Patents

Literature

51results about How to "Reduce the number of cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of fabricated lightweight inner partition board

InactiveCN106003415ASave materialReduce on-site workConstruction materialWallsSuperplasticizerSilicon

The invention relates to a production process of a fabricated lightweight inner partition board. The production process comprises the following steps: cleaning a die; coating and brushing die releasing oil; paving a bound reinforced cage and an embedded part in the die; pouring concrete, and vibrating the concrete; and performing surface finishing and die releasing maintenance after the concrete is fully vibrated; wherein the concrete comprises cement, silicon powder, ceramsite, crushed ceramics, glazed hollow bead, tackifier, a polycarboxylate superplasticizer and water. According to the production process, a lightweight material or physical bubbles are introduced into the above lightweight concrete, so that the volume weight of the lightweight board can be reduced to be 1000 to 1400kg / m<3>, and the intensity of the lightweight board is more than 8MPa; meanwhile, the concrete is outstanding in working capacity and applicable to construction; and in addition, various physical performance indexes of the concrete meet the lightweight board standard requirements.

Owner:安徽海龙建筑工业有限公司

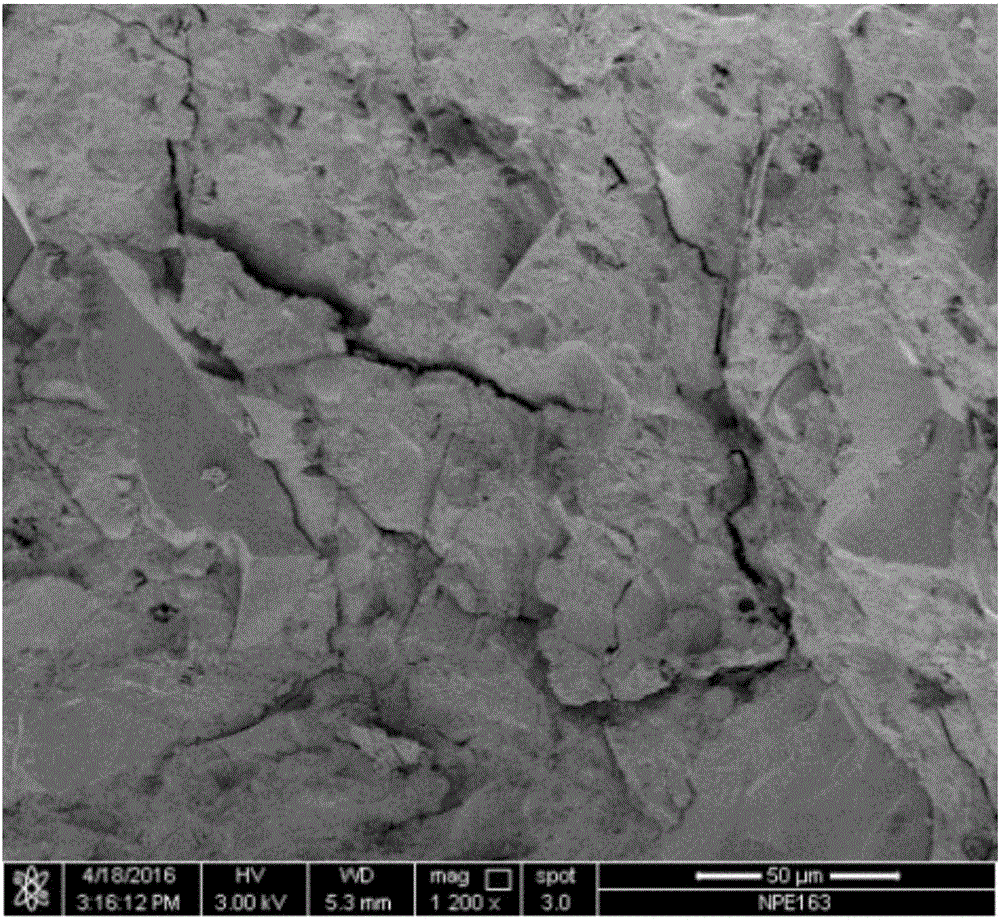

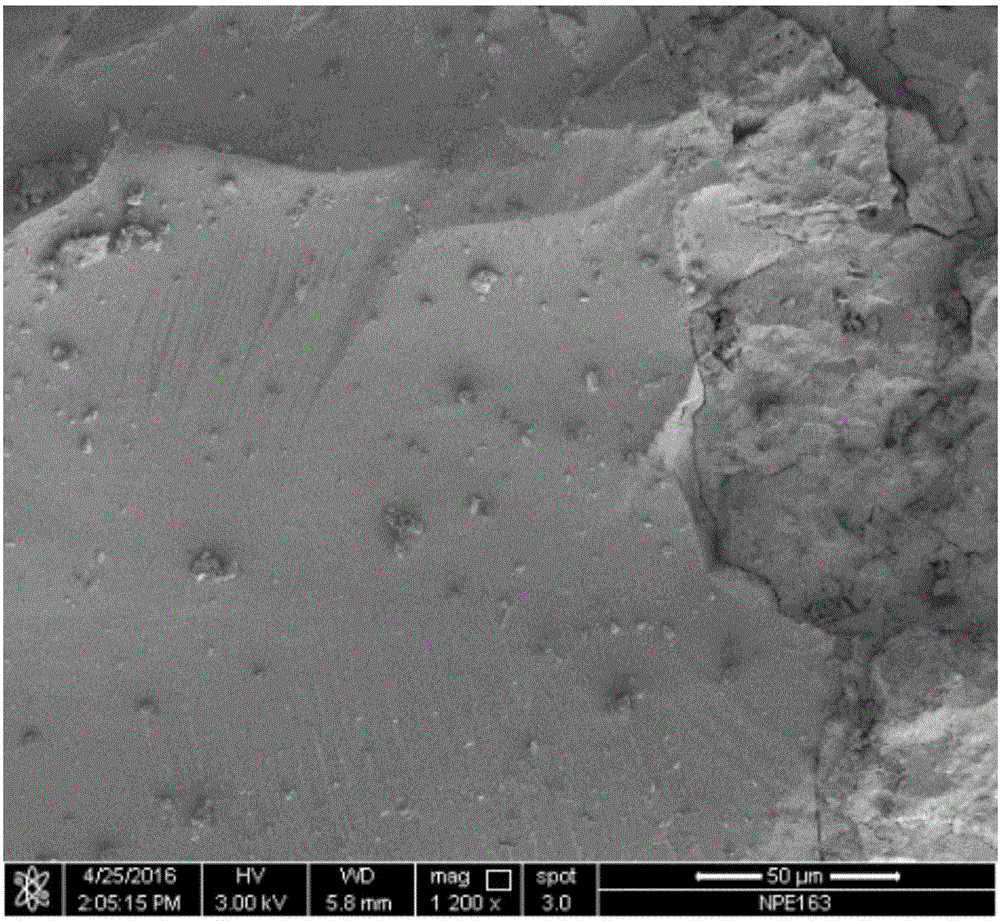

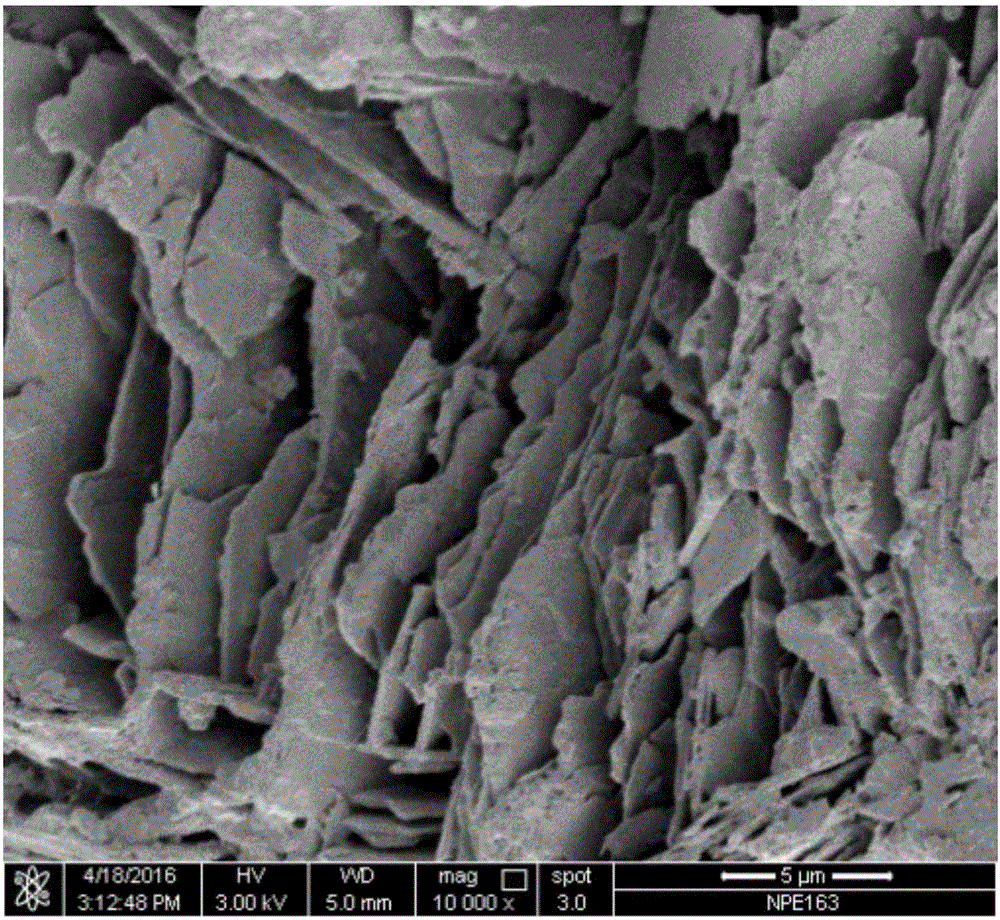

Silicon coated nano-titania-doped cement-based composite material and preparation method thereof

The invention discloses a silicon coated nano-titania-doped cement-based composite material. The silicon coated nano-titania-doped cement-based composite material contains cement, silicon coated nano-titania, silica fume, coal ash, sand, a water reducer and water. The invention further discloses a preparation method of the cement-based composite material. Experiment results show that the silicon coated nano-titania-doped cement-based composite material combines the advantages of titania and silicon dioxide and takes full advantage of the characteristics of toughening effects, filling effects, nucleation effects, volcanic ash effects and high strength and toughness of nano-titania and silicon dioxide, so that the rupture strength, compressive strength and durability of the silicon coated nano-titania-doped cement-based composite material are better that those of a silicon coated nano-titania-doped cement-based composite material. Besides, the silicon coated nano-titania-doped cement-based composite material further has electrical properties and can meet the requirements on multifunction and intelligence of structural materials in future.

Owner:DALIAN UNIV OF TECH

Exosome freeze-drying powder, preparation method of exosome freeze-drying powder and preparation comprising exosome freeze-drying powder

ActiveCN110279893ALong lastingGood filling effectPharmaceutical delivery mechanismProsthesisMedicineCentrifugation

The invention discloses exosome freeze-drying powder, a preparation method of the exosome freeze-drying powder and a preparation comprising the exosome freeze-drying powder. The preparation method of the exosome freeze-drying powder comprises the following steps of: preparing platelet factor-rich plasma: collecting autologous blood for centrifugation, preparing exosome: collecting autologous fat to prepare fat mesenchymal stem cells, and culturing the mesenchymal stem cells, preparing a freeze-drying liquid: mixing the platelet factor-rich plasma and the exosome and adding trehalose for mixing, and performing freeze-drying: performing freeze-drying on the freeze-drying solution. The preparation comprises the exosome freeze-drying powder, hyaluronic acid and saline. The preparation can effectively solve the problems that the existing cosmetic preparation has a poor filling effect, short maintenance time and high immunological rejection response.

Owner:CHENGDU QINGKE BIOTECH

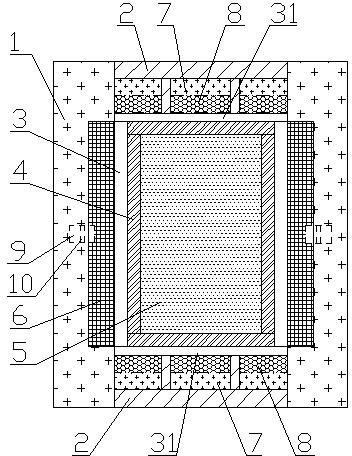

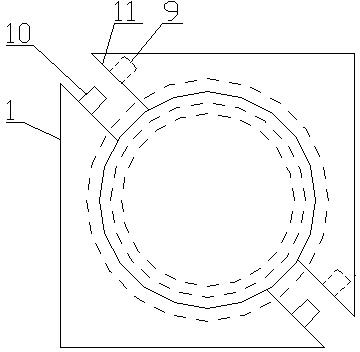

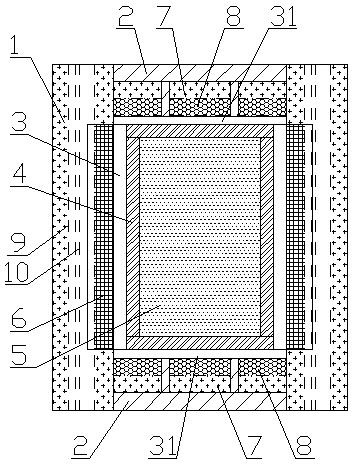

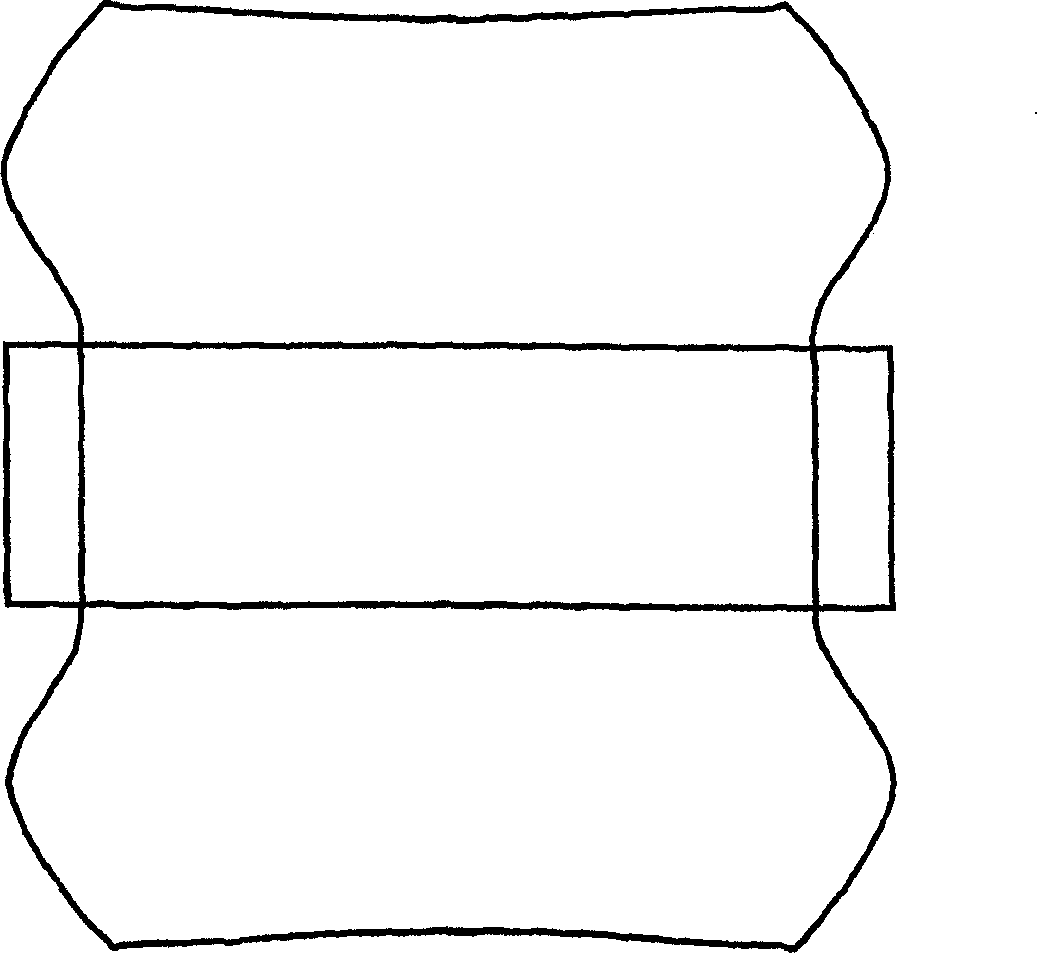

Sloping diamond synthesis block

InactiveCN102166498ACompression volume is smallReduce heat fatigueUltra-high pressure processesThermal fatiguePyrophyllite

