Vermiculite sealing material for high-temperature fuel cell

A high-temperature fuel cell and sealing material technology, applied in the field of vermiculite sealing materials, can solve problems such as unusability, and achieve the effect of meeting sealing requirements and facilitating operation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

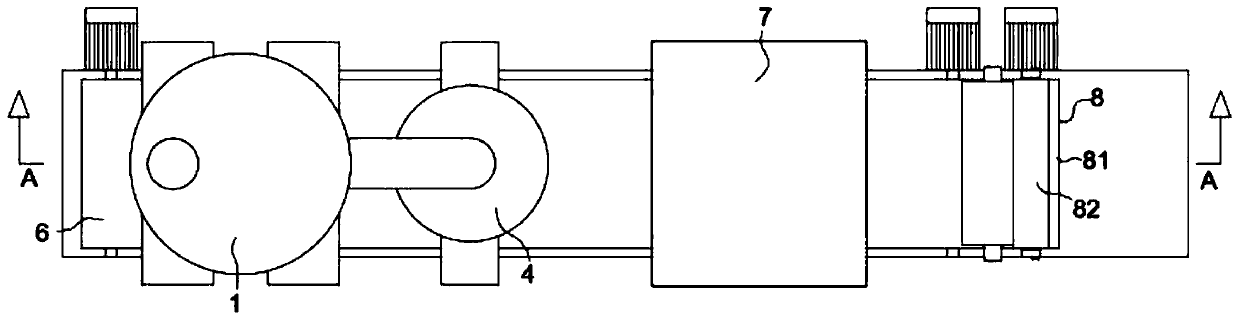

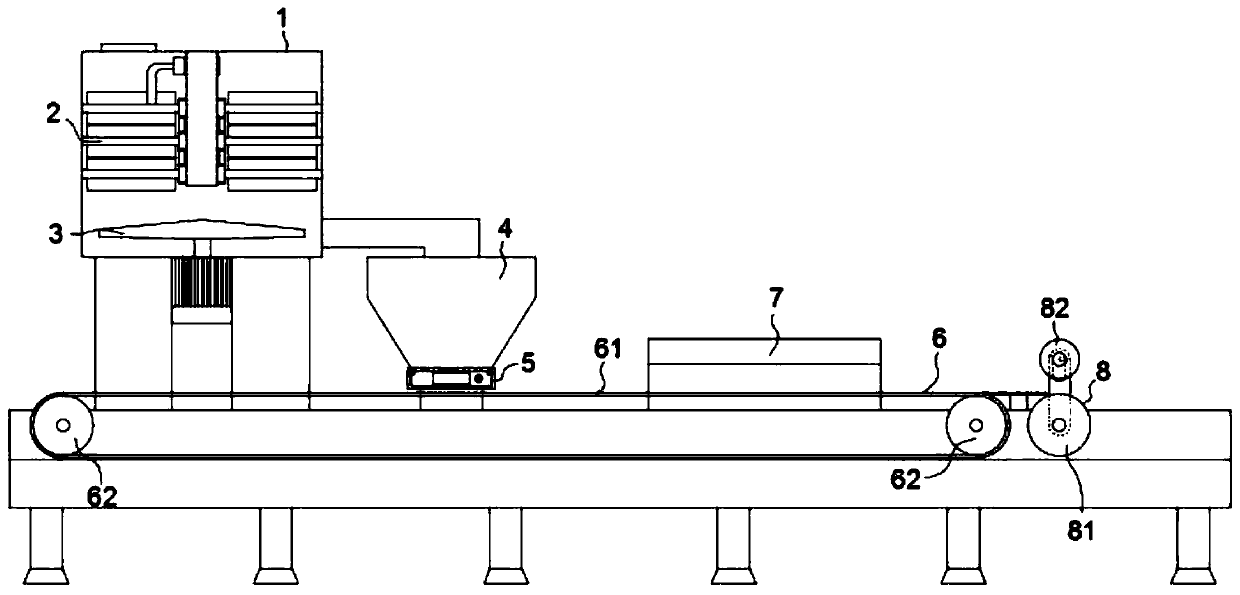

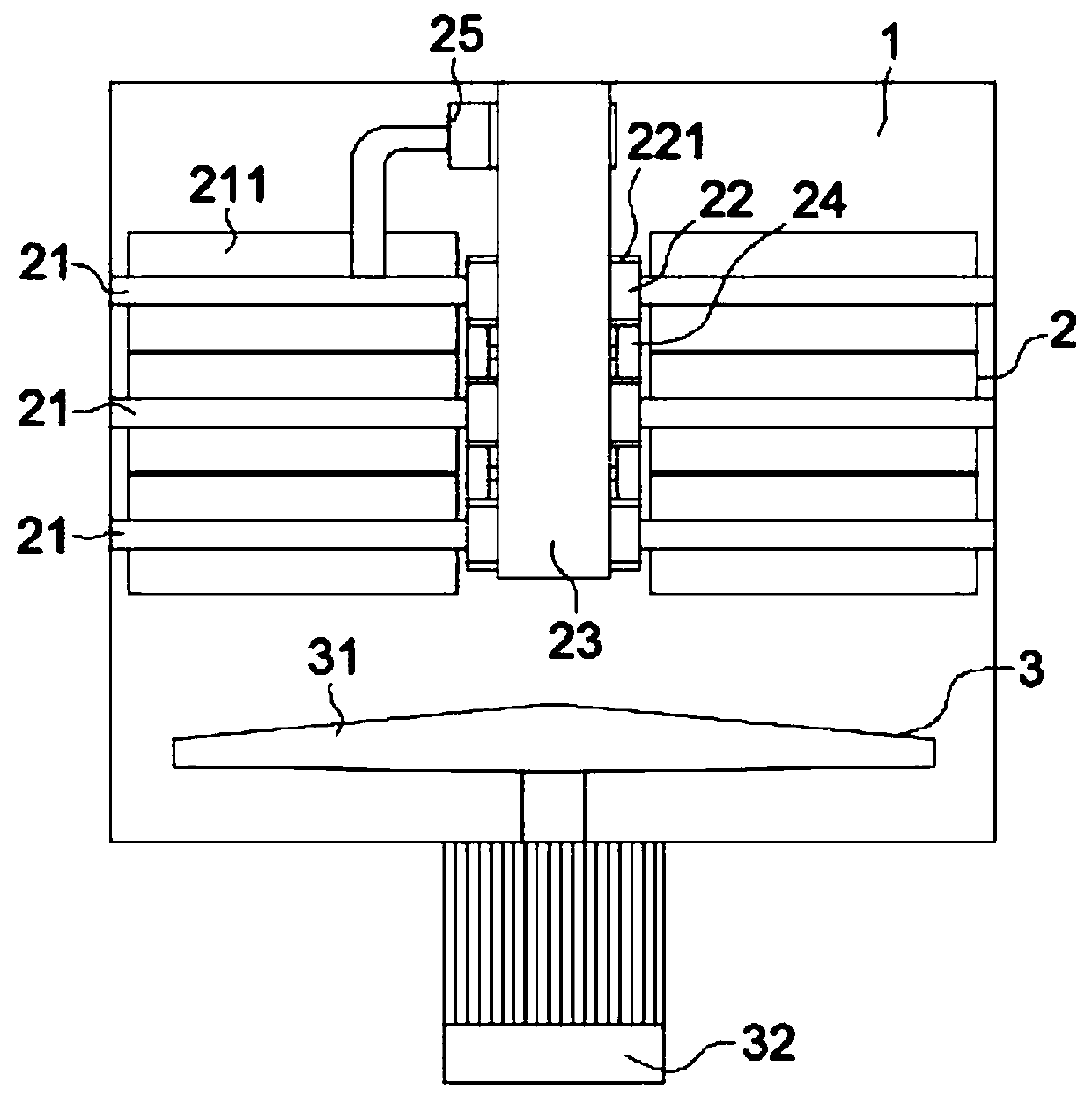

Method used

Image

Examples

Embodiment 1

[0043] A vermiculite sealing material for high-temperature fuel cells, mainly composed of the following components: 20% chemically expanded vermiculite, 10% thermally expanded vermiculite, 50% talc, 19% glass fiber, 0.5% graphene oxide, and a dispersant 0.2%, siloxane 0.3%. Vermiculite is used as the main raw material, and talc, glass fiber, graphene oxide and additives are added to prepare the plate, which can withstand high temperatures of 1000 ° C, has sealing and insulating properties, and can meet the sealing requirements of high-temperature fuel cells.

[0044] The preparation method of above-mentioned vermiculite sealing material comprises the following steps:

[0045] S1 raw material mixing: put chemically expanded vermiculite, thermally expanded vermiculite, talc, glass fiber, graphene oxide, dispersant, and siloxane into the feed hopper of the integrated machine according to the above mass ratio;

[0046] S2 homogeneous dispersion: grinding and high-speed dispersion...

Embodiment 2

