvercome defectsImprove reliabilityWrapper twisting/gatheringPackaging automatic controlLap jointEngineering

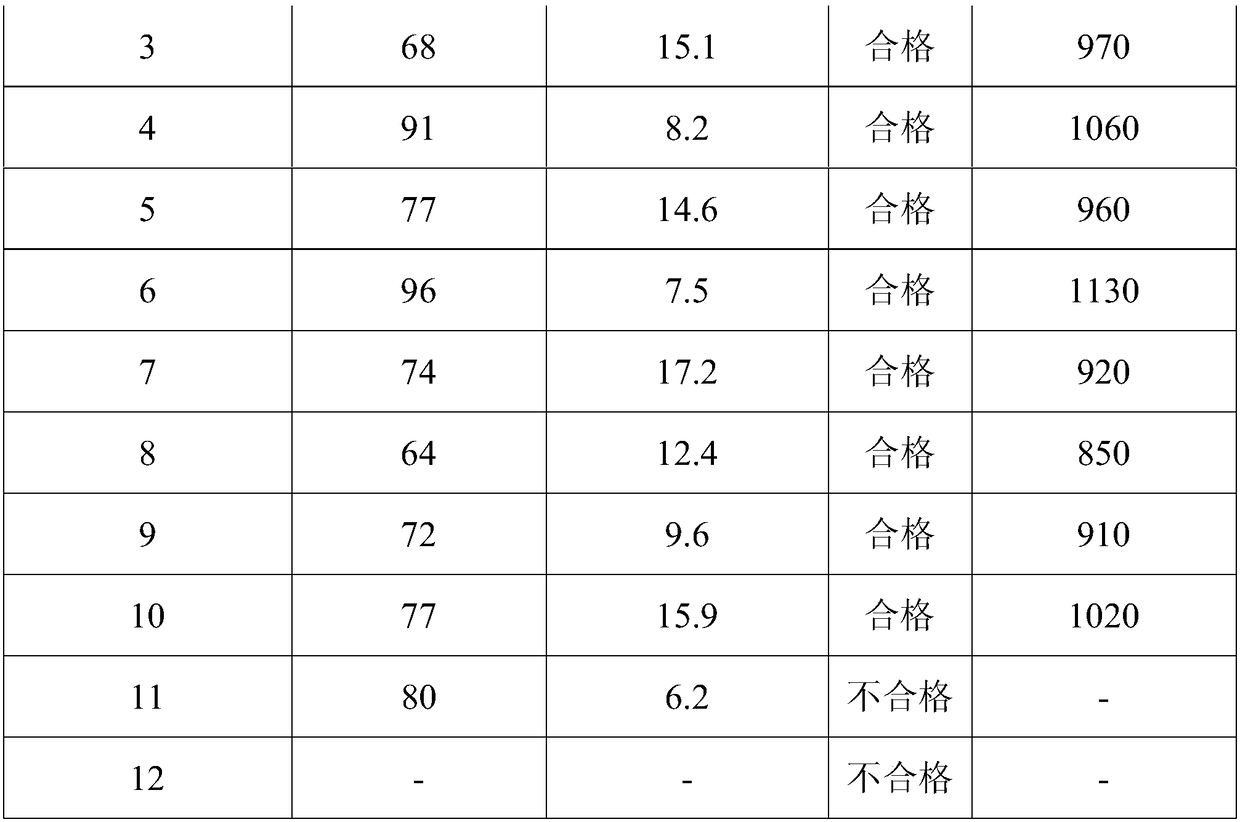

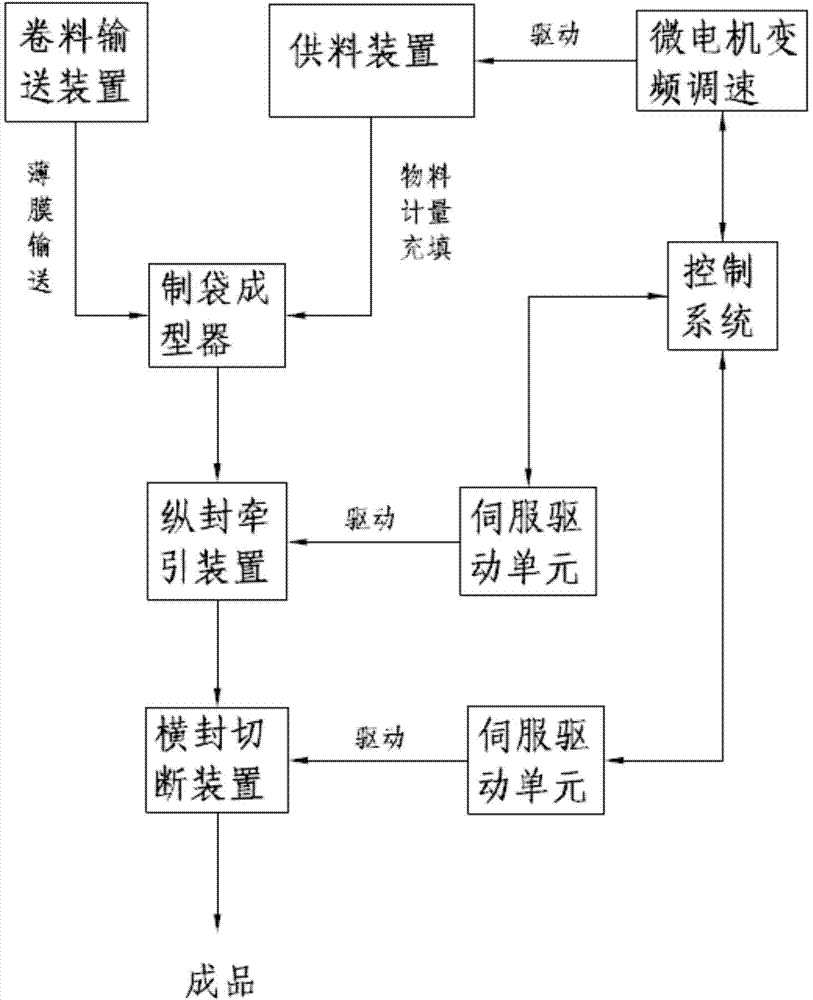

The invention discloses a particle material packaging machine which comprises a vertical machine frame, a rolled material conveying device, a material supply device, a bag-making forming device and an opening sealing device. The opening sealing device comprises a longitudinal traction device and a transverse-sealing cutting-off device. The longitudinal traction device is arranged above the transverse-sealing cutting-off device. The particle material packaging machine is of a vertical structure, all parts are ingenuously arranged, specific part improvement is performed, and the structure is greatly simplified, required occupied area is decreased. In addition, the reliability, packaging speed and finished product rate of the machine can be further effectively improved, operation is also simple and convenient, particle materials can be effectively, quickly and accurately packaged into pillow-shaped longitudinally-sealed lap joint bag products. A traction device is not needed to be independently arranged, the sealing demand is met through the original transverse-sealing cutting-off device, and meanwhile the demand that packaging films are sheared and cut off from the sealing positions and accordingly a shearing device is omitted is further met.

Owner:悦熙堂(山东)生物科技有限公司

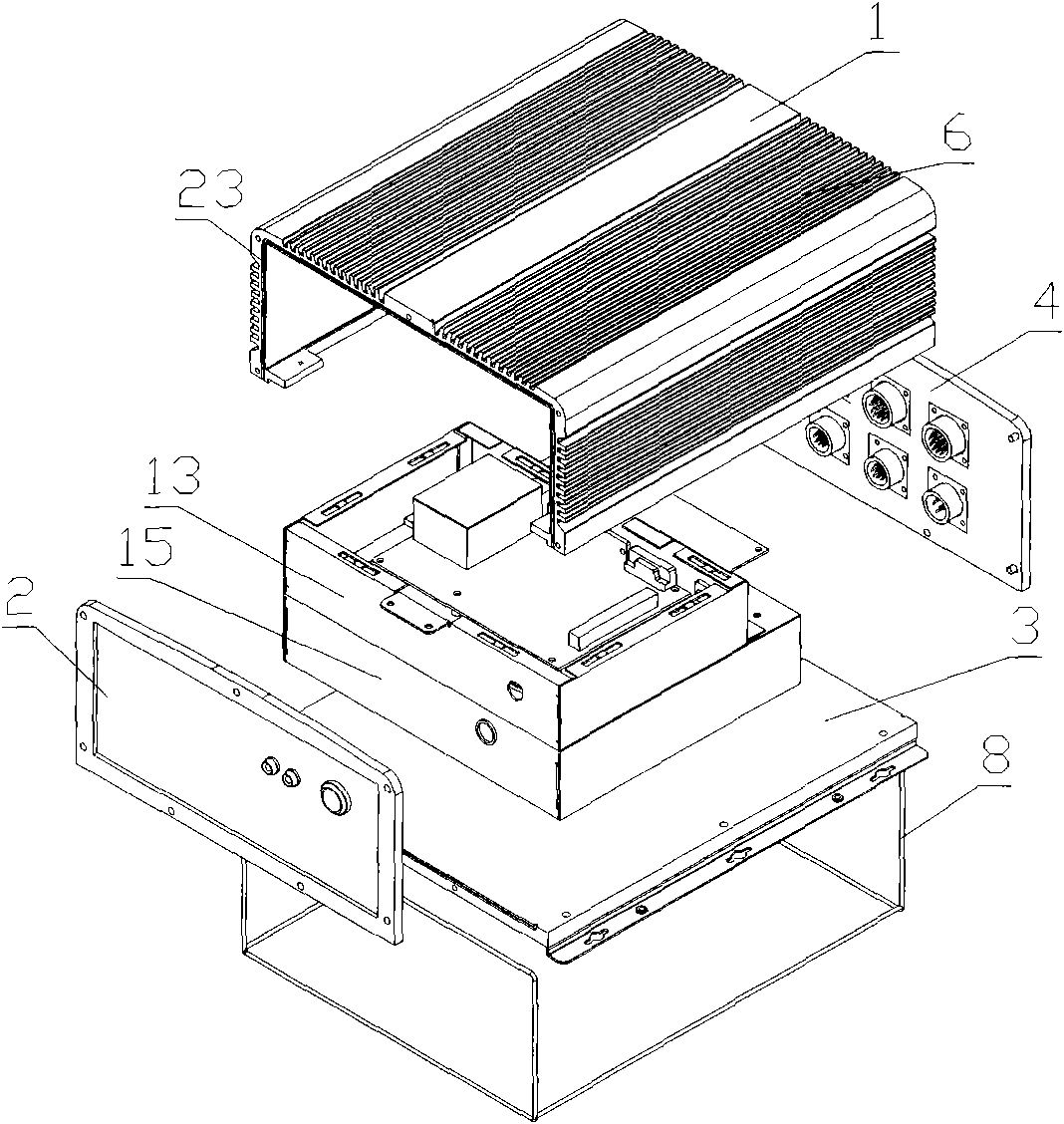

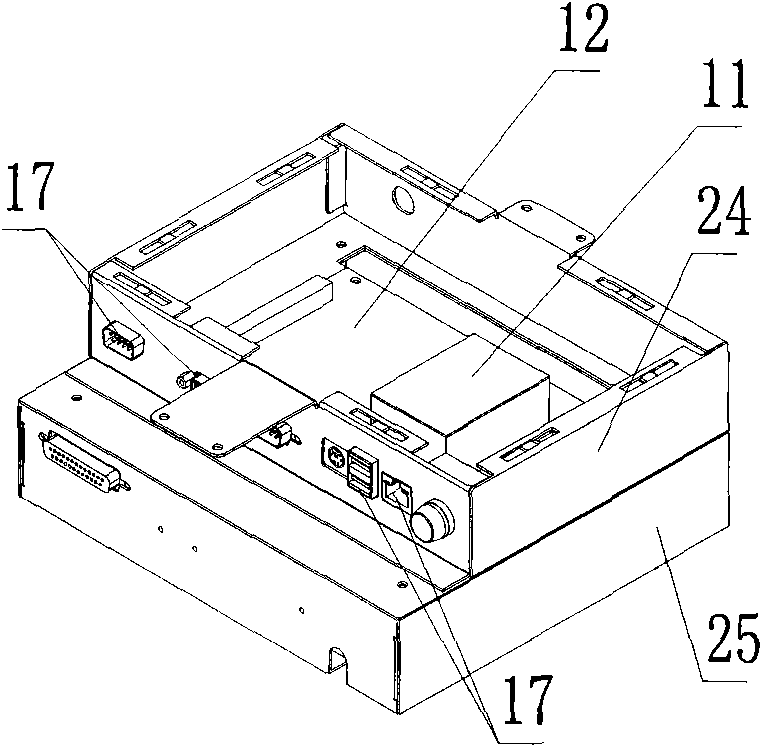

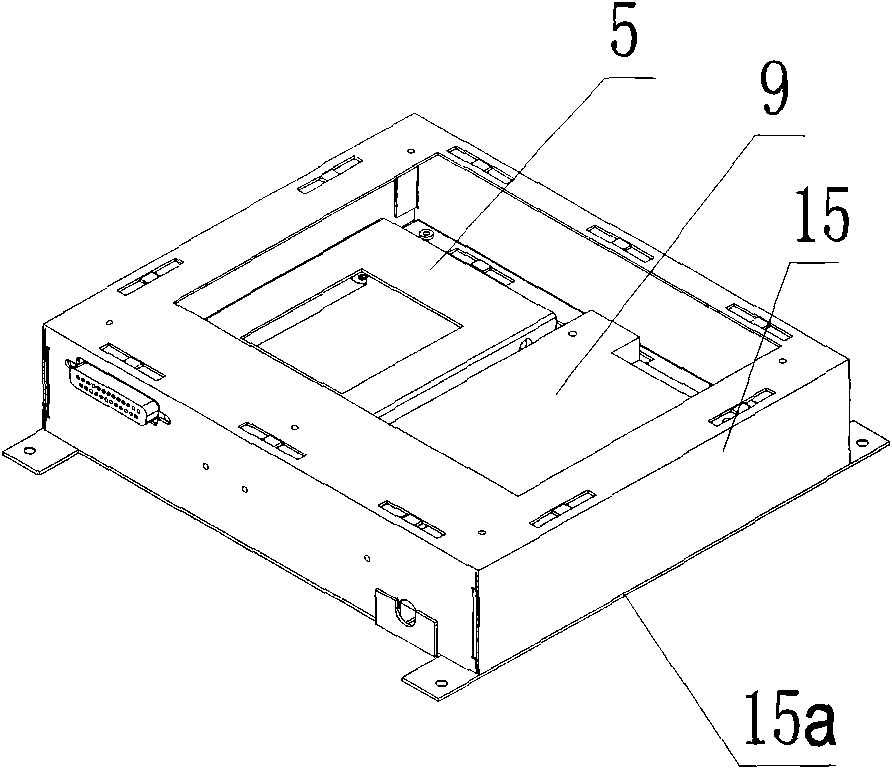

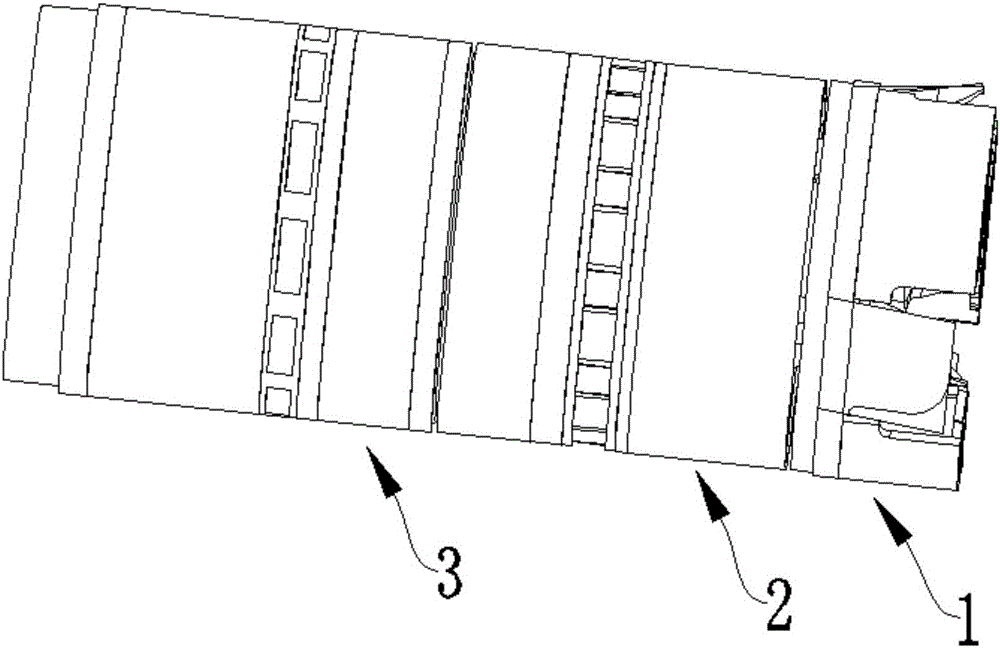

Special onboard computer

ActiveCN101625576AImprove the ability to resist electromagnetic interferenceGood anti-electromagnetic interference performanceDigital processing power distributionComputer caseOnboard computer

The invention discloses a special onboard computer, which comprises a case; a host computer module and a mainboard module are arranged in the case and fixedly connected with the case, and the case is formed by splicing case boards; the end faces of each case board are provided with mutually communicated seal grooves; and the insides of all the seal grooves of the case boards are respectively provided with an integrated seamless sealing ring not spliced. The special onboard computer provided by the invention can be adapted to a low atmospheric-pressure environment at a high altitude of 10,000 meters, and has high tightness, high electromagnetic interference resistance, high shock resistance, good radiating effect and strong erosion resistance.

Owner:EVOC INTELLIGENT TECH

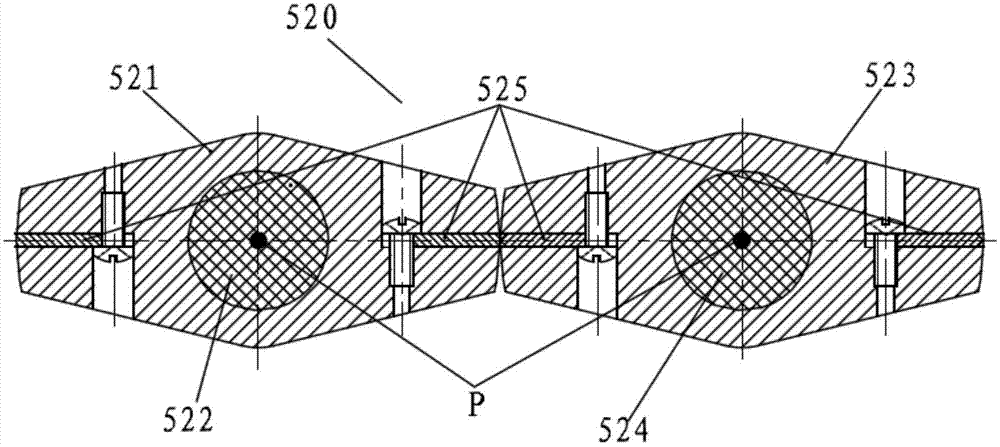

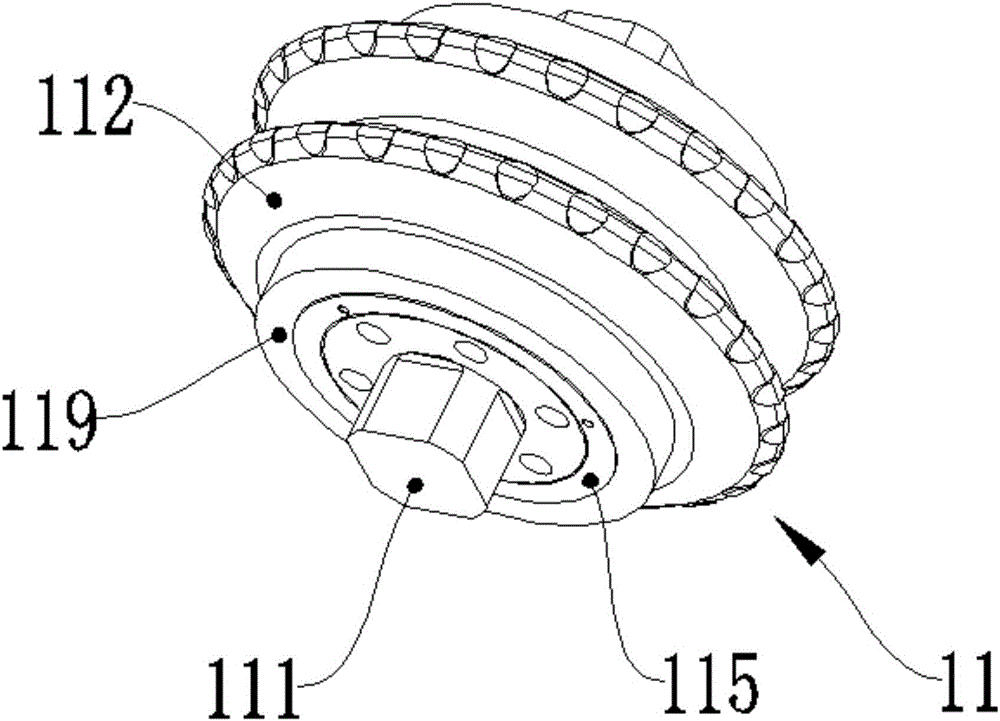

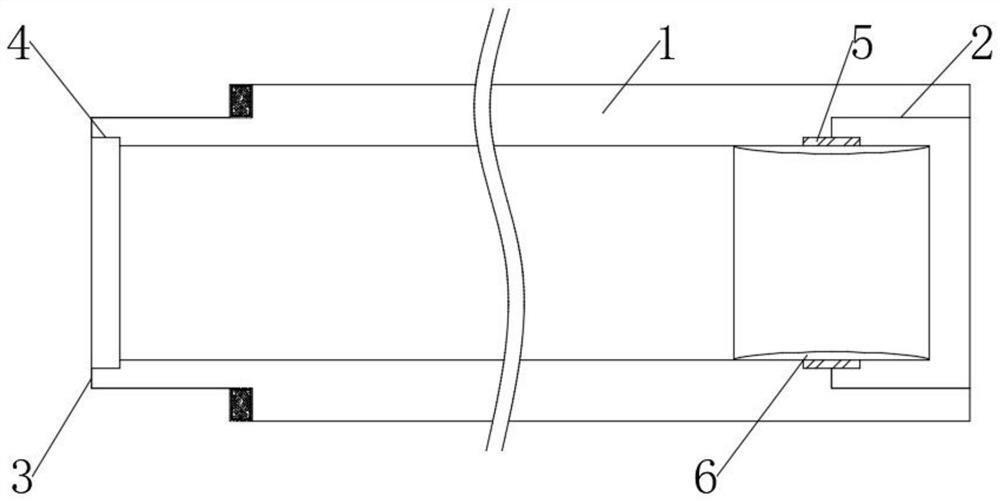

Hard rock push bench

The invention discloses a hard rock push bench. The hard rock push bench comprises a cutter head, a crushing compartment and a housing, wherein the front end of the crushing compartment is connected with the back side of the cutter head, and the tail end of the crushing compartment is connected with the front end of the housing. The hard rock push bench is used for performing excavation work in a pebble bed, or a gravel bed, or continuous hard rock. No single bearing is arranged on a hob of the hard rock push bench, but a bearing inner ring is integrated onto a cutter shaft, a bearing outer ring is integrated onto a cutter body, and therefore structure of the hob is simplified, and production cost and manufacturing difficulty are reduced. .By regulating degrees of tightness between a hob seal ring and an annular gland through a gland regulation bolt, starting torque of the hob can be quickly regulated, and then the hob can adapt to different geological environments.

