High-temperature sealing gum, and preparation method and application thereof

A high-temperature sealing and glass technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve problems such as carbonization, sealant cracking, and inability to withstand temperature, to achieve enhanced compatibility, Enhanced adhesion, good chemical and thermal stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

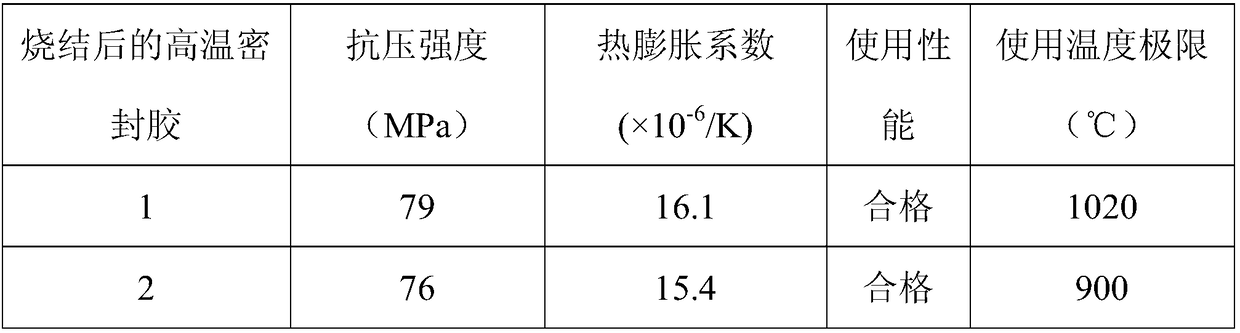

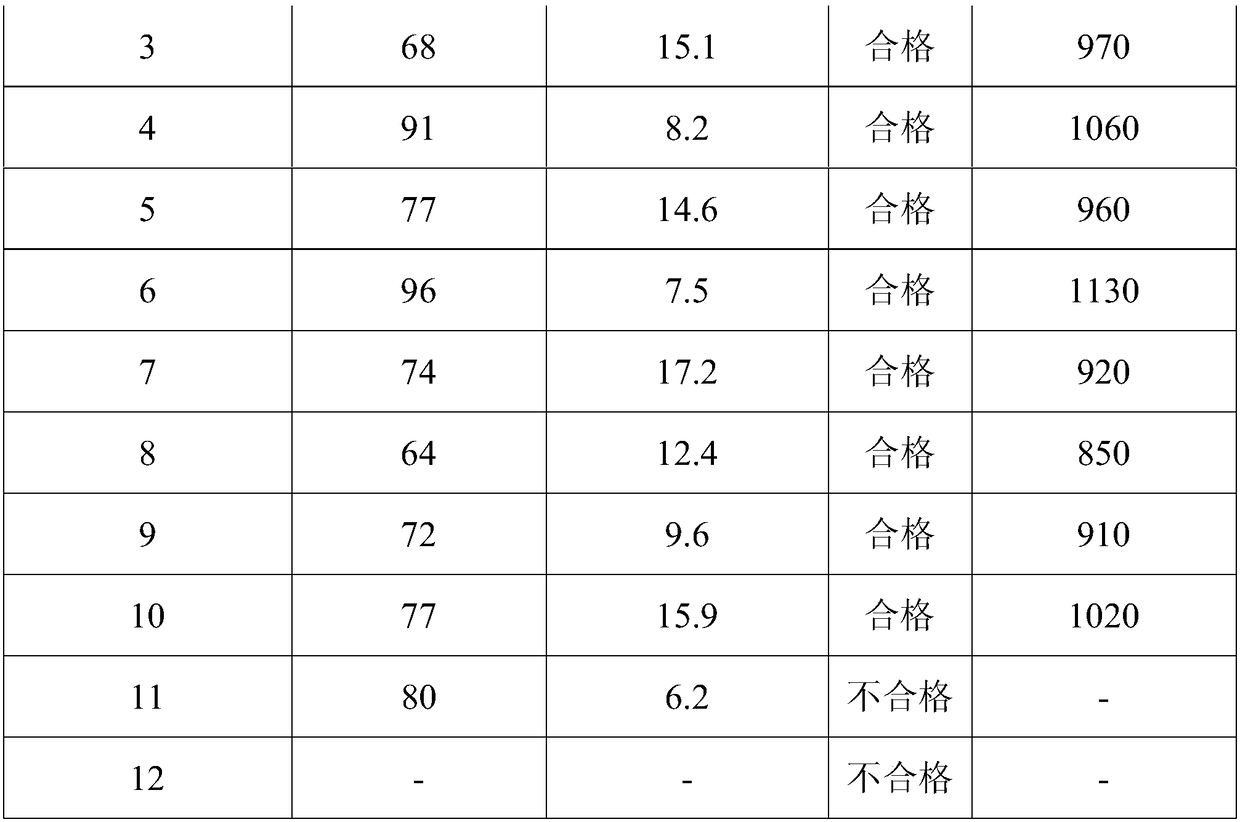

Examples

Embodiment 1

[0046] Prepare high temperature sealant 1 through the following steps:

[0047] Step (1), the network body oxide: 40g silicon dioxide, network intermediate oxide: 15g alumina, network outer body oxide: 37g barium oxide, 5g lithium oxide and 3g calcium oxide, filler: 3g lanthanum oxide and Mix 4g of titanium dioxide and 100g of ethanol evenly to obtain a mixture. The mixture is ground by a planetary ball mill for 10 hours, dried and placed in a muffle furnace, melted and reacted at 1600°C for 1 hour to obtain a molten glass, and then quickly pour the obtained molten glass into Cool in water to obtain a glass block, grind the glass block for 10 hours, and sieve to obtain glass powder with a particle size of 40 μm;

[0048] Step (2), get the glass powder that obtains in 70g step (1), 20g silver-copper alloy powder (wherein silver element accounts for 95wt%, copper element accounts for 5wt%) and 10g dispersant (by the terpineol of 90wt% and 10wt% obtained by mixing ethyl cellulos...

Embodiment 2

[0051] Prepare the high-temperature sealant 2 through the following steps:

[0052] The only difference from Example 1 is that the network host oxide added in step (1) is 32g of silicon dioxide and 8g of boron oxide.

[0053] In Example 2, a high-temperature sealant 2 was obtained.

Embodiment 3

[0055] Prepare high-temperature sealant 3 through the following steps:

[0056] The only difference from Example 1 is that the main network oxide added in step (1) is 35g of silicon dioxide, and the external network oxide is 35g of barium oxide, 5g of lithium oxide and 3g of calcium oxide.

[0057] In Example 3, a high-temperature sealant 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com