The invention discloses a sloping diamond synthesis block, which comprises a graphite column, conductive steel rings at the two ends of the graphite column, and pyrophyllite blocks in the periphery of the graphite column and the conductive steel rings; the conductive steel rings are filled with pyrophyllite rings and dolomite rings; the periphery of the graphite column is provided with a heating element; an insulating element is arranged between the heating element and the graphite column; the pyrophyllite block consists of two half blocks buckled with each other; and a graphite column cavity is formed in the middle of the two buckled half blocks, and each half block is in a triangular prism shape. The sloping pyrophyllite blocks are formed, and a joint seam of the sloping pyrophyllite blocks is at the corner of the pyrophyllite blocks, and is staggered from the middle part of a non-heating top hammer; hot gas cannot rush to the non-heating top hammer, so that thermal fatigue of the non-heating top hammer can be obviously mitigated, and the top hammer is effectively protected; and the number of the broken non-heating top hammers is greatly reduced, the broken hammer accidents are reduced, the consumption of the hard alloy top hammer is greatly reduced, and the production cost is lowered.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

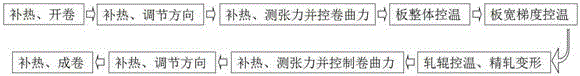

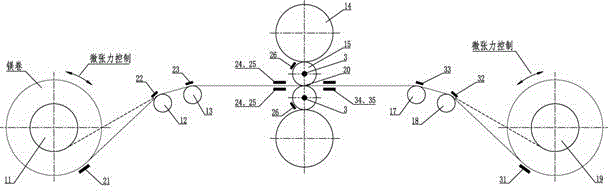

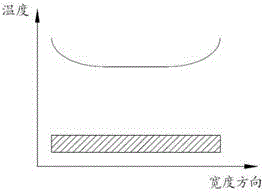

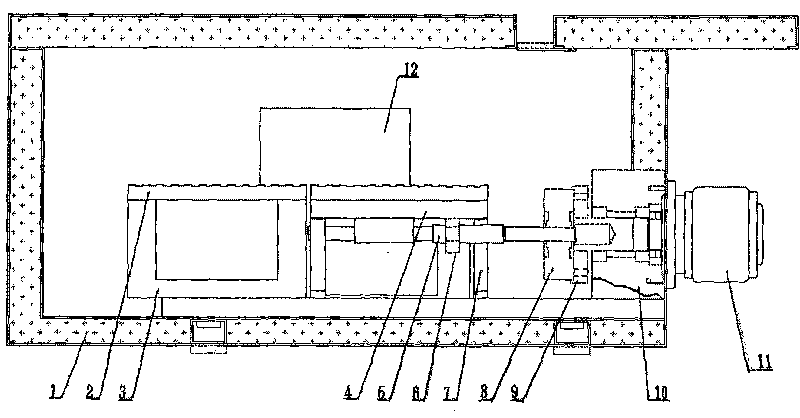

Temperature-controlled rolling technology of magnesium alloy coiled sheet

ActiveCN105834227AAvoid bumpingAvoid featuresTemperature control deviceMetal rolling arrangementsTemperature controlRolling mill

The invention discloses a temperature-controlled rolling technology of magnesium alloy coiled sheets. The steps comprise: (1) performing heating compensation on a magnesium coiled sheet and uncoiling the magnesium coiled sheet; (2) performing sheet heating compensation and adjusting turning directions of the magnesium alloy sheets; (3) measuring tension of the sheet and controlling a crimp force value; (4) performing integrated temperature control on a part which is to bite into the sheet; (5) performing gradient temperature control on the width direction of the part which is to bite into the sheet; (6) through a temperature-controlled roll, performing finishing rolling on the sheet and the sheet deforming; (7) measuring tension of the sheet and controlling a crimp force; (8) performing sheet heating compensation and adjusting turning directions of the magnesium alloy sheets; (9) performing sheet heating compensation and coiling the sheet in rolls; (10) if the thickness of the magnesium plate coil sheet does not reach the thickness (t0) of a target magnesium plate, reversely repeating the steps (1)-(9) on magnesium coiled sheets on a reversible temperature-controlled rolling mill according to the process steps, performing next temperature-controlled finish rolling processing; (11) if the thickness of the magnesium sheet reaches the thickness (t0) of the target magnesium plate, obtaining the magnesium alloy coiled sheet satisfying the thickness requirements.

Owner:BAOSHAN IRON & STEEL CO LTD

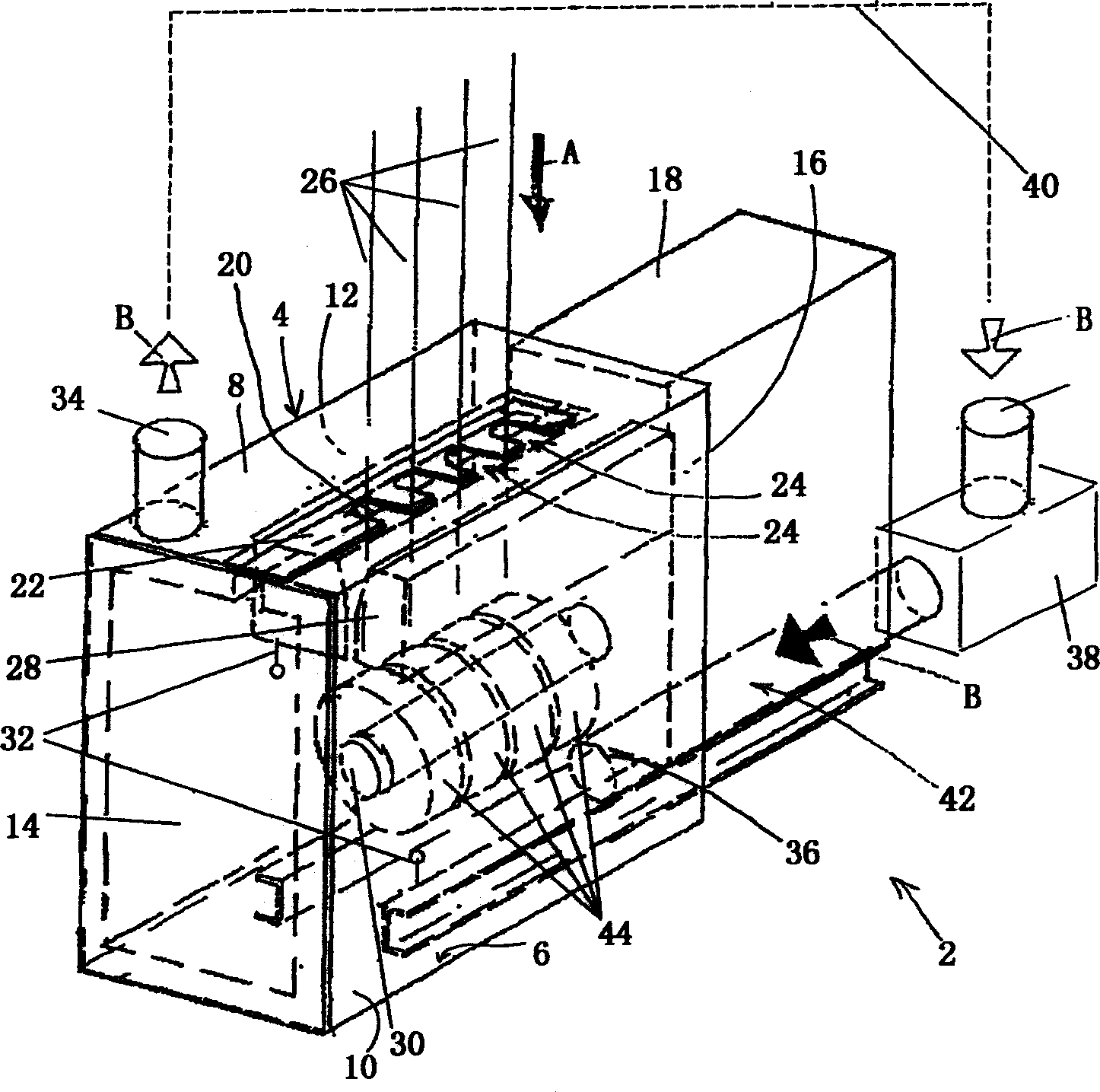

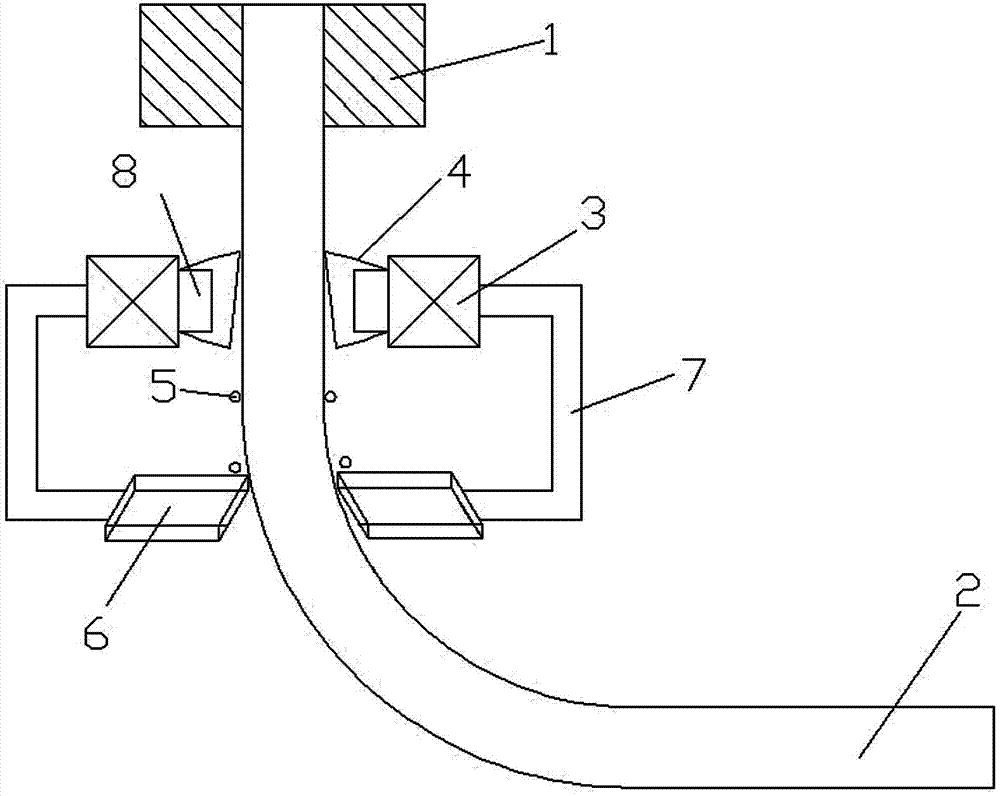

A process for the production and for the winding of polyester multi-filament yarns as well as the polyester multi-filament yarns obtainable by said method and a device for the winding of one or more m

InactiveCN1630741ALong-term stabilityNo unwinding problemNew-spun product collectionFilament handlingPolyethylene terephthalate glycolBobbin

The invention relates to a method for producing and winding at least one polybutylene terephthalate (PBT) and / or polyterephthalic acid in an amount of at least 90% by weight relative to the total weight of polyester multifilament yarns Process for polyester multifilament yarns of propylene glycol ester (PTMT), preferably PTMT, in order to provide at least one yarn package with long-term stability during storage and insensitivity to high temperatures during storage and transport, wherein the The wound package of at least one polyester multifilament yarn is heat treated at a temperature in the range >45°C to 65°C. Furthermore, the invention relates to said polyester multifilament yarn obtainable by said process, wherein its elongation at break is in the range >60 to 145% and its boiling shrinkage is in the range 0 to 10% . Finally, the invention also claims a device (2) for winding one and several multifilament yarns (26), comprising a housing (4) and a rotatable mandrel, in which A bobbin (30) can be fixed on the shaft so that the bobbin (30) is located in the housing (4), wherein the interior of the housing (4) is heatable.