Owner:FOSHAN CONSTANT HYDRAULIC MACHINERY

High-efficiency isolating and sealing device for optical cable

InactiveCN108873203AEasy to operateEasy to fixFibre mechanical structuresEngineeringOptical fiber cable

Owner:胡肖平

Tongue-and-groove type flexible joint reinforced concrete drainage pipe and machining process thereof

ActiveCN112720826AMeet sealing needsInhibit sheddingShaping reinforcementsPipe-jointsReinforced concreteArchitectural engineering

The invention discloses a tongue-and-groove type flexible joint reinforced concrete drainage pipe and a machining process thereof, belongs to the field of reinforced concrete drainage pipes. According to the tongue-and-groove type flexible joint reinforced concrete drainage pipe and the machining process thereof, low-temperature simulation is carried out on a connecting end of a drainage pipe body by using an ice ring embedded with an attaching net, so that the drainage pipe body is installed in a low-temperature state, namely, the drainage pipe body is installed in a cold contraction state, the drainage pipe body is in the minimum size at the moment, after installation is completed, the drainage pipe body only expands, and a compensation rubber mat serving as a sealing piece and the internal structure of the compensation rubber mat only need to resist extrusion of the drainage pipe body, before installation, the reinforced concrete drainage pipe is pretreated, so that the reinforced concrete drainage pipe is installed in a matched mode in a low-temperature contraction state, at the moment, a sealing device only needs to cope with the temperature rising expansion state of the reinforced concrete drainage pipe, and the use reliability of the sealing device is improved.

Owner:浙江银泰水泥构件股份有限公司

Base oil of cotton picker spindle lubricating grease

InactiveCN110499201AGood viscosity-temperature characteristicsMeet lubrication needsBase-materialsVegetable oilTemperature difference

Belonging to the technical field of lubricating compositions characterized by mixed ester, the invention in particular relates to a base oil of cotton picker spindle lubricating grease. The base oil of the cotton picker spindle lubricating grease comprises the following components: esterified modified epoxy vegetable oil, neopentyl glycol dioleate, isooctyl oleate and trimethylolpropane trioleate.The base oil of cotton picker spindle lubricating grease provided by the invention has good viscosity-temperature characteristics, and can meet the lubrication and sealing requirements of a cotton picker spindle bearing in a working environment with large temperature difference between day and night.

Owner:重庆化工职业学院

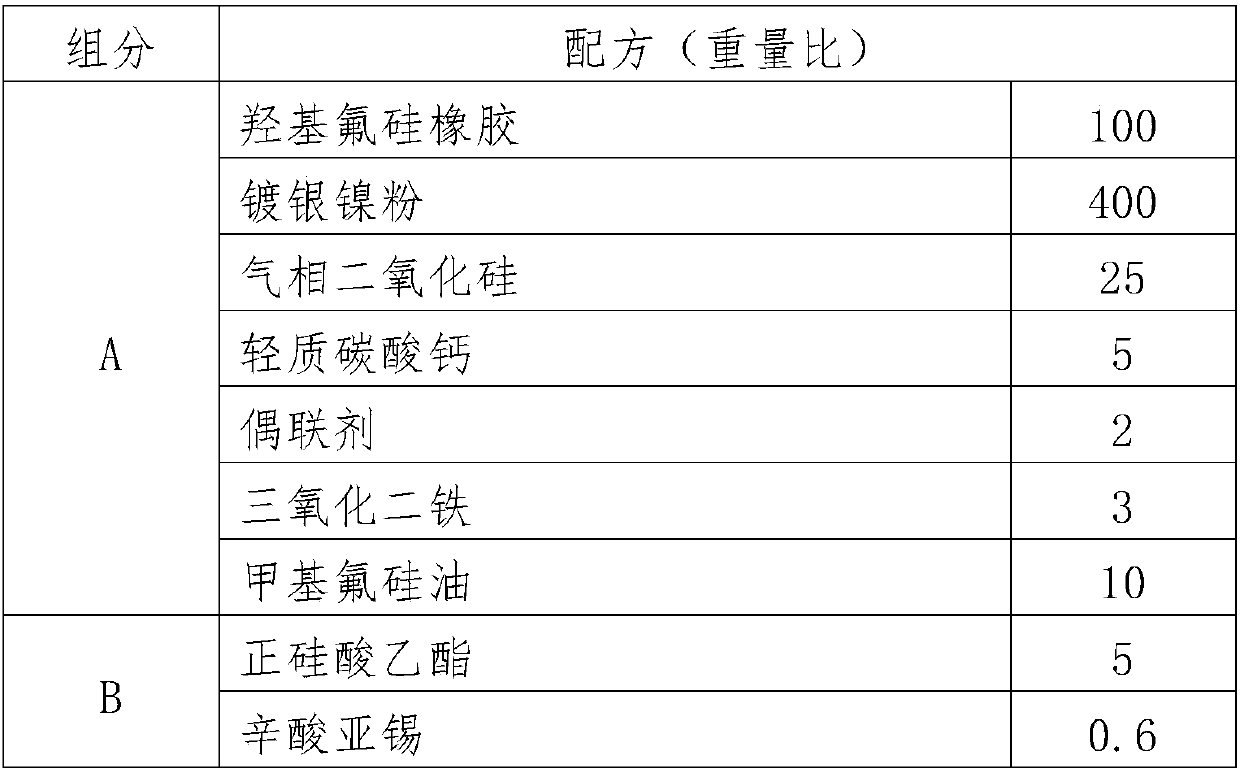

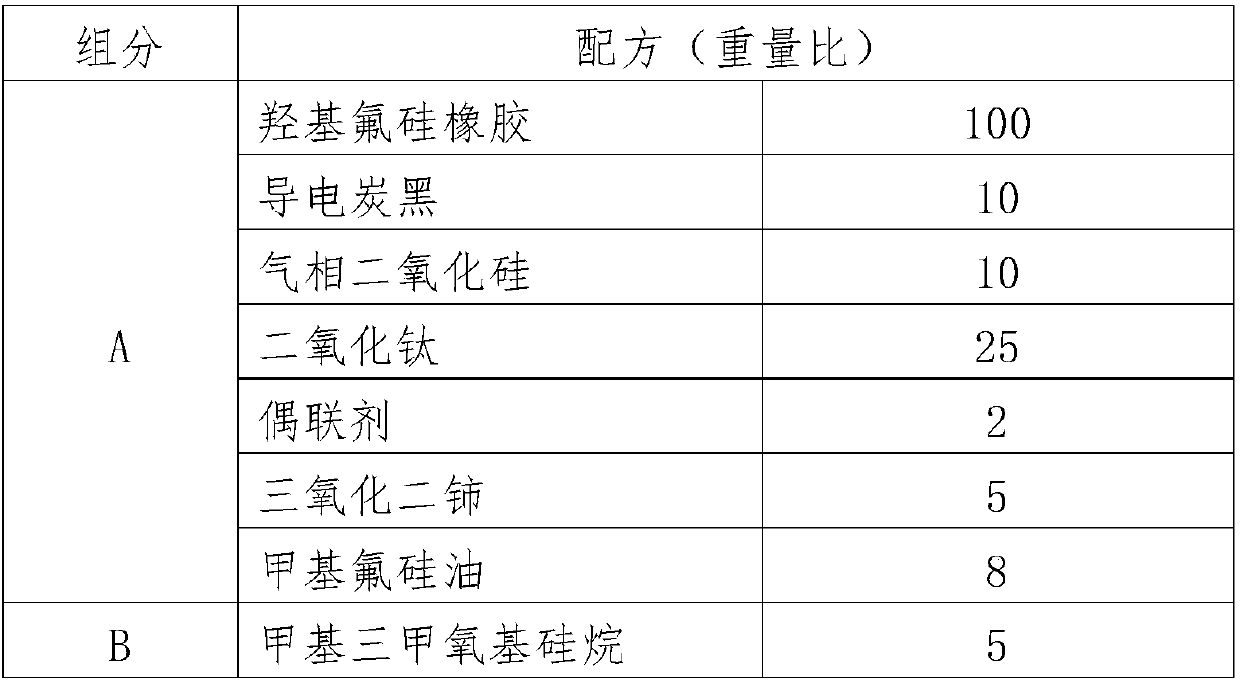

Conductive fluorosilicone sealant and preparation method thereof

InactiveCN107936576AHigh temperature resistanceImprove high temperature resistanceMaterials preparationFuel oil

The invention belongs to the technical field of sealant preparation, and relates to a fluorosilicone sealant with conduction performance and a preparation method thereof. The fluorosilicone sealant isprepared from an ingredient A and an ingredient B, wherein the ingredient A is prepared from hydroxy-terminated liquid fluorosilicone rubber, conductive fillers, reinforcing agents, heat-resistant agents, coupling agents and methyl fluorosilicone oil; the ingredient B is prepared from a vulcanizing agent and a catalyst. The steps for preparing the ingredient A include material preparation, roughly mixing and stirring; the steps for preparing the ingredient B include material preparation and mixing. The fluorosilicone sealant with conduction performance and the preparation method of the fluorosilicone sealant provided by the invention have the advantages that the medium resistant and temperature resistant grades of the conductive sealant are improved; the degree of degradation reaction generated in media such as fuel oil is weakened; the high-temperature-resistant performance is improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

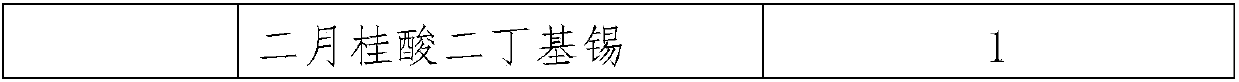

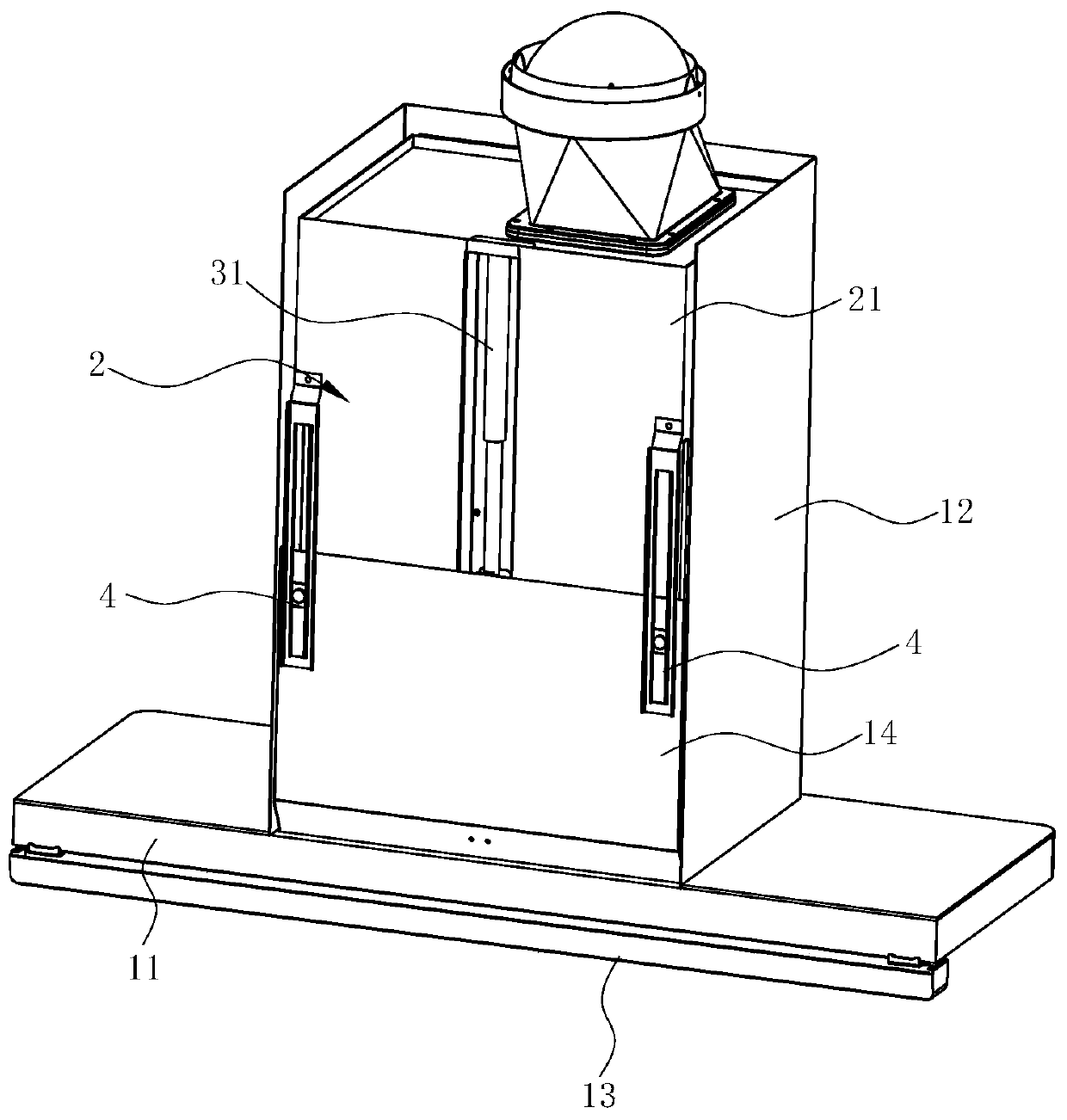

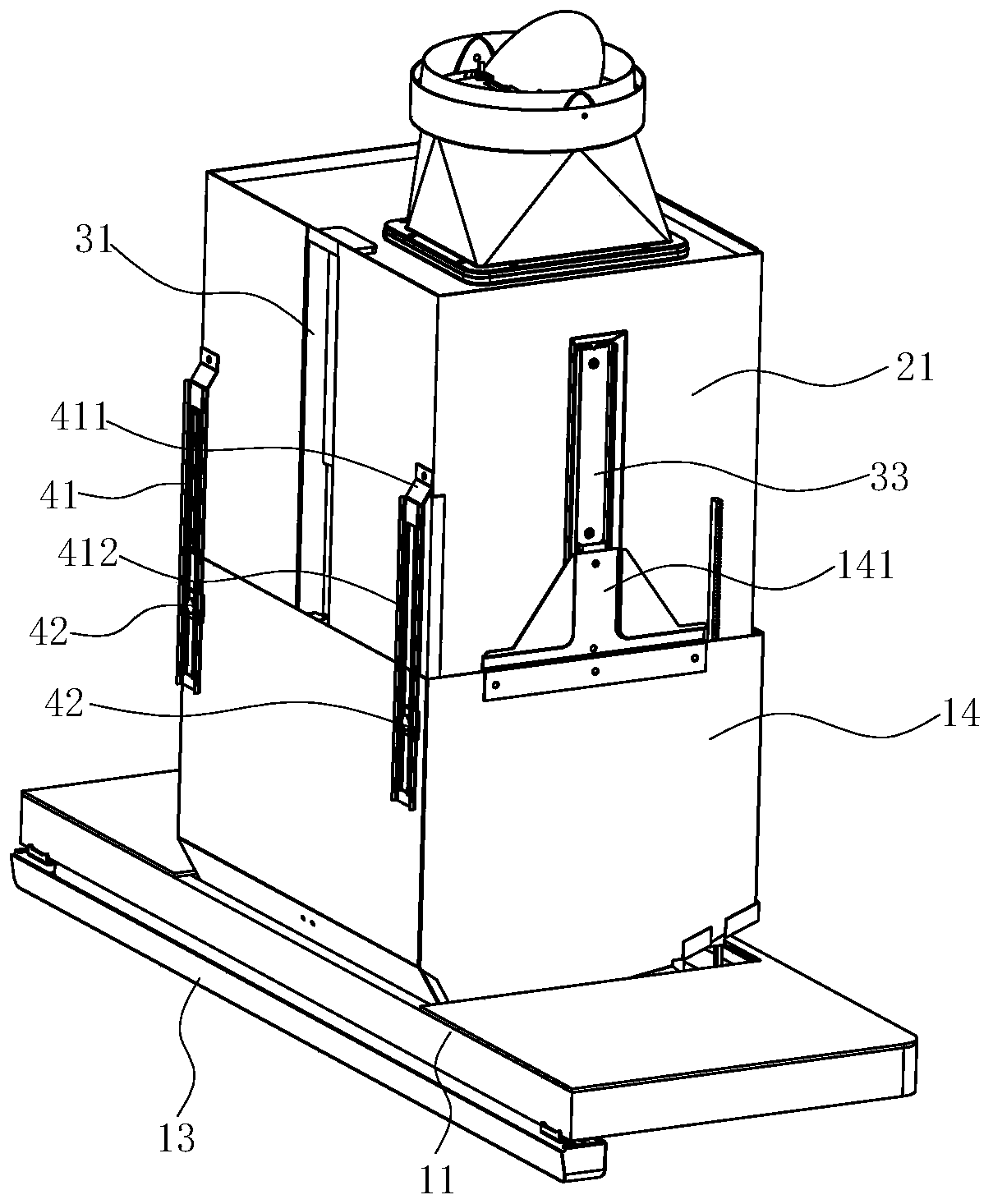

Extractor hood

ActiveCN111536562AAvoid damageLow movement resistanceDomestic stoves or rangesLighting and heating apparatusOil and greaseEngineering

The invention discloses an extractor hood. A movable component, a fixed component and a motion mechanism used for manually driving the movable component to ascend and descend relative to the fixed component are included. The movable component comprises a smoke gathering cover. The fixed component comprises a draught fan frame. The extractor hood is characterized in that the movable component further comprises a motion frame arranged above the smoke gathering cover, the smoke gathering cover is provided with an air inlet, the lower end of the motion frame is connected to the periphery of the air inlet, and the motion frame wraps the periphery of the draught fan frame. Compared with the prior art, the extractor hood has the advantages that the motion frame of the movable component wraps theperiphery of the draught fan frame of the fixed component, the oil path and seal requirements can be met, through only arrangement of one oil gathering component, grease collection can be achieved, and oil dripping in the extractor hood shutdown state is avoided; and through the arrangement of a supporting component, movable component damage due to friction with a wall in the lifting movement process can be avoided, the motion resistance is reduced, and the service life is prolonged.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

