Hard rock push bench

A pipe jacking machine and hard rock technology, which is applied to mining equipment, earthwork drilling, tunnels, etc., can solve the problems of difficult processing of hinged sealing devices, affecting construction progress, and high sealing costs, so as to reduce the difficulty of sealing and reduce the manufacturing cost. Difficulty, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

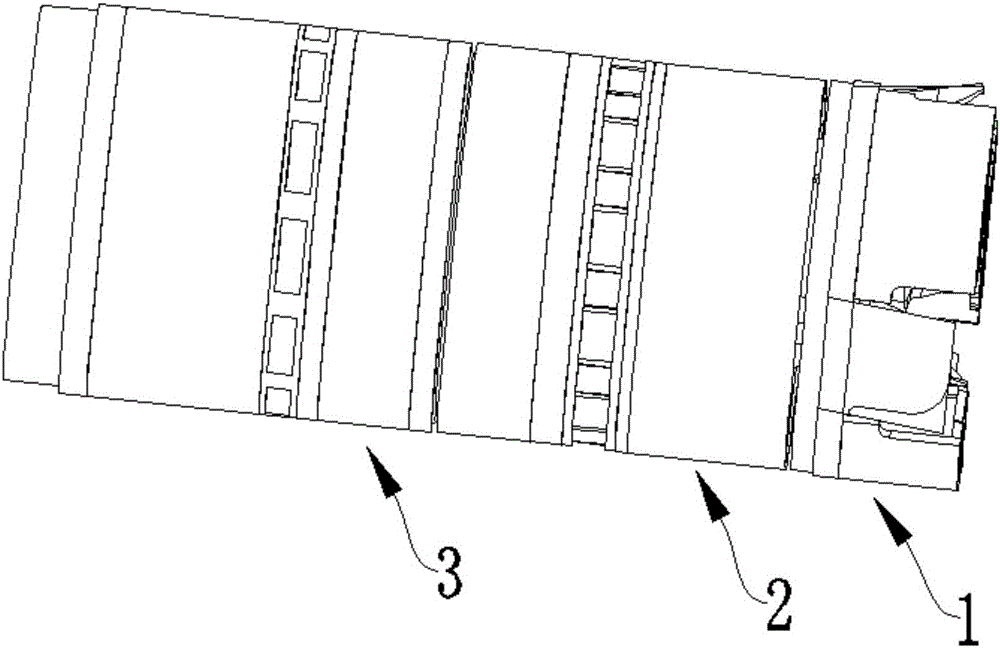

[0051] The hard rock pipe jacking machine of the present embodiment, as figure 1 As shown, it includes a cutting cutter head 1, a crushing bin 2 and a housing 3, the front end of the crushing bin 2 is connected to the back of the cutting cutter head 1, and the end of the crushing bin 2 is connected to the front end of the housing 3;