Owner:ZIMMER GMBH

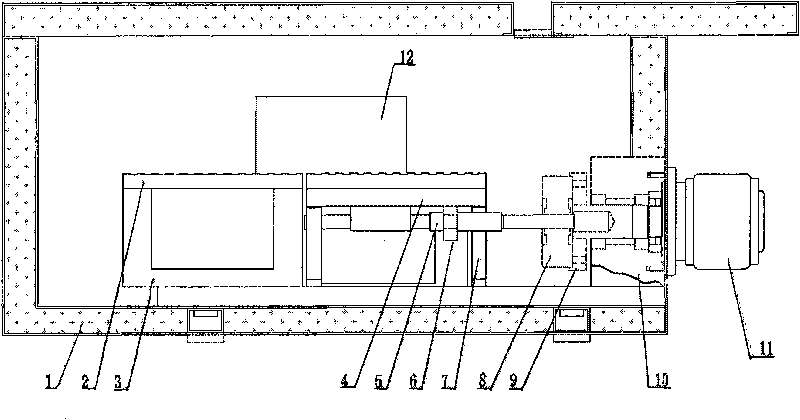

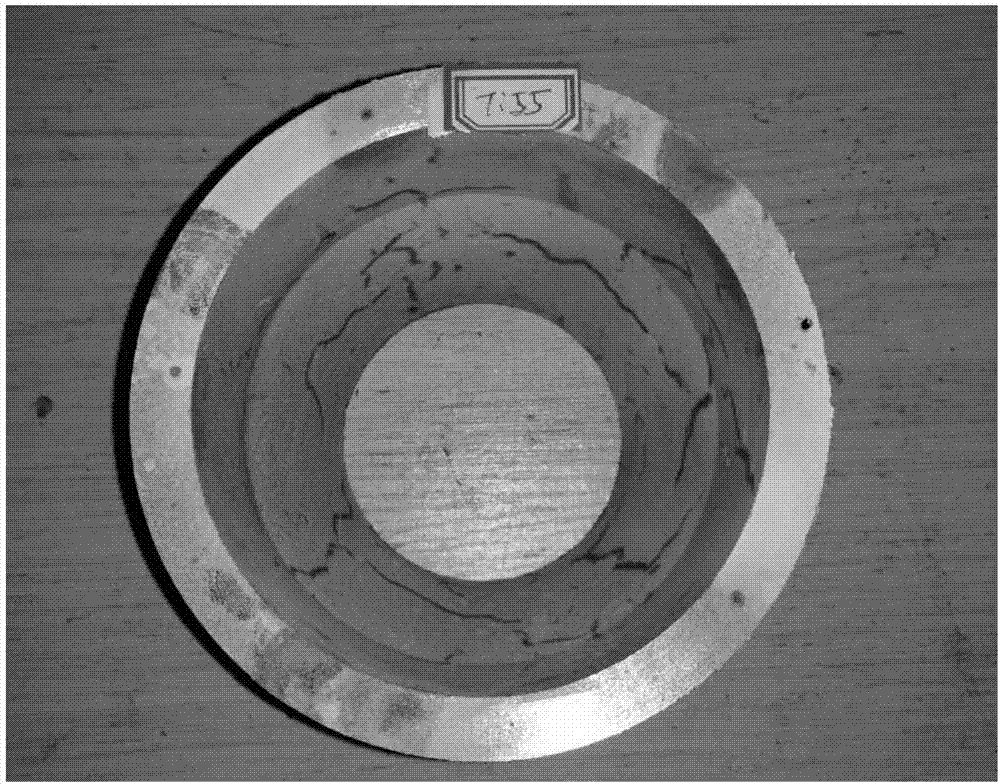

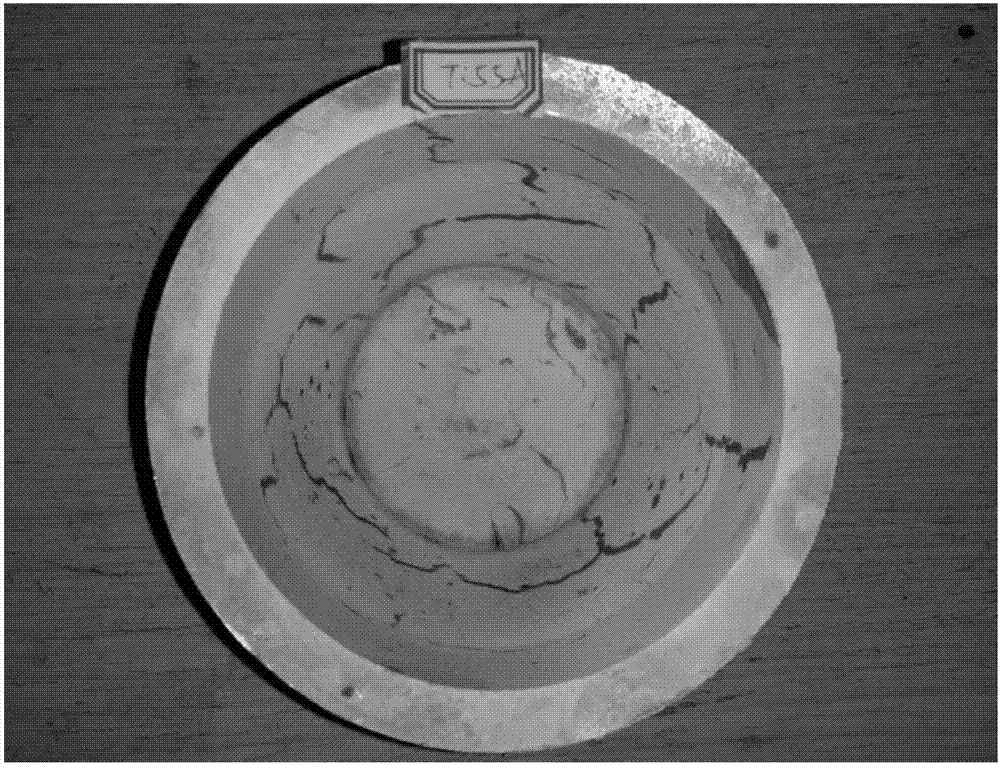

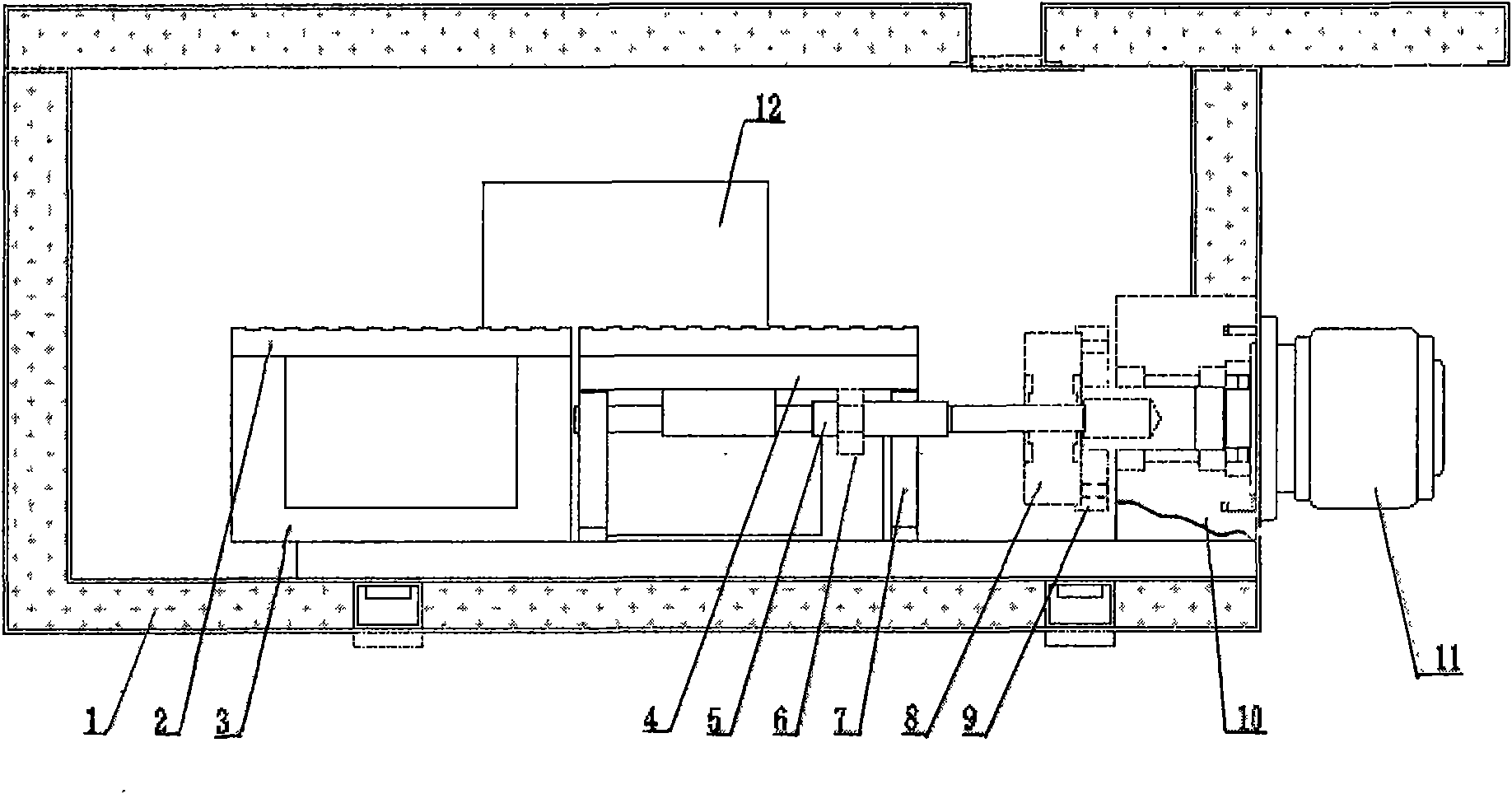

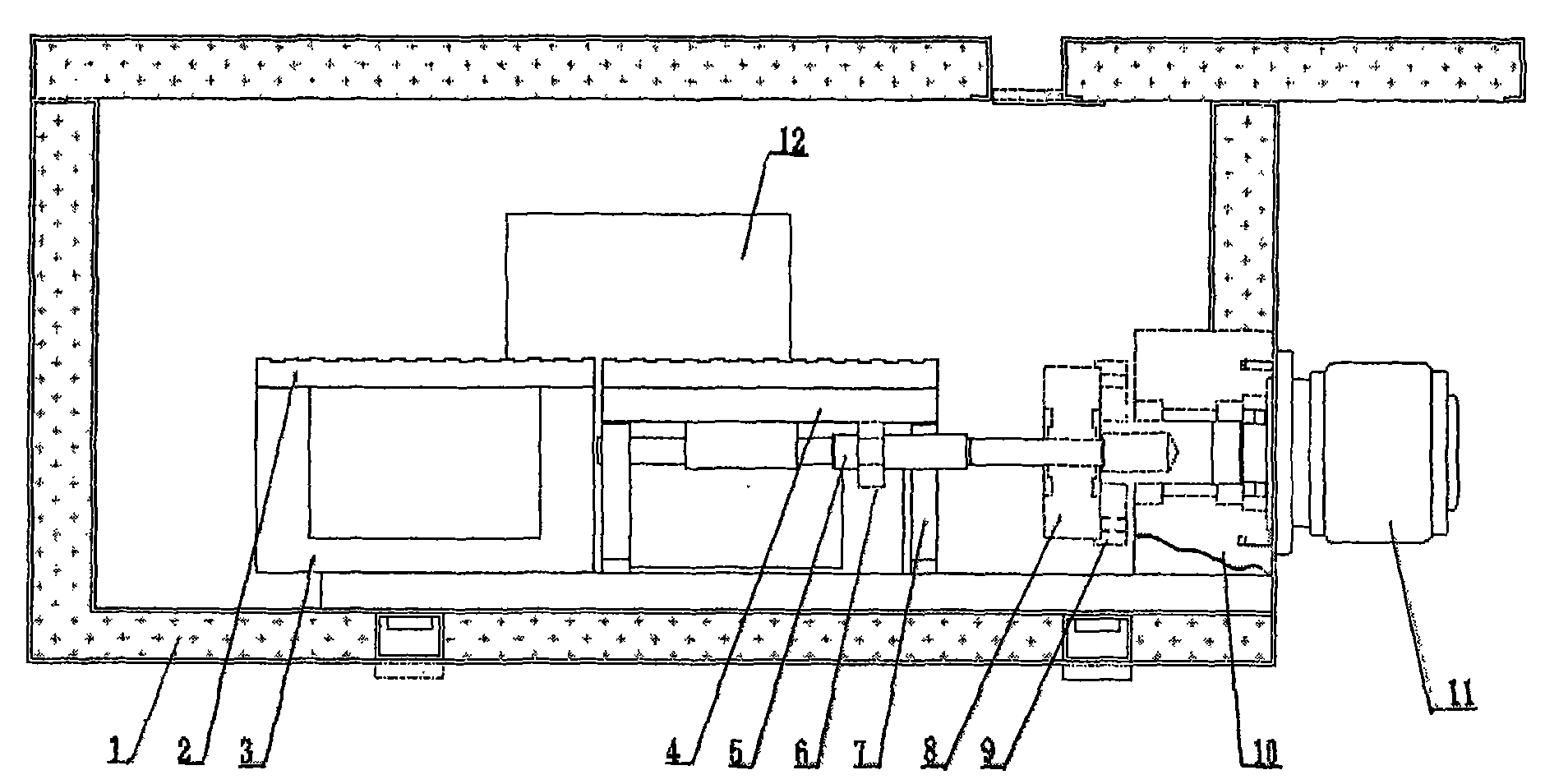

Pitch mixed material cracking resistance tester

ActiveCN101710043AStructural solutionSolve operational problemsStrength propertiesCrack resistanceMaterial Crack

The invention relates to a pitch mixed material cracking resistance tester which is used for solving the problem of test detection of pitch mixed materials and comprises an environmental box, a fixed support seat, a sticking platform plate, a slide plate, a slide plate displacement loading mechanism, a spoke type sensor, a rotating coupling and a servo motor, wherein the fixed support seat is installed in the environmental box; the sticking platform plate is installed on the fixed support seat and touches and is connected with the slide plate in a movable fit way; the bottom of the slide plate is connected with the slide plate displacement loading mechanism; the slide plate displacement loading mechanism is connected with the servo motor by the rotating coupling, and the spoke type sensor is connected to a coupling disk of the rotating coupling; a side support seat of which the bearing is embedded into the environmental box is installed on the rotating coupling; and the servo motor is connected outside the side body of the environmental box. The invention has simple structure and simple and convenient use and is suitable for carrying out a cracking resistance test on various pitch mixed materials.

Owner:沧州市市政工程股份有限公司

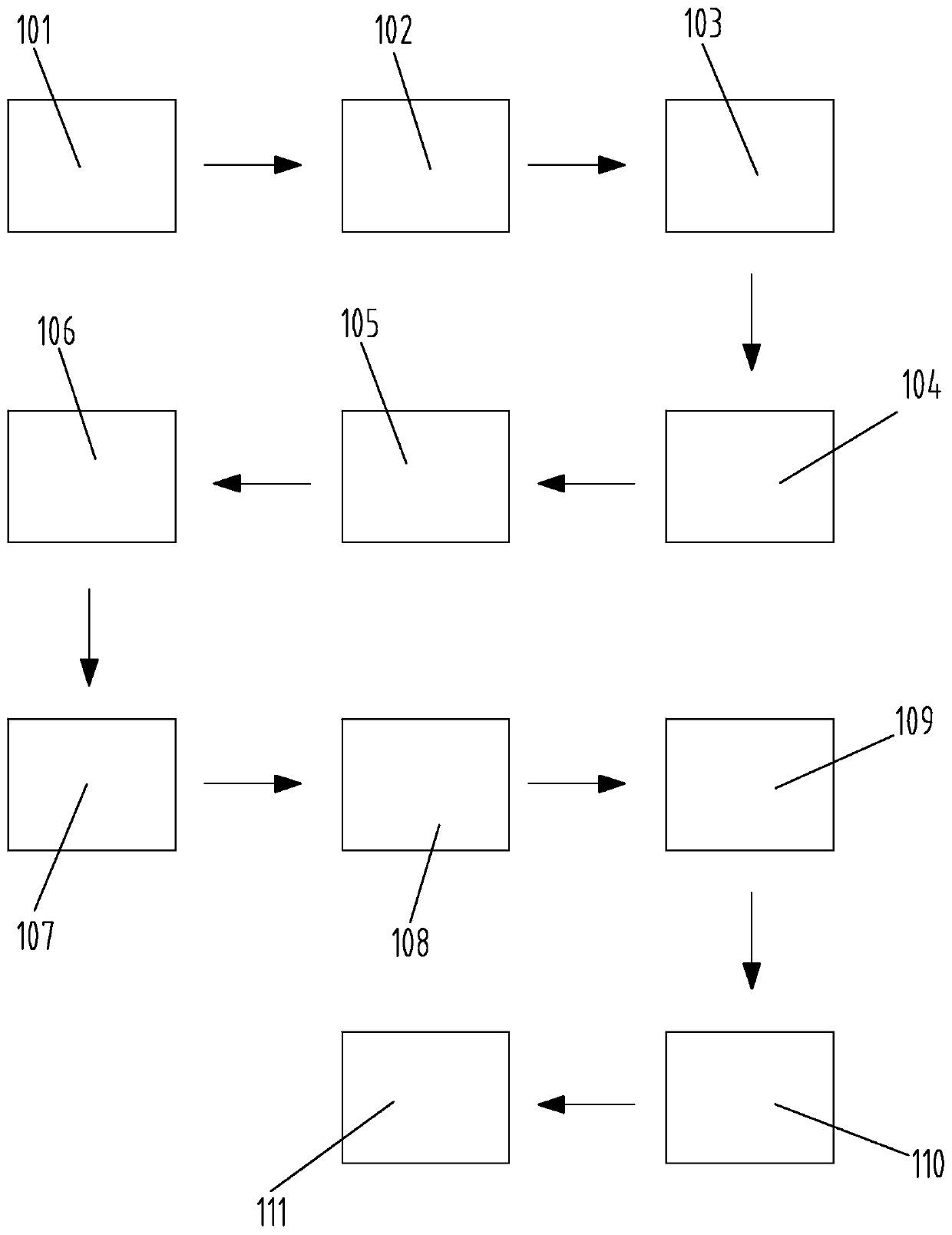

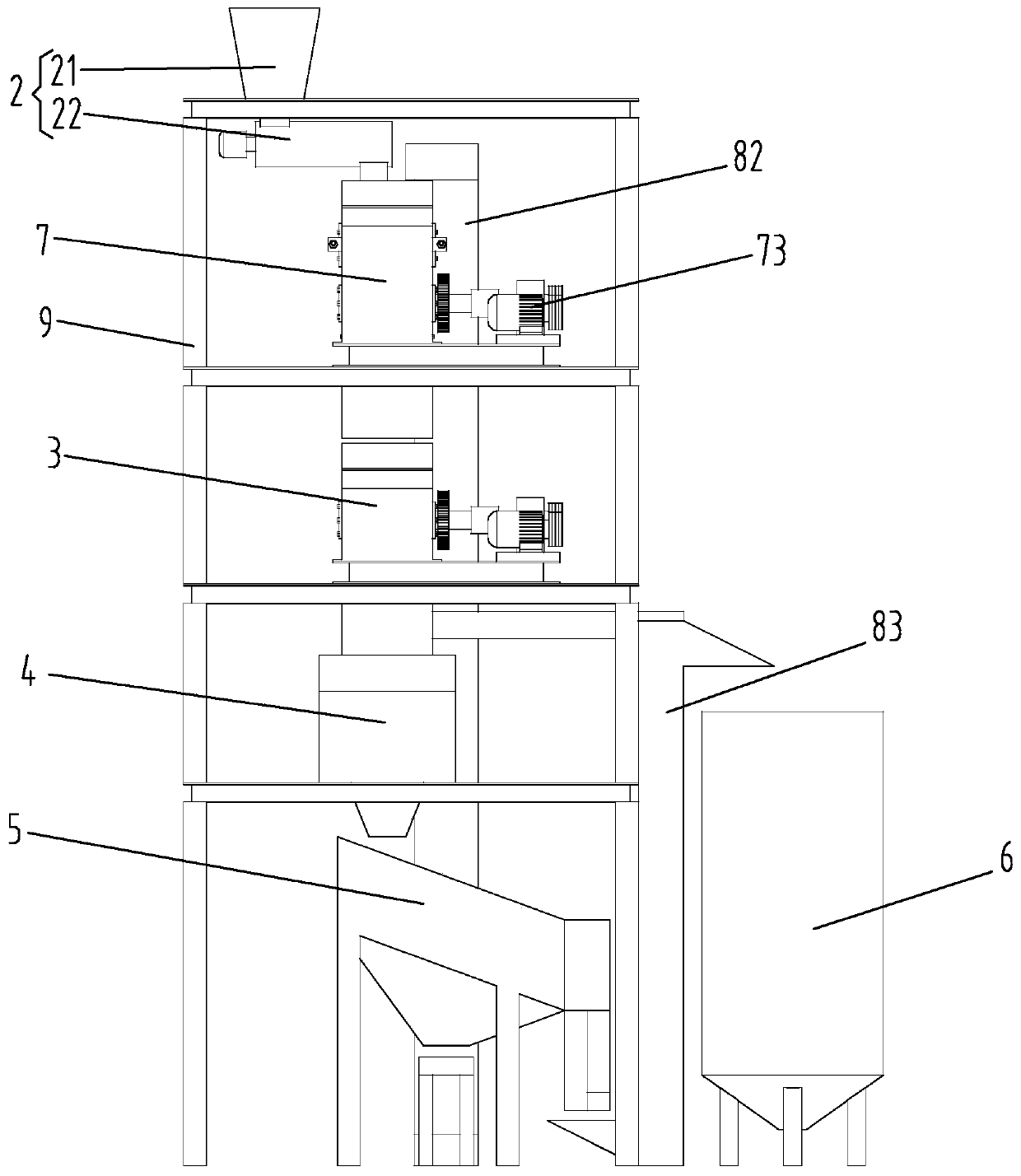

Production method and production line of whole-body large-particle stone-like ceramic thick plate

InactiveCN110885229AHigh degree of bindingGood corrosion resistanceCeramic shaping plantsAuxillary shaping apparatusPelletizingCorrosion resistant

The invention relates to the technical field of ceramic thick plates, and concretely relates to a production method and a production line of a whole-body large-particle stone-like ceramic thick plate.The production method of the whole-body large-particle stone-like ceramic thick plate comprises the processes of burdening, ball milling, granulating, forming, glazing, firing and the like. Blank rawmaterials of the large-particle stone-like ceramic thick plate and large-particle powder which is granulated and formed after extrusion have a high combination degree, and are not prone to cracking in the compression molding process and the sintering process, so the blank raw materials and the powder are suitable for manufacturing the large-thickness cylinder ceramic thick plate. Results of detection show that the thick plate has better hardness, antifouling property and corrosion resistance than natural stones; and the production line of the whole-body large-particle stone-like ceramic thickplate, provided by the inventor, has the advantages of high overall production efficiency, and effective reduction of the number of particle cracks, so the production quality and the customer experience effect are guaranteed.