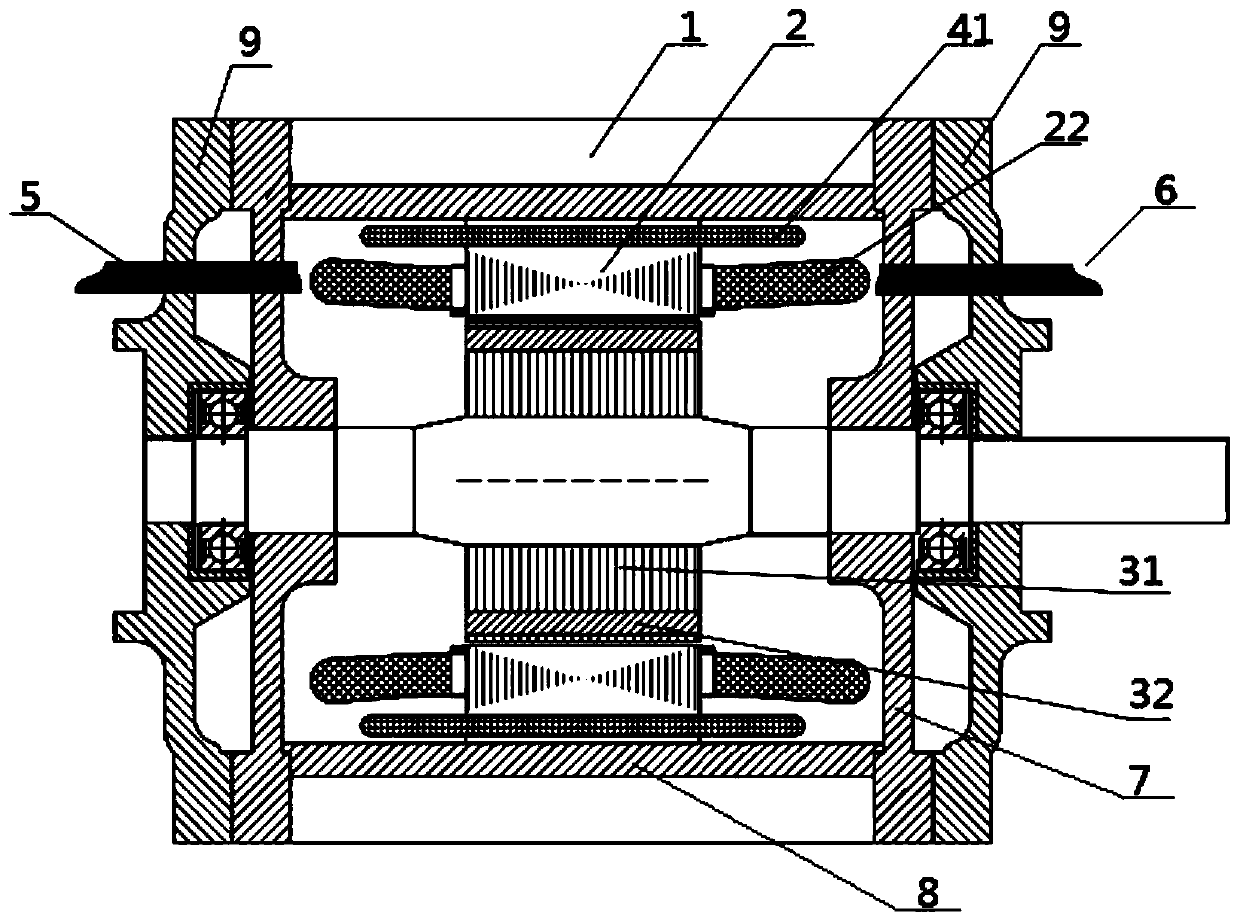

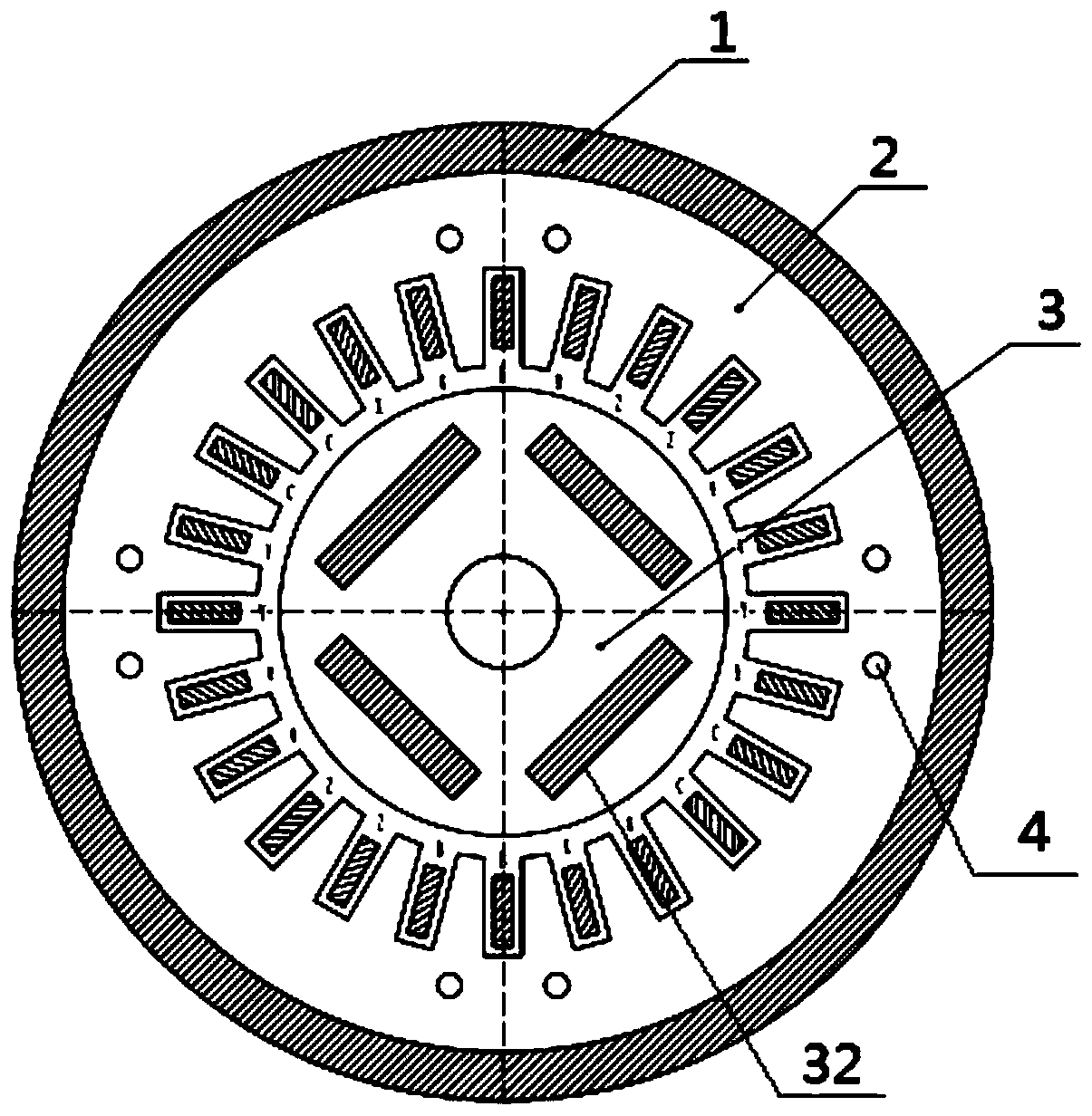

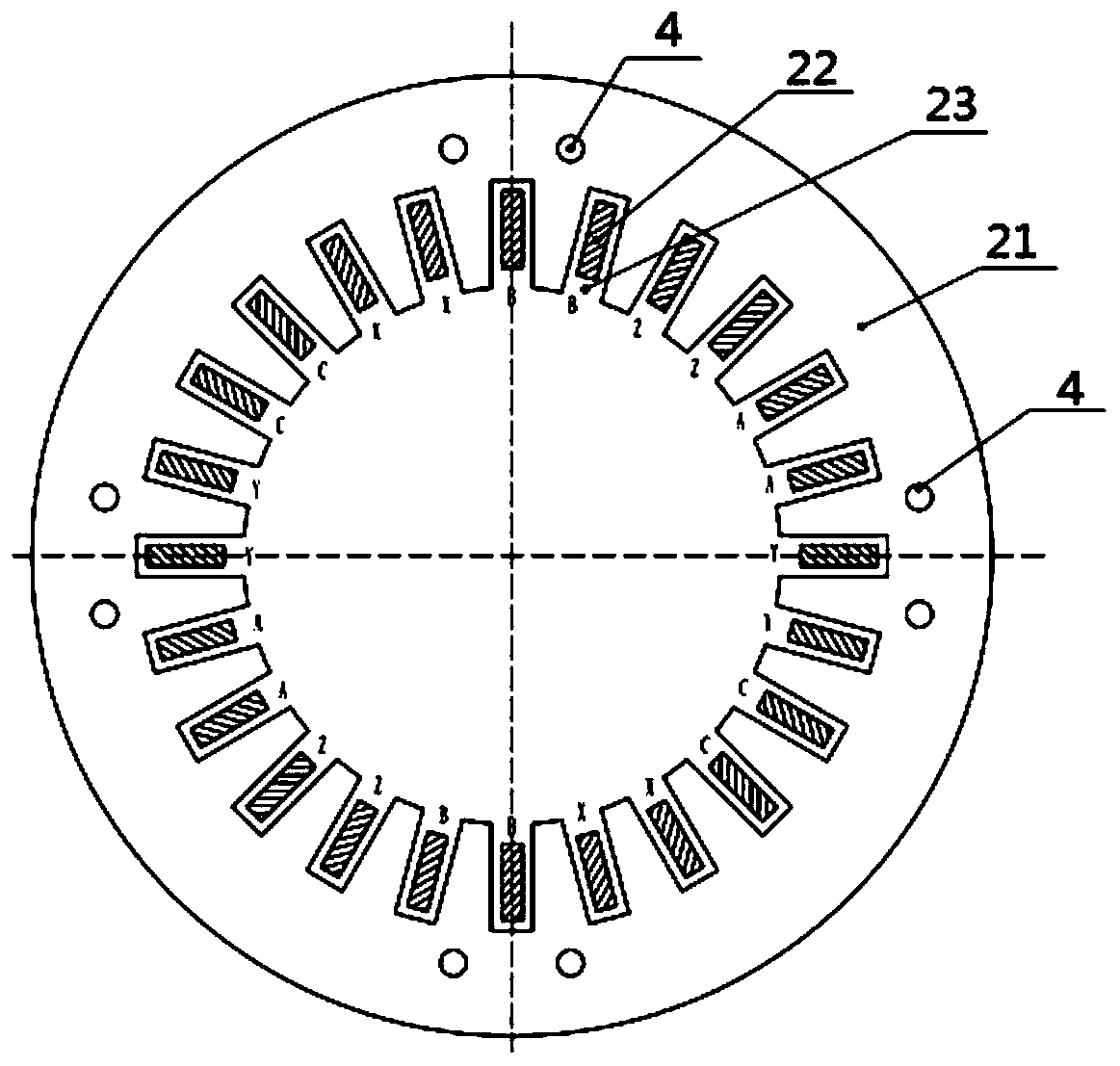

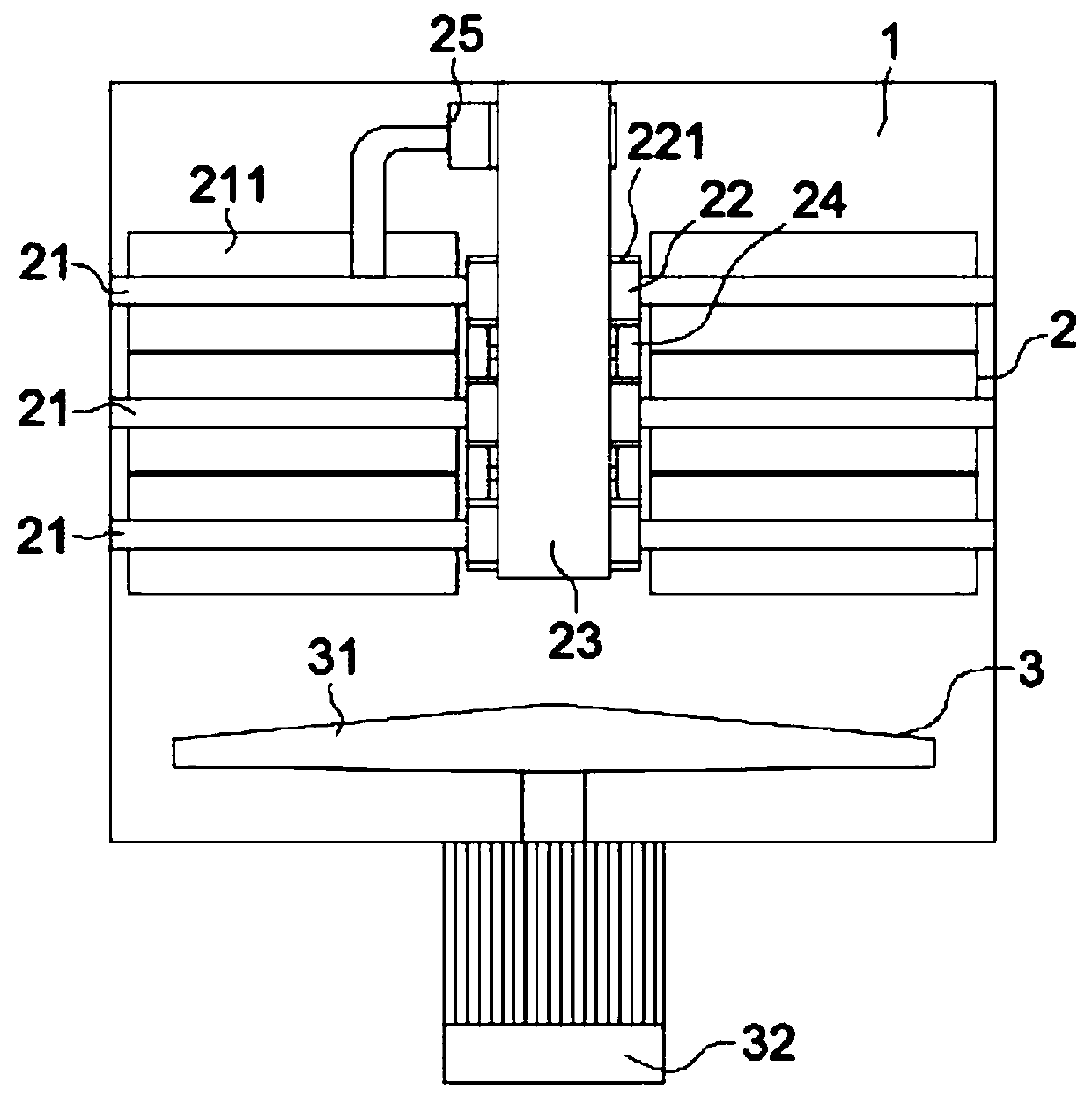

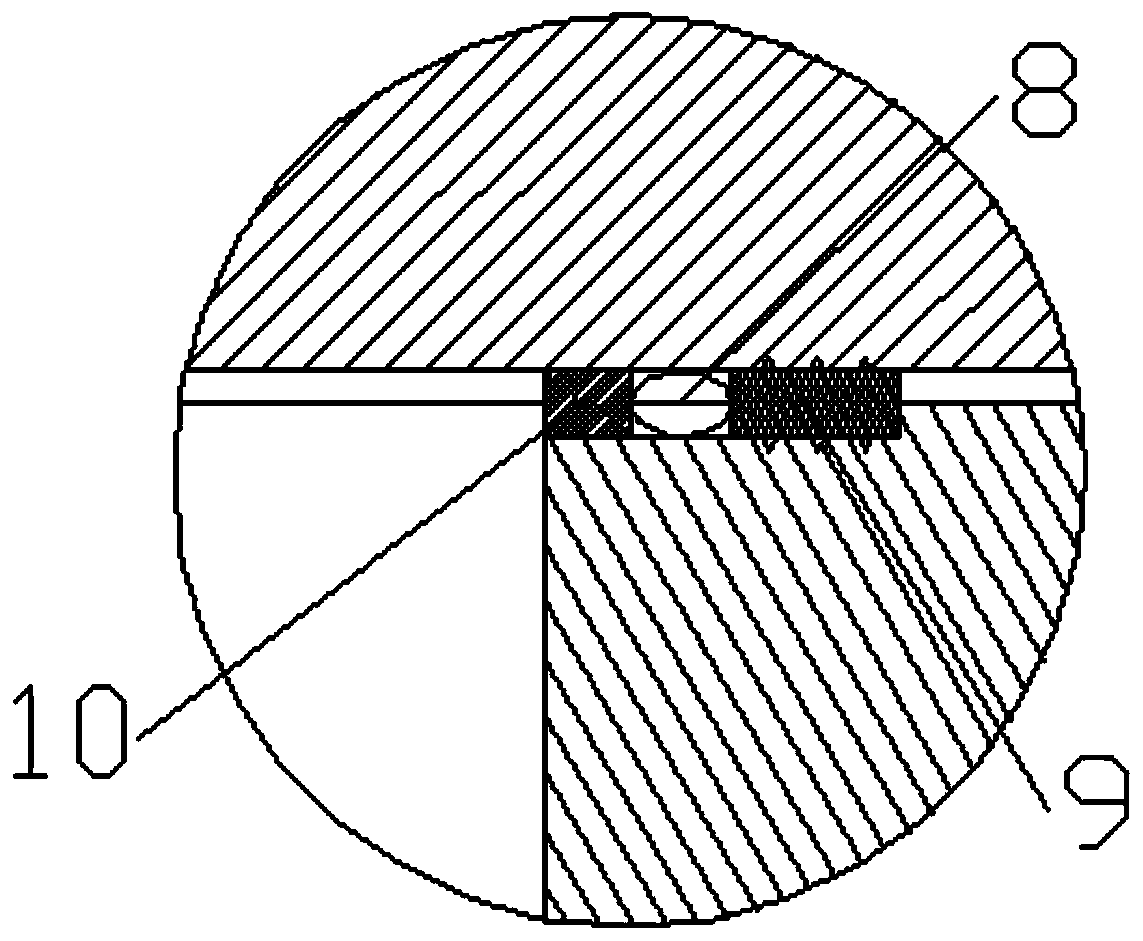

High-temperature superconducting motor

PendingCN110649789AAvoid rotating energized magnetizationReduce wearWindingsSupports/enclosures/casingsCooling mediumMaterials science

The invention discloses a high-temperature superconducting motor. The high-temperature superconducting motor comprises a motor shell, a stator and a rotor which are sequentially arranged from outsideto inside in the radial direction, the stator is provided with a stator winding, and the rotor is provided with a superconducting magnetic block; the stator is provided with a wire hole extending in the axial direction, and a superconducting wire used for being electrified to magnetize the superconducting magnetic block is arranged in the wire hole; the motor shell is sealed, and two ends of the motor shell are provided with end covers which are matched with the motor shell in a sealing manner; and a cooling medium used for maintaining the superconducting wire and the superconducting magneticblock at a superconducting critical temperature is introduced into the motor shell, and the stator and the rotor are immersed in the cooling medium. The high-temperature superconducting motor breaks through the restriction of dynamic electrification of the superconducting wire, and improves the convenience and reliability of magnetizing of the superconducting magnetic block.

Owner:卧龙电气(上海)中央研究院有限公司 +1

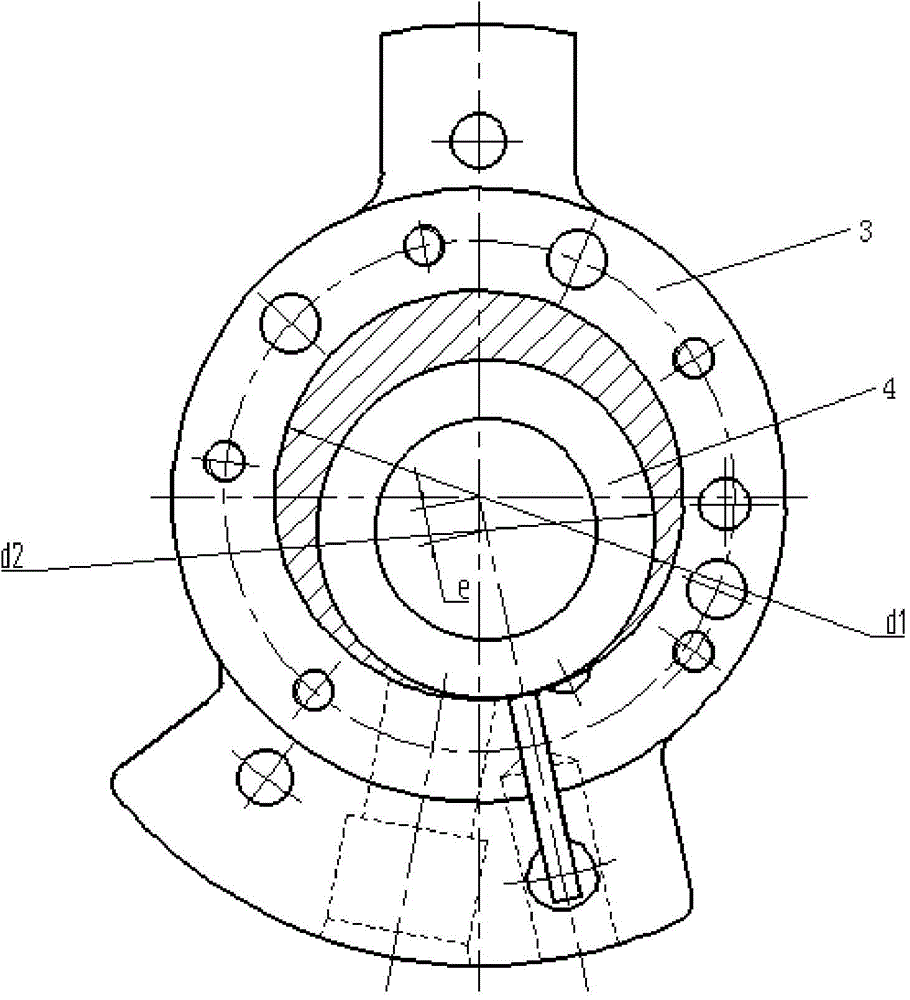

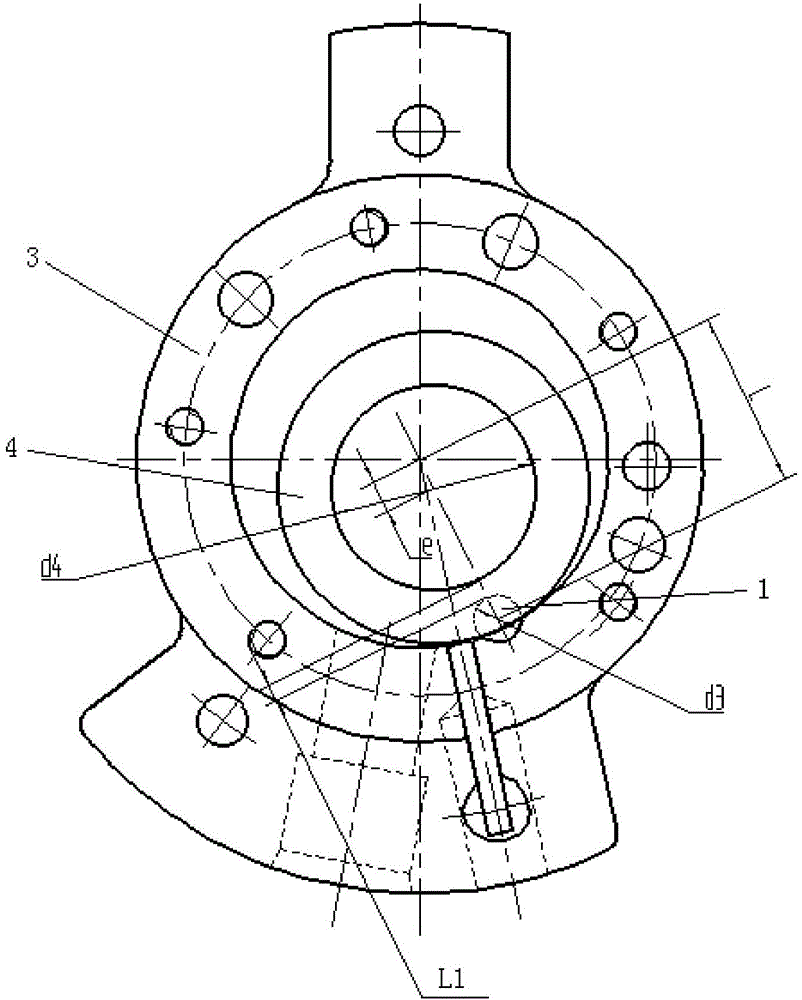

Compressor roller, compressor pump body and compressor

ActiveCN104153993AMeet sealing needsLarge displacementRotary/oscillating piston pump componentsLiquid fuel engine componentsFlange

The invention provides a compressor roller, a compressor pump body and a compressor. The compressor roller comprises a cylindrical roller main body, and an inner flange arranged at a first end of the roller main body. Under the condition of satisfying the sealing requirement of a compression cylinder, the displacement of the compressor can be increased, so that the displacement of the compressor reaches the highest theoretical displacement.

