Tongue-and-groove type flexible joint reinforced concrete drainage pipe and machining process thereof

A reinforced concrete, flexible interface technology, applied in rigid pipes, pipes/pipe joints/fittings, pipes, etc., can solve problems such as the decrease of the service life of the sealing device, affecting the sealing performance of the reinforced concrete drainage pipe connection, and the failure of the sealing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

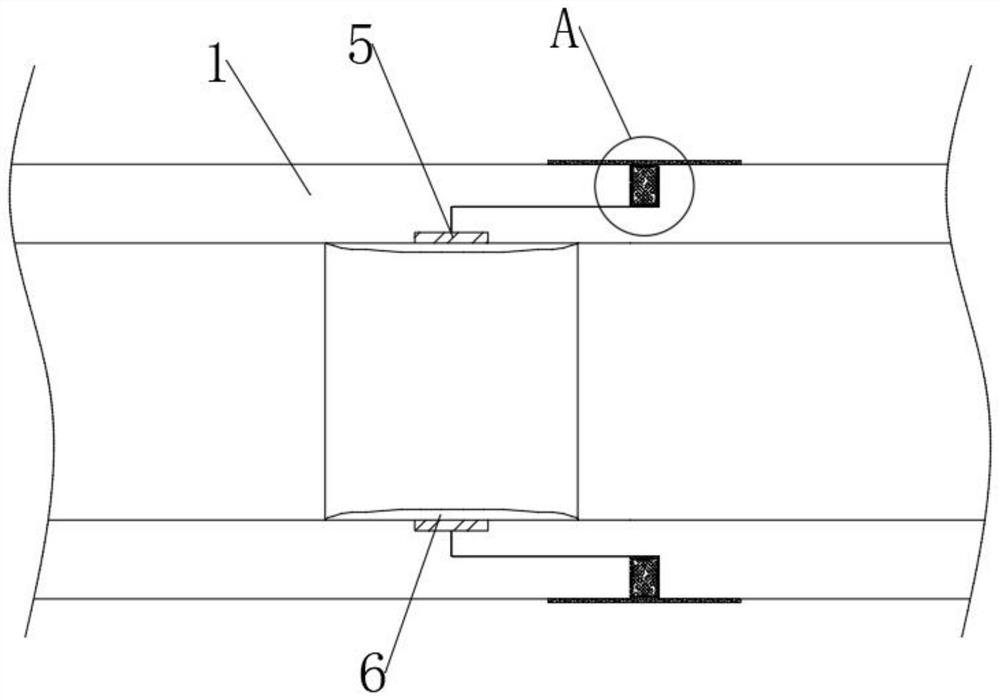

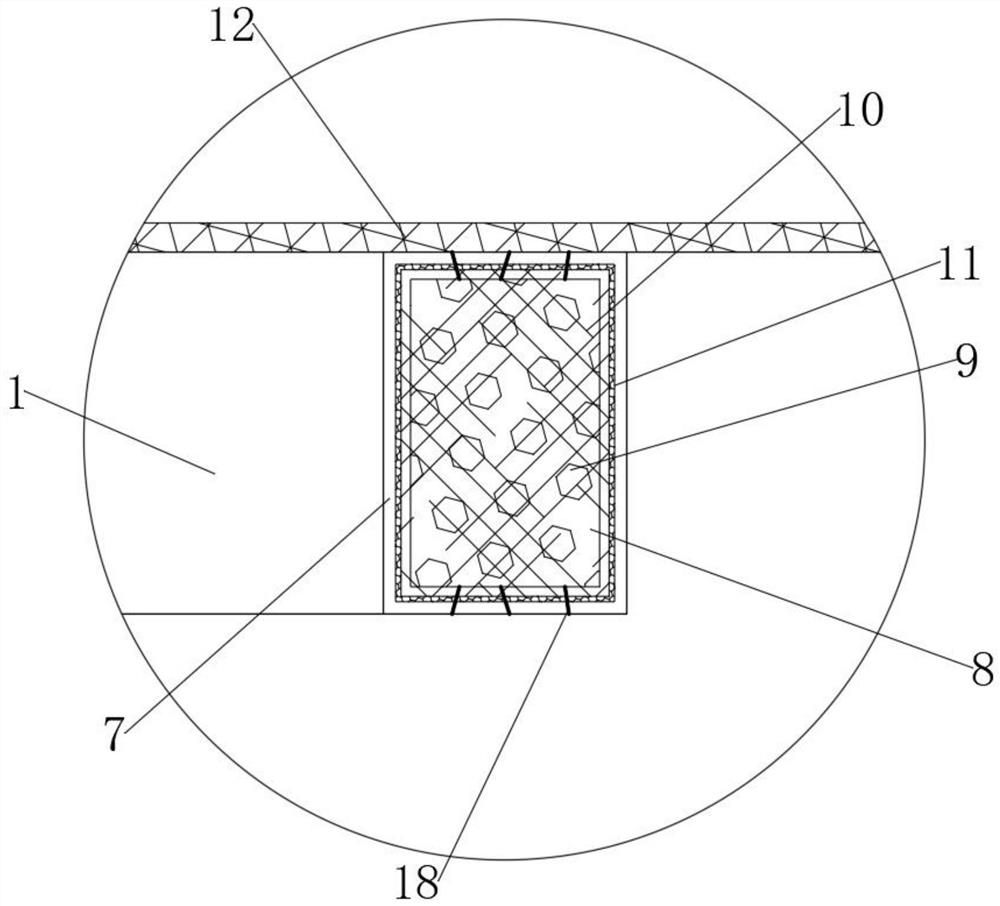

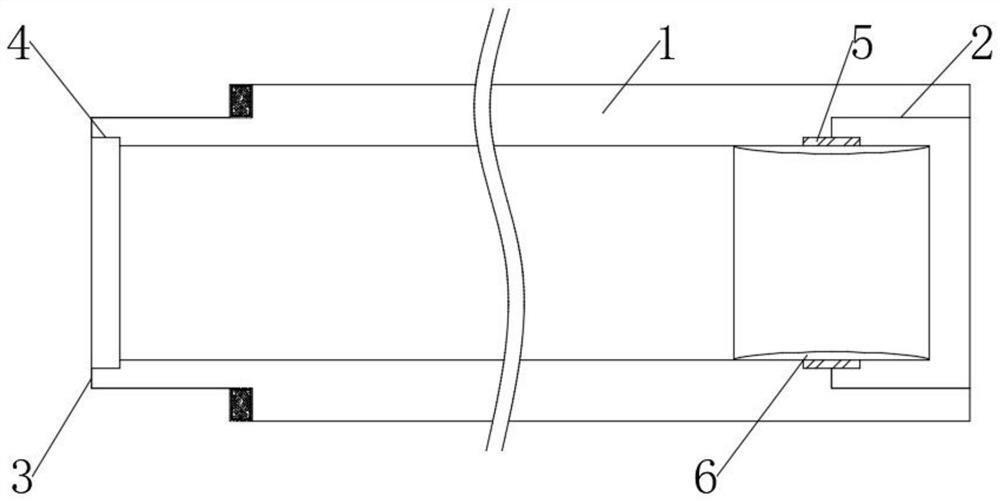

[0039] see Figure 1-3 , groove-and-groove flexible interface reinforced concrete drainage pipe and its processing technology, the reinforced concrete drainage pipe includes a drainage pipe main body 1, one end of the drainage pipe main body 1 is dug with an embedded groove 2, and the end of the drainage pipe main body 1 away from the embedded groove 2 The outer protruding end 3 that matches the inner embedding groove 2 is fixedly connected, and the two adjacent drainage pipe bodies 1 are spliced and installed through the inner embedding groove 2 and the outer protruding end 3. The bottom plate of the inner embedding groove 2 and the outer protruding end 3 The top end far away from the main body 1 of the drain pipe is drilled with matching fixing grooves 4, and the fixing groove 4 on the bottom plate of the embedded groove 2 is fixedly connected with a matching fixing block 5, and the fixing block 5 is far away from the end of the bottom plate of the fixing groove 4 A waterp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com