Split type thermal treatment furnace draught fan

A heat treatment furnace, split technology, applied in liquid fuel engines, mechanical equipment, non-variable-capacity pumps, etc., can solve the problems of scrapping fans, inability to meet heat treatment furnaces, easy high temperature oxidation and corrosion damage, etc., to achieve improved sealing performance, Great practical value, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

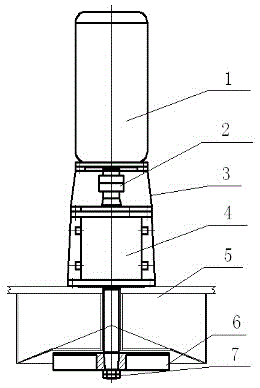

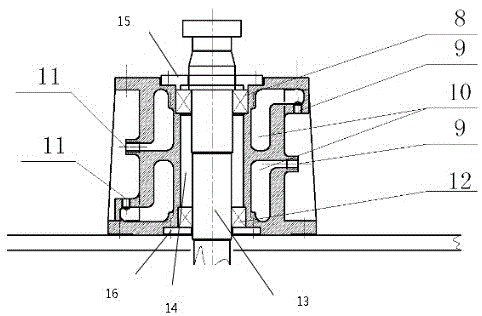

[0020] A split heat treatment furnace fan, such as Figure 1~2 : Including fan motor 1, detachable coupling 2, motor support 3, compartment transmission mechanism 4, furnace body 5, fan blade 6, fan blade fixing nut 7, upper sealing bearing 8, cooling water outlet 9, circulating cooling Water chamber 10, cooling water inlet 11, lower sealed bearing 12, fan shaft 13, lubricating oil chamber 14, upper sealed bearing gland 15, lower sealed bearing gland 16, wherein the fan motor 1 is fixed on the upper part of the motor support 3, and the motor The rotating shaft and the fan rotating shaft 13 are connected by a detachable coupling 2 in the motor support 3, and the fan blade 6 is fixed on the outer end of the fan rotating shaft 13 by a key and the fan blade fixing nut 7, and the motor support 3 and the furnace body 5 are provided with The water-cooled oil lubricated compartment, the upper and lower parts of the water-cooled oil lubricated compartment are respectively fixed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com