Liquid rocket engine turbine pump rotor low-temperature displacement measuring device

A turbo pump rotor, liquid rocket technology, applied in rocket engine devices, measuring devices, engine testing and other directions, to achieve the effect of ensuring low temperature sealing, high safety and reliability, and reducing temperature drift performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

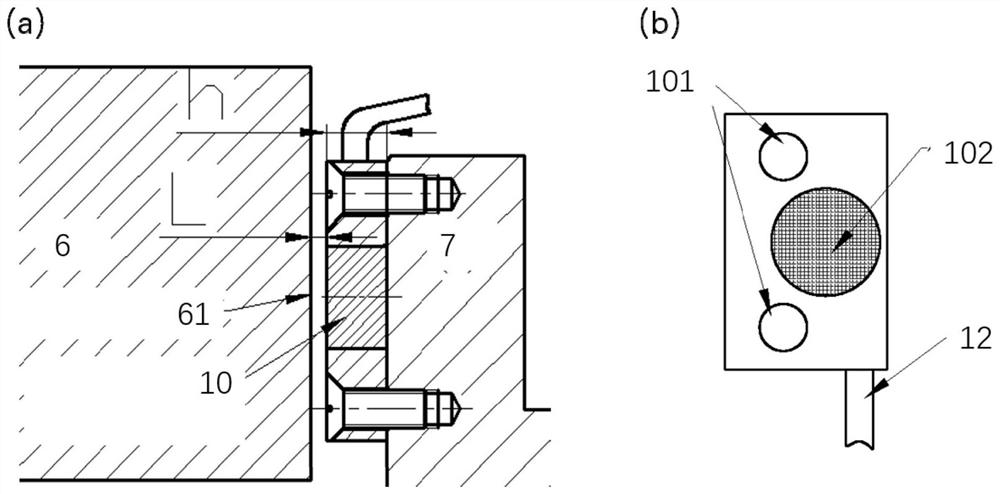

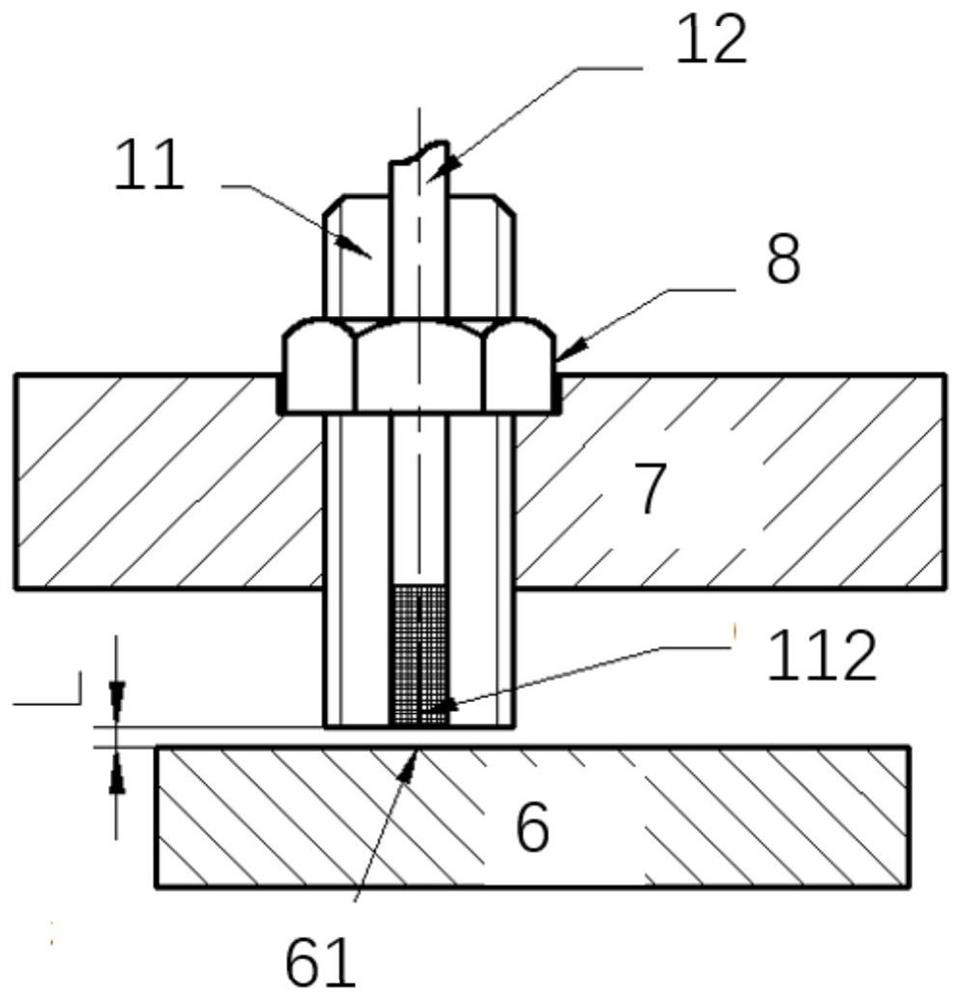

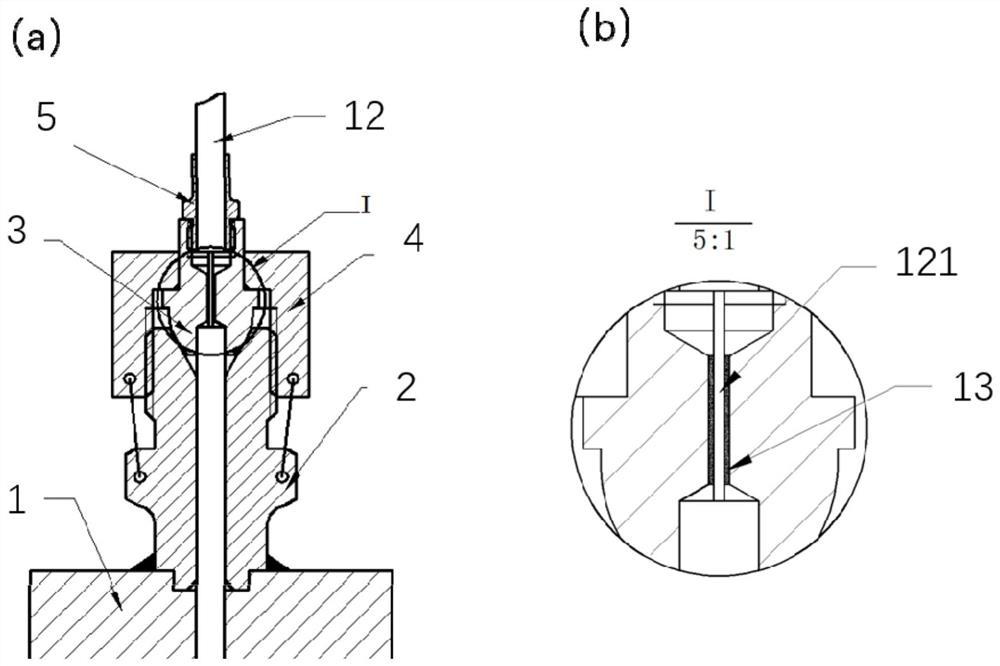

[0049] The installation diagram and sensor plan of the axial displacement sensor are as follows: figure 1 As shown, 6 in the figure represents the turbo pump rotor in the turbo pump rotor assembly or other moving parts that are relatively stationary with the turbo pump rotor. During the operation of the turbo pump, there will be an axial displacement relative to a stationary part 7 inside the turbo pump. 61 represents the measured surface, 10 is the axial displacement sensor, the type of sensor is an eddy current displacement sensor, and its plan view is as follows figure 1 As shown in (b), the internal axial space of the turbo pump is usually small, so the shape of the axial displacement sensor is generally designed as a prolate cuboid shape, the length can be controlled at 20mm, and the width is about 10mm, in which the circular area is where the sensor probes 102 are distributed. area, the sensor is fixed on the stationary part 7 by passing through two sensor installation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com