Conductive fluorosilicone sealant and preparation method thereof

A sealant and fluorosilicon technology, applied in the field of fluorosilicon sealant and its preparation, can solve the problems of low temperature resistance grade of epoxy rubber, prone to degradation reaction, limited application scope, etc., to improve high temperature resistance performance and deep curing. Good, expand the effect of the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of a conductive fluorosilicon sealant, preparing the conductive fluorosilicon sealant as described above, characterized in that the steps of preparation are as follows:

[0025] 1. Preparation of component A:

[0026] 1.1. Ingredients: Weigh liquid fluorosilicone rubber, conductive filler, reinforcing agent, heat-resistant agent, methyl fluorosilicone oil, and coupling agent in component A in proportion;

[0027] 1.2. Coarse mixing: use a three-roll mill to mix liquid fluorosilicone rubber, conductive filler, reinforcing agent, heat-resistant agent, and methyl silicone oil three times until uniform;

[0028] 1.3. Stirring: Put the ground mixture into a planetary mixer, add coupling agent in proportion, stir, set the speed at 500 rpm to 1000 rpm, stir for 30 minutes to 60 minutes, and obtain component A;

[0029] 2. Preparation of component B:

[0030] 2.1. Ingredients: Weigh the vulcanizing agent and catalyst in component B in proportion;

[0031...

Embodiment 1

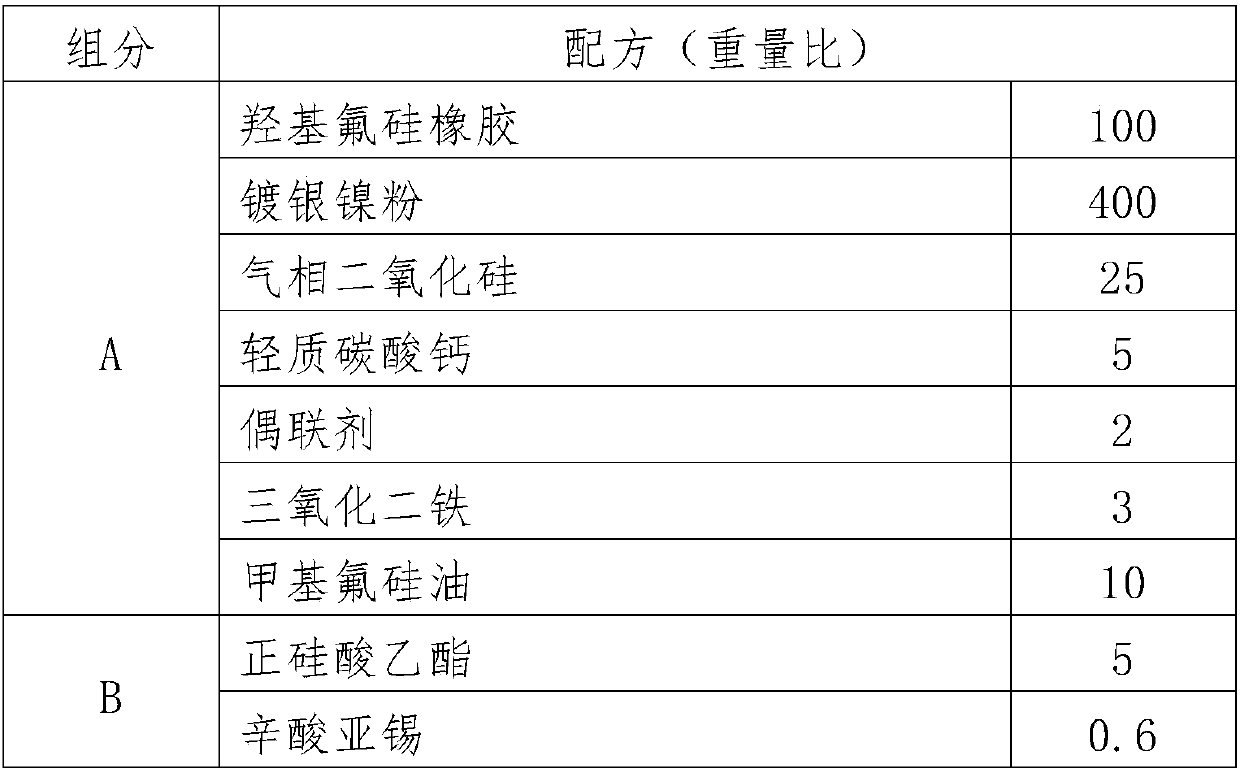

[0034] The composition formula of the medium-resistant and high-temperature-resistant conductive fluorosilicon sealant is shown in Table 1:

[0035] Table 1 Formula composition of medium-resistant and high-temperature-resistant conductive fluorosilicon sealant

[0036]

[0037] The volume resistivity of the test piece prepared by using this compound is 2.3×10 -3 Ω cm, the tensile strength is 1.21MPa, and the elongation at break is 148%; after the heat-resistant treatment at 200℃*24h, its appearance has not changed, and its volume resistivity is 3.1×10 -2 Ω·cm, the mechanical properties decreased slightly, the tensile strength was 1.08MPa, and the elongation at break was 109%; the sample did not become viscous after being resistant to 95# aviation gasoline at 60°C for 7d.

