Melting needle assembly and melting system suitable for treating hypertrophic cardiomyopathy

A hypertrophic cardiomyopathy and ablation needle technology, applied in the field of medical devices, can solve problems such as arrhythmia and conduction bundle damage, and achieve the effect of preventing damage to the conduction bundle and reducing the maximum width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

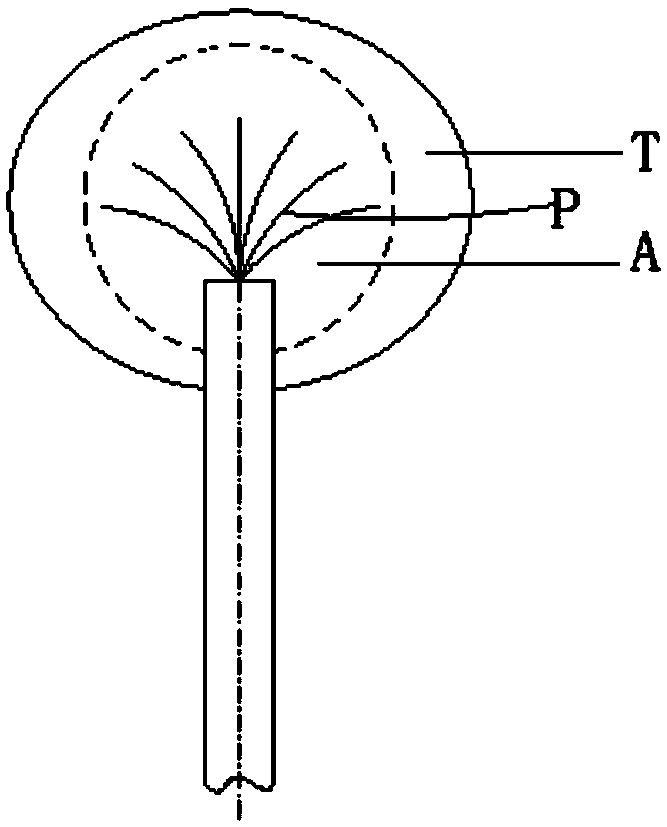

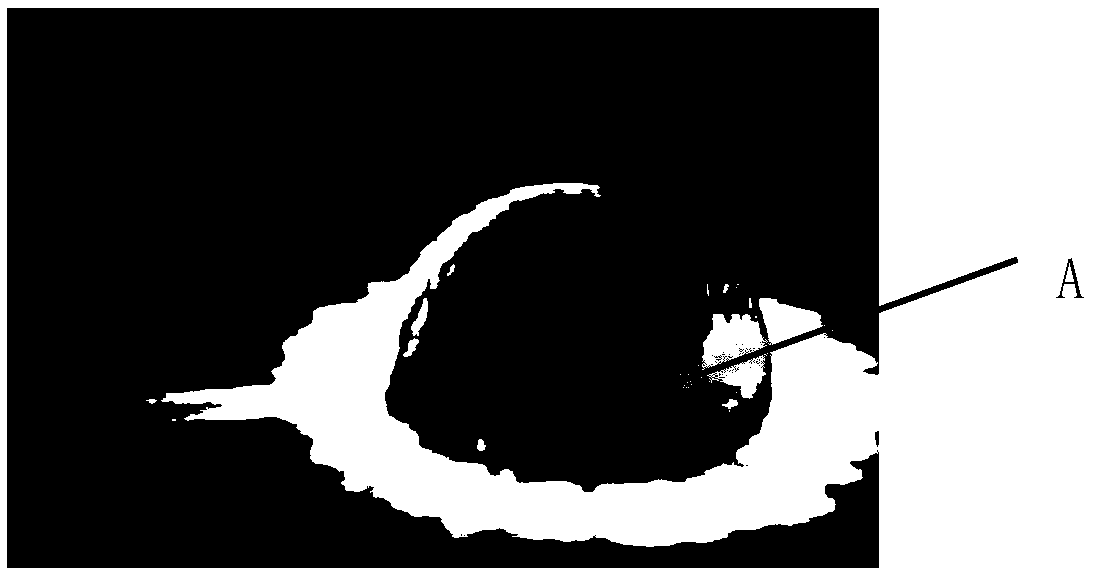

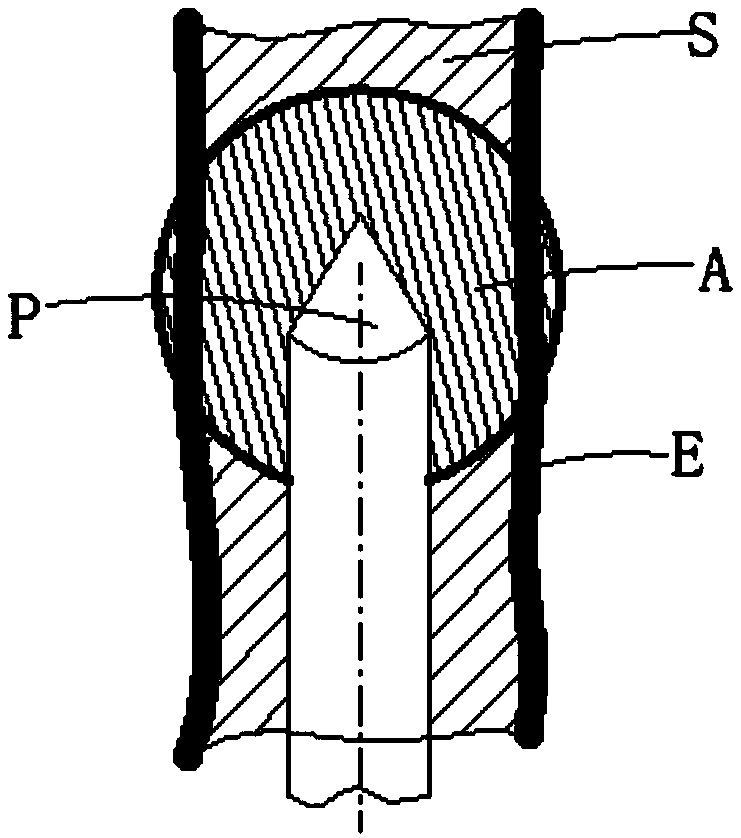

[0068] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Wherein, the accompanying drawings are used for illustrative purposes only, represent only schematic diagrams, and should not be construed as limiting the present invention.

[0069] In order to more clearly describe the structure of the ablation needle assembly and ablation system suitable for treating hypertrophic cardiomyopathy of the present invention, the terms "proximal end" and "distal end" are defined here as commonly used terms in the field of interventional medicine. Specifically, "distal end" means the end far away from the operator during the surgical operation, and "near end" means the end close to the operator during the surgical operation.

[0070] Unless otherwise defined, all technical and scientific terms used herein have the same meaning as commonly understood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com