Particle material packaging machine

A granular material and packaging machine technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of low degree of automation, slow packaging speed, large floor space, etc., and achieve simple operation and save the cost of setting shearing devices Requirement, effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

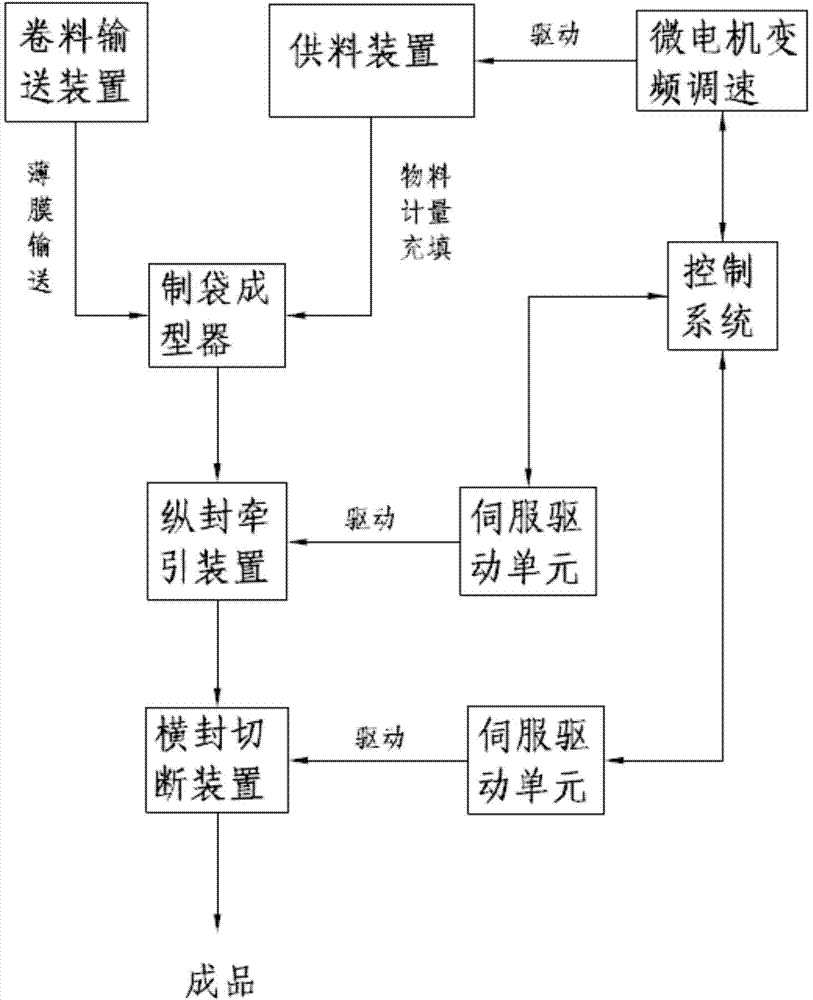

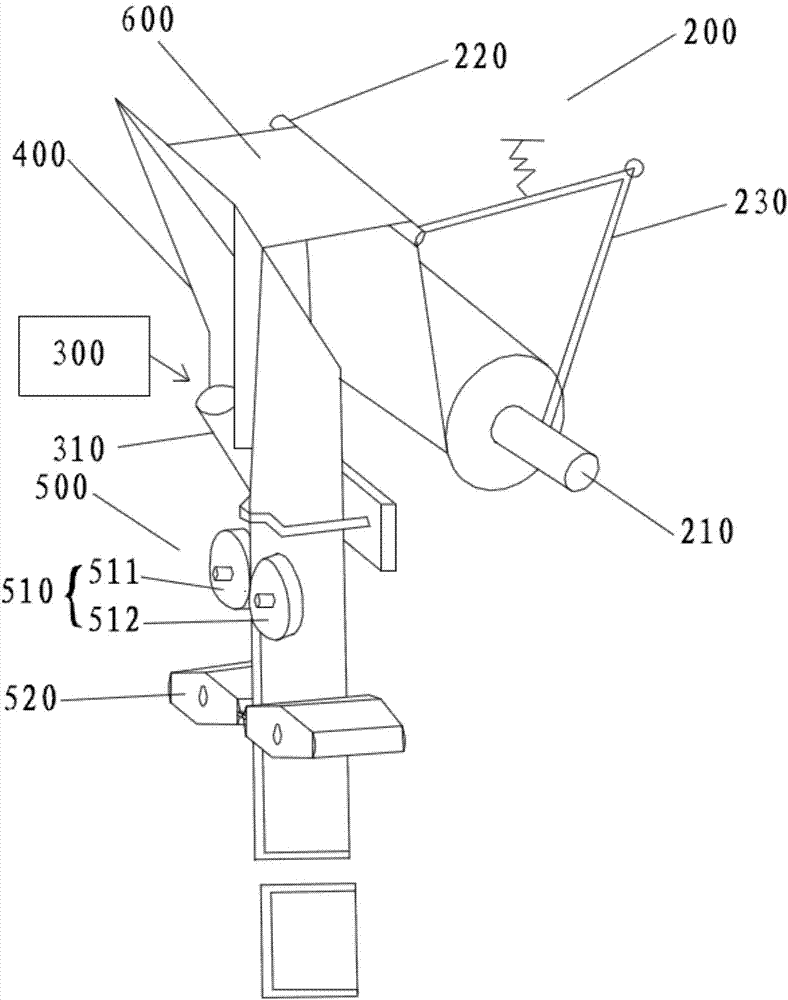

[0062] Such as figure 1 As shown, this embodiment discloses a granular material packaging machine, including: a vertical frame (not shown in the figure), a control system 100, a coil conveying device 200 for outputting packaging films, and a coil conveying device 200 for outputting granular materials The feeding device 