Owner:福建省南安宝达建材有限公司

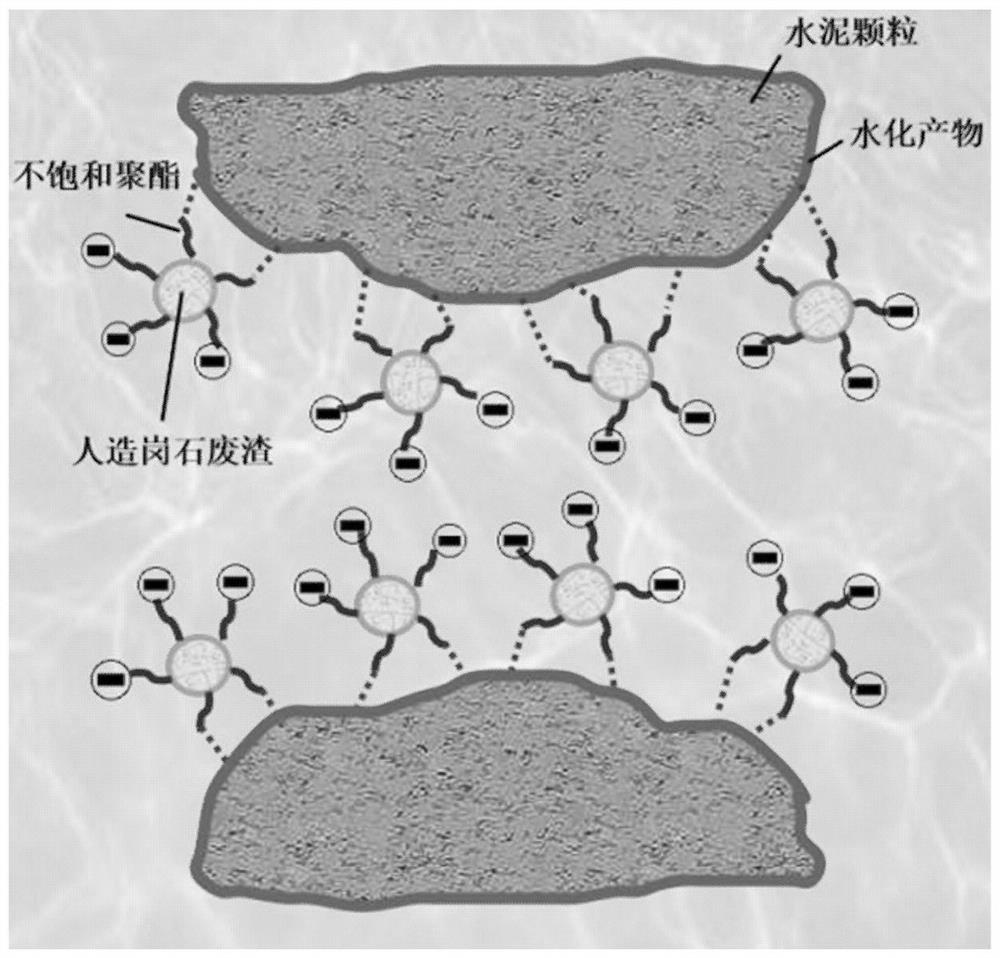

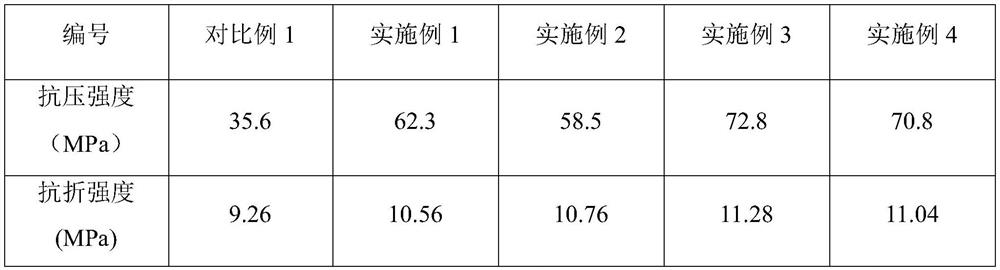

Artificial agglomerated stone waste residue-based cement mortar reinforcing agent and preparation method thereof

InactiveCN112430001ASolve pollutionRealize high-value utilizationSolid waste managementCompressive resistanceEconomic benefits

The invention discloses an artificial agglomerated stone waste residue-based cement mortar reinforcing agent and a preparation method thereof. The reinforcing agent comprises the following components:artificial agglomerated stone waste residues, a polymer emulsion and a water reducing agent. The preparation method comprises the following steps: drying and crushing the artificial agglomerated stone waste residue, modifying the artificial agglomerated stone waste residue powder by using the polymer emulsion, and finally mixing the artificial agglomerated stone waste residue powder or the polymer emulsion modified waste residue powder with the water reducing agent to obtain the artificial agglomerated stone waste residue-based cement mortar reinforcing agent. The cement mortar reinforcing agent provided by the invention can establish strong interface interaction with cement particles and hydrated products thereof, effectively reduce the porosity and the number of cracks in an interface transition region, greatly improve the compressive strength and the bending strength of cement mortar, reduce the dosage of a water reducing agent under the condition of ensuring the strength, and is high in economic benefit. The preparation method is simple and has an extremely wide market application prospect.

Owner:SICHUAN UNIV

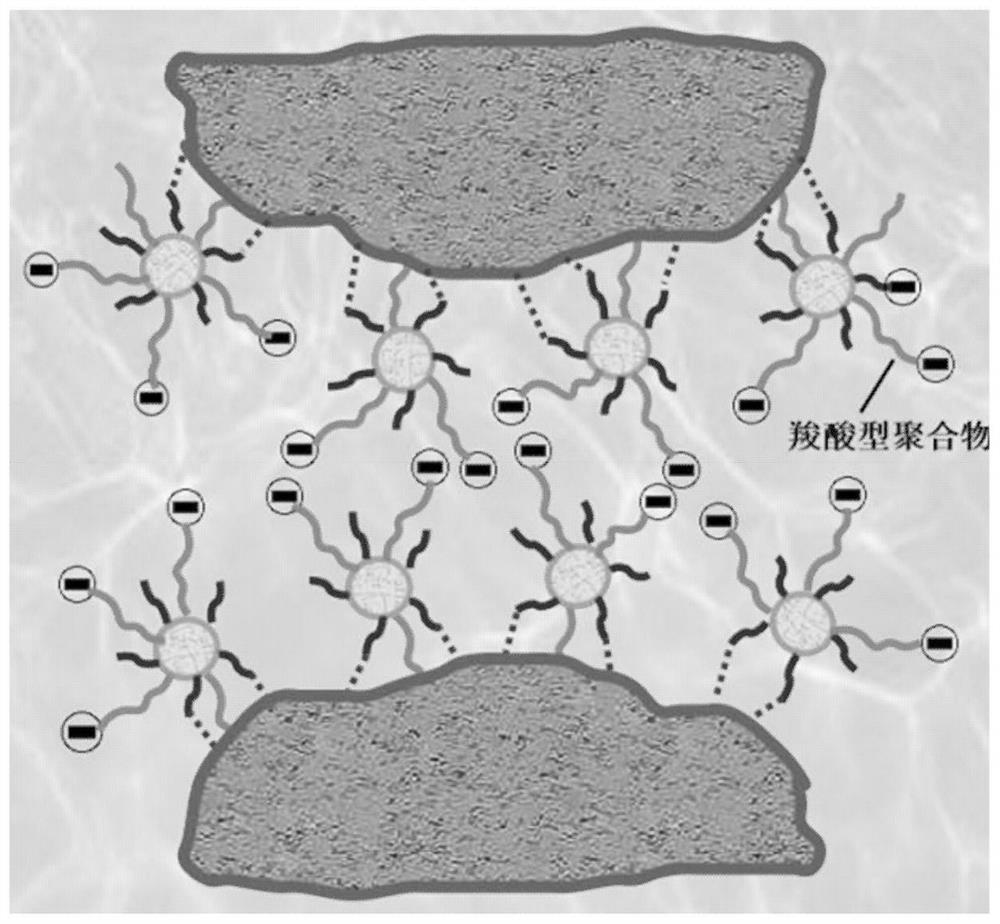

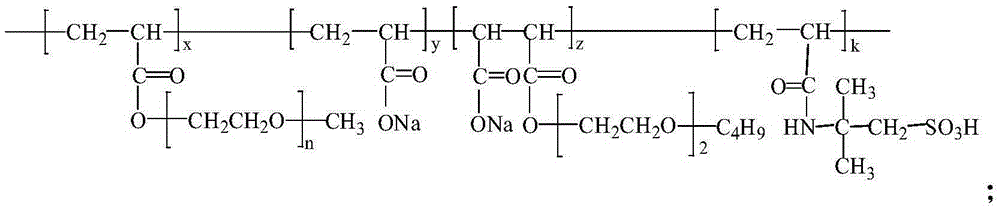

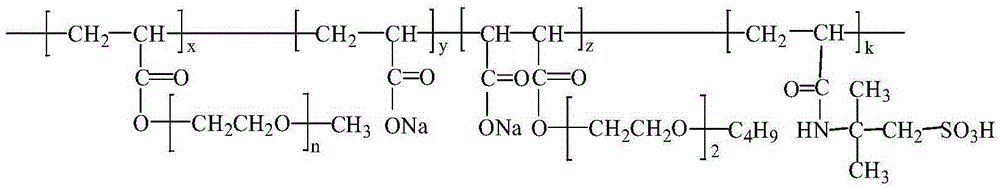

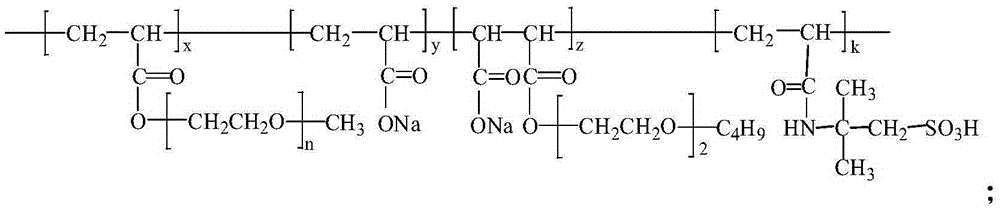

Multi-functional high-performance reduction material of polycarboxylic acid series and preparation method thereof

InactiveCN105330792AThe synthesis process is simpleEasy constructionDiethylene glycol monobutyl etherFirst-order reaction

The invention provides a multi-functional high-performance reduction material of polycarboxylic acid series and a preparation method thereof. The preparation method comprises the steps of raising the temperature of a 2-acrylamido-2-methyl propane sulfonic acid solution to 55-85 DEG C under a nitrogen protection environment, conducting sufficient stirring, dissolving the solution uniformly, dropwise adding a mixed solution of polyethylene glycol monomethyl ether methyl acrylate, acrylic acid, diethylene glycol monobutyl ether maleic anhydride monoester and an initiator solution to the 2-acrylamido-2-methyl propane sulfonic acid solution within 2-4 hours, and obtaining a first-order reaction solution after dropwise adding is completed; leaving the first-order reaction solution being subjected to treatment at the constant temperature of 55-85 DEG C for 1-2 hours, then adding a catalyst, conducting a reaction for 1-2 hours at the temperature of 55-100 DEG C, conducting vacuum filtration for two hours, after the reaction is ended, cooling the mixture to the room temperature, then using an alkali solution for adjusting the pH value to be 7, discharging the material, and obtaining the multi-functional high-performance reduction material of the polycarboxylic acid series. According to the multi-functional high-performance reduction material of the polycarboxylic acid series and the preparation method thereof, the main synthesis raw materials are abundant in source, the synthesis process is simple, and good construction performance, mechanical properties and volume stability are achieved.

