Transparent conductive substrate and manufacturing method thereof

A technology of transparent conduction and manufacturing method, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., which can solve problems such as difficult to use single-piece touch glass and easy to break, so as to improve strength and reduce quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

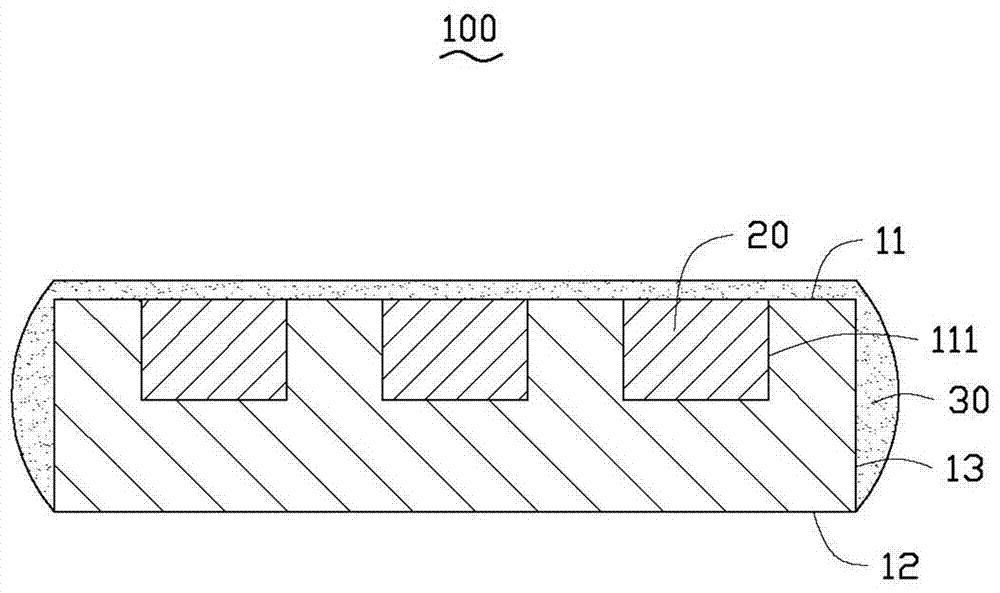

[0015] Such as figure 1 As shown, a transparent conductive substrate 100 provided by an embodiment of the present invention includes a glass substrate 10 , a transparent conductive adhesive 20 and an anti-reflection layer 30 .

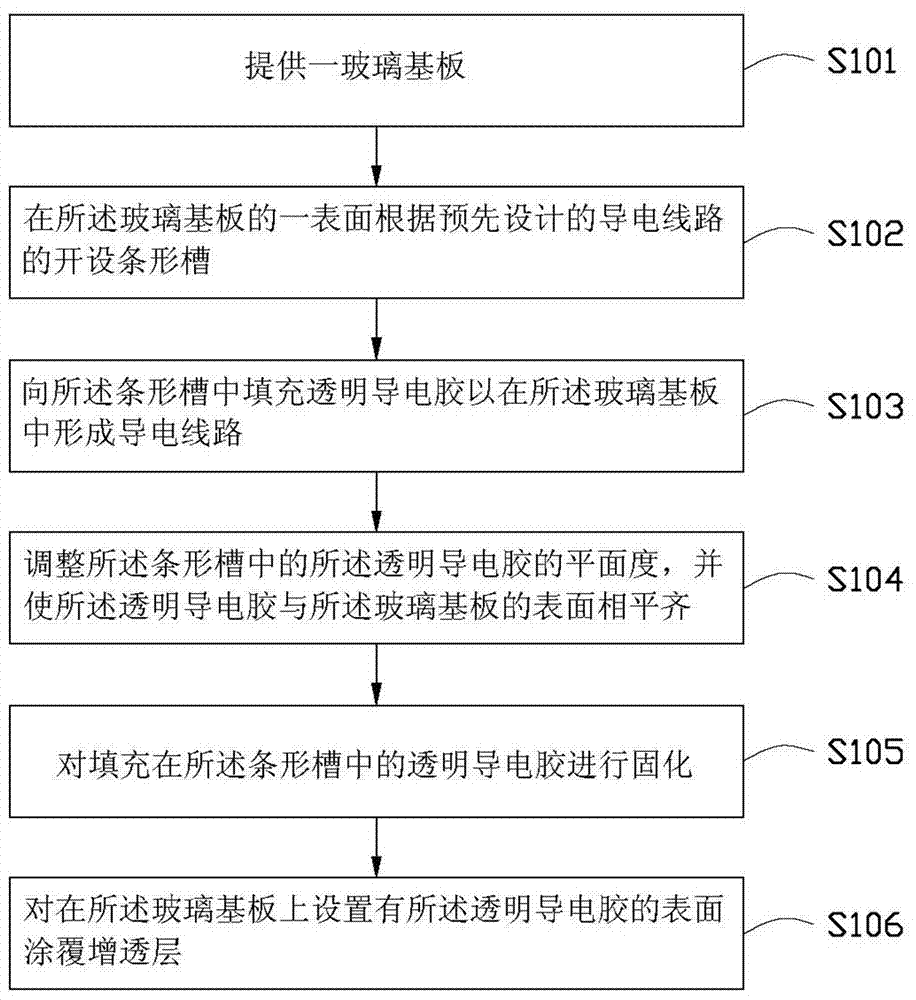

[0016] The glass substrate 10 is made of ordinary frosted glass, and its refractive index varies according to its composition. The glass substrate 10 includes an upper surface 11 , a lower surface 12 opposite to the upper surface 11 , and a side surface 13 connected between the upper surface 11 and the lower surface 12 . A strip-shaped groove 111 is formed on at least one of the upper surface 11 or the lower surface 12 according to the direction of the pre-designed conductive circuit. The width of the strip groove 111 on the surface of the glass substrate 10 along the direction perpendicular to the extension of the strip groove 111 is greater than 100 nm and less than 500 nm. When the width is less than 100 nm, it may not be able to meet the requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com