Built-in material liquid conveying pump under negative working condition

A material-liquid delivery pump, built-in technology, applied in the direction of rotary piston pumps, pumps, rotary piston/swing piston pump components, etc., can solve explosion accidents, cannot deliver material and liquid to designated locations, and centrifugal delivery Problems such as poor cavitation compatibility of the material pump, etc., to achieve the effect of meeting the sealing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

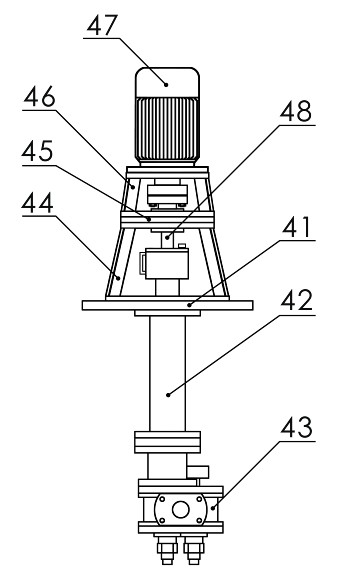

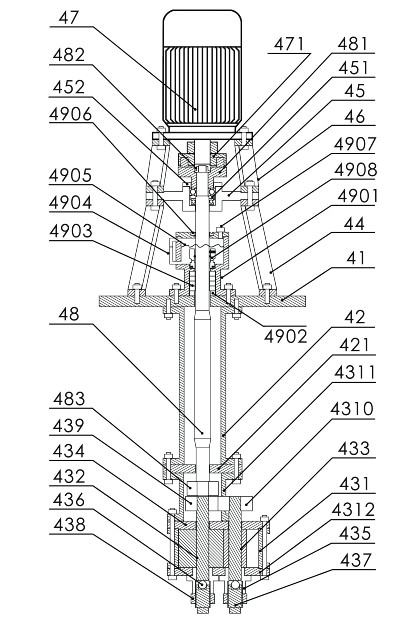

[0023] In this embodiment, a built-in negative pressure working condition feed liquid delivery pump, refer to the attached figure 1 , figure 2 and Figure 4 , in the figure: large cover 41, extension sleeve 42, positioning plate 421, pump head 43, pump cylinder housing 431, active rotor shaft 432, passive rotor shaft 433, pump body front end cover 434, shaft sleeve 435, pressure bearing 436 , Adjusting the top wire 437, adjusting the top wire lock nut 438, the driving gear 439, the driven gear 4310, the dial sleeve 4311, the rear end cover of the pump body 4312, the bearing bracket 44, the bearing housing 45, the bearing assembly 451, the bearing gland 452, power mechanism bracket 46, power mechanism 47, power mechanism dial 471, pump shaft 48, upper dial 481, dial lock nut 482, lower dial 483, sealing shell 4901, packing top ring 4902, sealing packing 4903 , Liquid level gauge 4904, sealing material liquid 4905, oil seal 4906, material liquid adding bolt 4907, mechanical s...

Embodiment 2

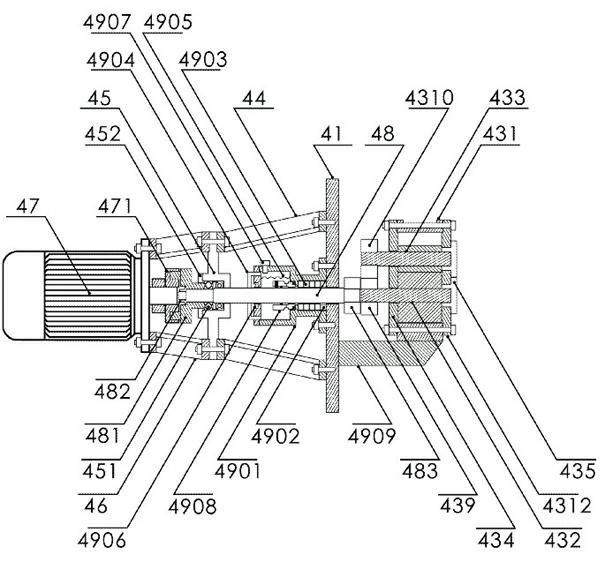

[0071] See attached image 3 , in the figure: large cover 41, pump head 43, pump cylinder housing 431, active rotor shaft 432, passive rotor shaft 433, pump body front cover 434, shaft sleeve 435, driving gear 439, driven gear 4310, pump body rear end Cover 4312, bearing seat bracket 44, bearing seat 45, bearing assembly 451, bearing gland 452, power mechanism bracket 46, power mechanism 47, power mechanism dial 471, pump shaft 48, upper dial 481, dial lock nut 482 , Lower dial 483, sealing shell 4901, packing top ring 4902, sealing packing 4903, liquid level gauge 4904, sealing material liquid 4905, oil seal 4906, feeding liquid adding bolt 4907, mechanical seal 4908, pump head bracket 4909.

[0072] The difference between this embodiment and the built-in negative pressure working condition feed liquid delivery pump structure in Embodiment 1 is that some components have increased or decreased due to changes in the use angle.

[0073] The built-in negative pressure working co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com