Owner:LIMING VOCATIONAL UNIV

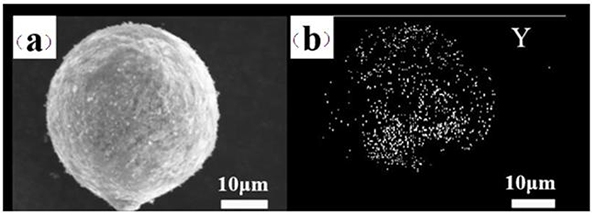

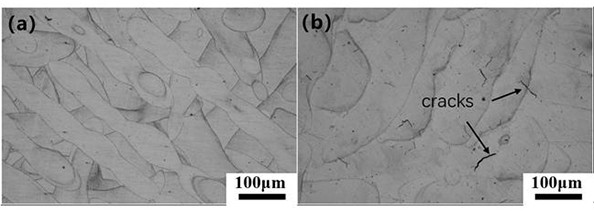

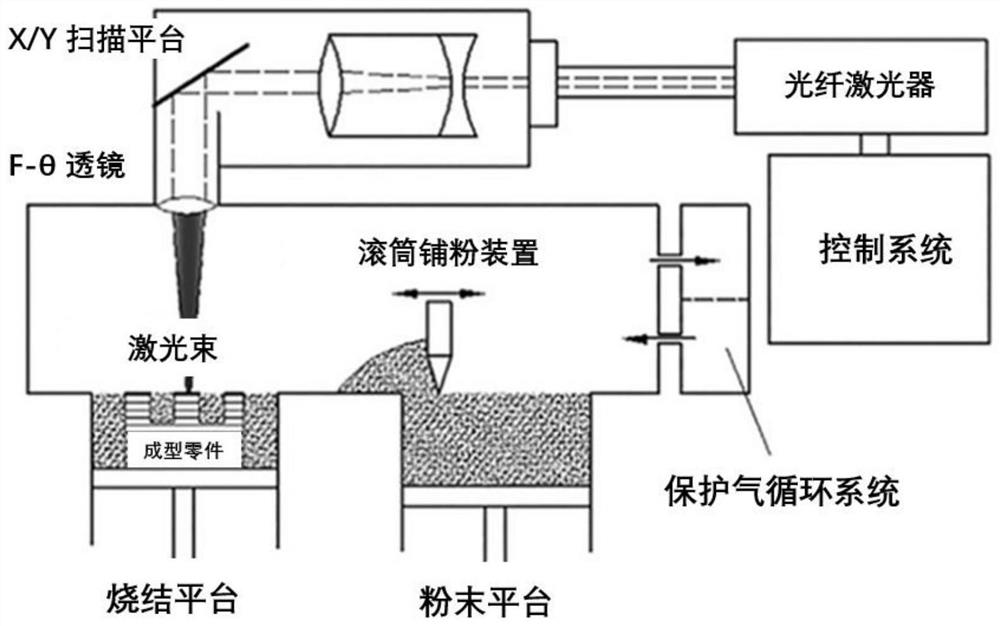

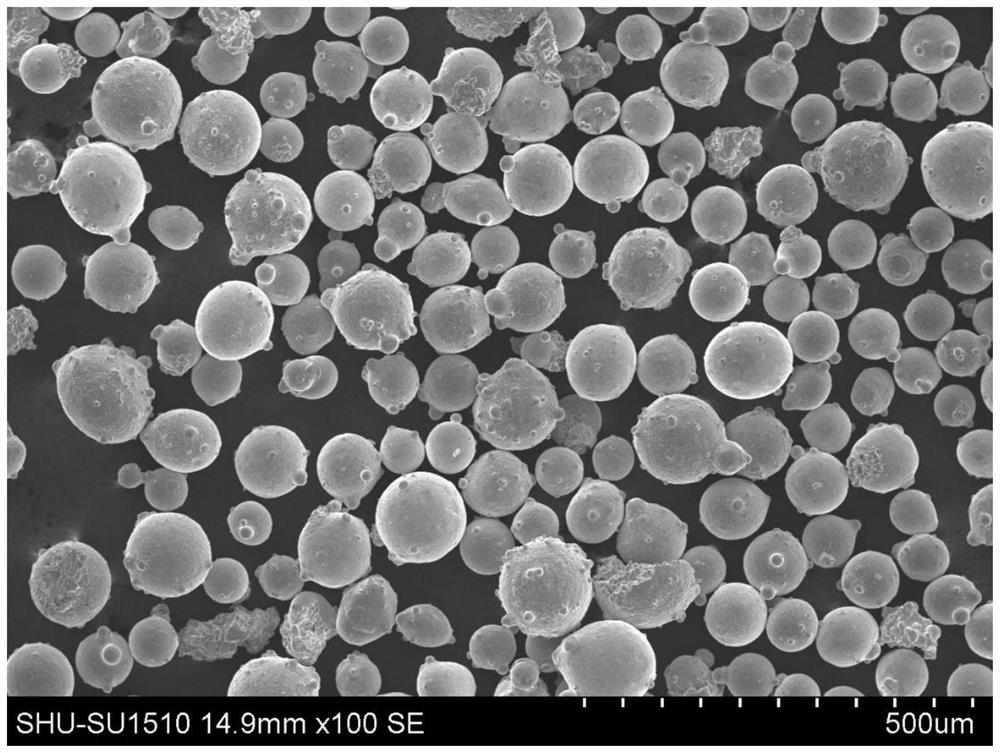

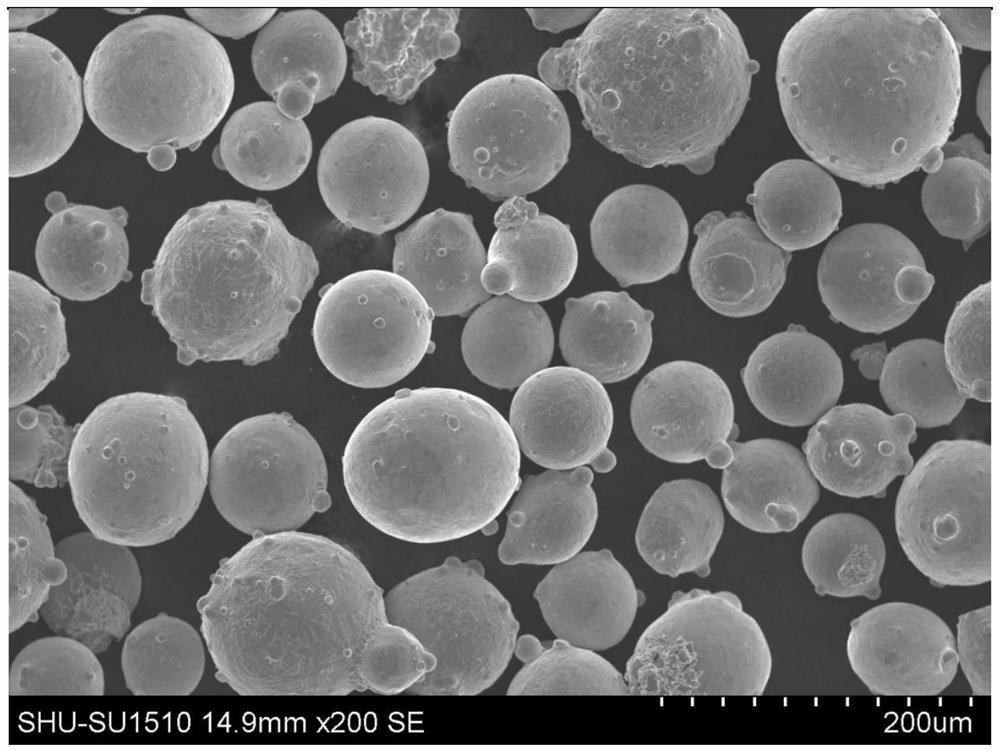

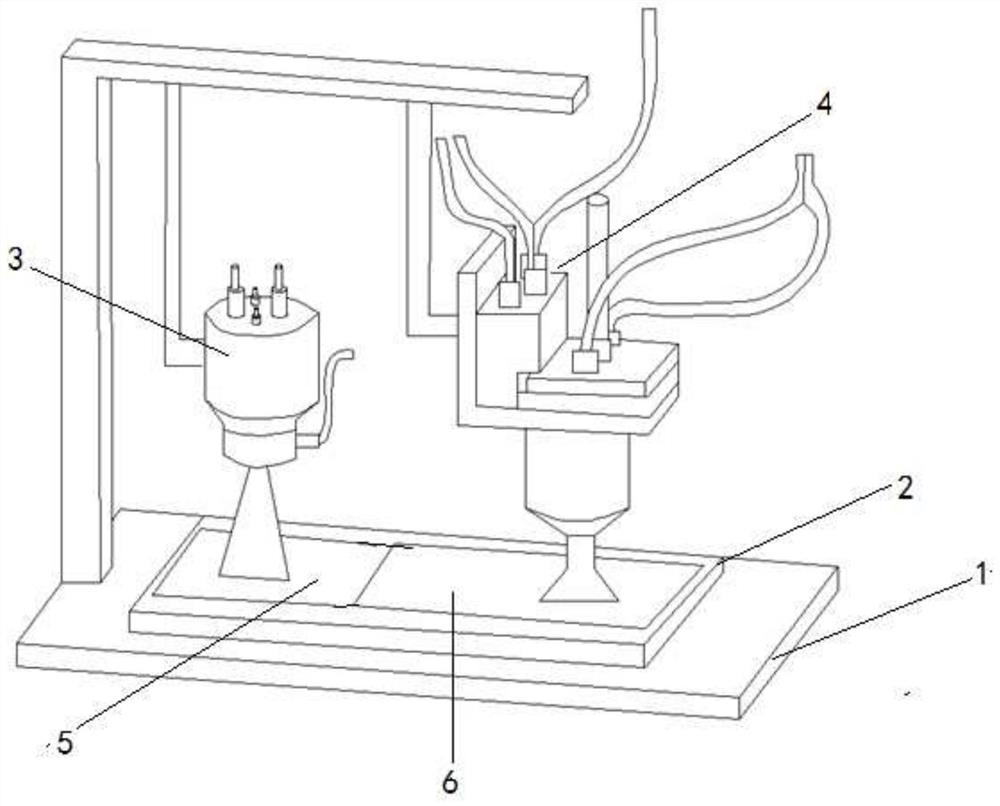

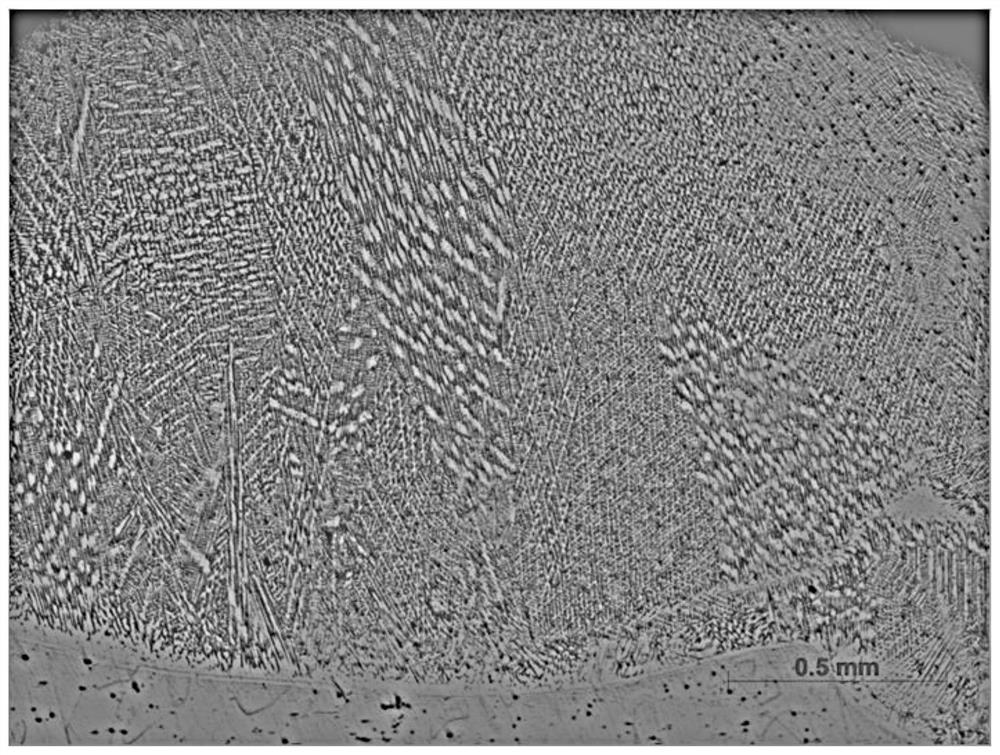

Method for reducing cracks of nickel-based superalloy formed by SLM (selective laser melting) and improving mechanical property

ActiveCN113042753AInhibition of large size cracksImprove mechanical propertiesAdditive manufacturing apparatusTransportation and packagingSelective laser meltingTube furnace

The invention provides a method for reducing cracks of nickel-based superalloy formed by SLM (selective laser melting) and improving mechanical property. The method comprises the following steps: pouring yttrium nitrate powder into absolute ethyl alcohol, and carrying out ultrasonic vibration stirring until the yttrium nitrate powder is completely dissolved; pouring GH3536 nickel-based high-temperature powder into a yttrium nitrate absolute ethyl alcohol solution, and carrying out ultrasonic vibration stirring, enabling metal powder and the solution to be fully contacted and wetted; drying the obtained solid-liquid mixture, then putting the solid-liquid mixture into a tubular furnace for calcining, and then cooling along with the furnace; grinding and screening the obtained calcined powder to obtain GH3536 powder uniformly coated with yttrium oxide; and preparing a GH3536 nickel-based high-temperature alloy block sample from the yttrium oxide uniformly coated GH3536 nickel-based high-temperature powder through a selective laser melting method. According to the method, the number of cracks in the SLM printed GH3536 nickel-based high-temperature alloy is effectively reduced, the microstructure state is improved, and the mechanical property of the GH3536 nickel-based high-temperature alloy is greatly improved.

Owner:TIANJIN UNIV

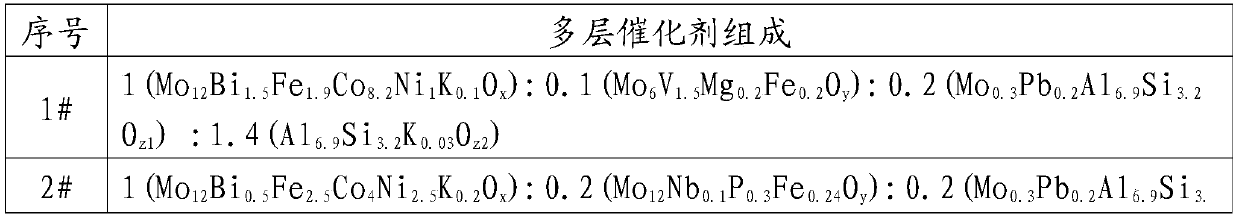

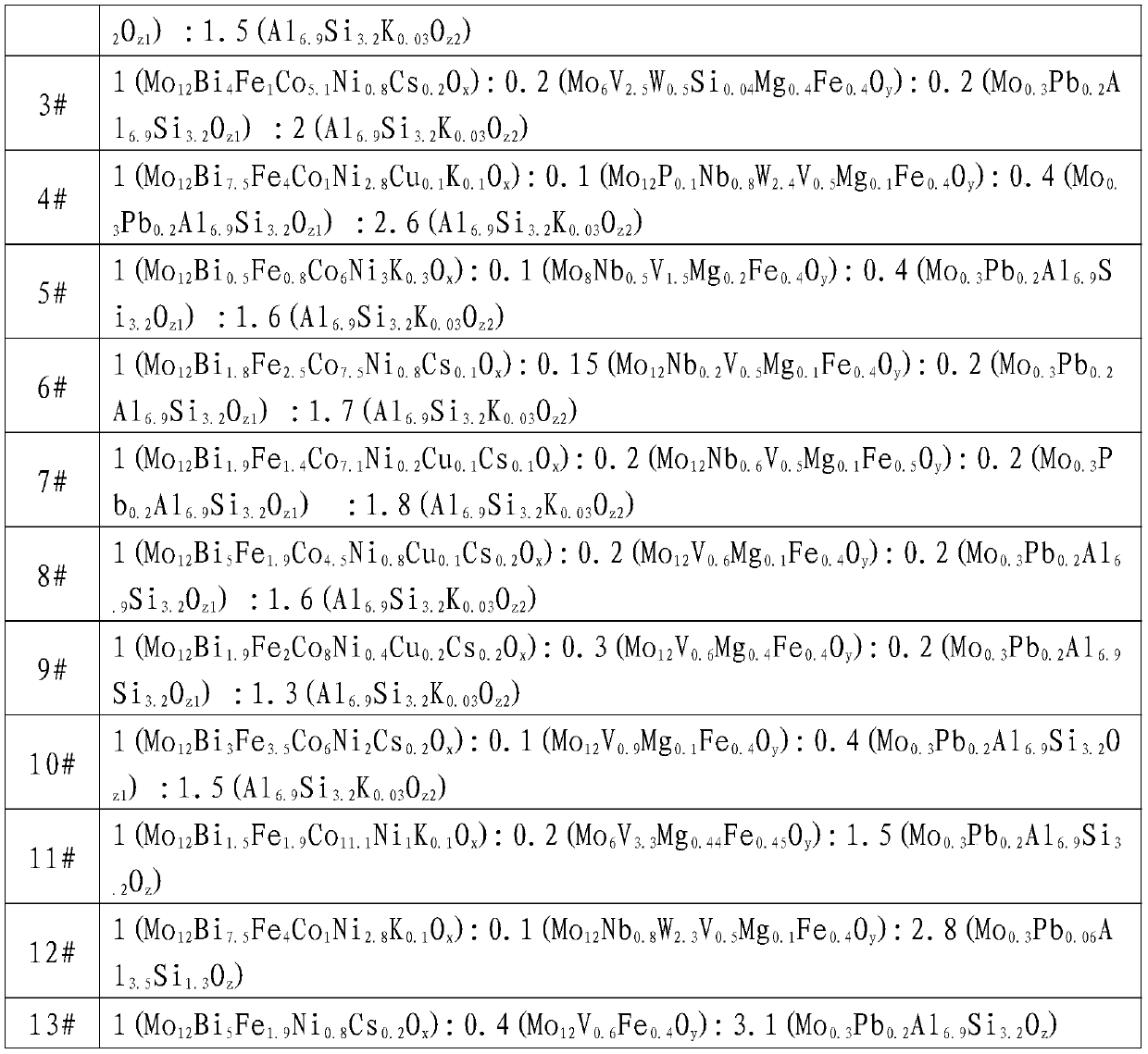

Catalyst, preparation method thereof and application in preparation of unsaturated aldehyde (acid)

PendingCN109999823AImprove heat resistanceExtend stability and service lifeOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationAldehydeHigh activity

The invention provides a catalyst, a preparation method thereof and an application in preparation of unsaturated aldehyde (acid). The catalyst has the characteristics of high activity, good heat resistance, long service life and the like. Meanwhile, the product selectivity and yield are higher when the catalyst is used for catalyzing unsaturated olefin for preparation of unsaturated aldehyde (acid). The catalyst comprises a core catalyst, an inner catalyst, a middle catalyst and an outer catalyst sequentially from inside to outside; all the catalysts have similar thermal expansion coefficientsin the range of (6.5-7.5)*10<-6> m / m.K; the composition and mass ratio of all the catalysts of the coated catalyst are shown in the following general formula: (Moa0BibFecCodNieAfOx):m(Moa1NbgVhWiBjOy):n1(Moa2PbkAll1Sip1Cq1Oz1):n2(All2Sip2Dq2Oz2).