Owner:郑州凌达压缩机有限公司

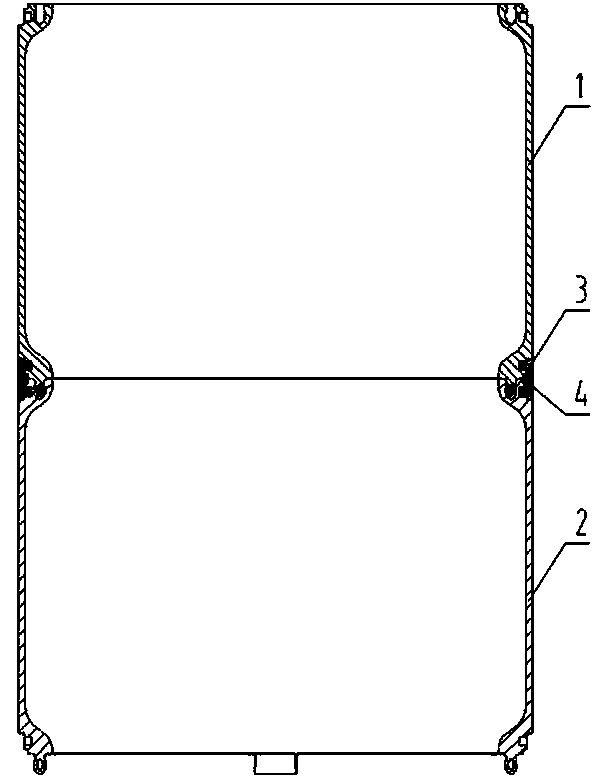

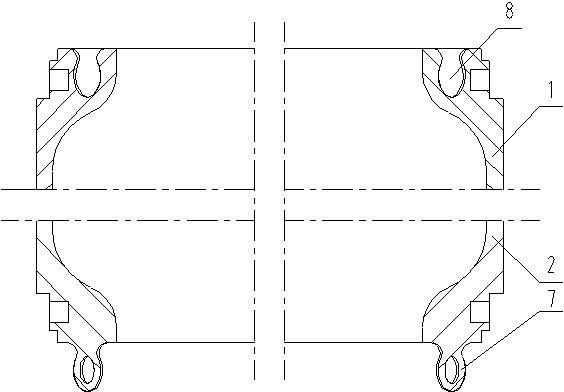

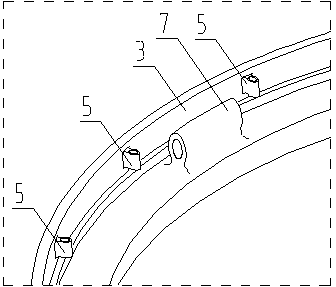

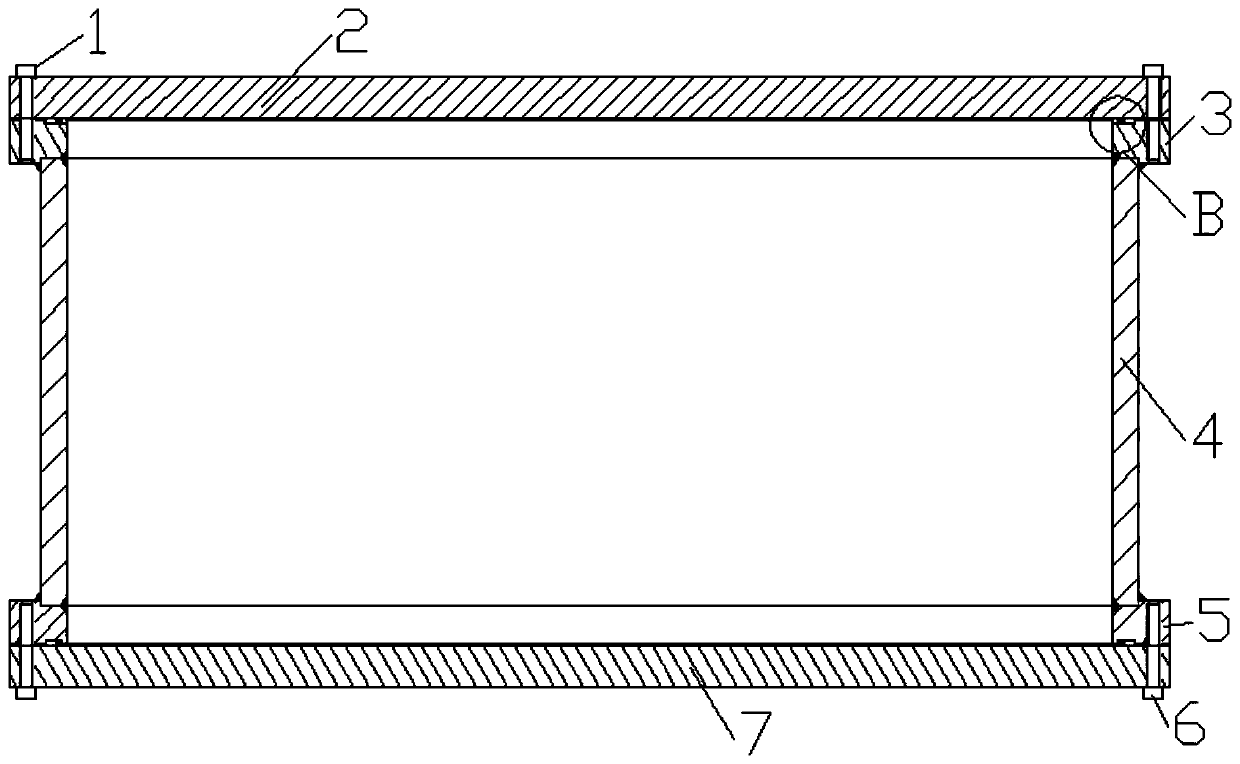

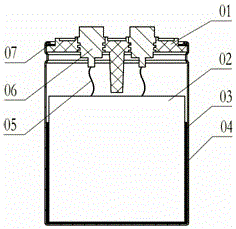

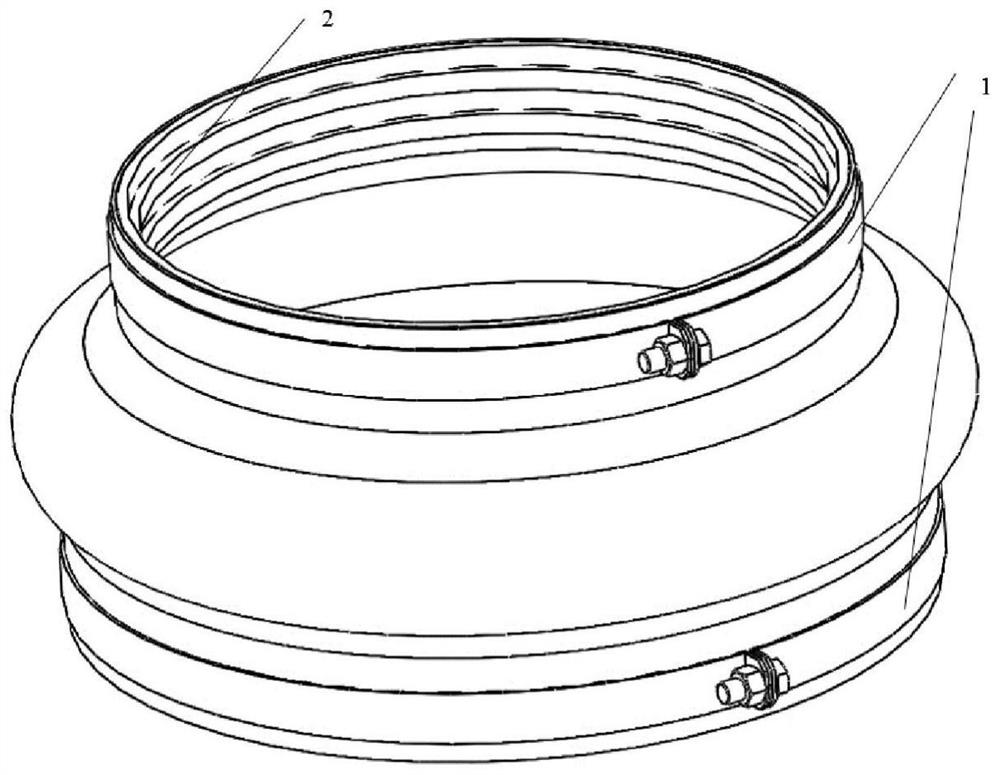

Industrial airtight container and connection method thereof

ActiveCN103832718AEasy to disassembleReduce processing difficultyLarge containersFastenerEngineering

The invention discloses an industrial airtight container. The industrial airtight container comprises a first air-tight bin and a second air-tight bin, wherein the first air-tight bin and the second air-tight bin are arranged in sequence in the extension direction of the industrial airtight container. The industrial airtight container further comprises a connecting device which is connected with the first air-tight bin and the second air-tight bin. The connecting device comprises a fastening and connecting snap fastener plate, seal rings, male snap fasteners, and female snap fasteners matched with the male snap fasteners, wherein the fastening and connecting snap fastener plate surrounds the periphery of the first air-tight bin and the periphery of the second air-tight bin in the circumferential direction; the seal rings are arranged between the fastening and connecting snap fastener plate and the first air-tight bin and between the fastening and connecting snap fastener plate and the second air-tight bin. The industrial airtight container is simple in connection structure, high in connection efficiency, low in cost, detachable, and convenient to maintain and examine. Meanwhile, the invention further provides a connection method of the industrial airtight container. The connection method realizes connection of the industrial airtight container and lowers the usage cost of the industrial airtight container.

Owner:SUS LAB FOR IND SCI & TECH

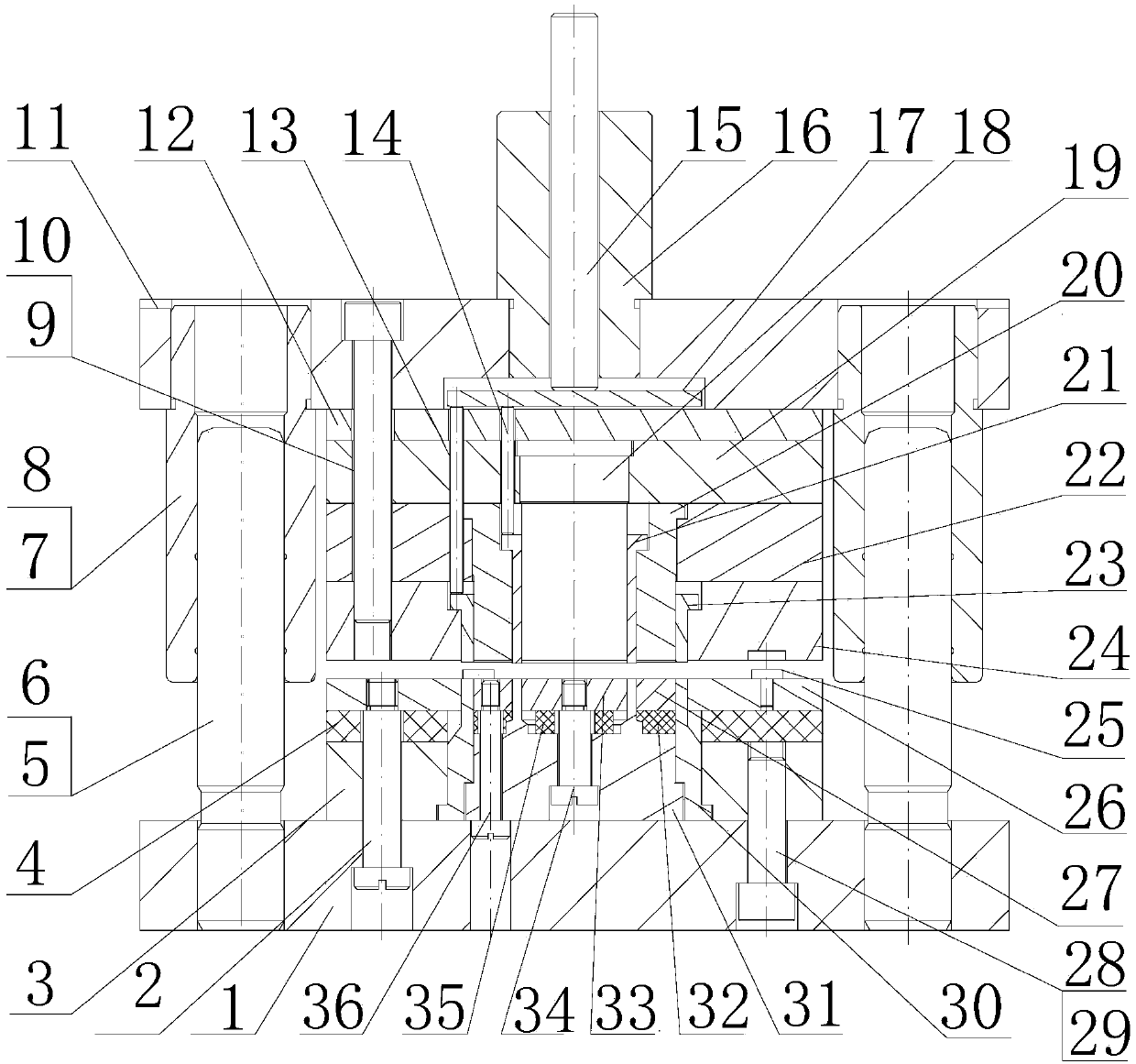

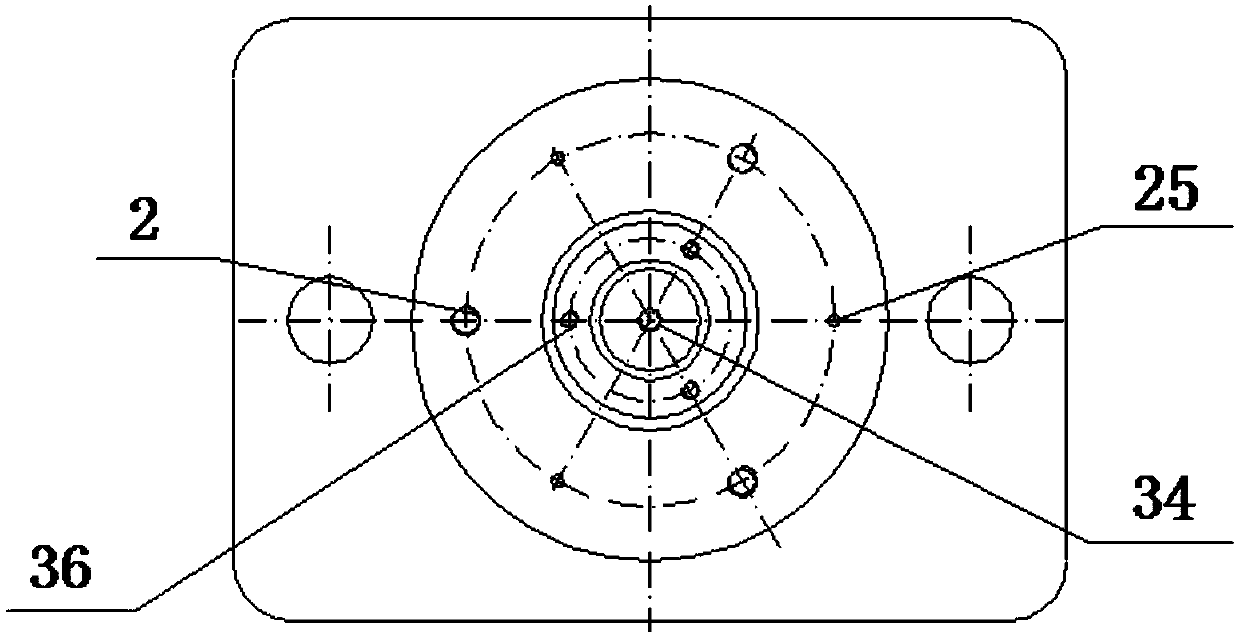

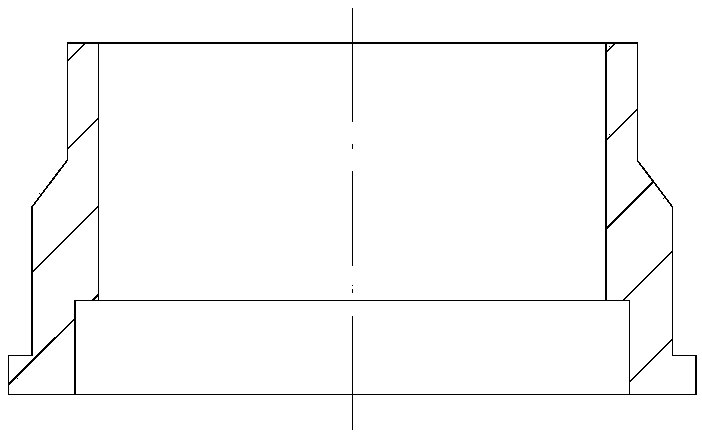

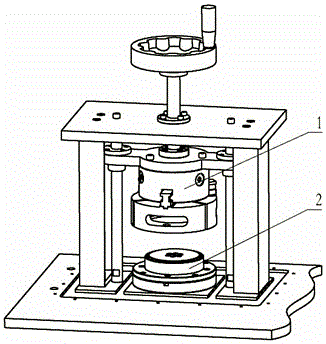

Composite die structure

ActiveCN108724342ANo feeding errorHigh precisionMetal working apparatusMotion spaceMechanical engineering

A composite die structure comprises an upper die and a lower die. A die handle (16) is arranged on an upper die plate of the upper die. A knockout rod (15) with an ejector plate (17) arranged at the bottom is arranged in the middle of the die handle in a sleeved manner. A small gasket inner hole convex die (18) is arranged in a small convex die clamp plate. A large gasket inner hole convex die (20) is arranged in a large convex die clamp plate. The large gasket inner hole convex die and the small gasket inner hole convex die stretch to the bottom of a large gasket shape blanking concave die (24). A large part pushing device (23) and a small part pushing device (21) are arranged on the outer sides of the bottoms of the large gasket inner hole convex die and the small gasket inner hole convex die correspondingly. A long ejector pin (13) is arranged between the ejector plate and the large part pushing device. A short ejector pin (14) is arranged between the ejector plate and the small part pushing device. Motion space which is at least equal to the height of a gasket is arranged between the ejector plate and the upper die plate. A large convex-concave die (30) is clamped in a lower die clamp plate of the lower die. A small convex-concave die (31) is arranged in the large convex-concave die. The top of the large convex-concave die and the top of the small convex-concave die extendto be flushed with the top of a discharging plate, and an elastic base plate and an ejection ring are arranged on the upper portions of inner cavities of the large convex-concave die and the small convex-concave die correspondingly.

Owner:LANDING GEAR ADVANCED MFG

Vermiculite sealing material for high-temperature fuel cell

The invention discloses a vermiculite sealing material for a high-temperature fuel cell. The vermiculite sealing material mainly comprises the following components: 20-80% of chemical expanded vermiculite, 0-50% of thermal expanded vermiculite, 0-50% of talc, 0-30% of glass fiber, 0-5% of graphene oxide, 0-5% of a dispersing agent and 0-5% of siloxane. Vermiculite is adopted as a main raw material, the talc, the glass fiber, the graphene oxide, auxiliaries and the like are added to prepare a plate, and the plate can resist the high temperature of 1000 DEG C, has sealing and insulating properties and can meet the sealing requirement of the high-temperature fuel cell.