300, the bag-making former 400 for guiding and forming the packaging film, and the sealing device 500 for heat-sealing the formed packaging film.

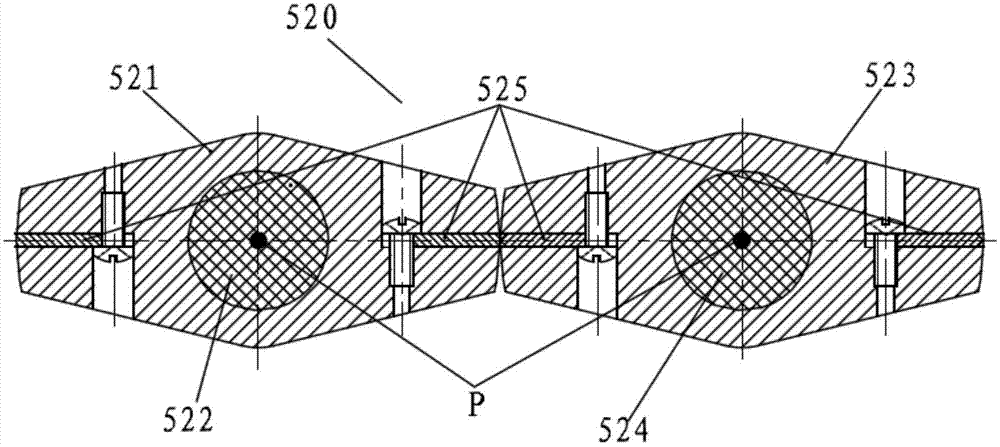

[0063] combine figure 2As shown, the coil conveying device 200 of the present embodiment is arranged on the upper part of the vertical frame, the bag forming device 400 is arranged in the middle of the vertical frame, and the sealing device 500 is arranged on the vertical frame The lower part of the lower part, the feeding port 310 of the feeding device 300 is set in the middle and lower part of the vertical frame, and the packaging film 600 is output from the coil conveying device 200 to the bag forming machine 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com