Owner:WANHUA CHEM GRP CO LTD

Continuous casting billet strengthening device and strengthening method in continuous casting process

The invention discloses a continuous casting billet strengthening device and a continuous casting billet strengthening method in a continuous casting process. The strengthening device is arranged at a secondary cold area below a crystallizer and is arranged near a continuous casting billet; and the strengthening device comprises a shot blaster, steel shots, a steel shot collecting box, a shot carrying pipeline and a shot spraying pipeline, wherein the shot blaster is connected with the steel shot collecting box by virtue of a shot carrying channel, the steel shot collecting box is arranged below the shot blaster, and the shot spraying channel is arranged at an exit of the shot blaster.

Owner:LAIWU IRON & STEEL GRP

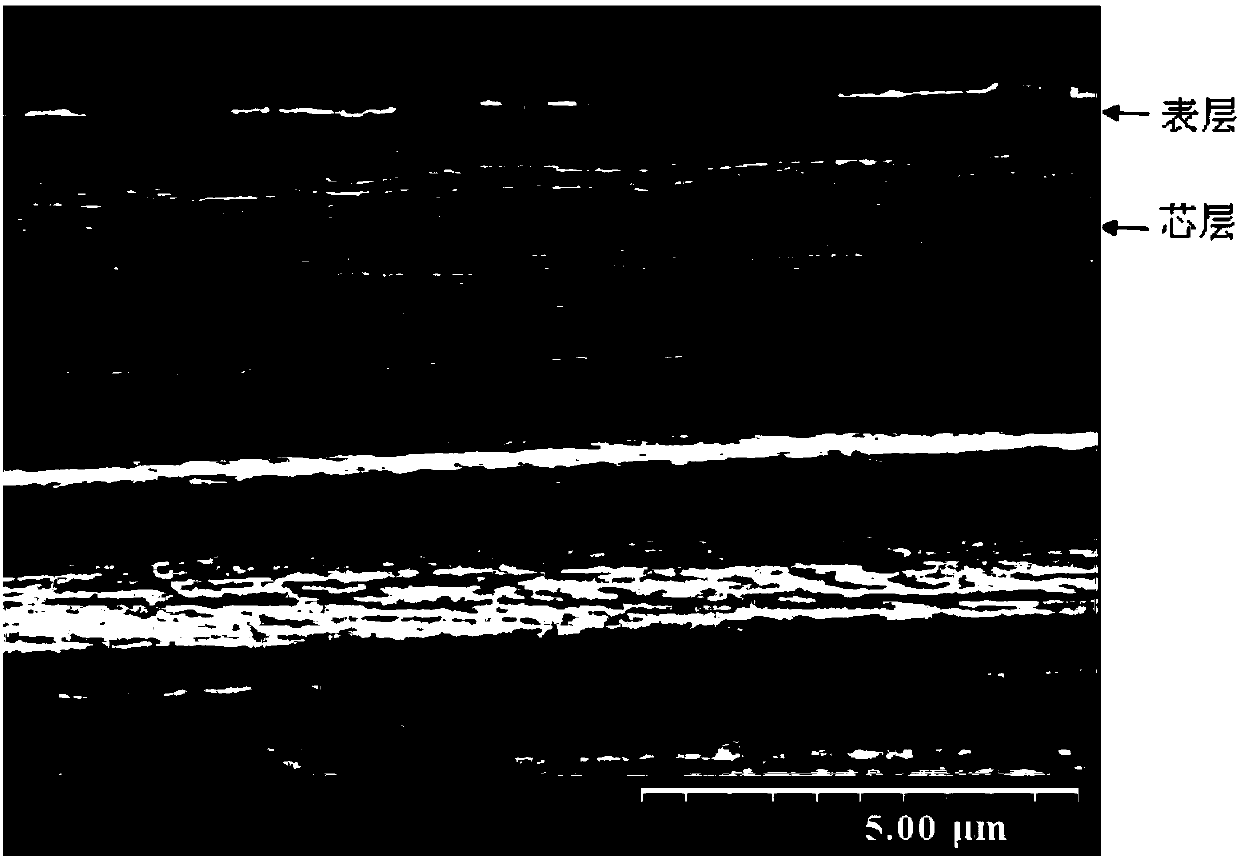

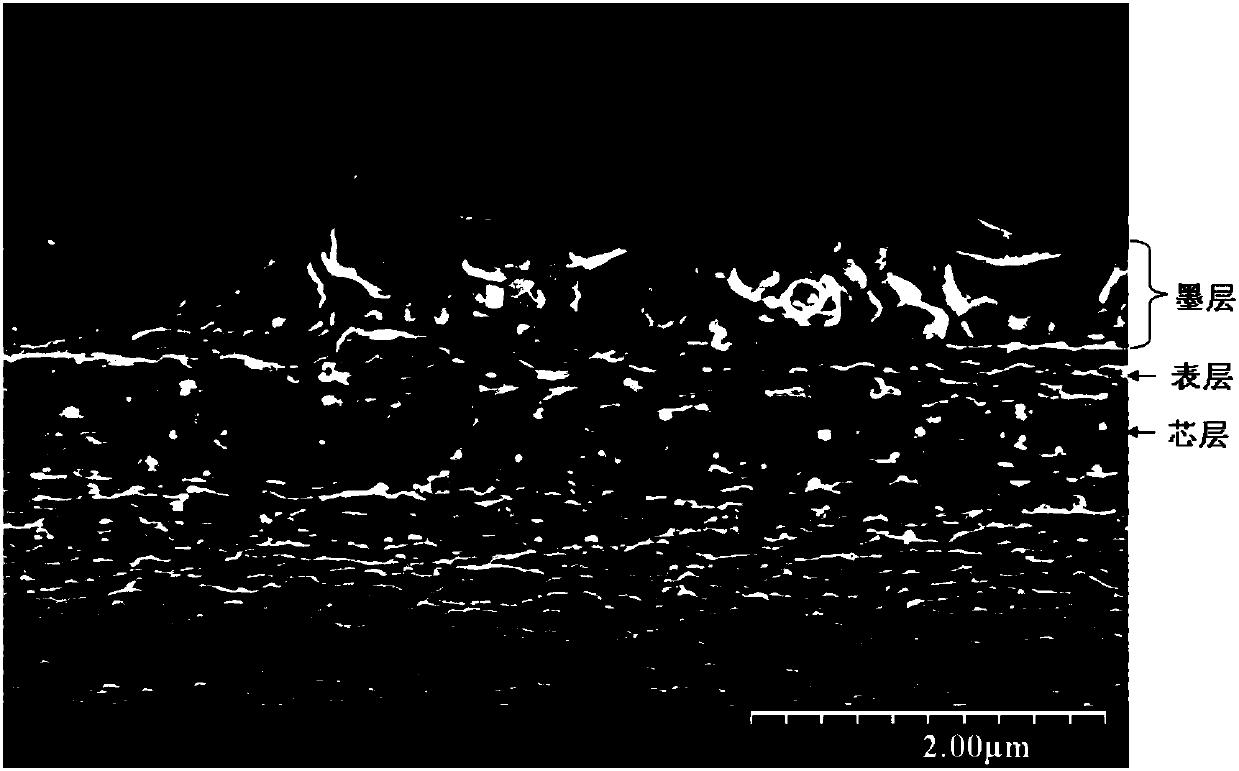

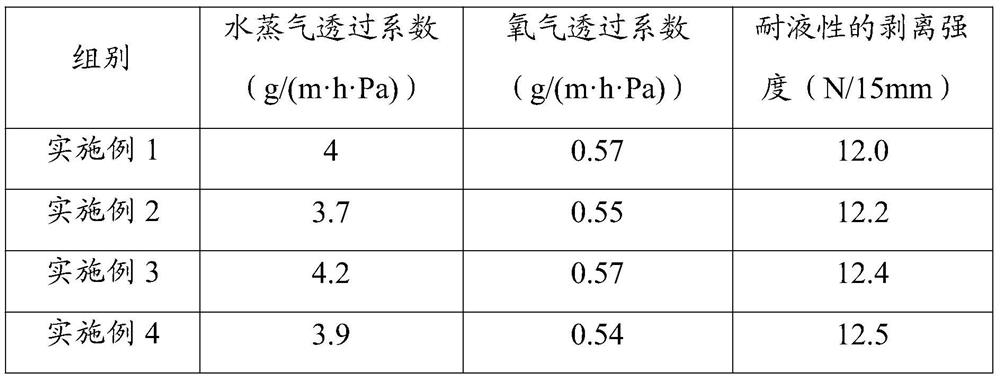

Modified polypropylene membrane, and preparation method thereof

The invention provides a modified polypropylene membrane, and a preparation method thereof. The preparation method comprises following steps: vinyl acetate, allyl glycidyl ether, and an initiator aresubjected to primary polymerization so as to obtain a vinyl acetate-allyl glycidyl ether copolymer; at least a part of the vinyl acetate-allyl glycidyl ether copolymer is used for modification of silicon dioxide so as to obtain a silicon dioxide modifying agent; a first polypropylene resin and the silicon dioxide modifying agent are subjected to melt blending and bidirectional stretching treatmentsuccessively so as to obtain the modified polypropylene membrane. According to the preparation method, polypropylene is injected among net-shaped fiber bundles, on one hand, it is beneficial for improving of the mechanical strength of the modified polypropylene membrane, and reducing the number and the length of cracks on the surface of the modified polypropylene membrane, and on the other hand,it is beneficial for formation of a compact structure of the surface of the modified polypropylene membrane, the compact structure is beneficial for reducing of diffusion rate of organic solvents, oxygen, and water vapor from the outside into the modified polypropylene membrane, and is beneficial for improving of the barrier properties of the modified polypropylene membrane.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Cast titanium alloy applicable to 560 DEG C-650 DEG C

The invention provides a cast titanium alloy applicable to 560 DEG C-650 DEG C. The cast titanium alloy comprises Ti, Al, Sn, Zr, Mo, Nb, Si, Ta and / or C, and the balance impurities. The cast titanium alloy is based on a Ti-Al-Sn-Zr-Mo-Si system basis, the content of Sn element reducing a casting property is controlled strictly, meanwhile, the content of all the elements is adjusted, and a small quantity of Nb, Ta and C elements are added properly. The cast titanium alloy is excellent in casting property, little in cracking tendency, capable of being used for a long time at 550 DEG C, and capable of serving for a short time at 600 DEG C-650 DEG C, and the creep resistance and the heat stability of the cast high-temperature titanium alloy can meet the use requirement at a high temperature.

Owner:重庆两航金属材料有限公司

Anti-crack coating agent used for investment-cast castings and preparing method for anti-crack coating agent

InactiveCN107321910AImprove pass rateReduce the number of cracksFoundry mouldsFoundry coresSodium metasilicateSodium phosphates

The invention provides an anti-crack coating agent used for investment-cast casting, and relates to the related technical field of investment casting. The anti-crack coating agent used for investment-cast casting comprises, by component, hydroxyl propyl methyl cellulose, alkylphenol ethoxylates, anti-crack metal liquid, sodium tetraborate, sodium metasilicate, sodium phosphate, the Malay powder, liquid paraffin, dodecanol and deionized water. According to the anti-crack coating agent used for the investment-cast casting, the qualification rate of investment casting products can be increased, the number of cracks and the burst degree of a casting piece are reduced, cracking probability of the casting pieces during the pouring process is reduced through using of the coating agent, and the product qualification rate is improved.

Owner:李吕军

Manufacturing method for prolonging service life of KR stirrer

The invention discloses a manufacturing method for prolonging the service life of a KR stirrer, specifically comprising the steps of: selecting a steel core, removing impurities on the surface of the steel core, washing and cleaning the steel core, and airing; welding a group of riveting pieces with different heights ranging from 30mm to 80mm on the surface of the steel core; covering a refractory fiber material layer with the thickness of 0-50mm on the surface of the steel core, coating a castable layer with the thickness of 60-120mm on the refractory fiber material layer, and baking the entire device for 36-60h at the temperature of 80-100 DEG C; and continuously heating the baked device to ensure that the temperature reaches 320-350 DEG C, and maintaining the temperature for 8-16h. The method is simple and energy-saving, and the used materials are not molten at high temperature and can stop the heat from being transmitted to the steel core, therefore, not only is the expansion degree of the steel core alleviated, but also the extrusion stress generated due to the expansion of the steel core can be effectively buffered so that the quantity of the cracks generated after the KR stirrer is baked can be reduced to the minimum.