Owner:杨云

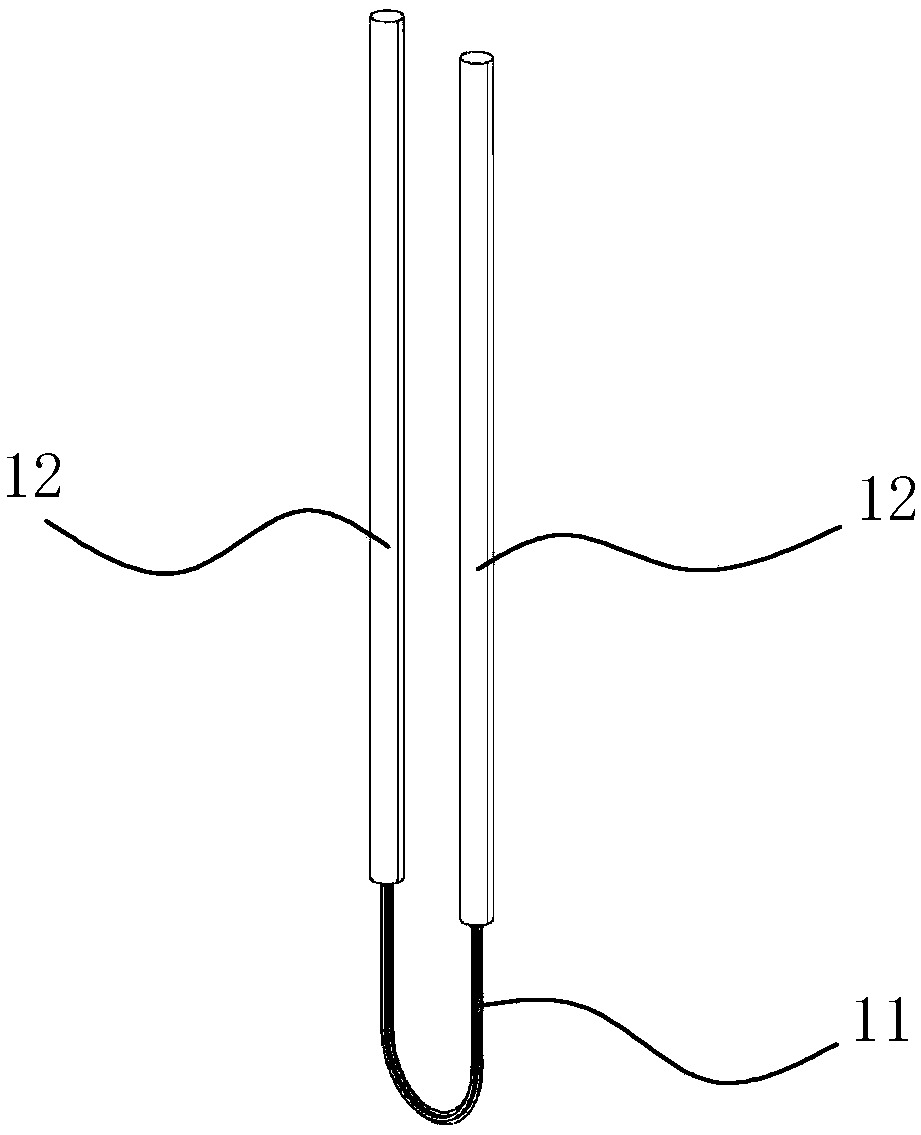

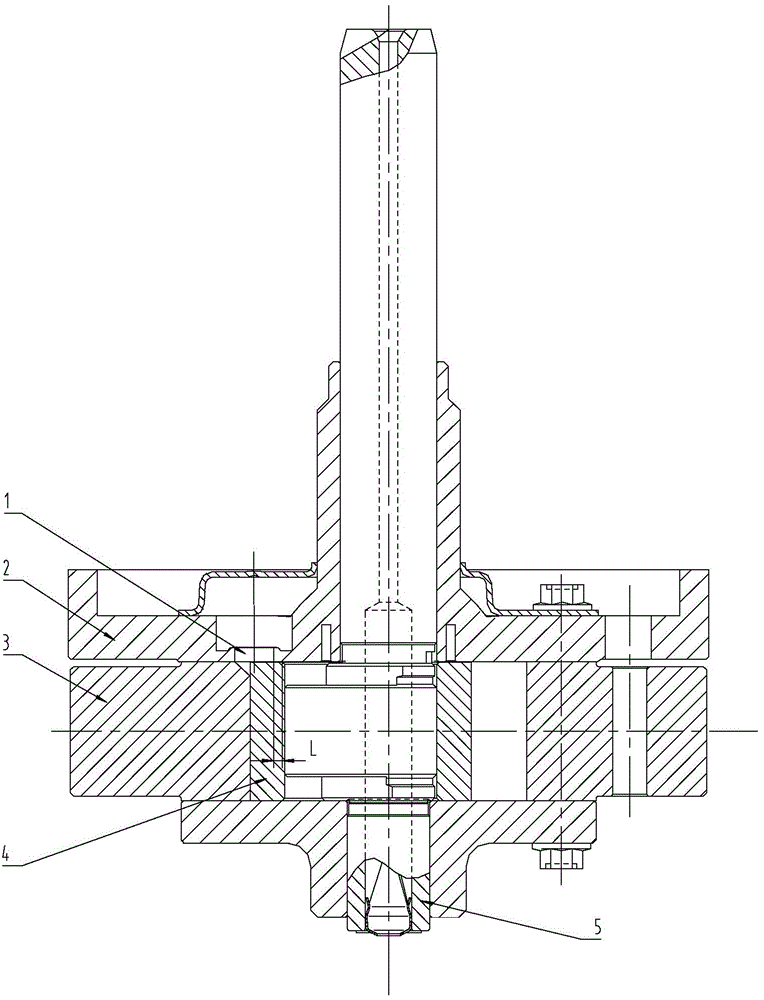

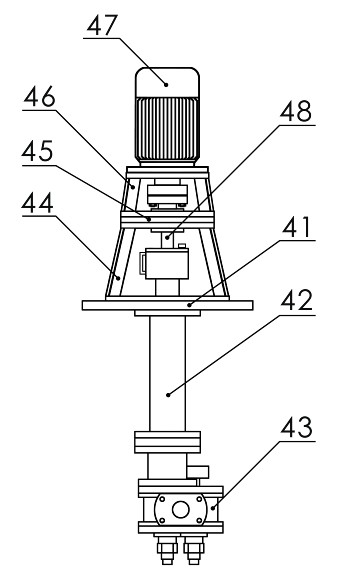

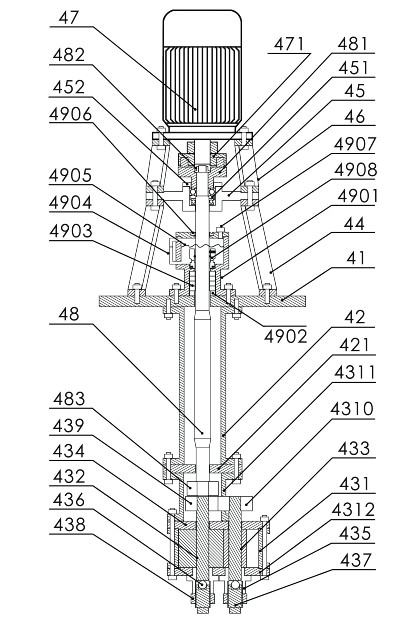

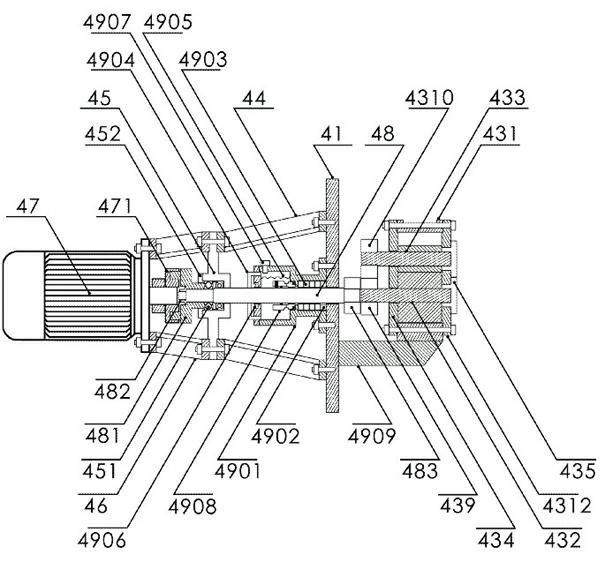

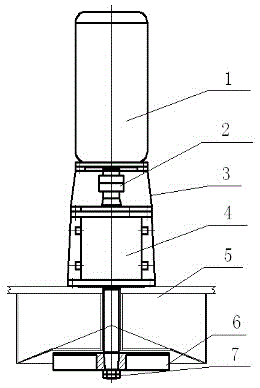

Built-in material liquid conveying pump under negative working condition

ActiveCN102671402AMeet sealing needsWon't leakRotary piston pumpsDistillation separationEngineeringCavitation

The invention relates to a material liquid conveying pump, in particular to a built-in material liquid conveying pump under a negative working condition. The built-in material liquid conveying pump under the negative working condition comprises a big cover, an elongated sleeve, a pump head, a bearing base support, a bearing base, a power mechanism support, a power mechanism, a pump shaft and a sealing casing, wherein the sealing casing is connected on one side of the big cover; the pump shaft penetrates through one end of the sealing casing and is connected with the power mechanism; the other end of the pump shaft is connected with the pump head; a sealing component and sealing material liquid are arranged between the sealing casing and the pump shaft; and the pump head has a volumetric structure. Compared with the prior art, the built-in material liquid conveying pump under the negative working condition has the advantages that: by adopting the structure that the big cover is connected with the sealing casing and the pump shaft penetrates through the sealing casing and is connected with the power mechanism, a sealing requirement of a decompressive short-path distilling device at a high temperature and a high vacuum degree can be met, no leakage of outside air into a vacuum heating tank can be absolutely ensured, and when the material liquid to be evaporated is sucked and exhausted, even through a certain degree of cavitation is caused, and the material liquid can be conveyed to an appointed position through the volume change of the pump cylinder.

Owner:吴国存

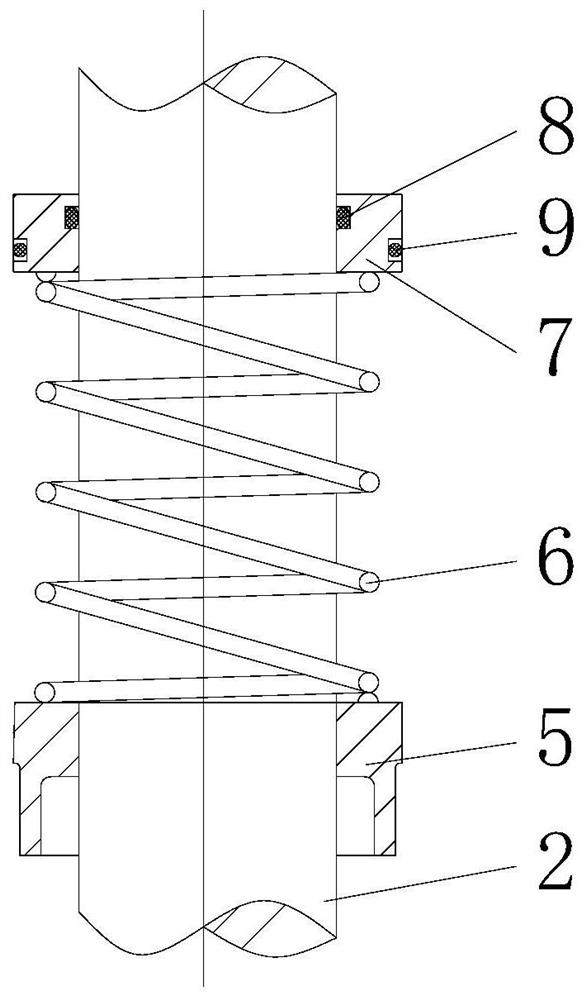

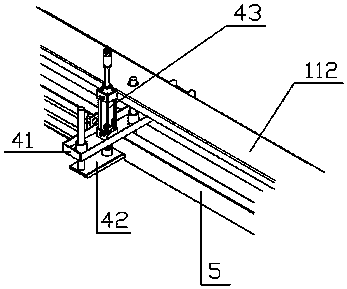

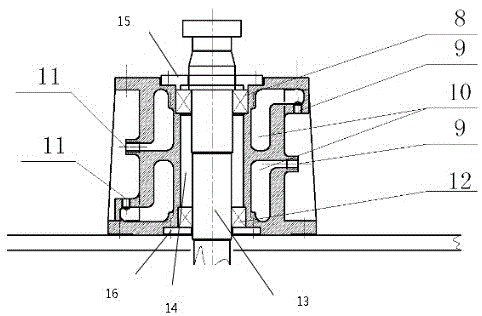

Liquid rocket engine turbine pump rotor low-temperature displacement measuring device

ActiveCN114198222AGuaranteed low temperature tightnessReduce temperature drift performanceGas-turbine engine testingThermometers using electric/magnetic elementsAxial displacementEngineering

The invention discloses a liquid rocket engine turbine pump rotor low-temperature displacement measuring device which comprises an axial displacement sensor, a radial displacement sensor and a sensor base assembly, the axial displacement sensor and the radial displacement sensor are installed in a turbine pump, and the sensor base assembly is provided with multiple seals. The low-temperature sealing performance of the turbine pump can be guaranteed while the wire is led out, the axial displacement and the radial displacement of the rotor assembly of the oxyhydrogen turbine pump in the low-temperature environment running process can be monitored in real time, the axial displacement and the axis track of the rotor are obtained on the basis, a criterion is provided for the working health state of the turbine pump, and the reliability of the turbine pump is improved. The system is especially suitable for on-line monitoring and fault early warning when an engine test and flight mission execution are carried out.

Owner:BEIJING AEROSPACE PROPULSION INST

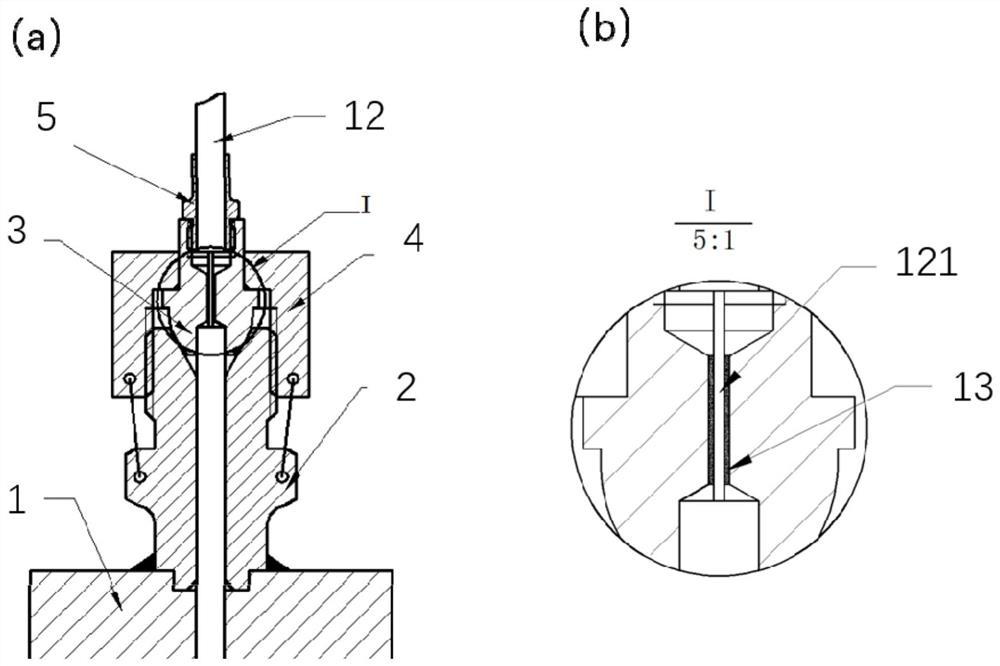

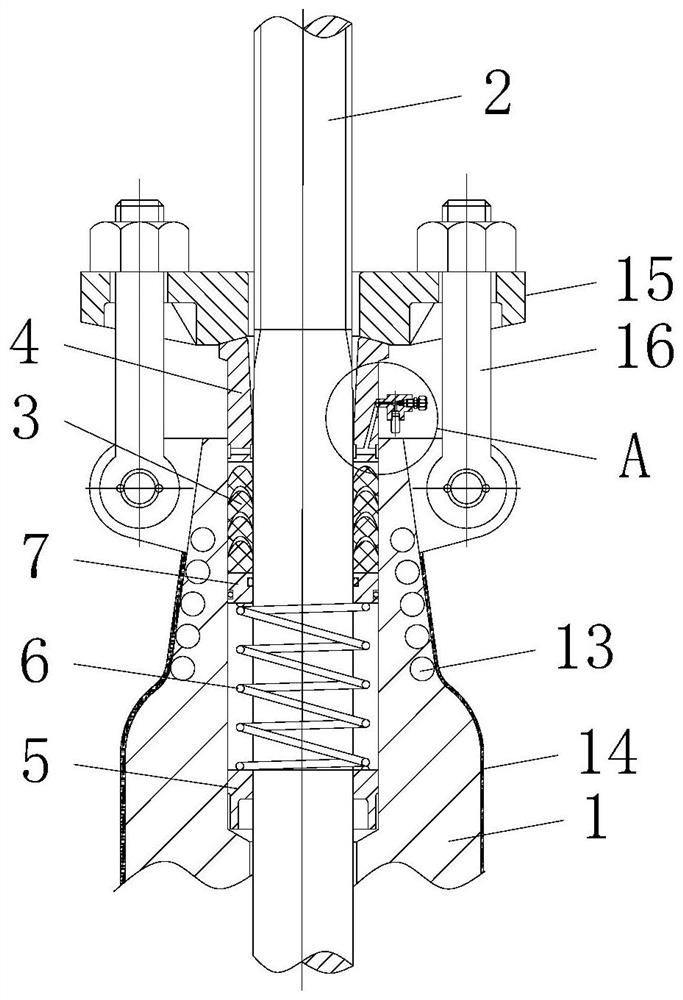

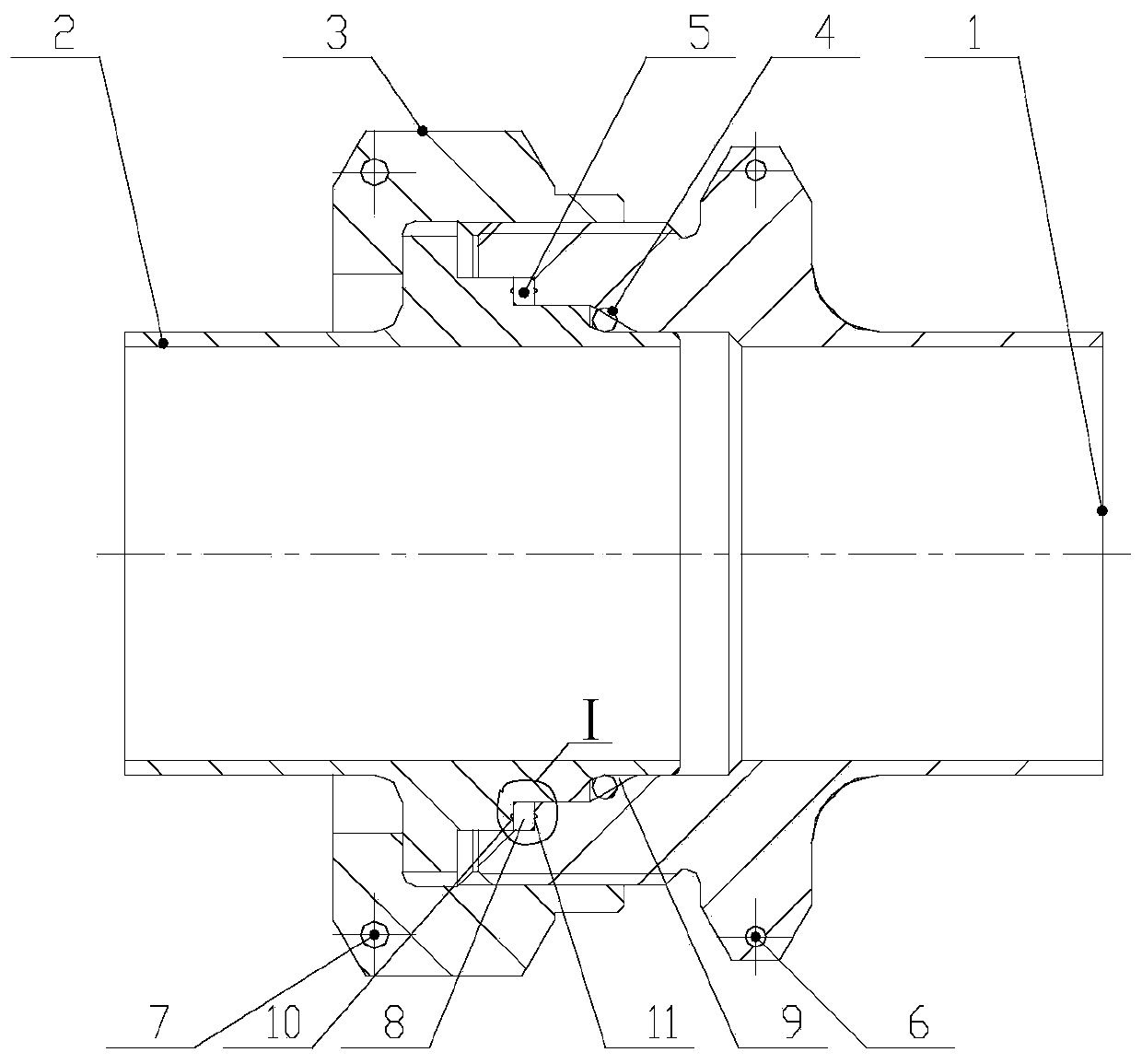

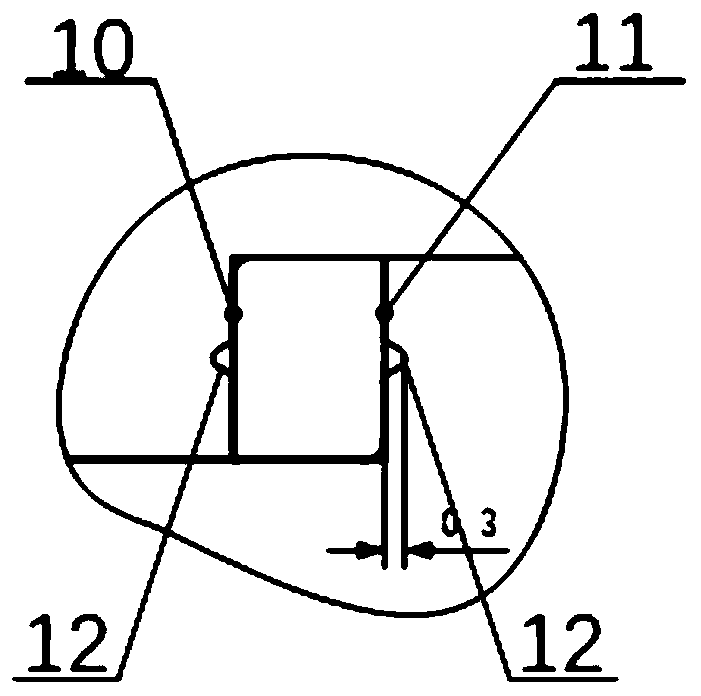

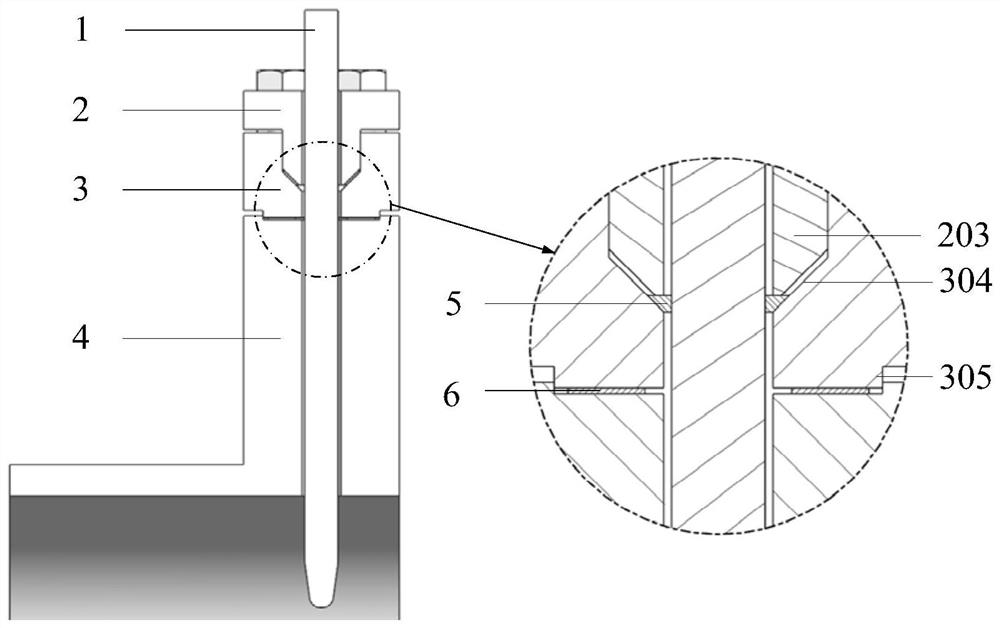

Valve rod sealing structure

The invention relates to a valve rod sealing structure. The valve rod sealing structure comprises a valve cover and a valve rod; the valve rod is arranged in a stuffing box hole of the valve cover in a partially penetrating mode; an elasticity assembly, V-shaped stuffing and a pressing sleeve are sequentially arranged between the valve rod and the stuffing box hole from bottom to top; the extension direction of the elasticity assembly is consistent with the axis direction of the valve rod; a leak detection and blocking assembly is arranged at the bottom of the pressing sleeve; and a pre-tightening assembly connected with the valve cover is arranged at the top of the pressing sleeve. The valve rod sealing structure can meet the sealing requirements under high-pressure and low-pressure working conditions and is good in compatibility; and whether sealing of the valve rod fails or not can be detected, blocking measures are provided for temporary sealing, medium leakage is avoided, and the using safety and reliability of a valve are improved.

Owner:DHV VALVE & FOUNDRY

High-temperature and high-pressure sealing device

PendingCN109826953AHigh pressure transmission efficiencySimple structureEngine sealsPressure transmissionEngineering

The invention provides a high-temperature and high-pressure sealing device. The high-temperature and high-pressure sealing device comprises an upper kettle cover. An upper flange is arranged on the lower side of the bottom of the upper kettle cover. The upper flange and the upper kettle cover are fixedly connected through peripheral first fastening bolts in a threaded mode. Barrel bodies are arranged on the lower sides of the bottoms of the upper flange. A lower flange is arranged on the lower sides of the bottoms of the barrel bodies. A lower kettle cover is arranged on the lower side of thebottom of the lower flange. The lower kettle cover and the lower flange are fixedly connected through peripheral second fastening bolts in a threaded mode. The high-temperature and high-pressure sealing device is suitable for a novel square liner model and is particularly suitable for a sealing form of a built-in model of a thin-wall structure, so that the pressure transmission efficiency of the built-in model is improved.

