Screw extruder for dehydration of steam-exploded plant straw materials

A technology of screw extruder and plant straw, applied in the direction of presses, manufacturing tools, etc., can solve the problems of no steam explosion plant straw screw extruder, etc., and achieve the effects of small resistance, stable operation and reduced length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention provides a screw extruder used for dehydration of steam-exploded plant straw materials to meet the dehydration requirements of steam-exploded materials in the technical field of comprehensive utilization of plant straws to produce biomass fuels, to adapt to the feeding mode with large fluctuations, and to make extrusion The dryness of steam explosion material reaches 40-65%, and the operation is stable, no blockage, and low power consumption.

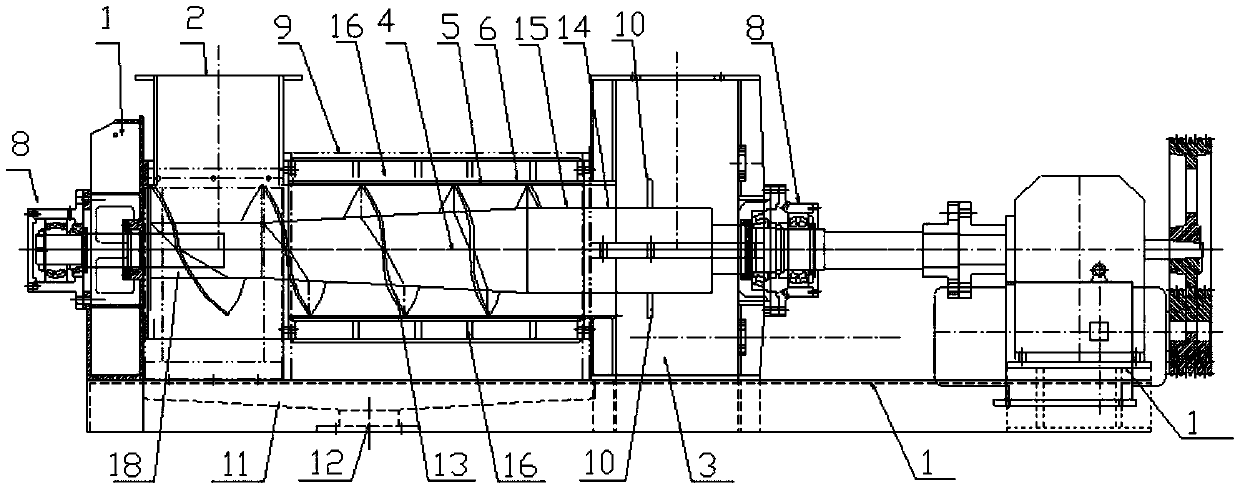

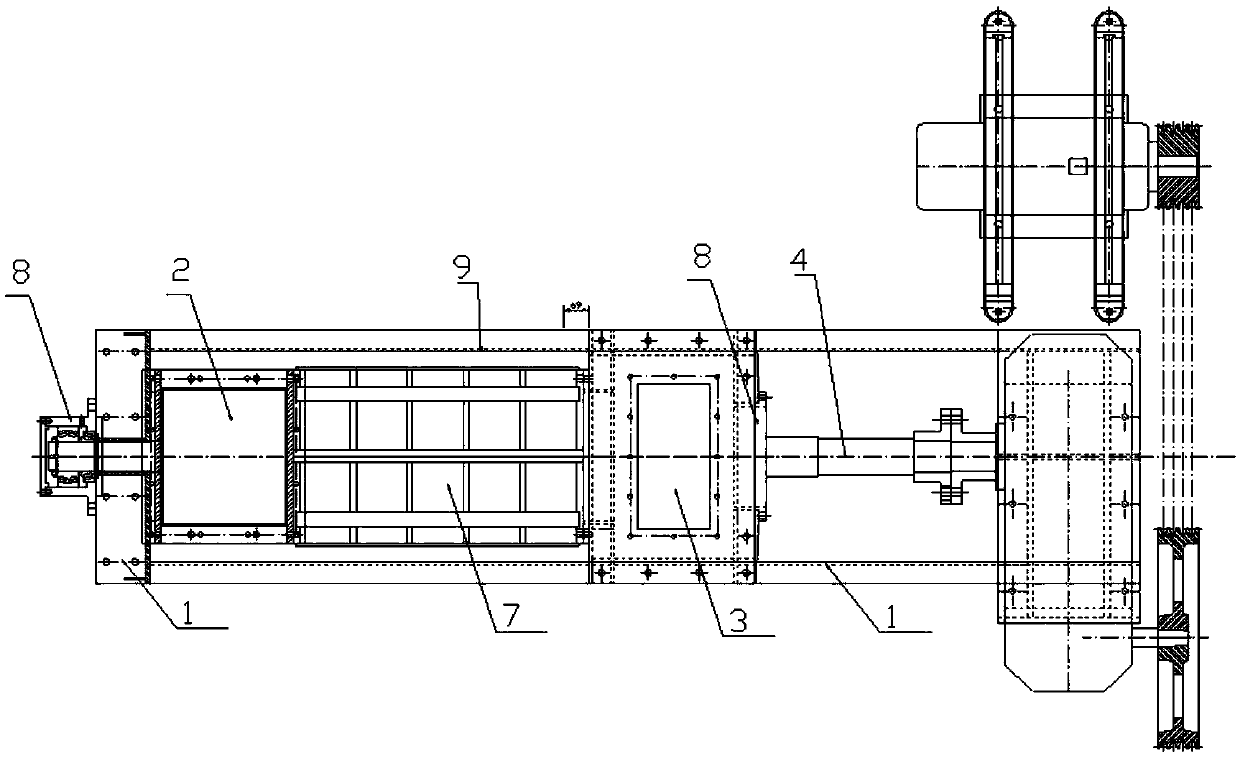

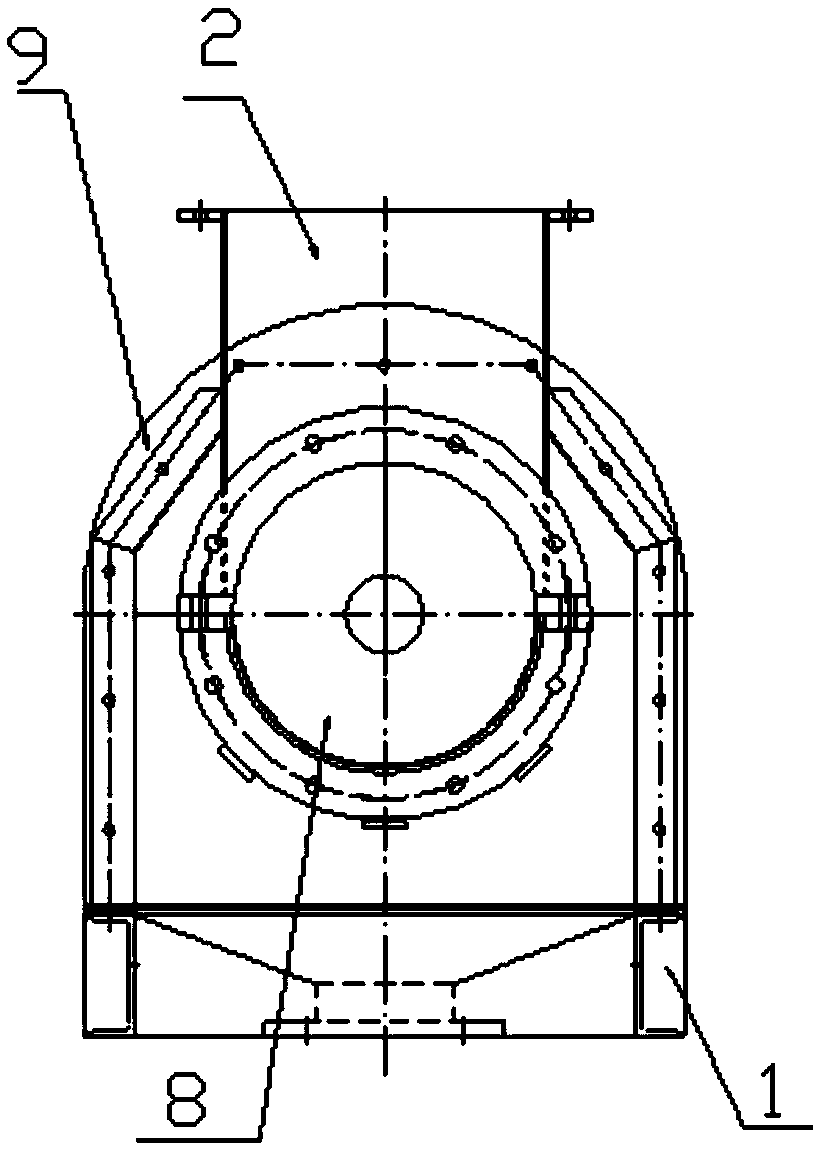

[0037] In order to achieve the above purpose, if Figure 1-Figure 3 As shown, the screw extruder used for steam-exploded plant stalk material dehydration of the present invention comprises: frame 1; the screw main shaft that is installed on the frame 1 and rotates relative to frame 1; the driving device that drives the screw main shaft to rotate; The screen cylinder 16 on the frame 1 and covered outside the screw spindle; the sealing cover 9 installed on the frame 1 and covered outside the screen cylinder 16; the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com