Rotor blade extension portion having skin located over framework

A technology of rotor blades and extensions, applied in the field of rotor blades, can solve problems such as material bending and deformation, and achieve the effects of reducing mass, improving flexibility, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

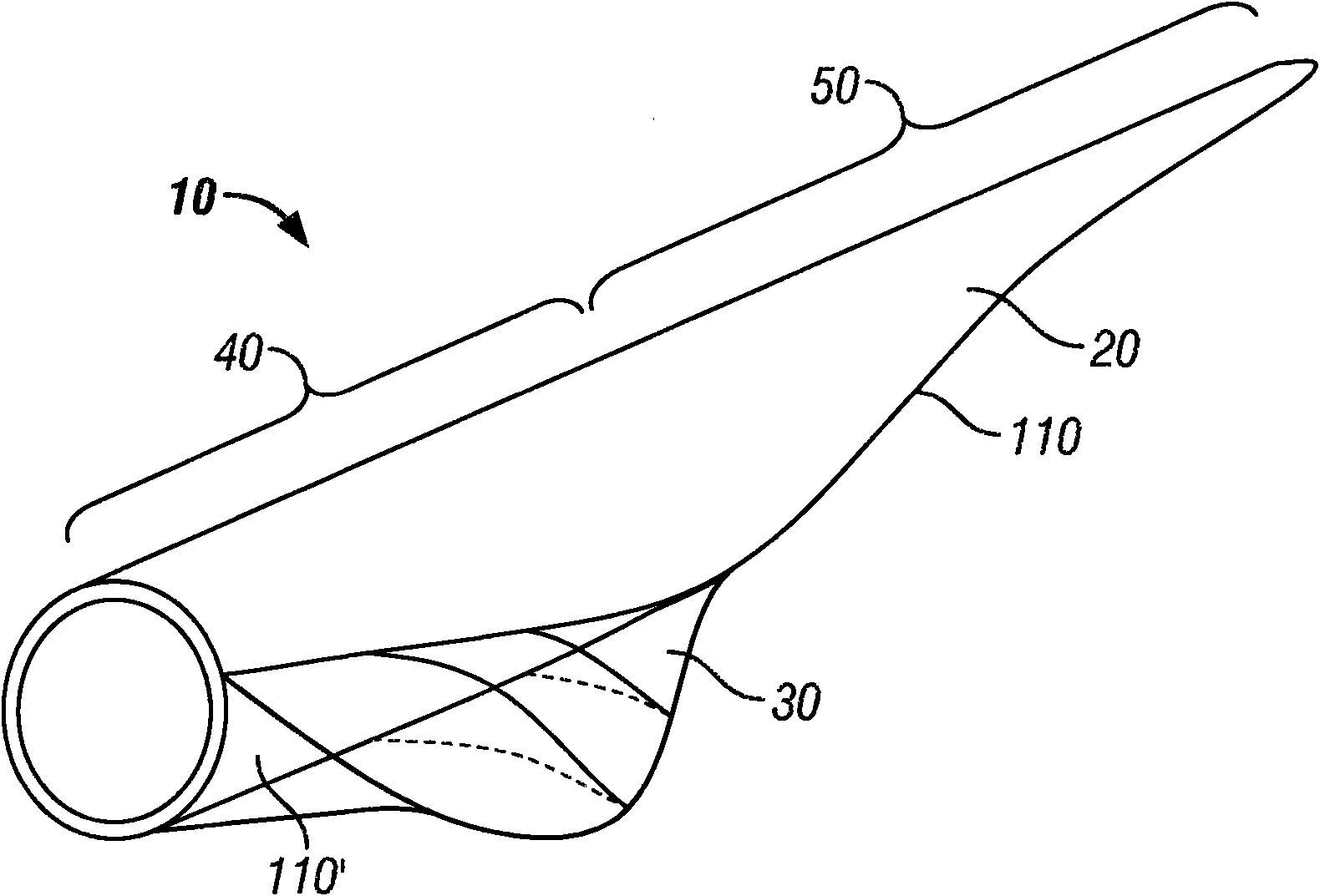

[0053] image 3 A rotor blade 10 comprising a blade portion 20 and an extension 30 is shown. The proximal or "root" end 40 of the blade portion 20 is configured to be connected to a rotor hub (not shown) of a wind turbine installation, while the distal end 50 of the blade portion 20 extends from the root end 40 and is thereby cantilevered. support. This distal portion 50 represents the “tip” of the blade 10 . The length of the rotor blade 10 may be in the range of 20 to 150 meters in length, but is typically in the range of 20 to 70 meters. The extension 30 is attached to the rearmost region of the root end 40 . In the illustrated embodiment, the protrusion 30 is attached to the extreme proximal position, close to where the rotor blade is connected to the rotor hub in use, however the protrusion 30 could be closer to the extreme towards the blade tip. The end positions are spaced apart.