Owner:宜兴市瑞华工业炉科技有限公司

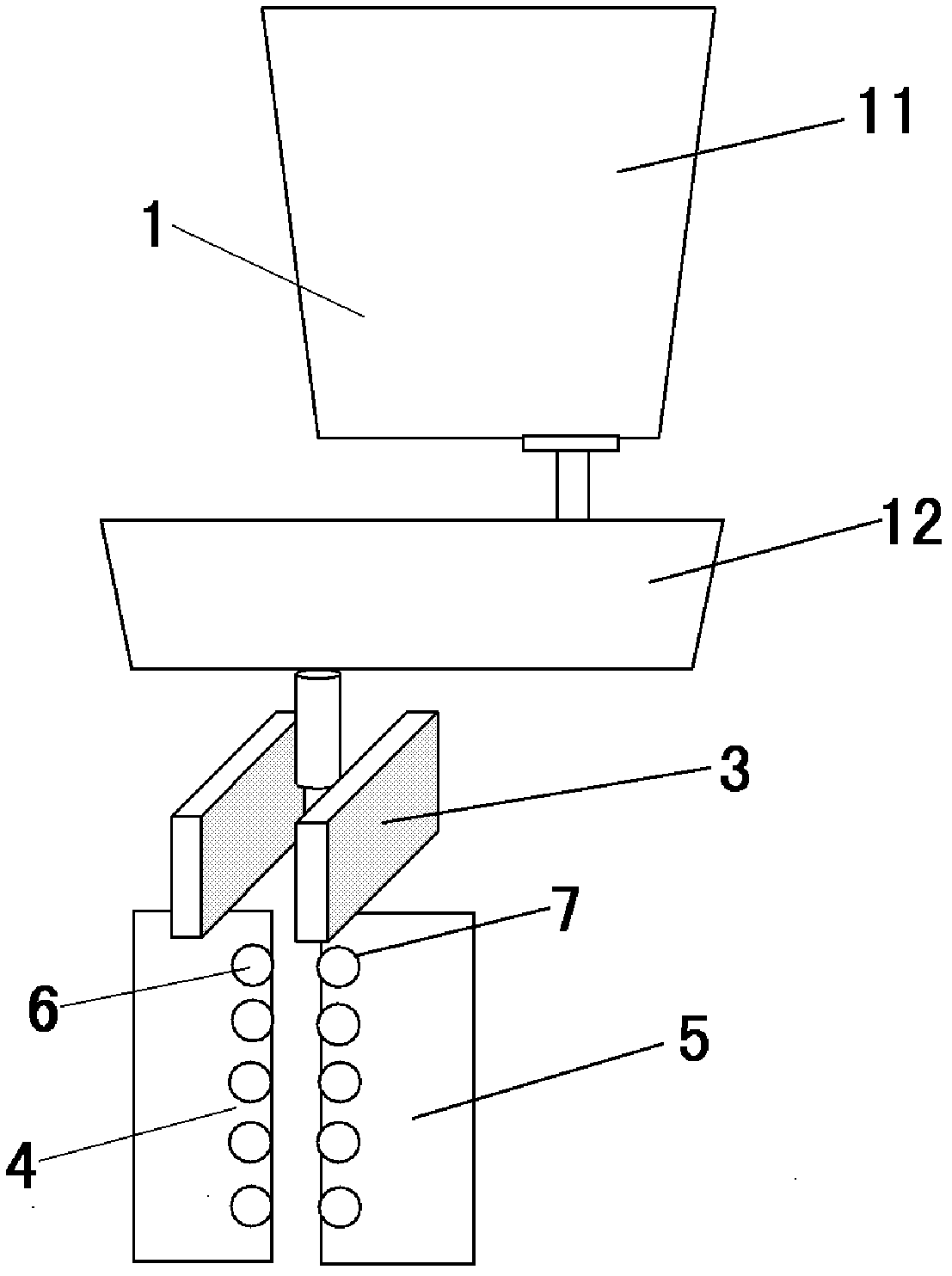

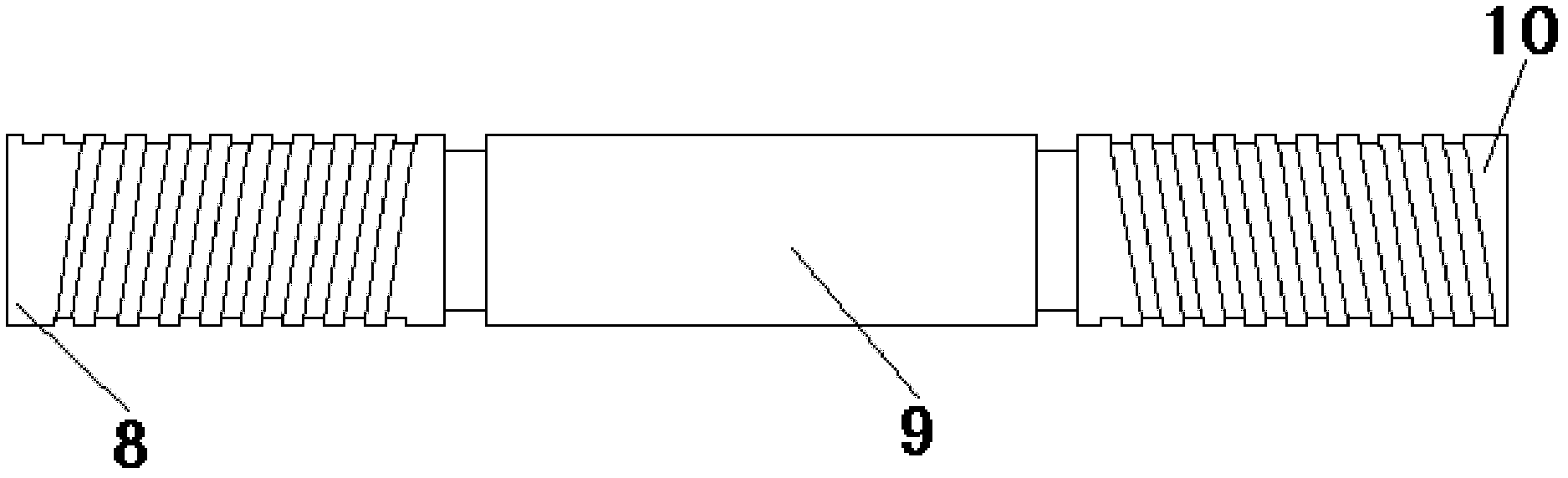

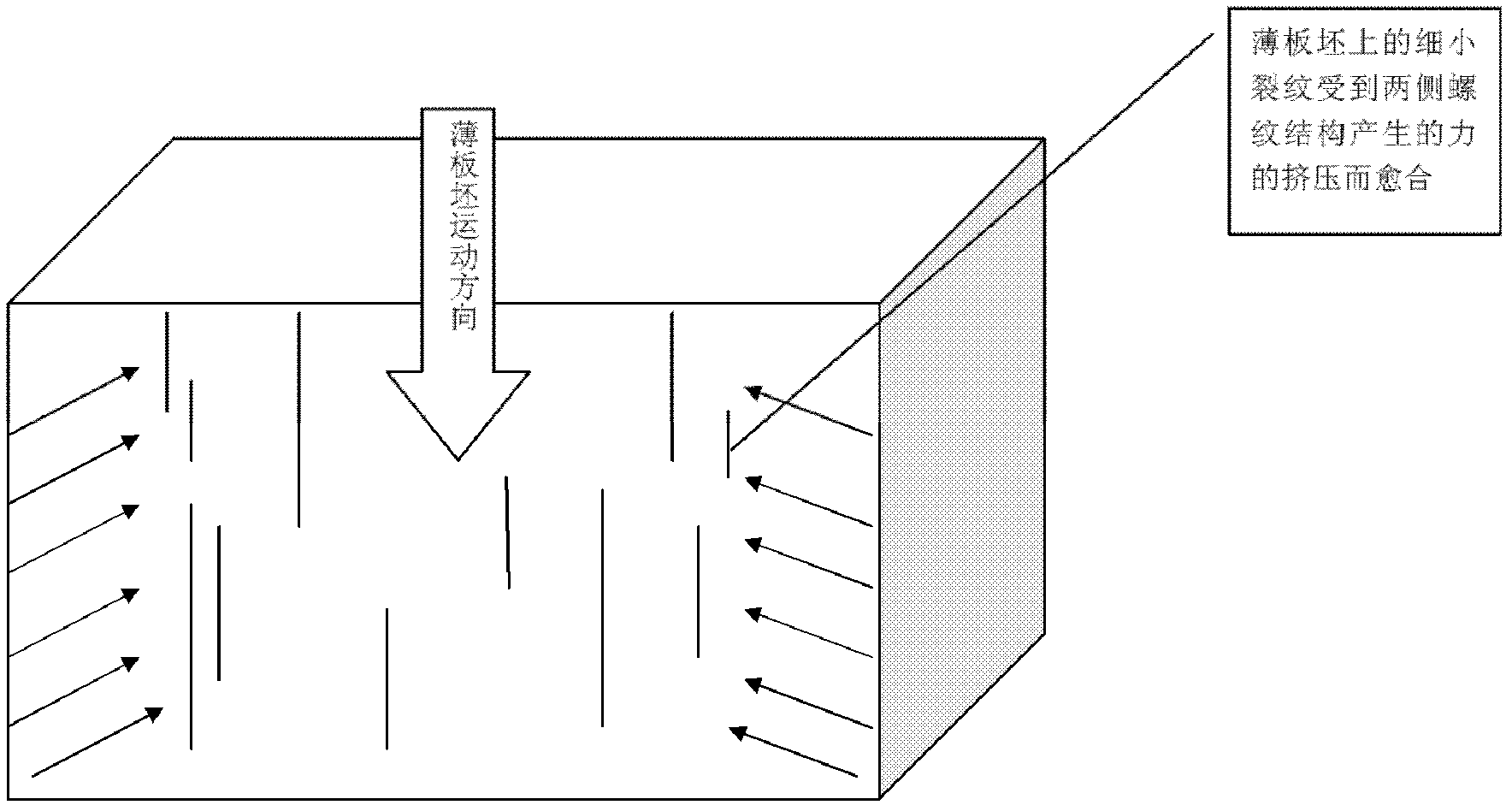

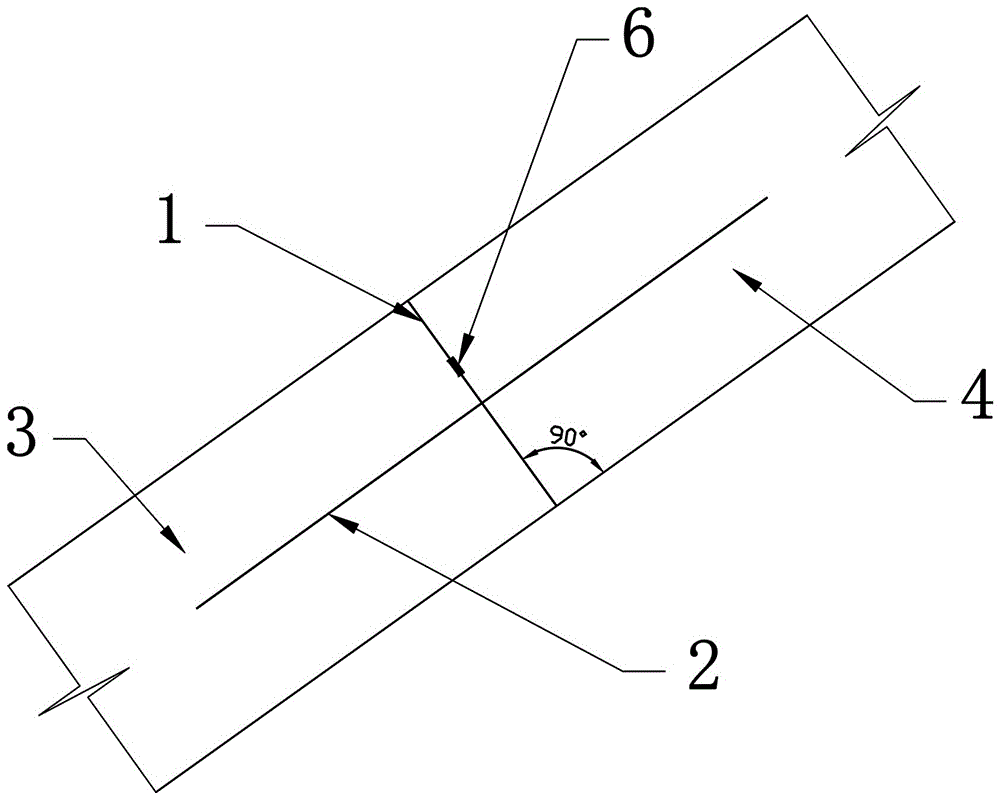

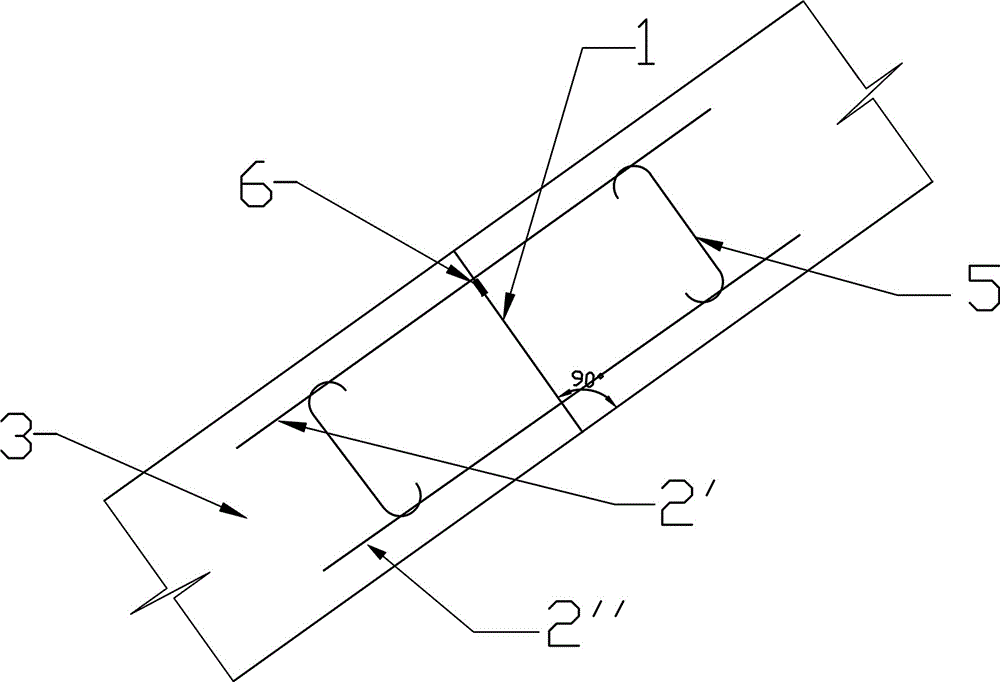

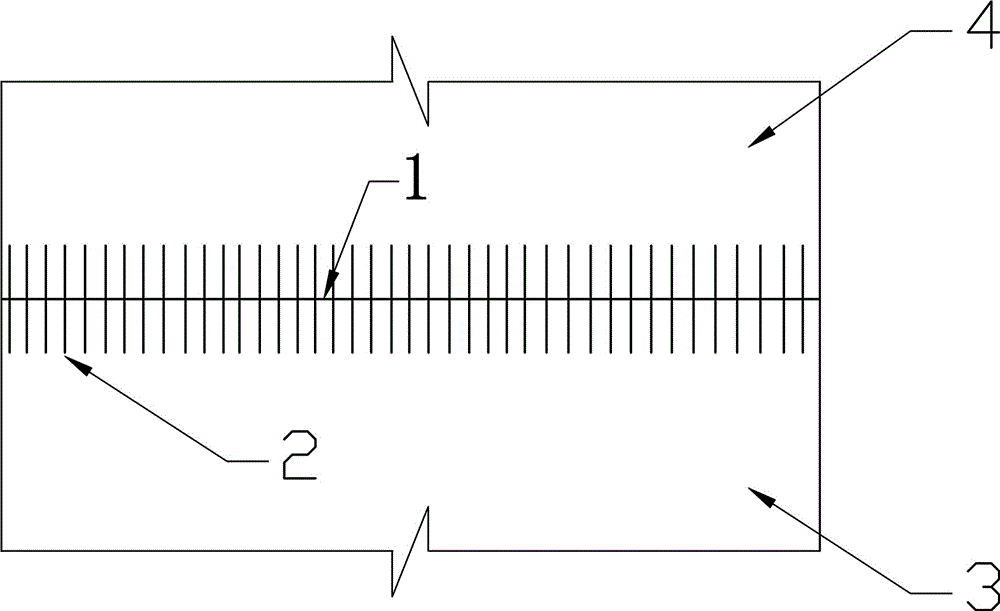

Production equipment used for thin slab continuous casting

The invention provides production equipment used for thin slab continuous casting, applied to the technical field of thin slabs. The production equipment comprises a steel ladle (1), a crystallizer (2) and a continuous casting guiding segment (3), wherein a thin slab enters into the continuous casting guiding segment (3) after being taken out from the crystallizer (2), the continuous casting guiding segment (3) is provided with a casting blank guide roller group I (4) and a casting blank guide roller group II (5), the casting blank guide roller group I (4) and the casting blank guide roller group II (5) respectively comprise multiple casting blank guide rollers I (6) and multiple casting blank guide rollers II (7) which are arranged in parallel, and the casting blank guide rollers I (6) and the casting blank guide rollers II (7) are of structures with thread lines. The production equipment used for thin slab continuous casting disclosed by the invention can realize the effect of repairing cracks on a thin slab, thus the number of the cracks is obviously reduced on the thin slab produced by adopting the production equipment disclosed by the invention, and scratches are almost entirely eliminated.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Horizontal construction joint of rockfill dam face and construction method of horizontal construction joint

InactiveCN106320274AEliminate weak pointsReduce the length of a pourEarth-fill damsRock-fill damsTemporary StoppingArchitectural engineering

The invention discloses a horizontal construction joint of a rockfill dam face and a construction method of the horizontal construction joint. The horizontal construction joint comprises a primarily poured block and a secondarily poured block, wherein a joint-crossing steel bar is arranged between the primarily poured block and the secondarily poured block, two ends of the joint-crossing steel bar are arranged in the primarily poured block and the secondarily poured block respectively and is perpendicular to a construction joint formed by the primarily poured block and the secondarily poured block. The joint-crossing steel bar can be arranged by crossing the joint in the middle of the face and can also be arranged in an upper-layer and lower-layer manner by crossing the joint in the face. Double-layer joint-crossing steel bars comprise an upper-layer joint-crossing steel bar and a lower-layer joint-crossing steel bar which are combined respectively to form an upper-layer reinforcing mesh and a lower-layer reinforcing mesh, and the upper-layer reinforcing mesh and the lower-layer reinforcing mesh are connected through connecting bars. With the adoption of the structure, the operation safety of a dam can be improved, the service life of the dam can be prolonged, deformation influences of the primarily poured block in the pouring process are reduced, and the horizontal construction joint is more suitable for being used under weighted cover and blanket zones of the long face rockfill dam and under the condition of temporary stopping of silo pouring due to construction causes.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

Preparation method of sandwich plate

InactiveCN110065108AHigh porosityImprove insulation effectLaminationLamination apparatusEpoxySardine

The invention discloses a preparation method of a sandwich plate, and belongs to the technical field of decorative material preparation. According to the preparation method, firstly, camphorwood is used as a raw material, and the camphorwood has the effects of insect prevention, mildew prevention and sterilization, so that the insulation property of an internal plate is greatly increased; then peanut oil is used a raw material, and micro-blasting wood pulp and the peanut oil are mixed and fermented, so that the internal plate of the preparation method has the effects of moisture protection, sterilization and bacteriostasis; zinc powder is soaked in a lanthanum nitrate solution, so that a lanthanum oxide protective film is formed on the surface of the zinc powder, the relative contact angleof the zinc powder is increased by the lanthanum oxide protective film, and the fire resistance of the zinc powder is good, so that an external plate has excellent flame resistance due to the use ofthe zinc powder; then sardines bones are used as raw materials, the sardines bones contain a large amount of fluorine, the fluorine has hydrophobicity, so that the moisture resistance of the modifiedzinc powder is increased, the modified zinc powder is used as the raw material to prepare the external plate, and two modified external plates are respectively bonded to the front and back surfaces ofthe modified internal plate by epoxy glue so as to prepare the sandwich plate. The preparation method has wide application prospects.