Embodiment 2

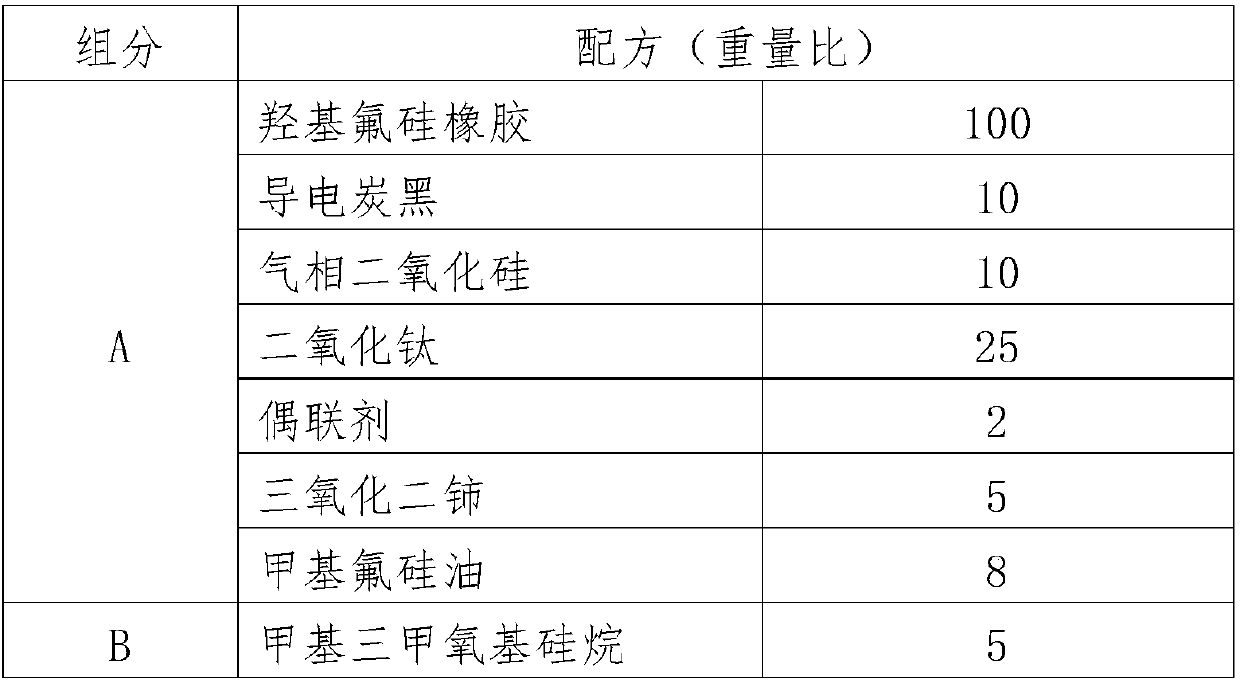

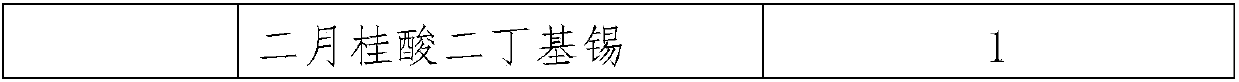

[0039] The composition formula of the medium-resistant and high-temperature-resistant conductive fluorosilicon sealant is shown in Table 2:

[0040] Table 2 Formula composition of medium-resistant and high-temperature-resistant conductive fluorosilicon sealant

[0041]

[0042]

[0043] The volume resistivity of the test piece prepared by using this rubber formula is 5.2×10 -3 Ω cm, the tensile strength is 1.04MPa, and the elongation at break is 179%; after the heat-resistant treatment at 200℃*24h, its appearance has not changed, and its volume resistivity is 4.9×10 -2 Ω·cm, the mechanical properties decreased slightly, the tensile strength was 0.87MPa, and the elongation at break was 147%; the sample did not become viscous after being resistant to 95# aviation gasoline at 60°C for 7d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com