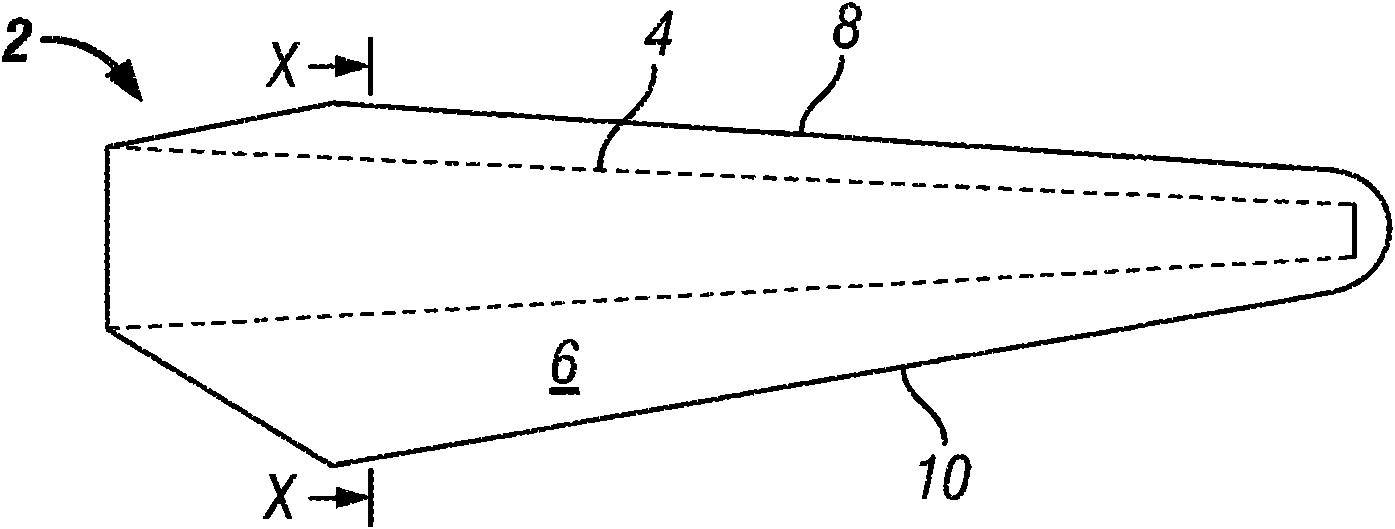

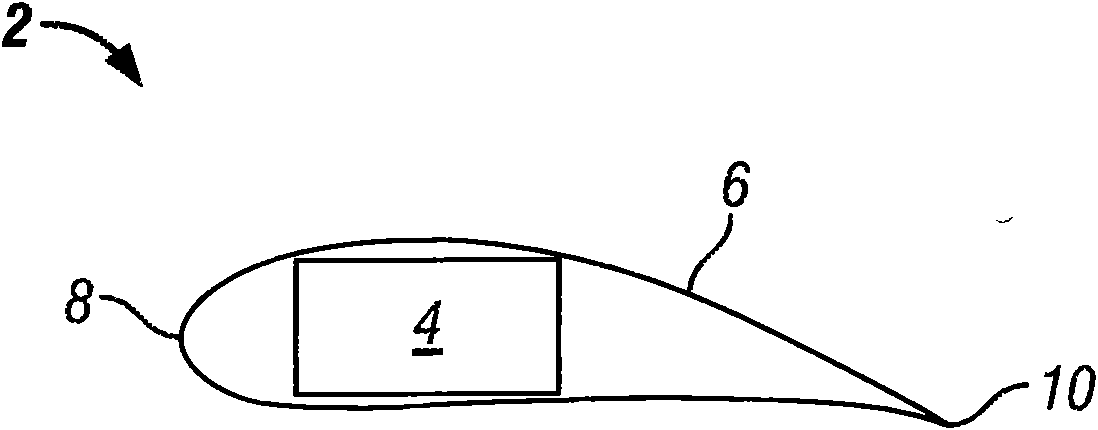

[0054] Figure 4 A schematic diagram is shown showing a cross-section of the root en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com