A method for synthesizing methane by adiabatic cooling type methanation

A methanation and chemical synthesis technology, applied in the petroleum industry, gas fuels, fuels, etc., can solve the problems of high energy consumption for isothermal methanation and high investment in adiabatic methanation, prolong service life, reduce side reactions of methanation, ensure effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

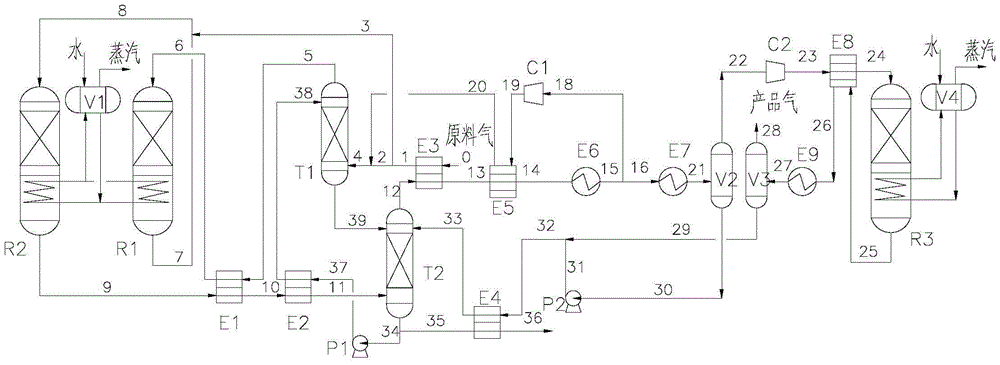

[0034] The technical flow of the low-pressure high-carbon monoxide raw material gas adiabatic cooling type methanation to synthesize methane in this embodiment is as follows:

[0035] Process such as figure 1 shown. In this embodiment, the raw material gas is a low-pressure high-carbon monoxide gas, the raw material gas pressure is ~0.93MPa(G), the temperature is normal temperature, and the flow rate is ~51000 Nm 3 / h, the main composition of the gas is CO: 20%, CO2: 3%, H2: 74%, CH4: 1.4%. It enters the heat exchanger E3 and exchanges heat with the gas at the outlet of the hot water tower. The raw gas is heated to ~110°C. Then it is divided into two parts: ~40% raw material gas is mixed with the same flow rate after heating, CO: ~10%, CO2: ~2%, H2: ~45.7%, CH4: ~38.5% after mixing, enter the saturation tower T1, the temperature of the raw material gas from the saturation tower T1 is ~129°C, the water content is ~26.5%, and it enters the heat exchanger E1 to exchange heat wi...

Embodiment 2

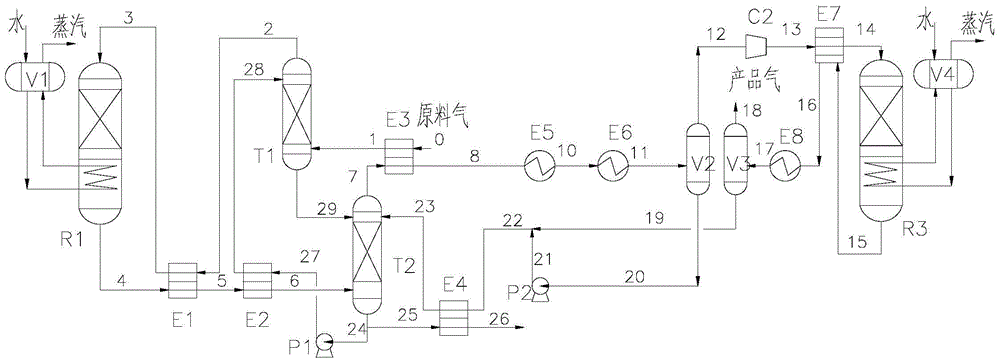

[0040] The low-pressure feed gas adiabatic cooling type methanation synthesis methane production process of LNG in this embodiment is as follows:

[0041] Process such as figure 2 shown. The raw material gas in this example is a low-pressure raw material gas, the raw material gas pressure is ~0.93MPa(G), the temperature is normal temperature, and the flow rate is ~60000 Nm 3 / h, the main composition of the gas is CO: 8.6%, CO2: 3%, H2: 60%, CH4: 24%, enters the heat exchanger E3 and exchanges heat with the gas at the outlet of the hot water tower T2, and the raw gas is heated to ~113°C , and then enter the saturation tower T1, the temperature of the raw material gas from the saturation tower T1 is ~123°C, the water content is ~22%, enter the heat exchanger E1 and exchange heat with the reaction gas coming out of the adiabatic cooling type methanation reactor R1, and the raw gas is heated to ~250°C enters the adiabatic cooling type methanation reactor R1, the temperature of ...

Embodiment 3

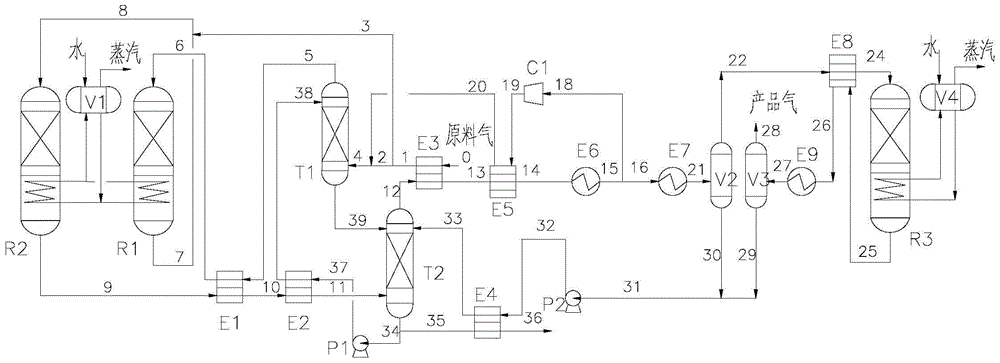

[0046] The flow process of the medium-pressure high-carbon monoxide raw material gas adiabatic cooling type methanation synthesis methane to LNG in this embodiment is as follows:

[0047] Process such as image 3 shown. In this example, the raw material gas is a medium-pressure high carbon monoxide gas, the raw material gas pressure is ~2.0MPa(G), the temperature is normal temperature, and the flow rate is ~51000 Nm 3 / h, the main composition of the gas is CO: 20%, CO2: 3%, H2: 74%, CH4: 1.4%, enters the heat exchanger E3 and exchanges heat with the gas at the outlet of the hot water tower T2, and the raw gas is heated to ~142°C , and then divided into two parts: ~45% raw material gas is mixed with the same flow rate after heating, after mixing CO: ~10%, CO2: ~2.1%, H2: ~45%, CH4: ~40%, enter saturation Tower T1, the temperature of the feed gas coming out of the saturated tower T1 is ~148°C, the water content is ~22%, and it enters the heat exchanger E1 to exchange heat with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com