Lightweight aggregate micro-expansion anti-cracking concrete with adjustable expansion performance

An expansion performance, lightweight aggregate technology, applied in the direction of climate sustainability, sustainable waste treatment, ceramic products, etc., can solve the problem that the drying shrinkage of concrete structures cannot be effectively compensated, the expansion performance is not highly controllable, and there is no Use efficiency and economic cost optimization and other issues, to achieve the optimization of engineering practical effects, reduction of crack gaps, and optimization of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described below with specific examples, but not intended to limit the present invention.

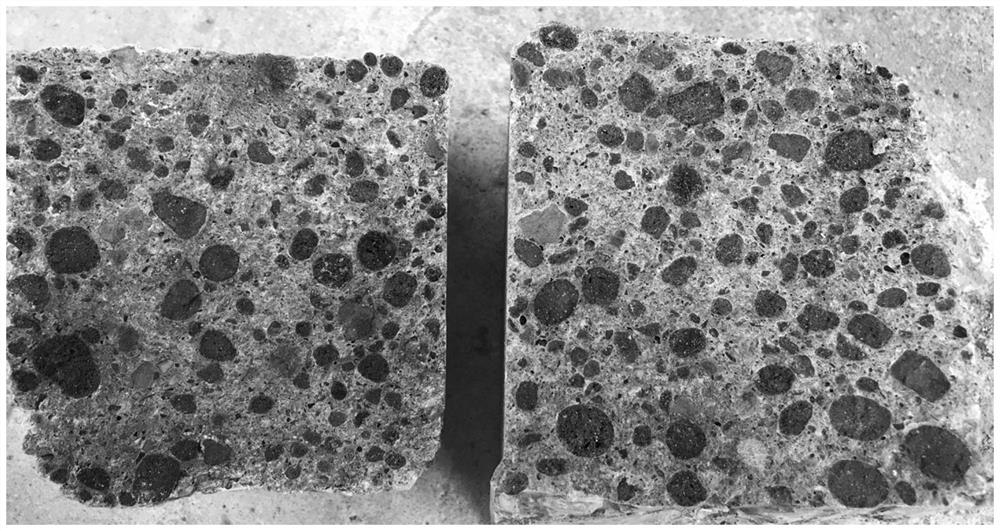

[0019] A lightweight aggregate micro-expansion anti-cracking concrete with adjustable expansion performance, which is composed of cement, aggregate, and expansion agent (in addition to ordinary calcium sulfoaluminate and calcium oxide, there is also a new type of magnesium oxide expansion agent) It is prepared with water in a proportion of compressive strength below 100MPa, mixed and stirred. Part of the aggregate is replaced with an equal volume of light aggregate, and the replacement rate is 5%-100%. The expansion agent used in concrete is not limited to sulfur and aluminum. Calcium acid type, calcium oxide type expansion agent, and magnesium oxide expansion agent with an activity of 90-200s.

[0020] By controlling the activity of the magnesia expansion agent, the concrete can reach a lower content of light aggregate, as low as 5%, which can meet t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com