Cast titanium alloy applicable to 560 DEG C-650 DEG C

A technology of high-temperature titanium alloy and allowance, which is applied in the field of titanium alloy, can solve the problems of poor casting performance, mismatch of strength and plasticity, etc., and achieve the effect of improving high-temperature strength and high-temperature creep performance, reducing crack cracking tendency, and improving casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is a cast high temperature titanium alloy comprising 86.5% Ti, 5.81% Al, 2.15% Sn, 3.46% Zr, 0.46% Mo, 0.65% Nb, 0.18% Si and 0.53% Ta, the remainder is impurities, and the stated percentages are mass percentages.

[0030] A cold crucible suspension melting furnace was used to cast the test bar sample, and the obtained cast cylindrical test bar was 14.5 mm in diameter and 180 mm in length. The cast test bar was subjected to hot isostatic pressing at 920℃ / 130MPa / 2h to remove the internal defects of the casting.

[0031] The test bar after hot isostatic pressing is subjected to solution + aging treatment, and the heat treatment process is 1030 ° C / 2h / AC+700 / 2h / AC. The tensile standard sample size and sample tensile test method are in accordance with GB / T228- 2010 to be implemented. The tensile properties of the test bars at different temperatures are shown in Table 2, where σ b is the tensile strength, σ 0.2 is the yield strength and δ is the elongatio...

Embodiment 2

[0033] This embodiment is a cast high temperature titanium alloy, including 86.3% Ti, 5.89% Al, 1.8% Sn, 3.47% Zr, 0.81% Mo, 0.63% Nb, 0.16% Si, 0.48% Ta and 0.06% C, the remainder are impurities, and the percentages are mass percentages.

[0034] The preparation method, hot isostatic pressing and heat treatment process of the test bar in this example are the same as those disclosed in Example 1, and Table 2 shows the tensile properties of the test bar at different temperatures.

Embodiment 3

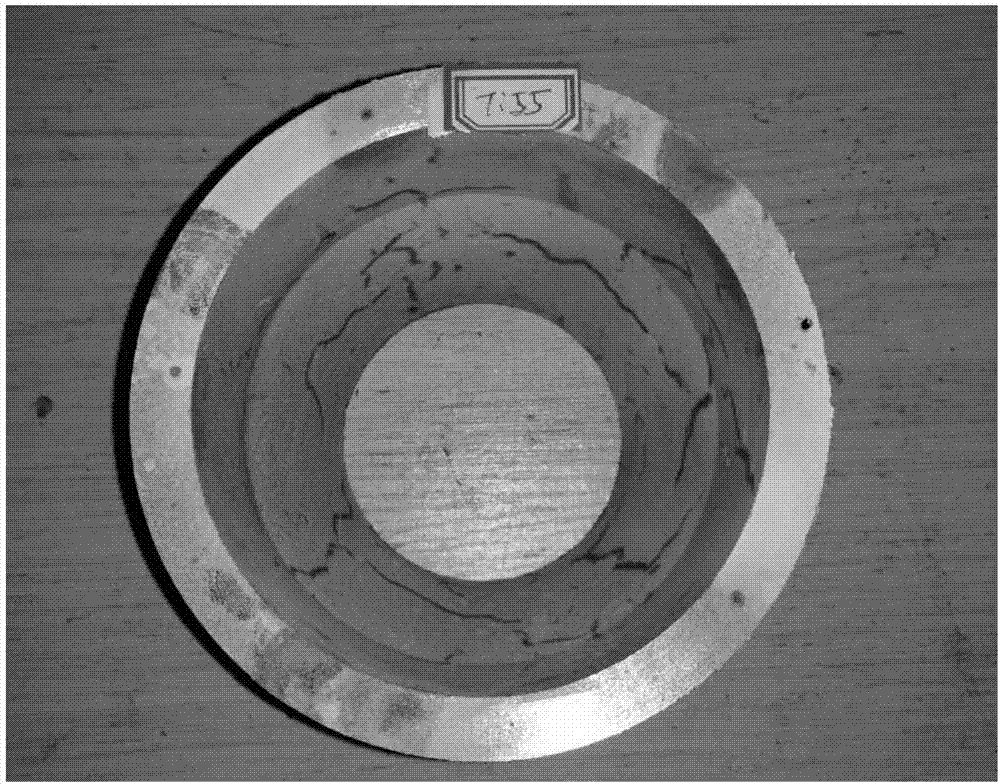

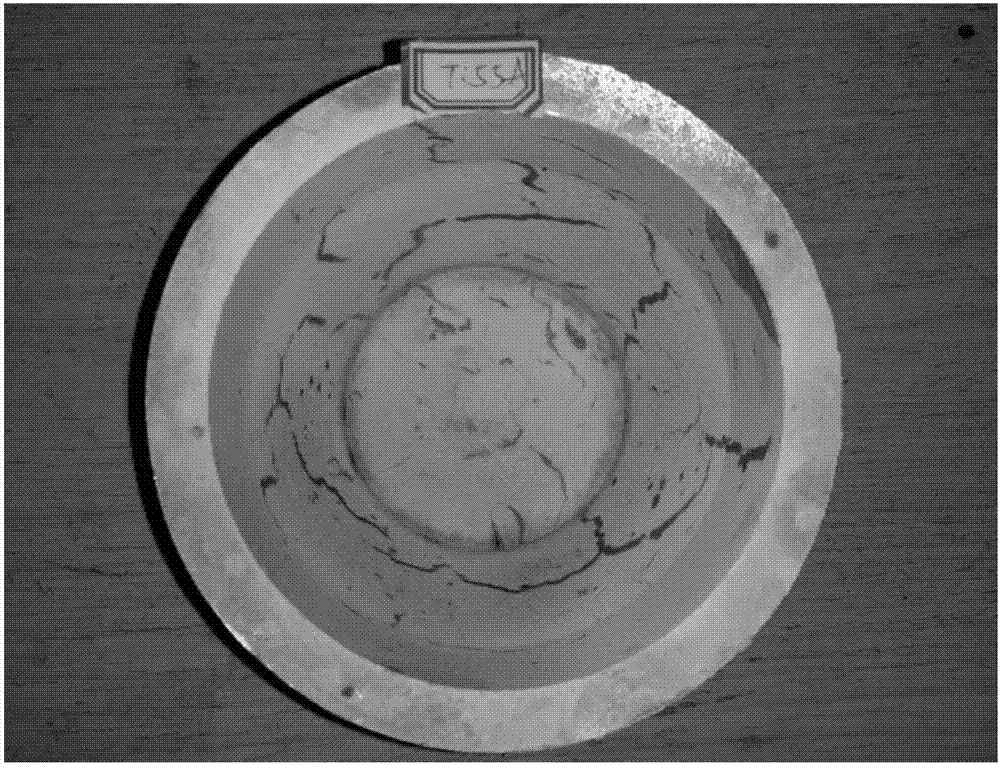

[0036] This embodiment is a cast high temperature titanium alloy, including 86.1% Ti, 5.7% Al, 2.3% Sn, 3.4% Zr, 0.9% Mo, 0.5% Nb, 0.12% Si, 0.7% Ta, the remainder is impurities, and the stated percentages are mass percentages. The cracked cup samples were poured in a cold crucible suspension melting furnace, and the poured crack samples were subjected to penetration test analysis to compare the number and size of cracks generated. The results are shown in Table 2. figure 1 A schematic diagram of the crack after coloring of the cracked cup is given.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com