Owner:BEIJING RUILAIBO PETROLEUM TECH

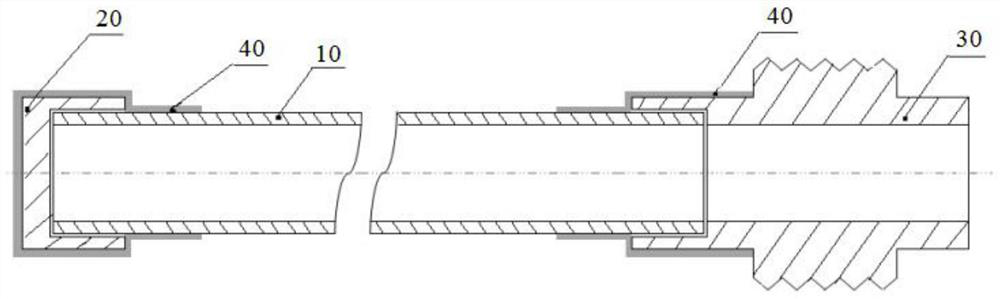

Propellant-resistant double-channel sealing structure

InactiveCN111473174ACapable of withstanding high temperature of 350°CUsableJoints with sealing surfacesNutsAxial forceConductor pipe

The invention discloses a propellant-resistant double-channel sealing structure. The sealing structure comprises a filler neck, a pipe joint, a cap nut, an O-shaped ring and a copper gasket. One end of the filler neck and one end of the pipe joint are fixedly connected with a propellant conveying guide pipe, the other end of the filler neck is matched with the other end of the pipe joint, a firstconical sealing groove and a second sealing groove are formed in a matched position, the O-shaped ring is arranged in the first conical sealing groove, and the copper gasket is arranged on the secondsealing groove. The cap nut sleeves the pipe joint and is fixedly connected with the filler neck to ensure axial force required by the copper gasket and the O-shaped ring. The structure is provided with the two sealing grooves, and the copper gasket and the O-shaped ring serve as sealing elements, so that the sealing structure is resistant to the high temperature of 350 DEG C, can be repeatedly used, has the high-low-temperature cycling capability, is simple in structure and low in assembling requirement, and meets the requirement for the sealing leakage rate.

Owner:SHANGHAI AEROSPACE SYST ENG INST

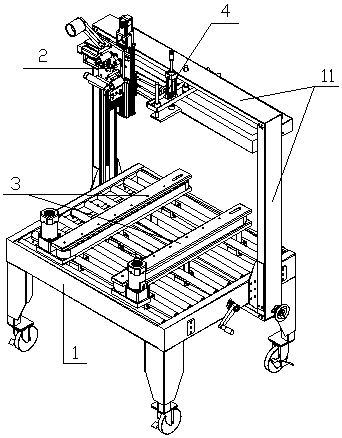

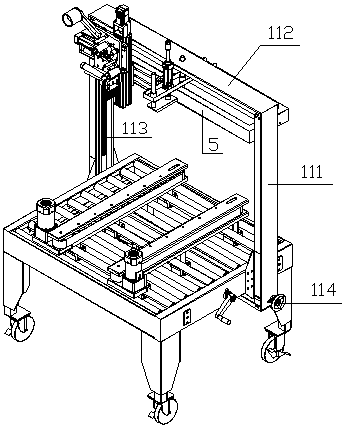

An automatic box sealing machine

ActiveCN106395011BMeet sealing needsStable supportWrapper twisting/gatheringArticle deliveryControl systemEngineering

The invention discloses an automatic box sealing machine. A box sealing mechanism, a box body guide mechanism, a top pressing mechanism, a sensor and a control system are arranged on a rack, so that an integral automatic box sealing machine is formed. The box sealing mechanism mainly comprises an adhesive tape feeding and sticking device, an adhesive tape is provided by virtue of an adhesive tape bearing roller and a guide roller, a part of adhesive tape is rolled onto the front surface of a box body by a pressing and sticking roller, the other part of the adhesive tape is brushed onto the upper surface of the box body by a hair brush, and the stuck adhesive tape is cut off by a cutter; the top pressing mechanism is used for fixing a to-be-sealed box body on a working platform, and reliable support force is provided for the sealing of the box body with the adhesive tape; and the height of a bearing bridge on a mechanism support frame and the distance between two guide tapes of the box body guide mechanism are adjusted, so that the box sealing requirements of different types of box bodies can be satisfied. The automatic box sealing machine has the advantages of stability and reliability in operation, reasonable design, simple structure, low cost and long service life.

Owner:抚州久合机电设备有限公司

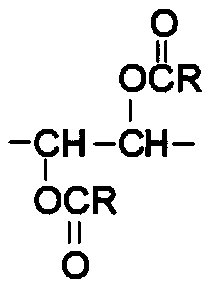

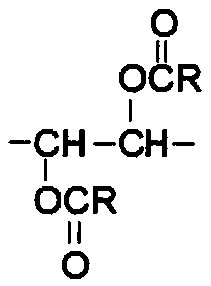

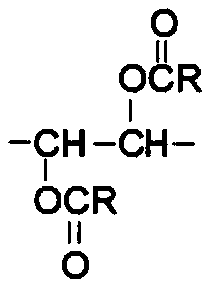

Copolymerization fluorosilicone grease composition

The invention relates to a copolymerization fluorosilicone grease composition which is prepared by taking a mixture of liquid copolymerization fluorosilicone rubber, linear organic siloxane and a silane coupling agent as base oil and modified fumed silica as a thickening agent, and has the characteristics of lubricating oil resistance, solvent resistance, low cost, and long service life.

Owner:长春物恒新技术有限公司

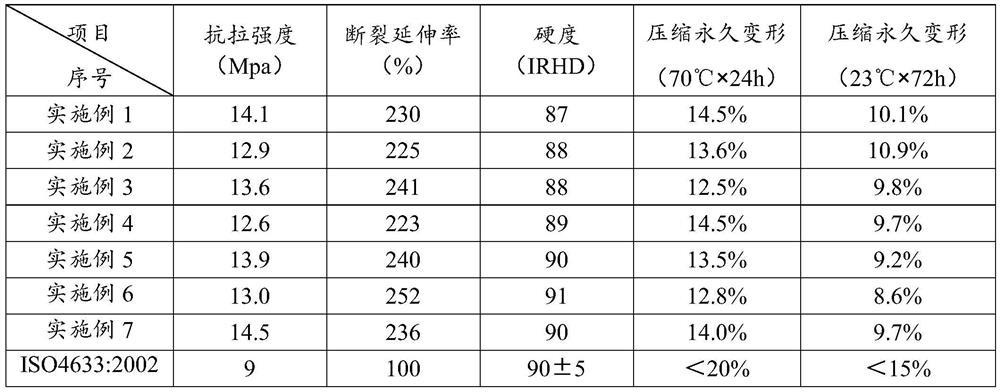

High-hardness support sealing ring rubber material

The invention discloses a high-hardness support sealing ring rubber material, which comprises the following raw materials in parts by weight: 40-60 parts of natural rubber, 40-60 parts of butadiene-styrene rubber, 1.5-3.5 parts of sulfur, 2-4 parts of an accelerant, 3-5 parts of zinc oxide, 1-4 parts of stearic acid, 7-13 parts of tackifying resin, 120-170 parts of general carbon black, 4-8 partsof an anti-aging agent. 1-3 parts of paraffin, 1-3 parts of a dispersing agent, 0.5-2.5 parts of an anti-scorching agent and 2-5 of pine tar; wherein the accelerant comprises an accelerant CZ and an accelerant DM. The rubber material has the advantages of high hardness, favorable sealing performance, high support strength, excellent water resistance, excellent wear resistance and long service life, and can satisfy the requirements for long-term use.

Owner:JIHUA 3517 RUBBER PROD

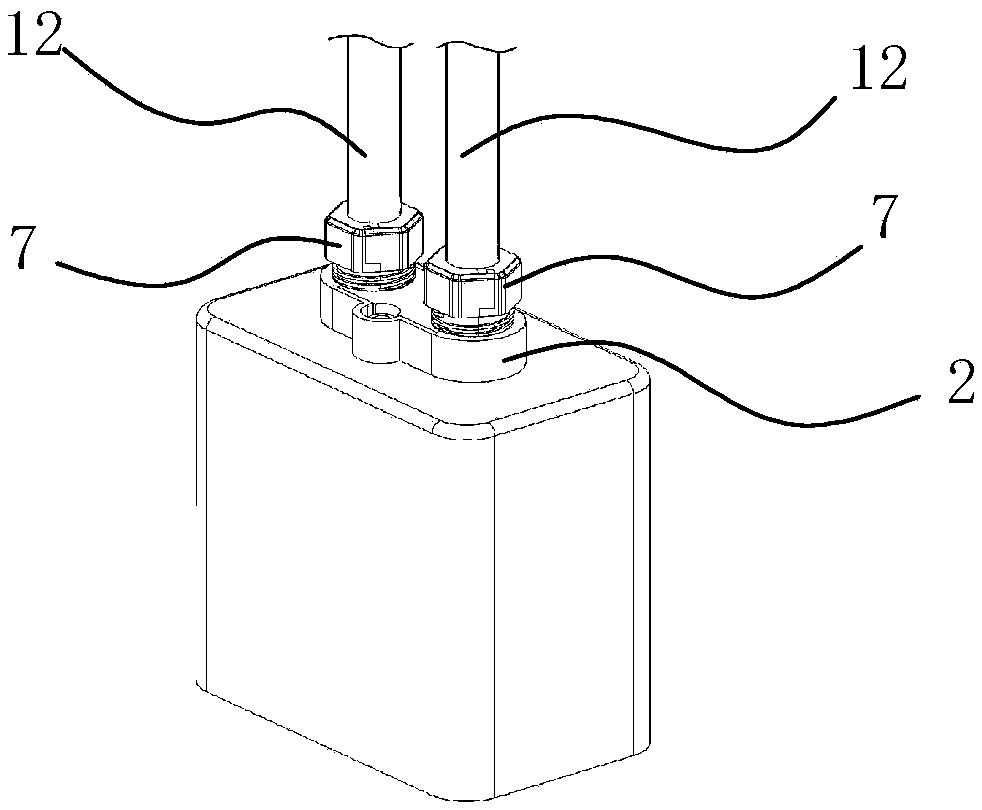

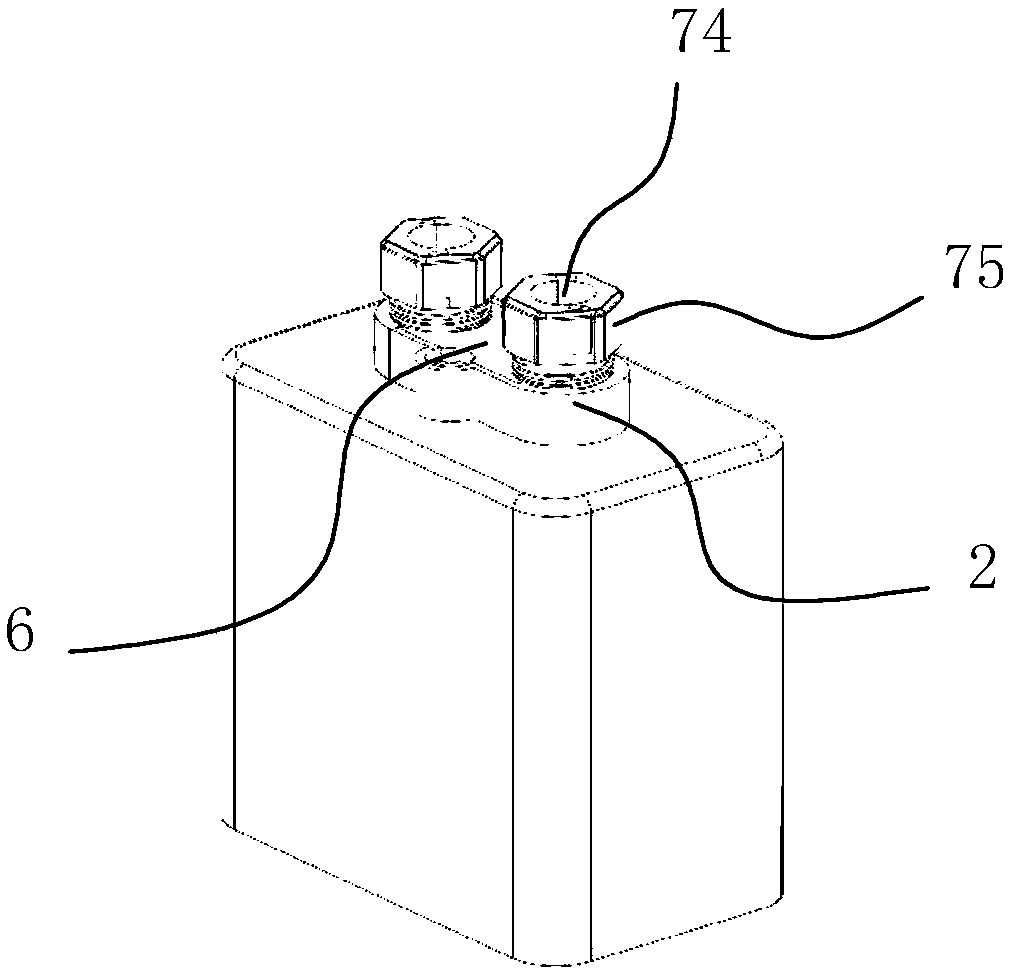

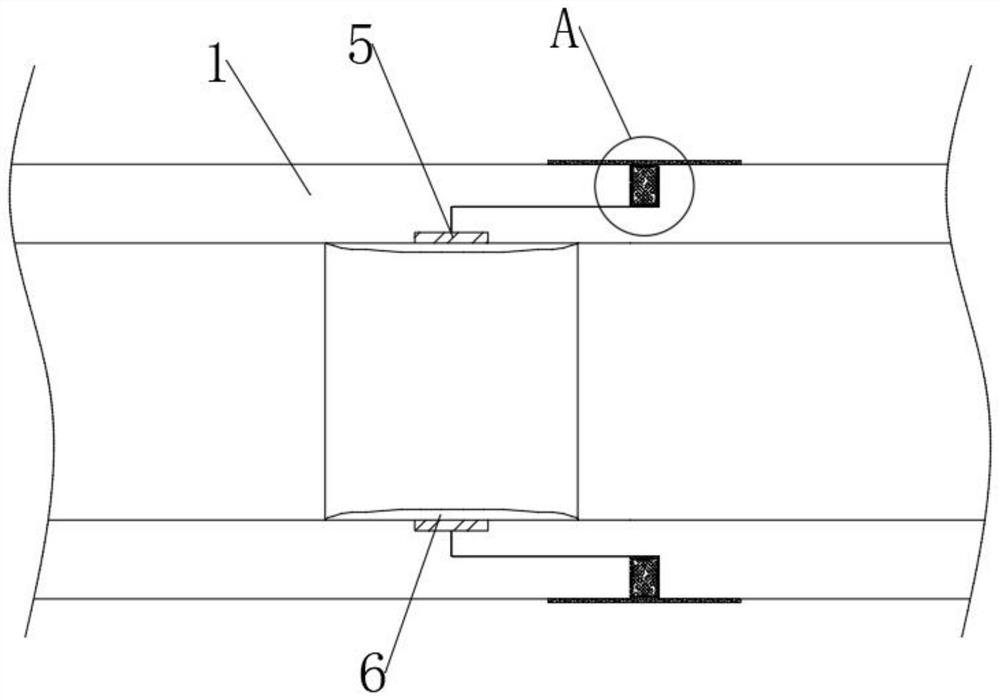

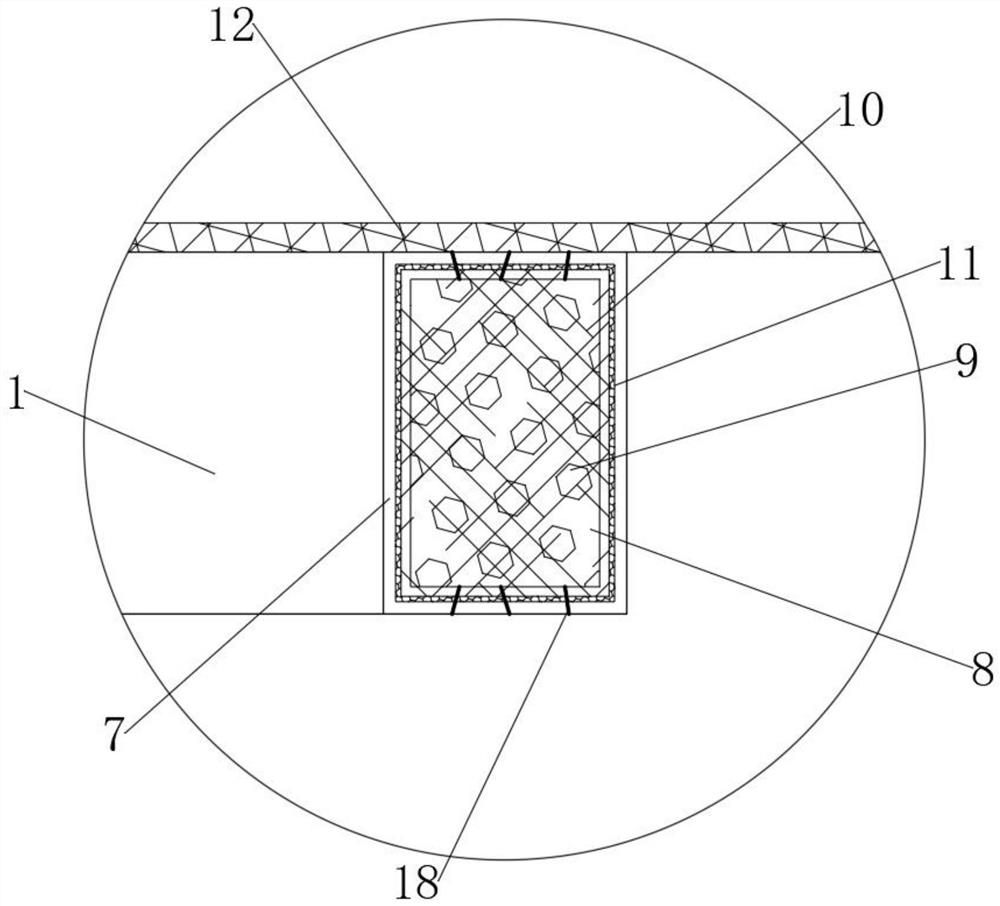

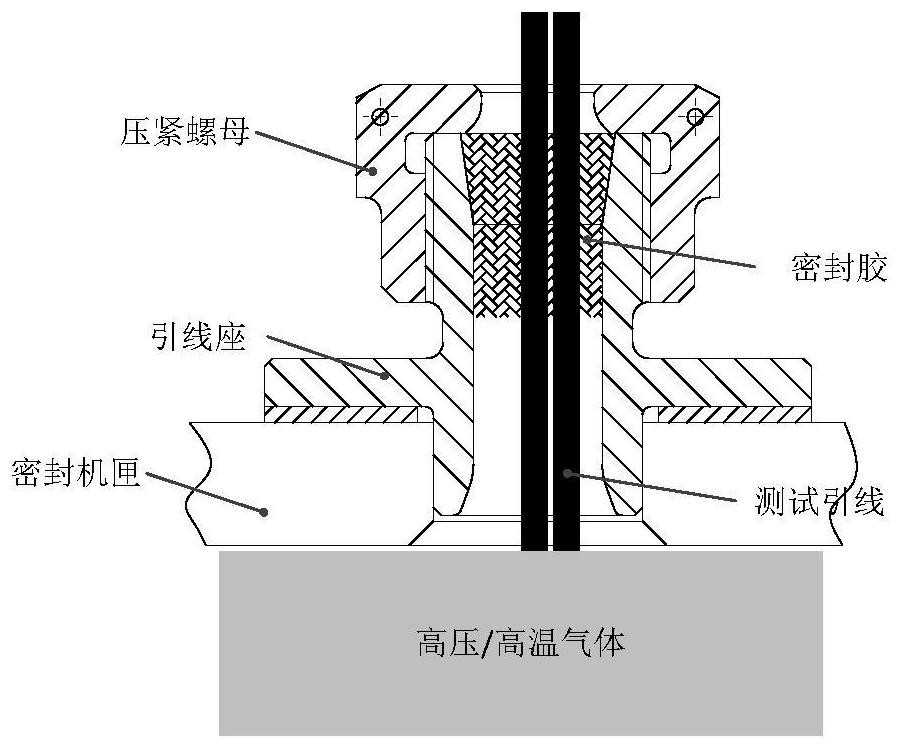

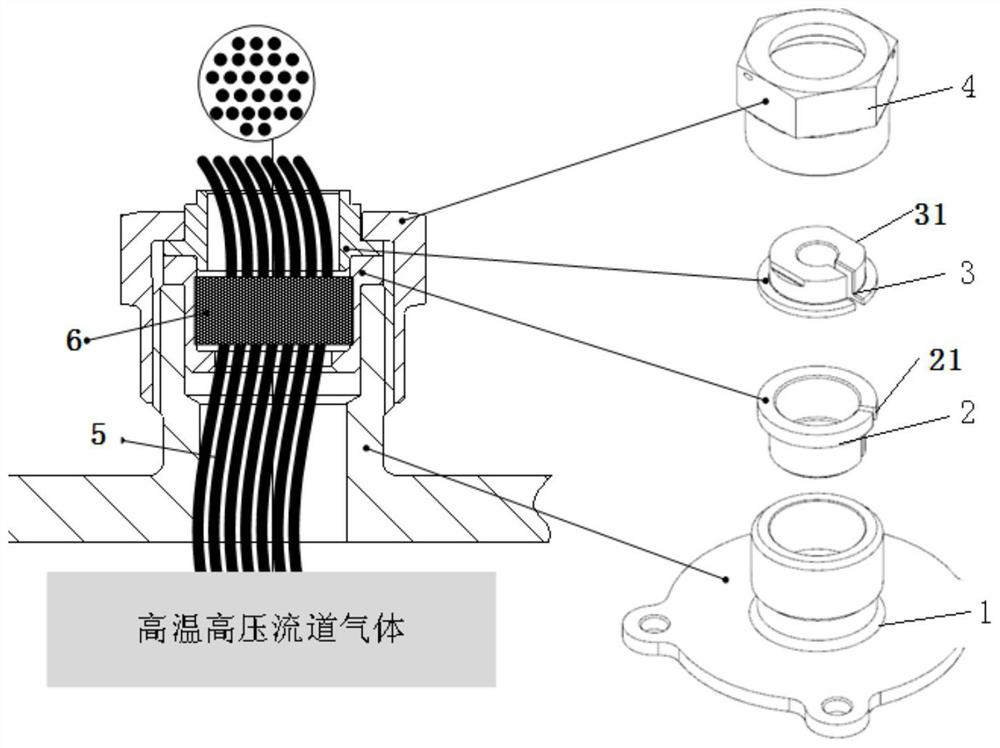

Test lead cluster sealing device for test

PendingCN114156679AFully compactedImprove sealingSecuring/insulating coupling contact membersCable inlet sealing meansEngineeringMechanical engineering

