High-hardness support sealing ring rubber material

A technology of rubber materials and sealing rings, applied in the field of rubber, can solve the problems of unable to meet the support strength requirements of pipeline sealing rubber rings, poor wear resistance, and pipeline leakage, so as to shorten the vulcanization time, improve aging resistance, and prevent The effect of leaking pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

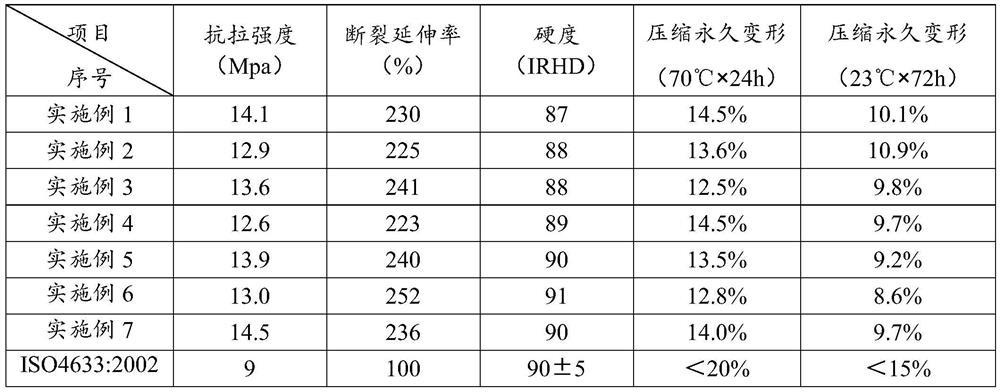

Examples

Embodiment 1

[0026] A high-hardness supporting sealing ring rubber material, comprising the following raw materials in parts by weight: 40 parts by weight of natural rubber, 40 parts by weight of styrene-butadiene rubber, 1.5 parts by weight of sulfur, 2 parts by weight of accelerator, 3 parts by weight of zinc oxide, stearic acid 2 parts by weight, 7 parts by weight of alkylphenolic resin, 120 parts by weight of general carbon black, 4 parts by weight of antioxidant, 1 part by weight of paraffin, 1 part by weight of dispersant, 0.5 parts by weight of anti-scorch agent, 2 parts by weight of pine tar; Agents include Accelerator CZ and Accelerator DM.

[0027] Specifically, among the accelerators, the ratio by weight of the accelerator CZ to the accelerator DM is 2:3;

[0028] The anti-aging agent includes anti-aging agent RD and anti-aging agent 4020, and the ratio of anti-aging agent RD to anti-aging agent 4020 is 1:2.

Embodiment 2

[0030] A high-hardness support sealing ring rubber material, comprising the following raw materials in parts by weight: 60 parts by weight of natural rubber, 60 parts by weight of styrene-butadiene rubber, 3.5 parts by weight of sulfur, 4 parts by weight of accelerator, 5 parts by weight of zinc oxide, stearic acid 4 parts by weight, 13 parts by weight of tackifying resin, 170 parts by weight of universal carbon black, 8 parts by weight of antioxidant, 3 parts by weight of paraffin, 3 parts by weight of dispersant, 2.5 parts by weight of anti-scorch agent, 5 parts by weight of pine tar; Accelerator Including Accelerator CZ and Accelerator DM.

[0031] Specifically, among the accelerators, the ratio by weight of the accelerator CZ to the accelerator DM is 3:1;

[0032] The anti-aging agent includes anti-aging agent RD and anti-aging agent 4020, and the ratio of anti-aging agent RD to anti-aging agent 4020 is 2:1.

Embodiment 3

[0034] A high-hardness supporting sealing ring rubber material, comprising the following raw materials in parts by weight: 45 parts by weight of natural rubber, 45 parts by weight of styrene-butadiene rubber, 2 parts by weight of sulfur, 2.5 parts by weight of accelerator, 3.5 parts by weight of zinc oxide, stearic acid 2.5 parts by weight, 8 parts by weight of tackifying resin, 140 parts by weight of universal carbon black, 5 parts by weight of antioxidant, 1 part by weight of paraffin, 1 part by weight of dispersant, 1 part by weight of anti-scorch agent, 2 parts by weight of pine tar.

[0035] Specifically, in the accelerator, the ratio of accelerator CZ to accelerator DM is 4:3;

[0036] The anti-aging agent includes anti-aging agent RD and anti-aging agent 4020, and the ratio of anti-aging agent RD to anti-aging agent 4020 is 2:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com