Owner:常州新之雅装饰材料有限公司

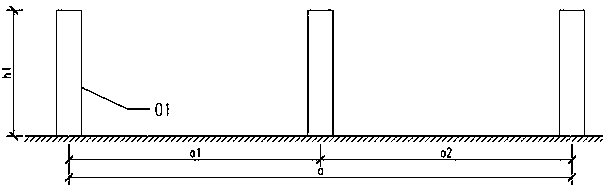

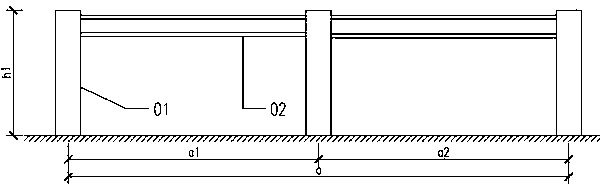

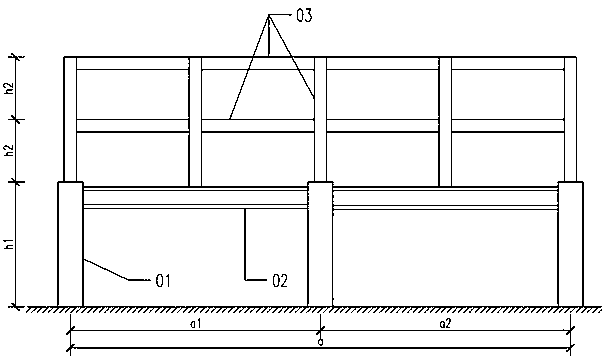

Profile steel concrete transfer beam and reverse construction method thereof

InactiveCN109057149AReduce loadReduce the number of cracksGirdersJoistsReinforced concreteEngineering

The invention discloses a profile steel concrete transfer beam and a reverse construction method thereof. The profile steel concrete transfer beam comprises lower structure columns; a transfer beam body is arranged at the upper ends of the lower structure columns; a superstructure is arranged on the transfer beam body; profile steel in the transfer beam body supports the superstructure, so that the number of steel bars in the transfer beam body is reduced and the cross section of the transfer beam body is reduced. The reverse construction method of the profile steel concrete transfer beam comprises the following steps: constructing the lower structure columns; constructing the profile steel in the transfer beam body on the lower structure columns; constructing the superstructure on the profile steel; binding profile steel external transfer beam steel bars; pouring transfer beam concrete. The profile steel concrete transfer beam disclosed by the invention has the advantages that the load borne by the reinforced concrete part in the transfer beam can be reduced, and the crack quantity and crack width of the profile steel concrete transfer beam are effectively reduced; moreover, the material utilization rate of the profile steel, relatively close to the middle part of the transfer beam, is increased.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Preparation method of polypropylene film layer capable of improving barrier property

The invention discloses a preparation method of a polypropylene film layer capable of improving barrier property, which specifically comprises the following steps: (1) in the presence of hydrogen, catalyzing propylene polymerization by using a catalytic system consisting of a metallocene catalyst and an alkylaluminoxane cocatalyst by using a styrene derivative as a chain transfer agent to obtain isotactic polypropylene; (2) blending the isotactic polypropylene with polypropylene random copolymer, an isotactic polypropylene bpolyethylene glycol diblock copolymer, polyvinyl alcohol, a silicon dioxide modifier, a nucleating agent and a compatilizer, performing sufficient melt blending in a screw extruder after blending, and performing extrusion and bidirectional stretching to obtain a polypropylene film layer, wherein the nucleating agent is a beta crystal form nucleating agent. The aluminum-plastic film prepared from the polypropylene film layer provided by the invention is better in gas-liquid barrier property, higher in safety and longer in service life, and has a good application prospect.

Owner:GUANGDONG ANDELI NEW MATERIALS CO LTD

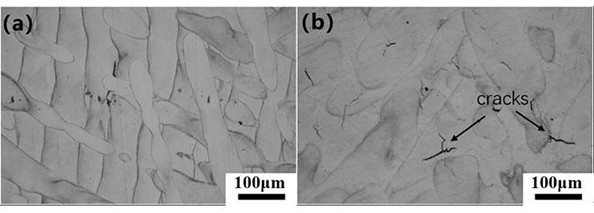

Ni3Al-based alloy and additive manufacturing method thereof

ActiveCN114427052AImprove surface qualityImprove toughnessAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingAl powder

The invention belongs to the technical field of Ni3Al-based alloys, Al powder is added into pre-alloyed Ni3Al powder to increase the Al content in the alloy, so that a beta-NiAl phase is introduced, the obdurability of a gamma '-Ni3Al phase is improved, the phase composition and the structure morphology of the Ni3Al-based alloy are changed, the number of cracks is reduced, and the Ni3Al-based alloy shows high high-temperature mechanical properties; and the high-temperature mechanical property of the Ni3Al-based alloy is further improved by controlling the laser power of selective laser melting. The result of the embodiment shows that the tensile strength at 650 DEG C of the Ni3Al-based alloy prepared by the method provided by the invention is 927.1 MPa, the elongation at break at 650 DEG C is 4.4%, the tensile strength at 1000 DEG C is 193.5 MPa, and the elongation at break at 1000 DEG C is 47.5%.

Owner:SHANGHAI UNIV

Pitch mixed material cracking resistance tester

ActiveCN101710043BImprove paving qualityImprove service levelStrength propertiesCrack resistanceCoupling

The invention relates to a pitch mixed material cracking resistance tester which is used for solving the problem of test detection of pitch mixed materials and comprises an environmental box, a fixed support seat, a sticking platform plate, a slide plate, a slide plate displacement loading mechanism, a spoke type sensor, a rotating coupling and a servo motor, wherein the fixed support seat is installed in the environmental box; the sticking platform plate is installed on the fixed support seat and touches and is connected with the slide plate in a movable fit way; the bottom of the slide plate is connected with the slide plate displacement loading mechanism; the slide plate displacement loading mechanism is connected with the servo motor by the rotating coupling, and the spoke type sensoris connected to a coupling disk of the rotating coupling; a side support seat of which the bearing is embedded into the environmental box is installed on the rotating coupling; and the servo motor isconnected outside the side body of the environmental box. The invention has simple structure and simple and convenient use and is suitable for carrying out a cracking resistance test on various pitchmixed materials.

Owner:沧州市市政工程股份有限公司

Corrosion-resistant and wear-resistant coating with laminated and columnar composite structure and preparation method thereof

ActiveCN109321861BImprove stabilityReduce residual stressMolten spray coatingSuperimposed coating processAlloyWear resistance

The present invention discloses a layer -like and column -shaped composite structure of corrosion -resistant coating and preparation methods. It is a alloy layer on the surface of the pre -processing substrate to spray alloy powder through the low -pressure plasma spraying method.Preheat the surface of the alloy layer on the surface of the alloy alloy layer to obtain a composite melting layer of the columnar structure through the plasma melting technology melting alloy powder and ceramic powder mixed powder, and the cycle is re -to obtain until the multi -layer layer and column that continuously changes along the thick direction performance alternately alternately alternately alternatelyGradient structure.The present invention not only improves the binding force and corrosion resistance of the coating and the matrix; it can also obtain a multi -layer and column intercess of the multi -layer and column alternative gradient structure that continuously changes along the thick direction, and improve the impact performance of the coating material.

Owner:SHANDONG UNIV OF SCI & TECH

A kind of cement-based composite material containing silicon nano-titanium dioxide and its preparation method

The invention discloses a silicon coated nano-titania-doped cement-based composite material. The silicon coated nano-titania-doped cement-based composite material contains cement, silicon coated nano-titania, silica fume, coal ash, sand, a water reducer and water. The invention further discloses a preparation method of the cement-based composite material. Experiment results show that the silicon coated nano-titania-doped cement-based composite material combines the advantages of titania and silicon dioxide and takes full advantage of the characteristics of toughening effects, filling effects, nucleation effects, volcanic ash effects and high strength and toughness of nano-titania and silicon dioxide, so that the rupture strength, compressive strength and durability of the silicon coated nano-titania-doped cement-based composite material are better that those of a silicon coated nano-titania-doped cement-based composite material. Besides, the silicon coated nano-titania-doped cement-based composite material further has electrical properties and can meet the requirements on multifunction and intelligence of structural materials in future.

Owner:DALIAN UNIV OF TECH

Lightweight aggregate micro-expansion anti-cracking concrete with adjustable expansion performance

PendingCN114524682AReduce max widthReduce internal tensile stressSolid waste managementCeramicwareCompressive strengthCalcium aluminates

The invention relates to lightweight aggregate micro-expansion anti-cracking concrete with adjustable expansion performance, which is prepared by mixing and stirring cement, aggregate, an expanding agent and water according to a mixing ratio with compressive strength of less than 100MPa, part of the aggregate is replaced by the lightweight aggregate with the same volume, the replacement rate is 5-100%, and the expansion performance is adjustable. The expanding agent comprises at least one of a calcium sulphoaluminate expanding agent, a calcium oxide expanding agent and a magnesium oxide expanding agent. The method has the advantages that the internal tensile stress caused by the coupling effect of temperature shrinkage, autogenous shrinkage and drying shrinkage in the concrete is effectively reduced, so that the generated crack can be effectively controlled, the maximum width of the crack appearing in the concrete is reduced, the crack gap is reduced, and the number of the crack is reduced. The novel magnesium oxide expanding agent is added to adjust the expansion performance under different working conditions, and has a sufficient compensation effect on drying shrinkage besides autogenous shrinkage and temperature shrinkage. Therefore, the engineering practical effect and the economic benefit are optimized.

Owner:林志海 +1

A kind of exosome freeze-dried powder and its preparation method and preparation comprising the exosome freeze-dried powder

ActiveCN110279893BLong lastingGood filling effectPharmaceutical delivery mechanismSkeletal/connective tissue cellsFreeze-dryingBlood plasma

The invention discloses a freeze-dried exosome powder, a preparation method thereof, and a preparation containing the freeze-dried exosome powder. The preparation method of the freeze-dried exosome powder includes the following steps: preparation of platelet-rich factor plasma: taking Autologous blood, prepared by centrifugation, prepared by exosomes; obtained from autologous fat, prepared adipose-derived mesenchymal stem cells, and cultured the mesenchymal stem cells; prepared by lyophilization: platelet-rich factor plasma, and exosomes The body is mixed, and trehalose is added therein, and mixed to obtain the preparation; freeze-drying: the freeze-dried liquid is subjected to freeze-drying to obtain the preparation. The preparation includes freeze-dried exosome powder, hyaluronic acid and physiological saline, which can effectively solve the problems of poor filling effect, short maintenance time and large immune rejection in existing cosmetic preparations.

Owner:CHENGDU QINGKE BIOTECH

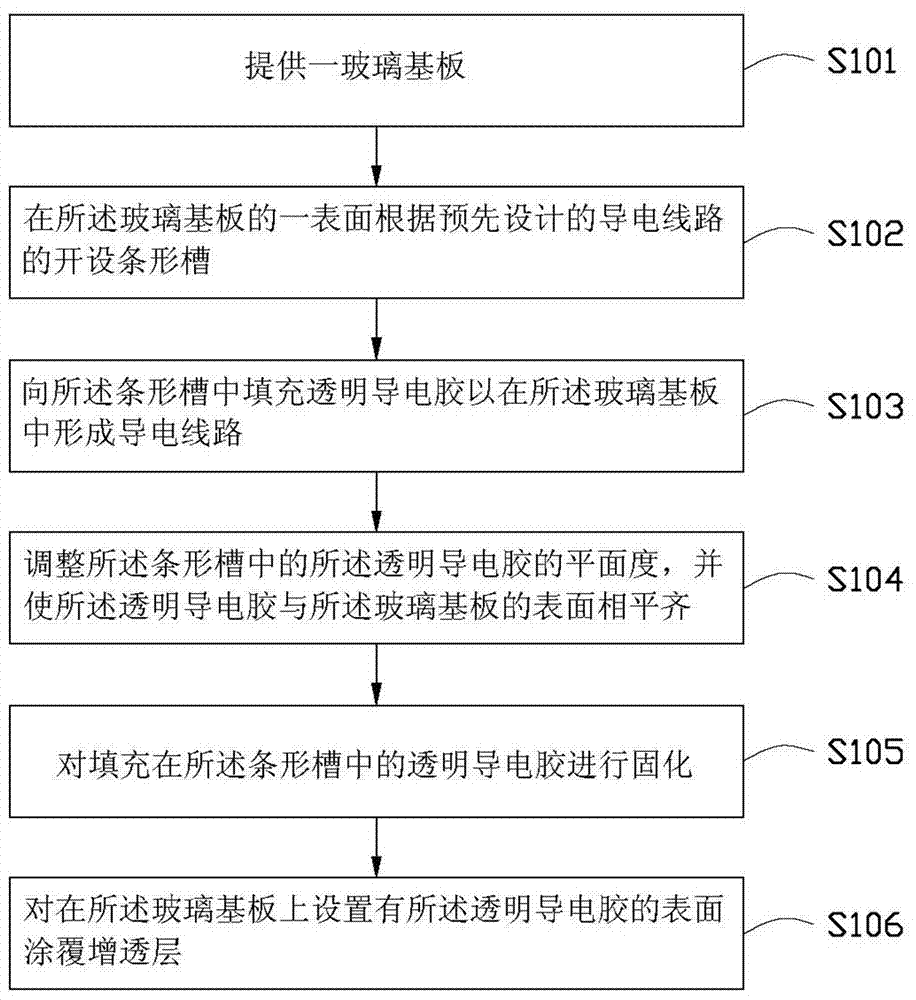

Transparent conductive substrate and manufacturing method thereof

InactiveCN103871546BHigh strengthReduce the number of cracksConductive layers on insulating-supportsCable/conductor manufactureConductive pasteUltimate tensile strength

The invention provides a transparent conductive substrate, which includes a glass substrate and a transparent conductive adhesive. A strip-shaped groove is provided on one surface of the glass substrate according to the direction of the pre-designed conductive circuit. The transparent conductive glue is filled in the strip grooves to form conductive lines in the glass substrate. The transparent conductive substrate and its manufacturing method provided by the present invention open a strip-shaped groove according to a pre-designed conductive circuit on the glass substrate, and fill the transparent conductive glue into the strip-shaped groove to form a conductive circuit, thereby reducing The number of cracks on the surface of the glass substrate effectively improves the strength of the transparent conductive substrate. The invention also provides a manufacturing method of the transparent conductive substrate.

Owner:SCIENBIZIP CONSULTINGSHENZHENCO

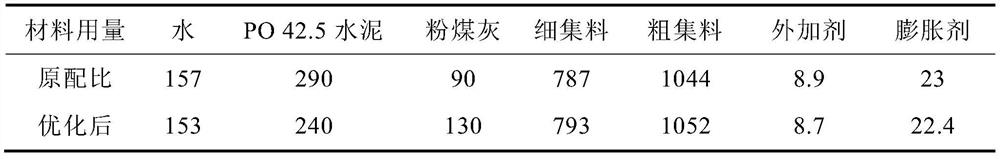

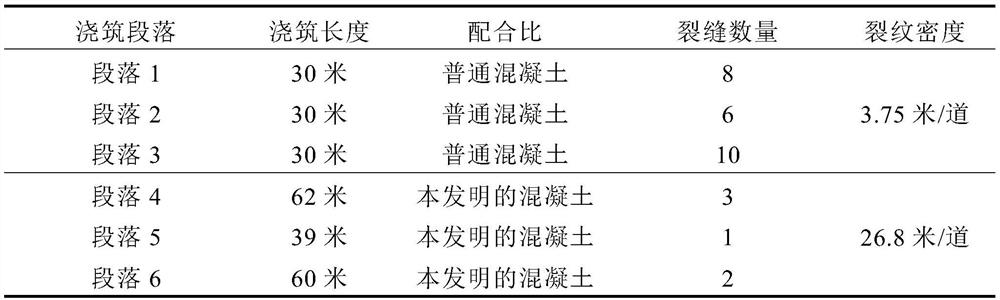

Concrete capable of reducing underground pipe gallery wallboard cracks

The invention provides concrete capable of reducing underground pipe gallery wallboard cracks, which is composed of cement, fly ash, coarse aggregate, fine aggregate, an additive, an expanding agent and water. Per cubic meter of the concrete contains 240 kg of cement, 130 kg of fly ash, 1052 kg of coarse aggregate, 793 kg of fine aggregate, 8.7 kg of additive, 22.4 kg of expanding agent and 153 kg of water. The problem that cracks are easily generated on the wall surface of the underground pipe gallery wallboard when the existing concrete with a common mix proportion is used for coating the wall surface of the underground pipe gallery wallboard is solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com