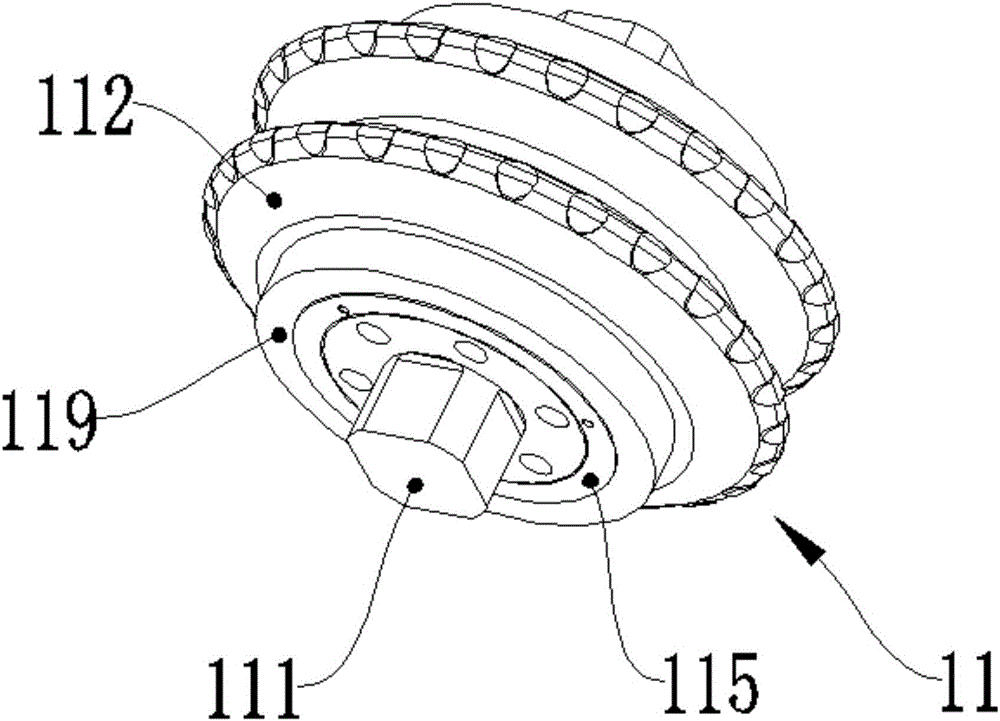

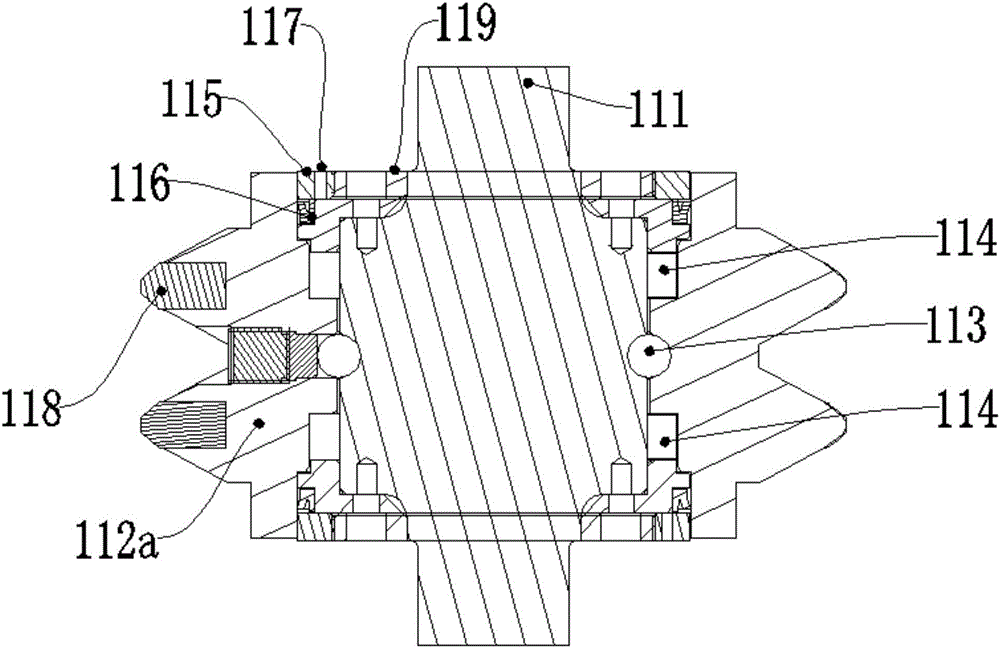

[0052] like figure 2 , image 3 As shown, a plurality of hobs 11 are also included, and the hobs 11 are arranged on the front of the cutting cutter head 1; the hobs 11 include a cutter shaft 111, a cutter body 112, an annular gland 115, and a hob sealing ring 116. Gland adjusting bolt 117 and cutter body mounting flange 119, the cutter body 112 is a ring structure, and the outer side of the cutter body 112 is provided with a cutter ring 112a;

[0053] like Image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com