[0051] A vermiculite sealing material for high-temperature fuel cells, mainly composed of the following components: 40% chemically expanded vermiculite, 23% thermally expanded vermiculite, 20% talc, 15% glass fiber, 1% graphene oxide, and a dispersant 0.5%, siloxane 0.5%. Vermiculite is used as the main raw material, and talc, glass fiber, graphene oxide and additives are added to prepare the plate, which can withstand high temperatures of 1000 ° C, has sealing and insulating properties, and can meet the sealing requirements of high-temperature fuel cells.

[0052] The preparation method of above-mentioned vermiculite sealing material comprises the following steps:

[0053] S1 raw material mixing: put chemically expanded vermiculite, thermally expanded vermiculite, talc, glass fiber, graphene oxide, dispersant, and siloxane into the feed hopper of the integrated machine according to the above mass ratio;

[0054] S2 homogeneous dispersion: grinding and high-speed dispersion o...

Embodiment 3

[0059] A vermiculite sealing material for high-temperature fuel cells, mainly composed of the following components: 55% chemically expanded vermiculite, 30% thermally expanded vermiculite, 5% talc, 4% glass fiber, 2.5% graphene oxide, and a dispersant 1.5%, siloxane 2%. Vermiculite is used as the main raw material, and talc, glass fiber, graphene oxide and additives are added to prepare the plate, which can withstand high temperatures of 1000 ° C, has sealing and insulating properties, and can meet the sealing requirements of high-temperature fuel cells.

[0060] The preparation method of above-mentioned vermiculite sealing material comprises the following steps:

[0061] S1 raw material mixing: put chemically expanded vermiculite, thermally expanded vermiculite, talc, glass fiber, graphene oxide, dispersant, and siloxane into the feed hopper of the integrated machine according to the above mass ratio;

[0062] S2 homogeneous dispersion: grinding and high-speed dispersion of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com