Owner:AECC SHENYANG ENGINE RES INST

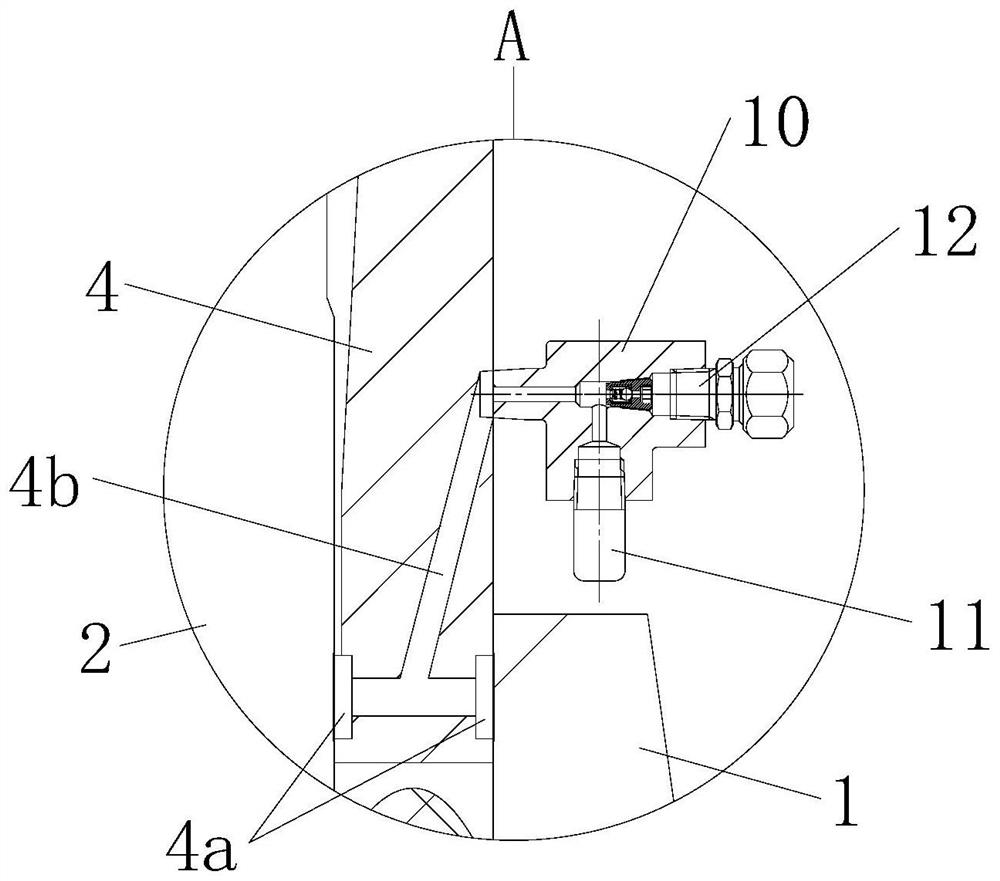

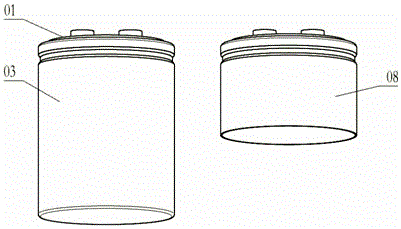

Clamping loading and sealing structure for capacitor sealing strength detection

ActiveCN105865904AMeet sealing needsImprove sealingEngine sealsMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

The invention discloses a clamping loading and sealing structure for capacitor sealing strength detection. The clamping loading and sealing structure comprises a clamping loading mechanism and a sealing mechanism. The clamping loading mechanism comprises a top plate, stand columns, a table plate, linear bearings, a chuck installation plate, guide shafts, a nut, a lead screw, a hand wheel, a clamp ring, a three-jaw chuck assembly and jaws. The sealing mechanism comprises an oil way connecting disc, a rubber plate, a filling piece and an expansion stopping ring. The clamping loading mechanism clamps an aluminum shell test piece, a trapezoid lead screw and nut mechanism drives the rubber plate to closely press the opening of the aluminum shell test piece to achieve end face sealing, the expansion stopping ring limits external expansion deformation generated in the hydraulic loading process of the aluminum shell test piece, and thus sealing is reliable. The clamping loading and sealing structure can be applied to aluminum shell test pieces of different diameters for sealing strength detection tests by replacing the jaws, the filling piece and the expansion stopping ring.

Owner:NANTONG HICON ELECTRONICS

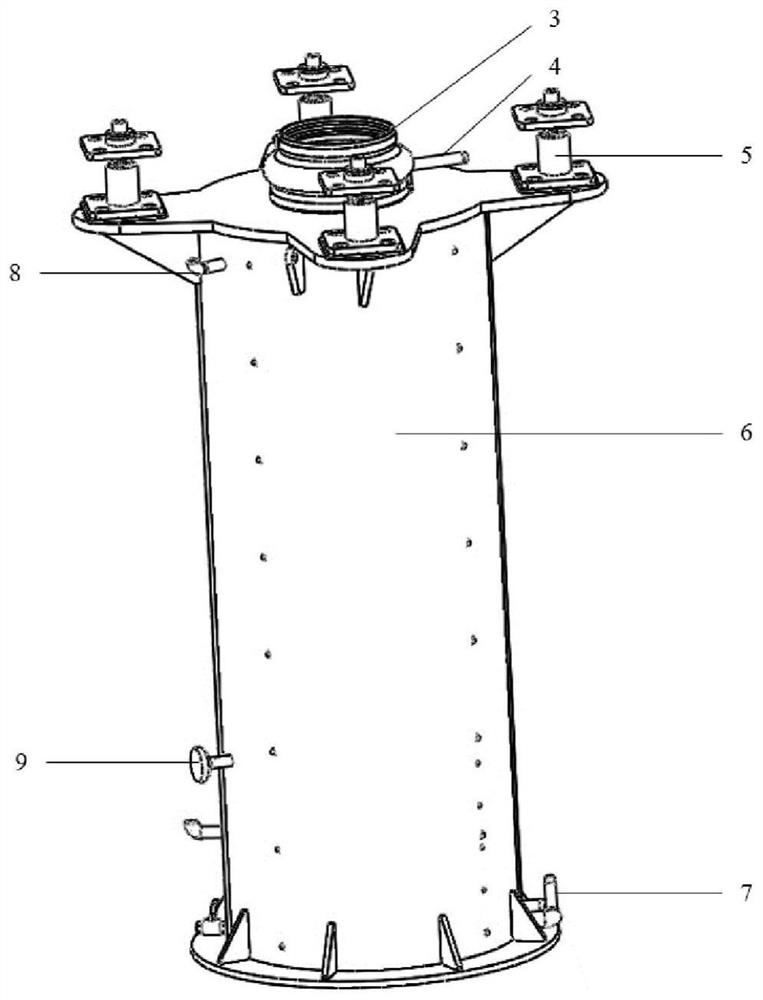

Sealed smoke hood suitable for rotary electrode vacuum electroslag remelting technology

InactiveCN112342401AReduce oxygen contentReduce hydrogen contentIncreasing energy efficiencyWaste heat treatmentMetallurgyEngineering

The invention discloses a sealed smoke hood suitable for a rotary electrode vacuum electroslag remelting technology. A smoke hood body is connected with a lifting platform of a rotary electrode vacuumelectroslag furnace in rotary electrode vacuum electroslag remelting equipment through a smoke hood suspension device arranged at the upper end of the smoke hood body; a rotary shaft of a rotary electrode vacuum electroslag furnace in the rotary electrode vacuum electroslag remelting equipment penetrates through an upper end opening of the smoke hood to enter the smoke hood body, the lower portion of the smoke hood body is in butt joint with a crystallizer of the electroslag furnace, a sealing sleeve is arranged on the upper portion of the smoke hood body, the upper end face where a pump-outpipeline is arranged and the side edge of the sealing sleeve are connected with of a vacumm pump of the rotary electrode vacuum electroslag furnace; and a water inlet pipe and a water outlet pipe arerespectively arranged at the upper part and the lower part of the side wall of the smoke hood body and communicate with a water circulation system in the rotary electrode vacuum electroslag remeltingequipment. By improving the sealing smoke hood, the problems of rotating body sealing and vacuum environment sealing in a rotary electrode vacuum electroslag remelting system are solved, the refiningeffect of an electroslag remelting process is improved, the structure is simple, and the sealing performance is good.

Owner:NORTHEASTERN UNIV

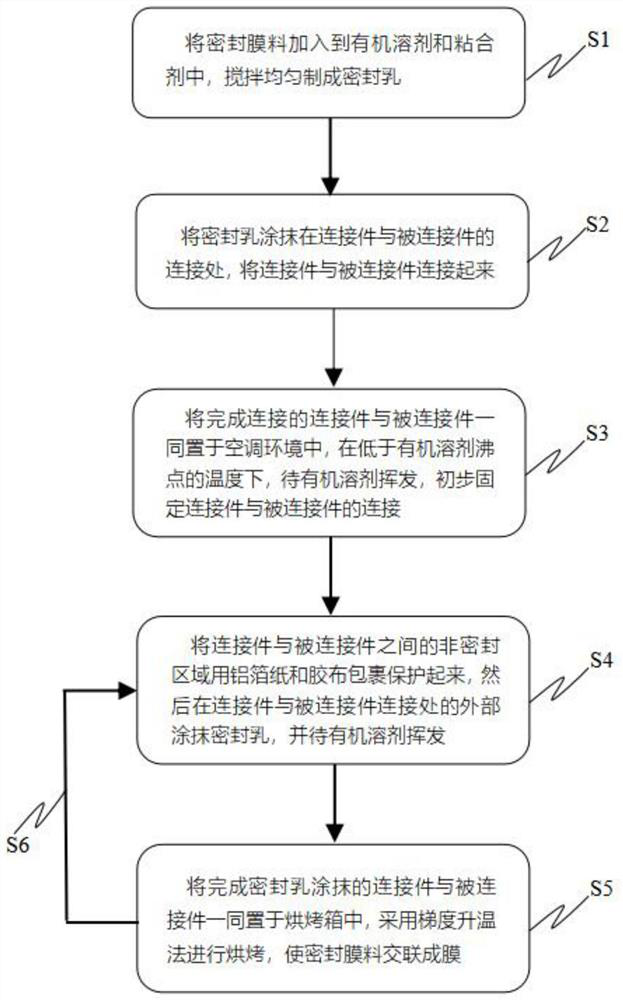

Forming method of sealing membrane sleeve

A method for producing a sealing film sleeve, which is used to form a sealing film sleeve at the joint between a connecting piece and a connected piece, comprising adding a sealing film material to an organic solvent and an adhesive and stirring to form a sealing emulsion, and applying the sealing emulsion on Connect the connecting piece and the connected piece at the joint between the connecting piece and the connected piece, place the connected piece and the connected piece at a temperature lower than the boiling point of the organic solvent until the organic solvent volatilizes, and initially fix the gap between the connecting piece and the connected piece After the connection, wrap the non-sealed area between the connecting piece and the connected piece with aluminum foil and adhesive tape, and then apply sealing emulsion on the outside of the connection between the connecting piece and the connected piece and wait for the organic solvent to evaporate, and seal the connecting piece and the connected piece The pieces are placed together in a baking oven and baked with a gradient heating method to cross-link the sealing film material to form a film. Repeat the last two steps until a sealing film sleeve that meets the requirements is produced. The sealing membrane sleeve produced by the invention has high compactness, good sealing performance, low sealing failure rate, simple operation and improved work efficiency.

Owner:上海亿鼎电子系统集成有限公司

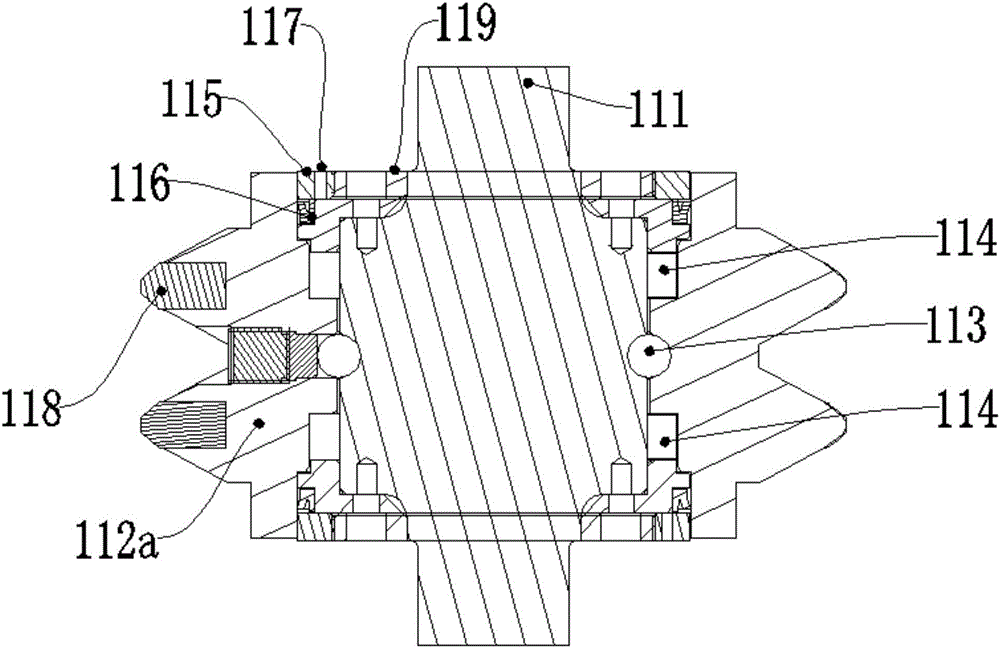

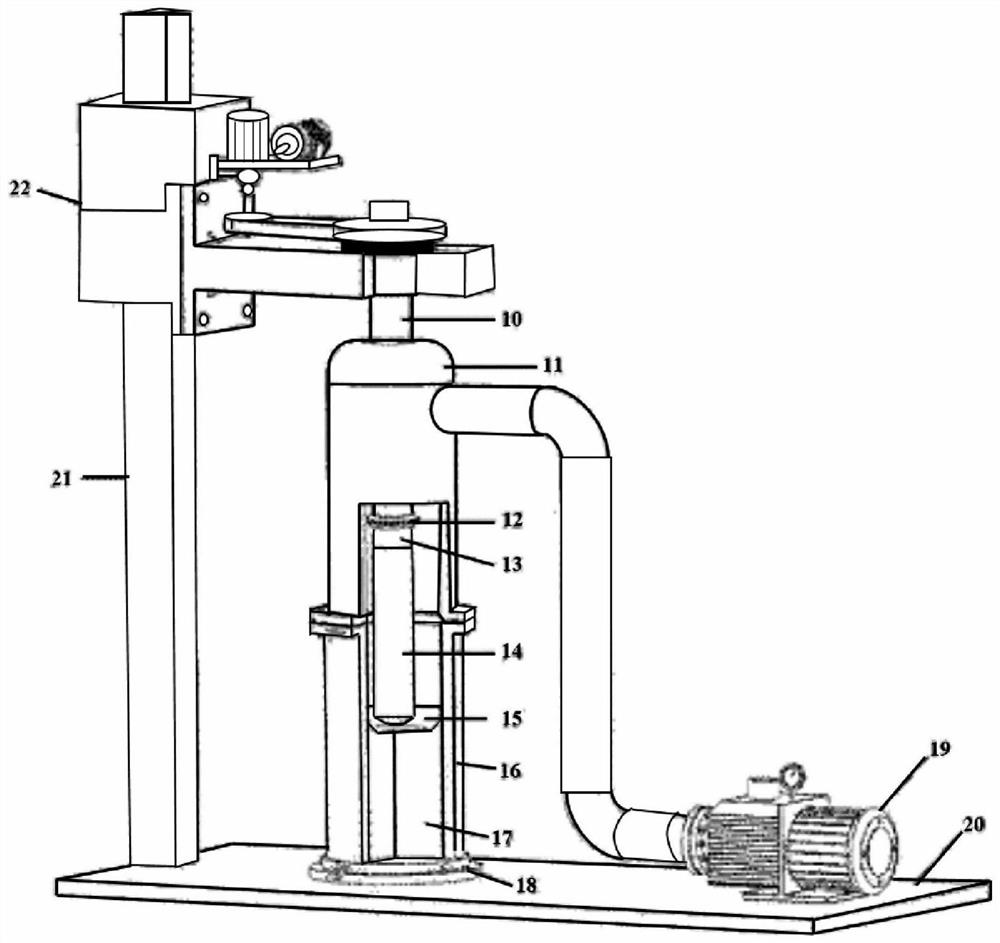

Split type thermal treatment furnace draught fan

InactiveCN105604966AImprove utilization efficiencyHigh utility valuePump componentsPump installationsVacuum furnaceThermal treatment

The invention discloses a split type thermal treatment furnace draught fan. The draught fan comprises a draught fan motor, a motor support, a detachable coupling, fan blades, a fan blade fixing nut, a furnace body, a motor rotating shaft and a draught fan rotating shaft, the draught fan motor is fixed to the upper portion of the motor support, the motor rotating shaft and the draught fan rotating shaft are connected in the motor support through the detachable coupling, the fan blades are fixed to the outer end of a draught fan shaft through a key and the fan blade fixing nut, a water-cooling oil-lubricating bay transmission device is arranged between the motor support and the furnace body, the upper portion and the lower portion of the water-cooling oil-lubricating bay transmission device are fixed to the bottom of the motor support and the upper portion of the furnace body through nuts respectively, and the draught fan rotating shaft passes through a water-cooling oil-lubricating bay. According to split type thermal treatment furnace draught fan, the water-cooling oil-lubricating bay is additionally arranged to improve sealing performance of the furnace draught fan, therefore, the furnace draught fan can meet the requirement, for sealing performance, of a carburizing furnace or a vacuum furnace, and meanwhile the modularization maintenance function of the furnace draught fan can be achieved.

