Collector box for a motor vehicle

A technology of motor vehicle and header box, applied in the field of header box, can solve the problem of high cost of header box, achieve the effect of optimizing compactness and helping positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

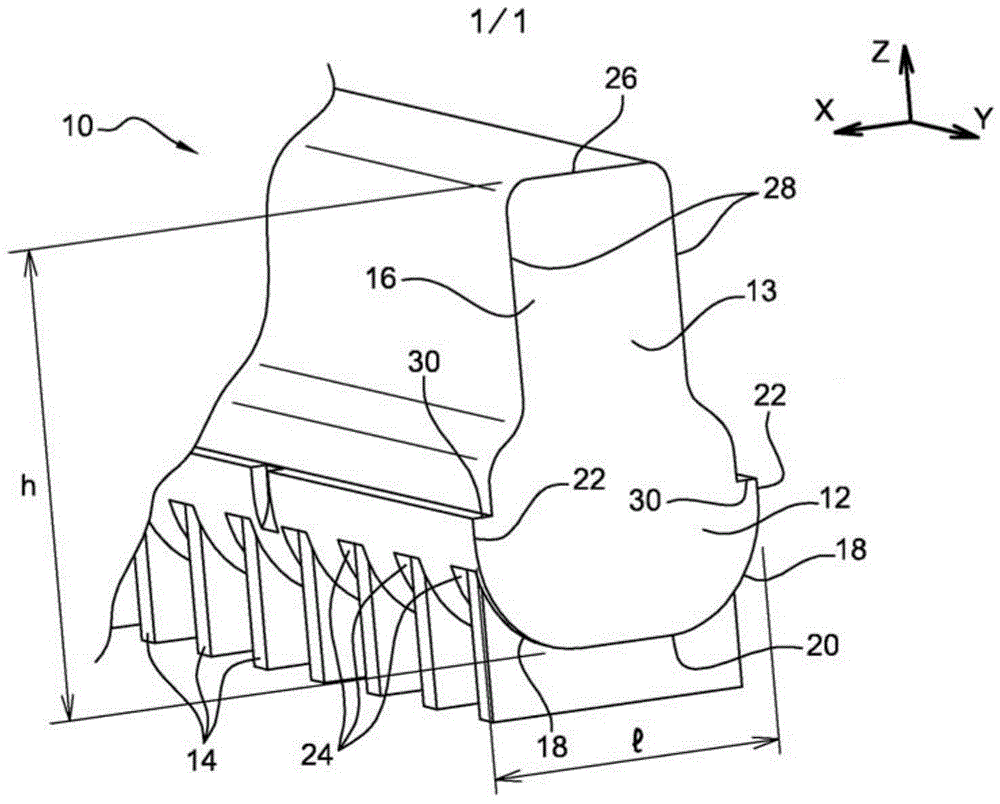

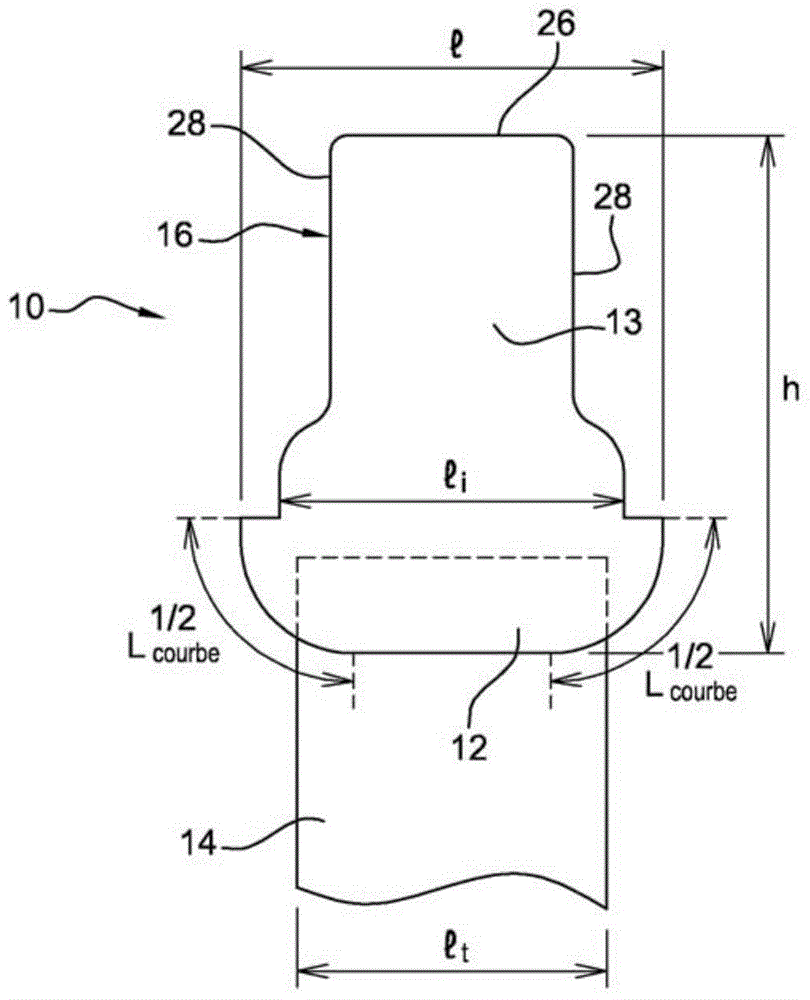

[0026] figure 1 Shown is a header tank 10 for a heat exchanger, more particularly intended for use on a radiator of an auxiliary cooling passage. The radiator is here configured to cause circulation of a mixture of water and glycol. The header tank 10 includes a header 12 for receiving heat exchange tubes 14 and also includes a cover 16 mounted on the header 12 .

[0027] In this specification, the header tank 10 extends in the longitudinal direction Y, and has a cross section defined by the intersection of the header tank 12 with a plane (X, Z) perpendicular to the longitudinal direction Y. Said cross-section of the header tank is defined by a maximum height h and a maximum width l. In this example, the maximum height h is at least one and a half times greater than the maximum width l, ie h is approximately 30 mm and l is approximately 19 mm. However, it is conceivable that the maximum height h is greater than twice the maximum width l.

[0028] The header 12 is a metal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com