Compressor roller, compressor pump body and compressor

A compressor pump, compressor technology, applied in the direction of machine/engine, pump components, mechanical equipment, etc., can solve the problem that the eccentricity of the crankshaft 5 cannot reach the theoretical maximum value, the maximum displacement is small, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

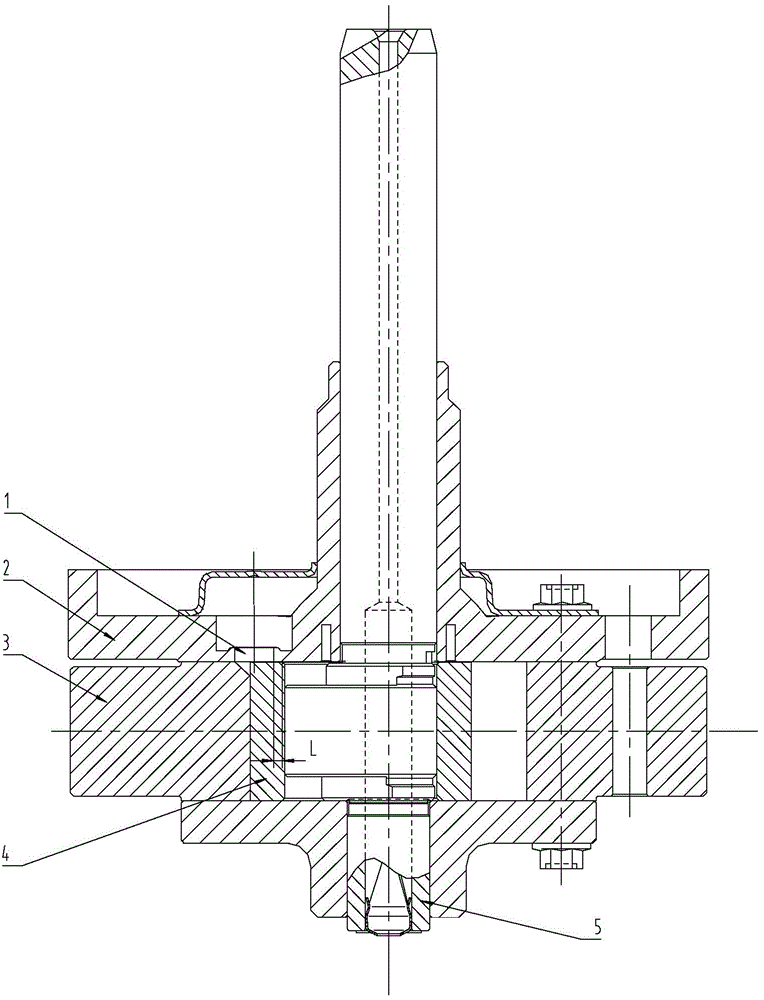

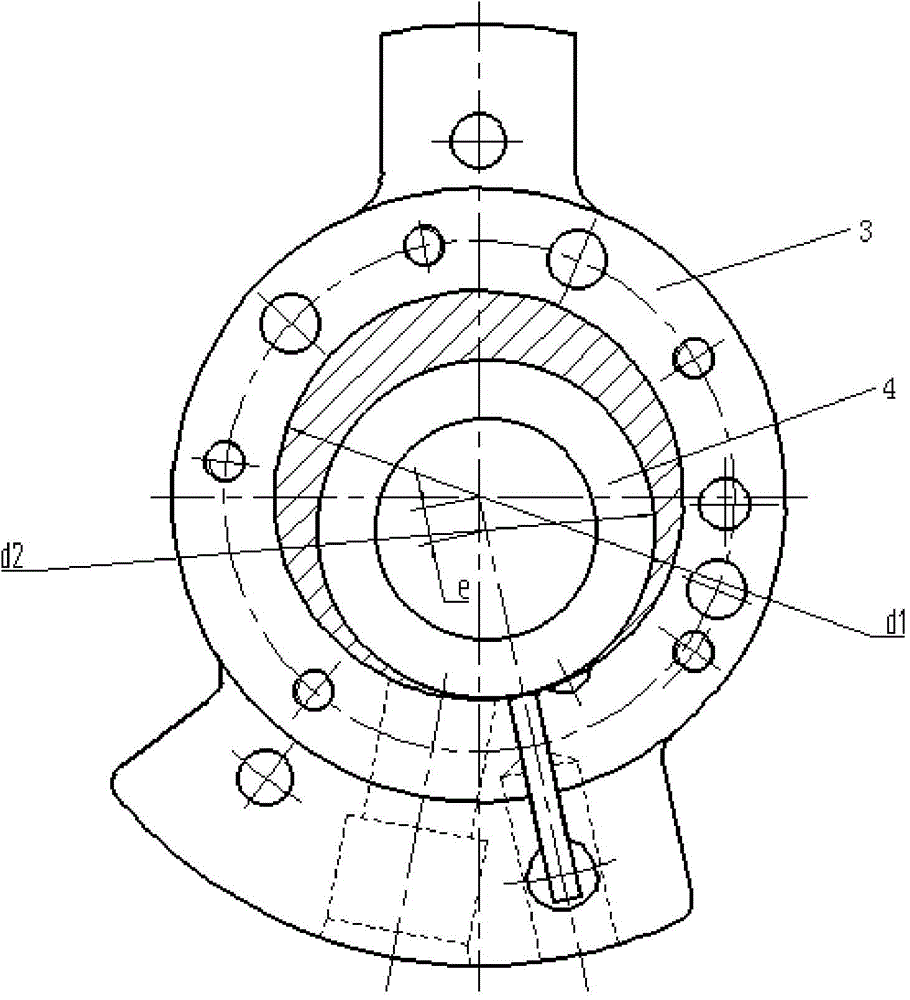

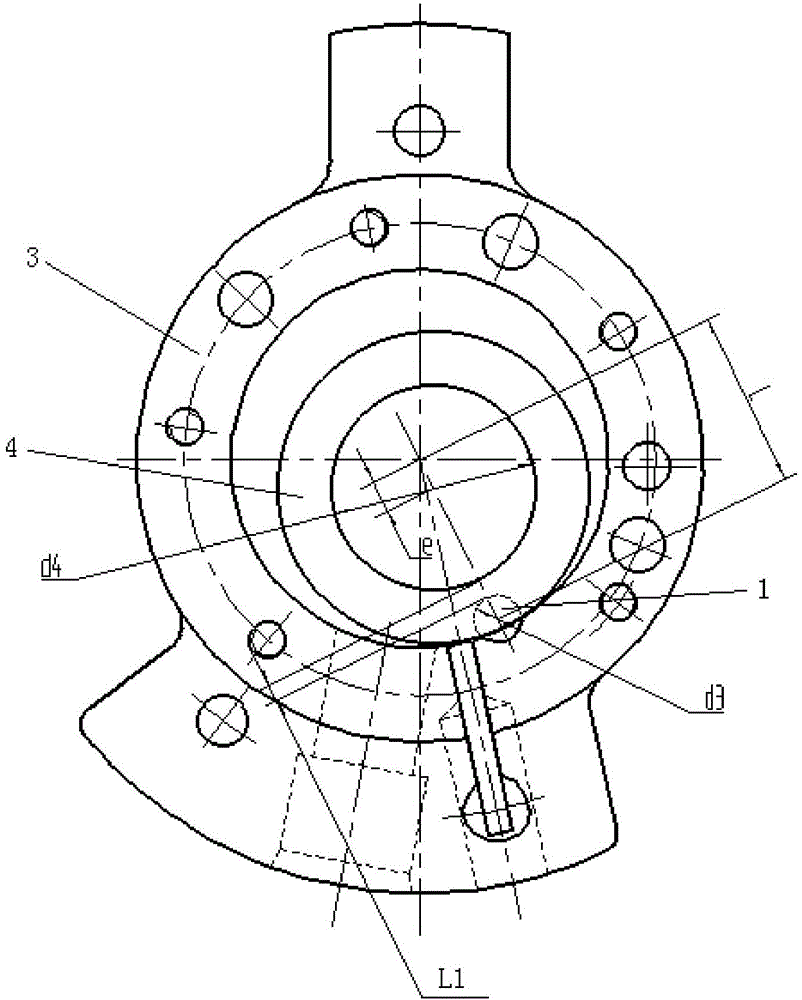

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0030] see Figure 4 and Figure 9 As shown, according to the first implementation of the compressor roller of the present invention, a compressor roller is provided, which includes a cylindrical roller body 10 and a first end of the roller body 10 Inner flange 60. Due to the inner flange 60 of the compressor roller in this embodiment, the setting of the inner flange 60 can meet the sealing requirements of the compression cylinder 30, form a longer sealing band, and avoid the leakage phenomenon of the compression cylinder 30. At the same time, due to The compressor rollers already have an inner flange 60 to prevent compressor leakage. At the same time, the sealing zone of the compressor with the largest displacement using the original roller struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com