Owner:HUBEI MILALION METALLURGICAL MACHINERY CO LTD

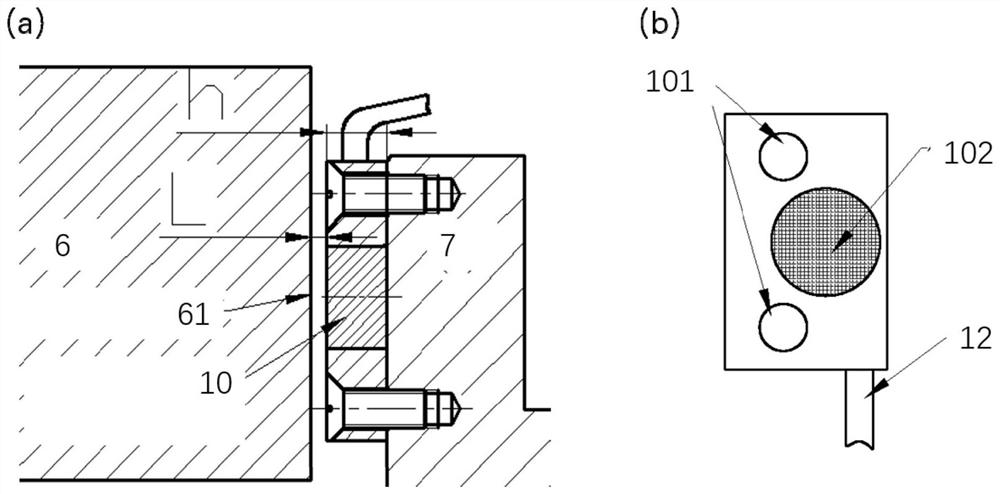

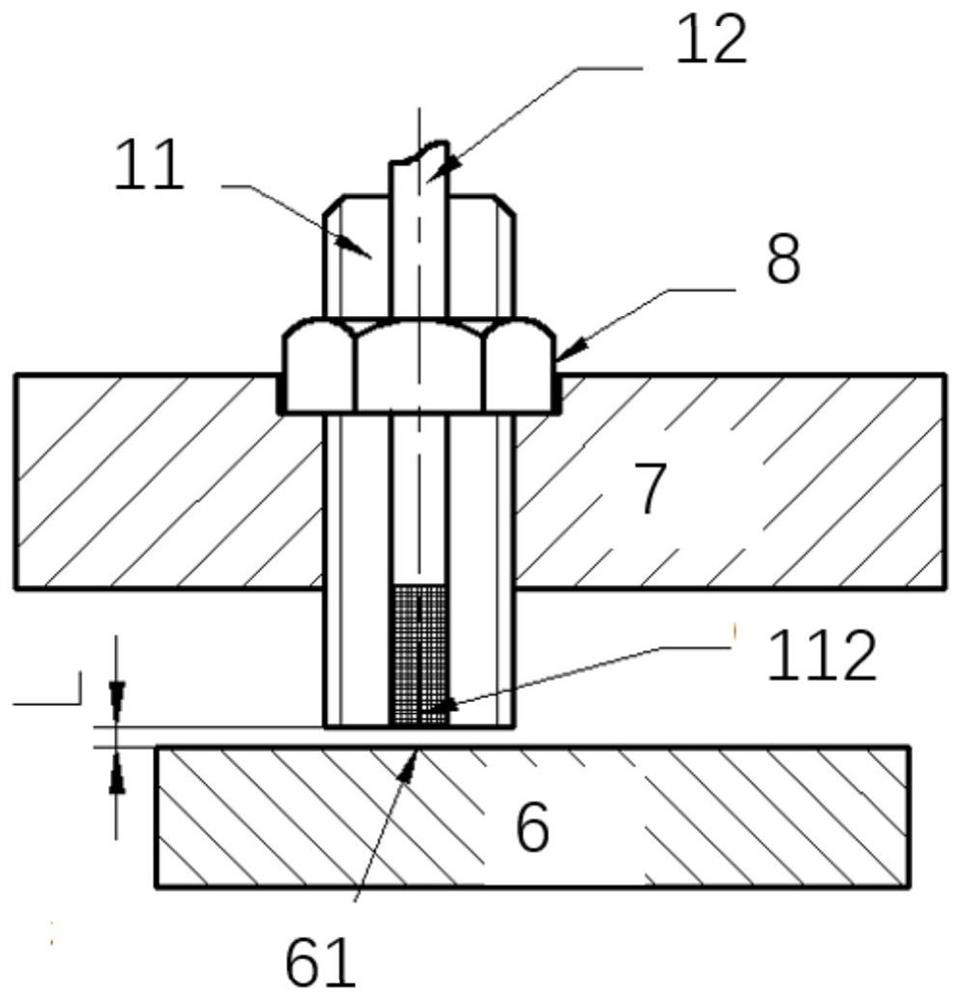

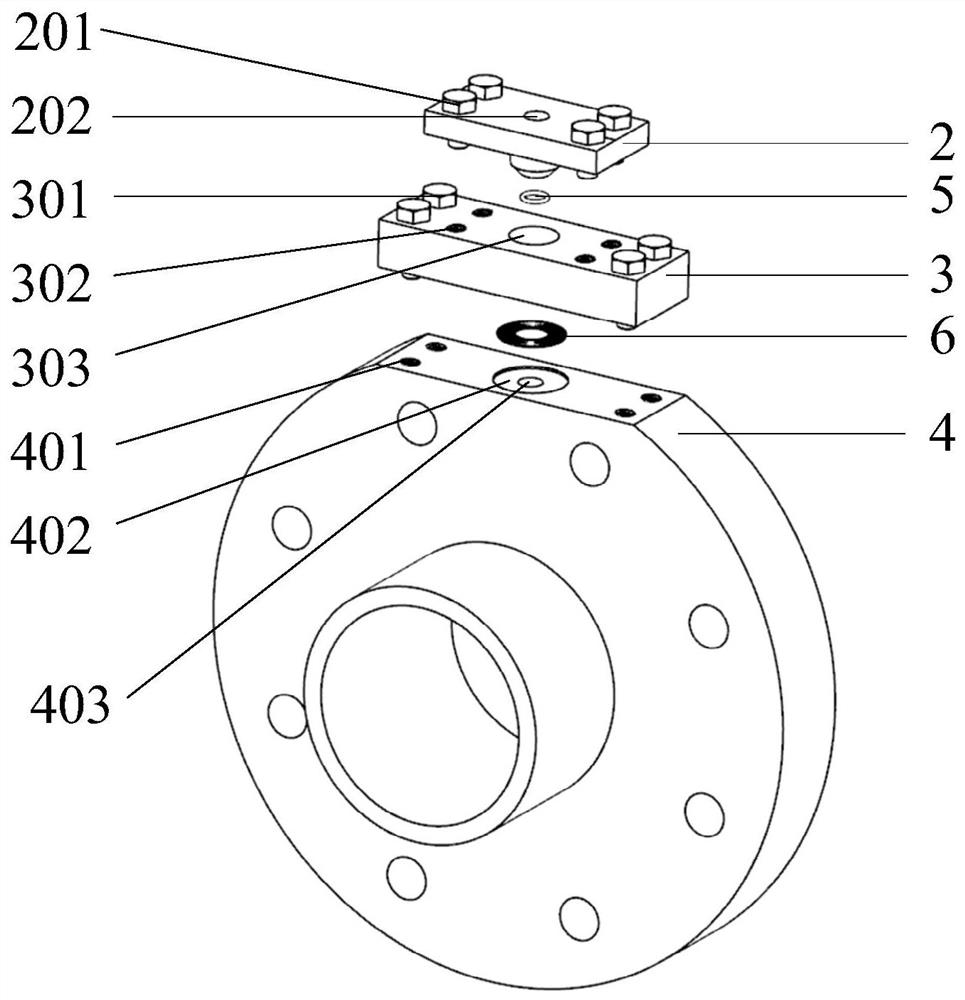

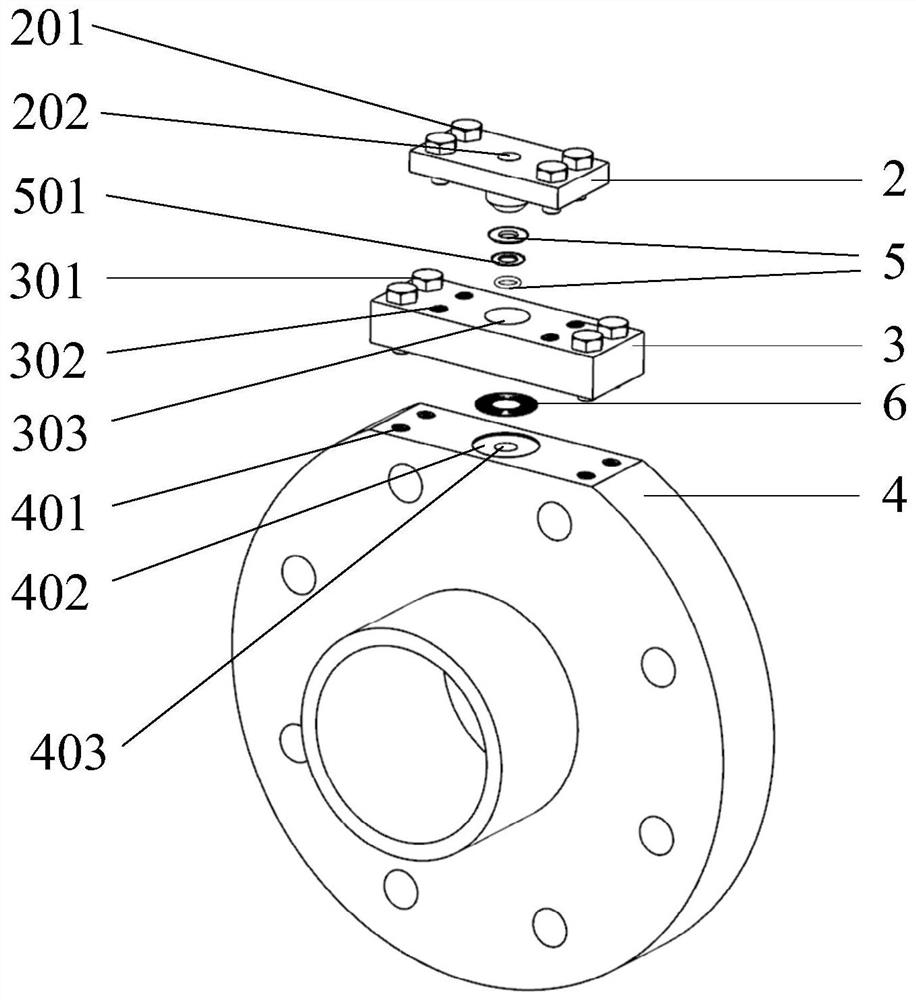

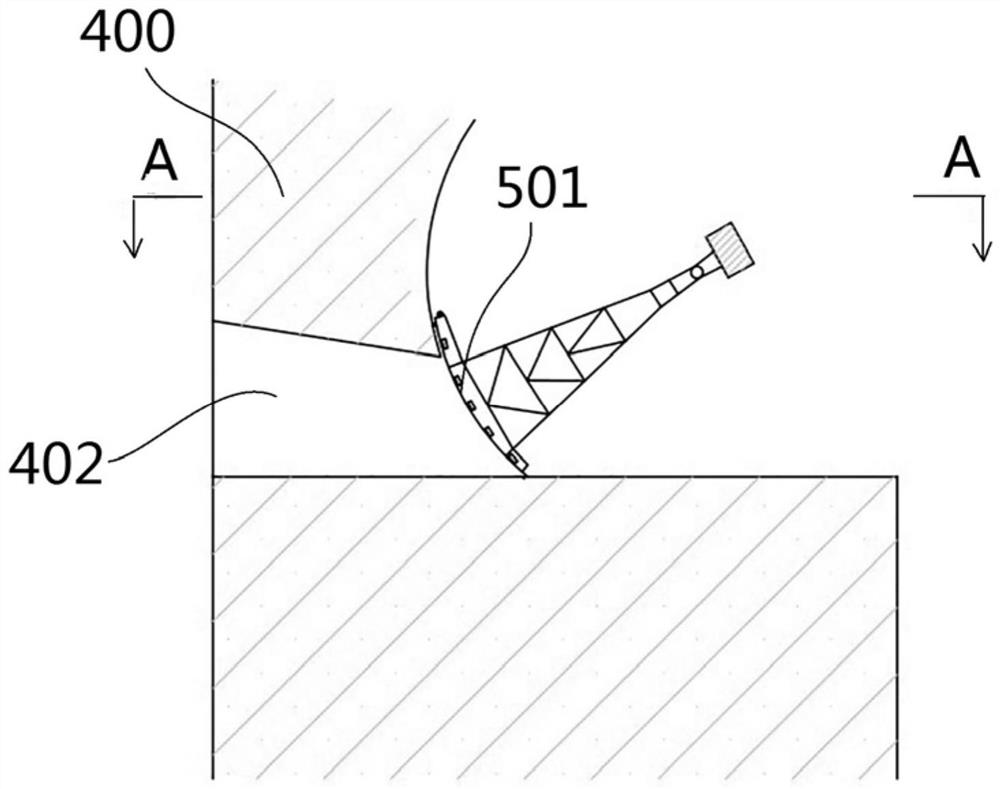

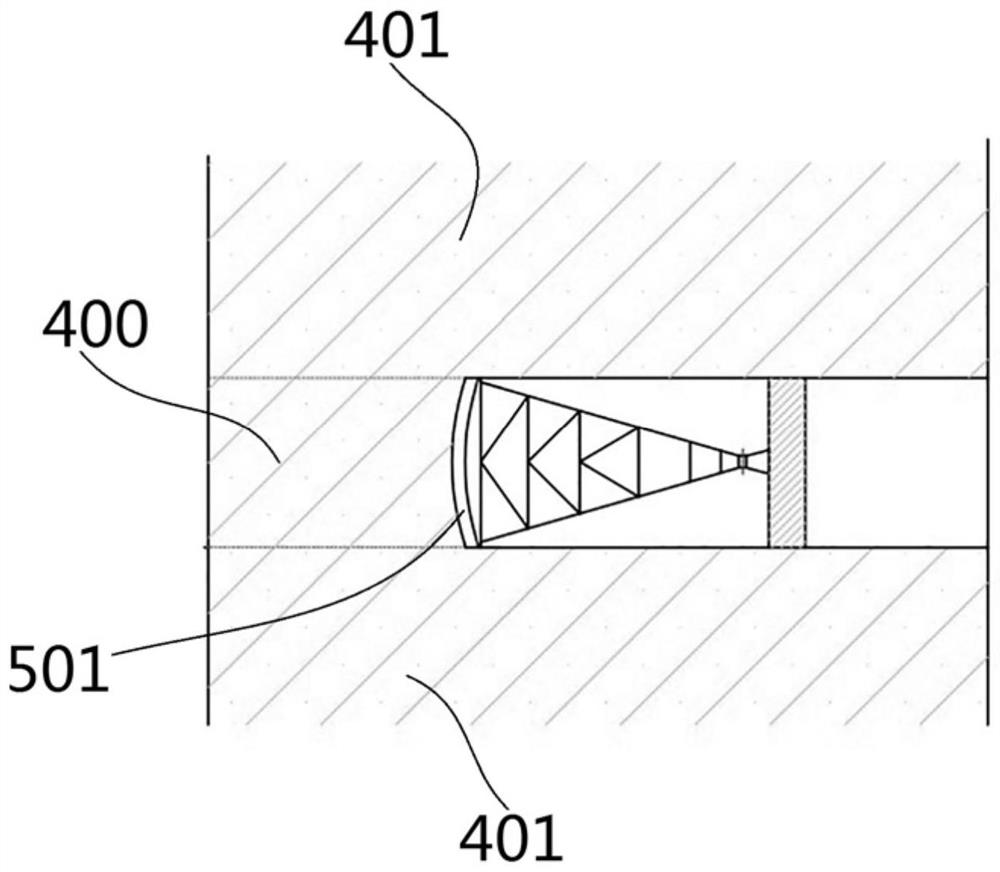

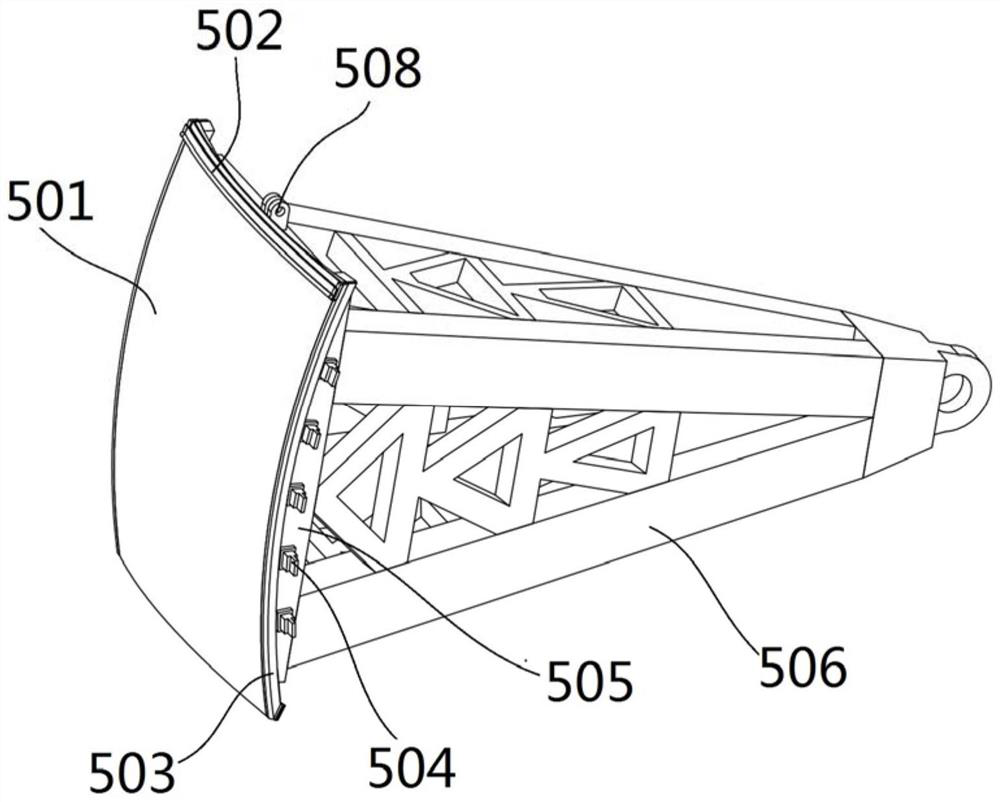

Probe sealing structure for high-pressure fluid pipeline

ActiveCN112483648AAvoid damageIncrease the pressing forceEngine sealsPipeline systemsEngineeringFluid Leak

The invention relates to a probe sealing structure for a high-pressure fluid pipeline. The probe sealing structure comprises a probe hole, a sealing cover plate, a fastening cover plate and other sealing parts positioned on a flange plate, and a sealing gasket, an elastic sealing ring and other sealing media for sealing high-pressure fluid leaked from the probe hole. The probe hole is formed in the outer end face of the flange in the radial direction, so that a probe sleeve located on the outer wall of a pipeline in the prior art is omitted, and damage to the high-pressure pipeline due to drilling, welding and the like in the sleeve mounting process is avoided; and meanwhile, the sealing components such as the sealing cover plate and the fastening cover plate are designed for the high-pressure environment in the pipeline, and also the high-pressure fluid leaked from the probe hole is sealed by arranging auxiliary sealing structures matched with a pressing ring, a sealing ring, a sealing groove and the like, so that the sealing effect of a probe in the high-pressure environment is enhanced, and the stability and reliability of the structure are improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Flood discharge gate and flood discharge system

ActiveCN114753323AReduce thicknessImprove the state of stressBarrages/weirsHydro energy generationFlood openingStructural engineering

The invention provides a flood discharge gate and a flood discharge system, and belongs to the technical field of hydraulic engineering, and the flood discharge gate comprises a panel structure rotationally arranged on a flood discharge opening in a blocking mode; the panel structure is provided with a panel body, and the upstream face of the panel body is in a cambered surface shape in at least two different directions. One end of the supporting structure is connected with the side, away from the upstream face, of the panel body, and the other end of the supporting structure is rotationally connected with the supporting block between the flood discharge hole side walls; according to the flood discharge gate, the upstream face of the panel body is in the cambered surface shape (called hyperbolic curved surface) in at least two different directions, so that the stress state is optimal, the mechanical property is improved, the thickness of the panel is reduced, and manufacturing materials are saved.

Owner:CHINA THREE GORGES CORPORATION

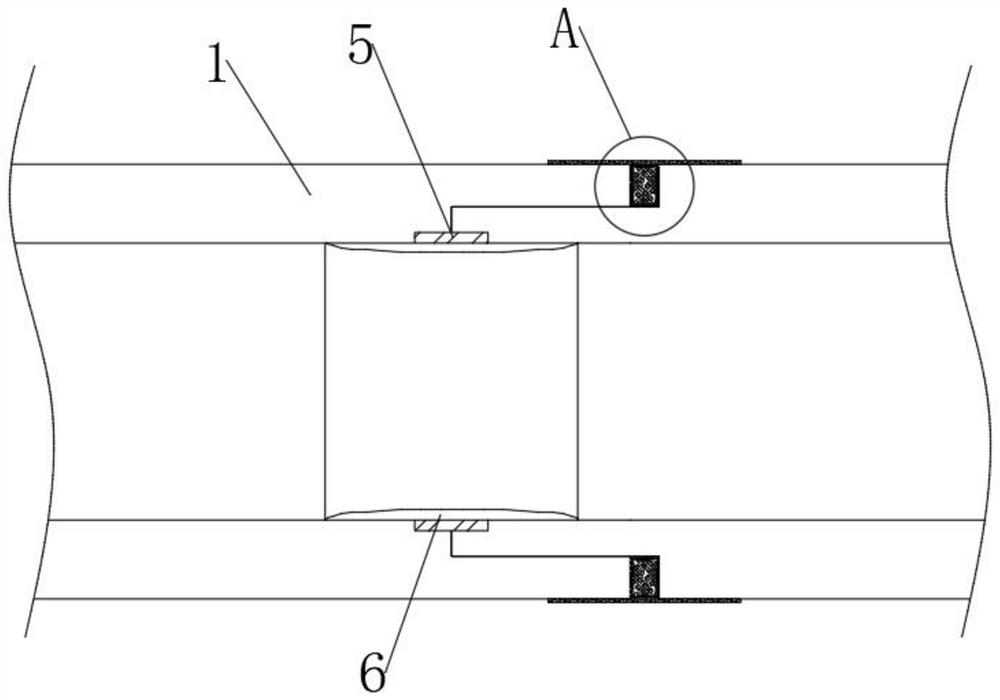

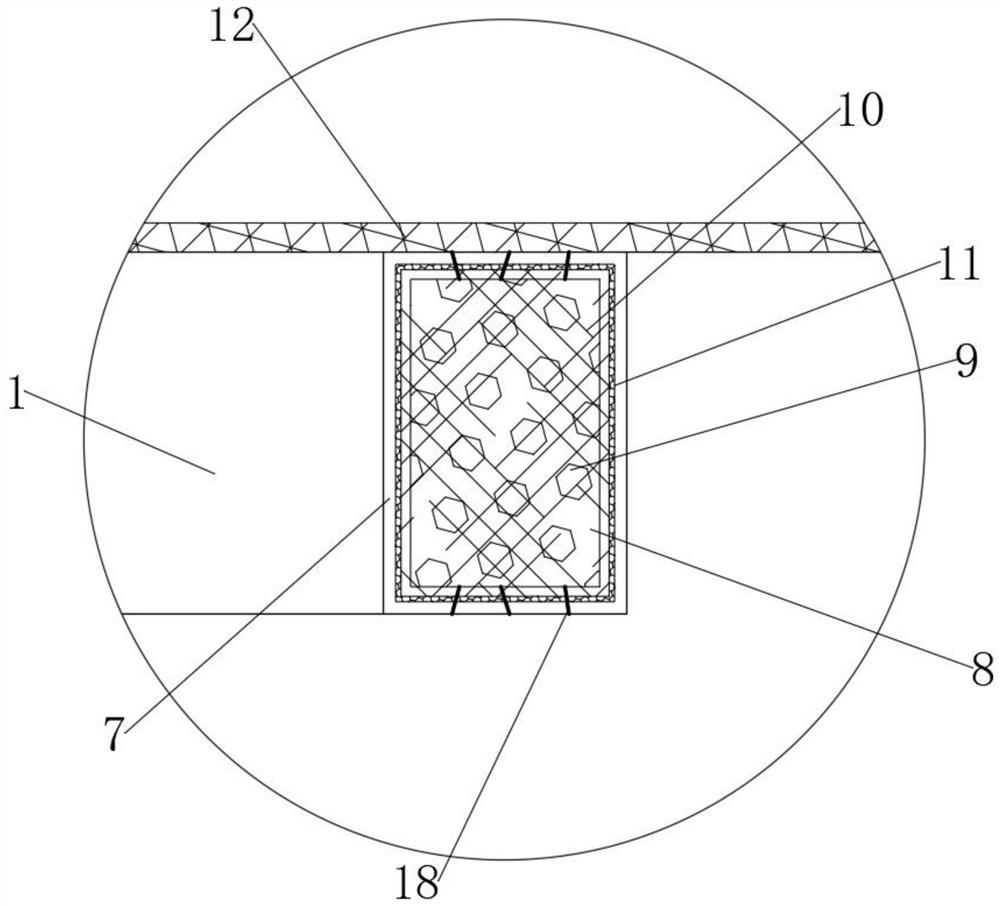

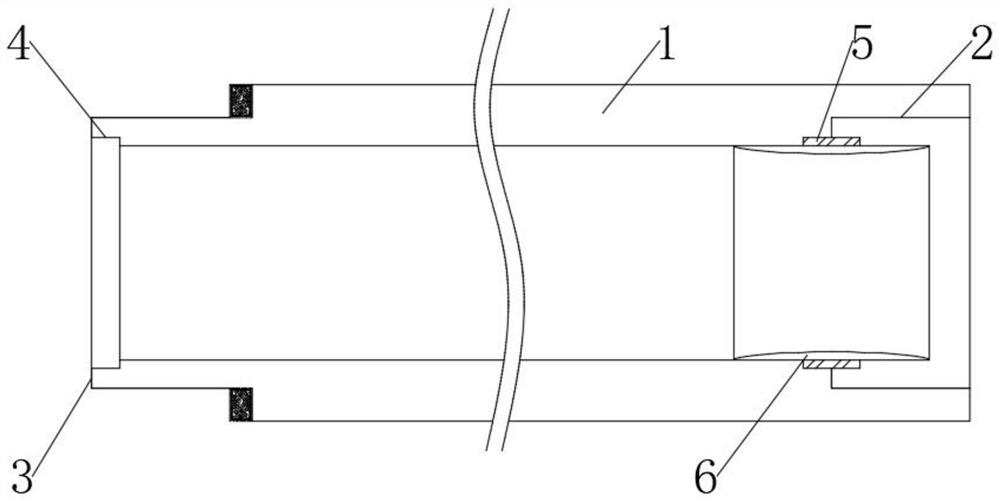

Reinforced concrete drainage pipe with tongue-and-groove flexible interface

ActiveCN112720826BMeet sealing needsInhibit sheddingShaping reinforcementsPipe-jointsReinforced concreteRebar

The invention discloses a reinforced concrete drainage pipe with a tongue-and-groove flexible interface, which belongs to the field of reinforced concrete drainage pipes. The reinforced concrete drainage pipe with a tongue-and-groove flexible interface uses an ice ring buried with an attached net to perform low-temperature simulation on the main connection end of the drainage pipe, so that The main body of the drain pipe is installed at low temperature, that is, it is installed under the state of cold shrinkage. At this time, the main body of the drain pipe is at the minimum size. After the installation is completed, the main body of the drain pipe will only expand, and the compensation pad used as the seal And its internal structure only needs to be able to resist the extrusion of the main body of the drainage pipe. It can be realized that the reinforced concrete drainage pipe is pretreated before installation, so that the reinforced concrete drainage pipe is in a low-temperature shrinkage state for matching installation. At this time, the sealing The device only needs to cope with the temperature rise and expansion of the reinforced concrete drain pipe, which increases the reliability of the sealing device.

Owner:浙江银泰水泥构件股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com