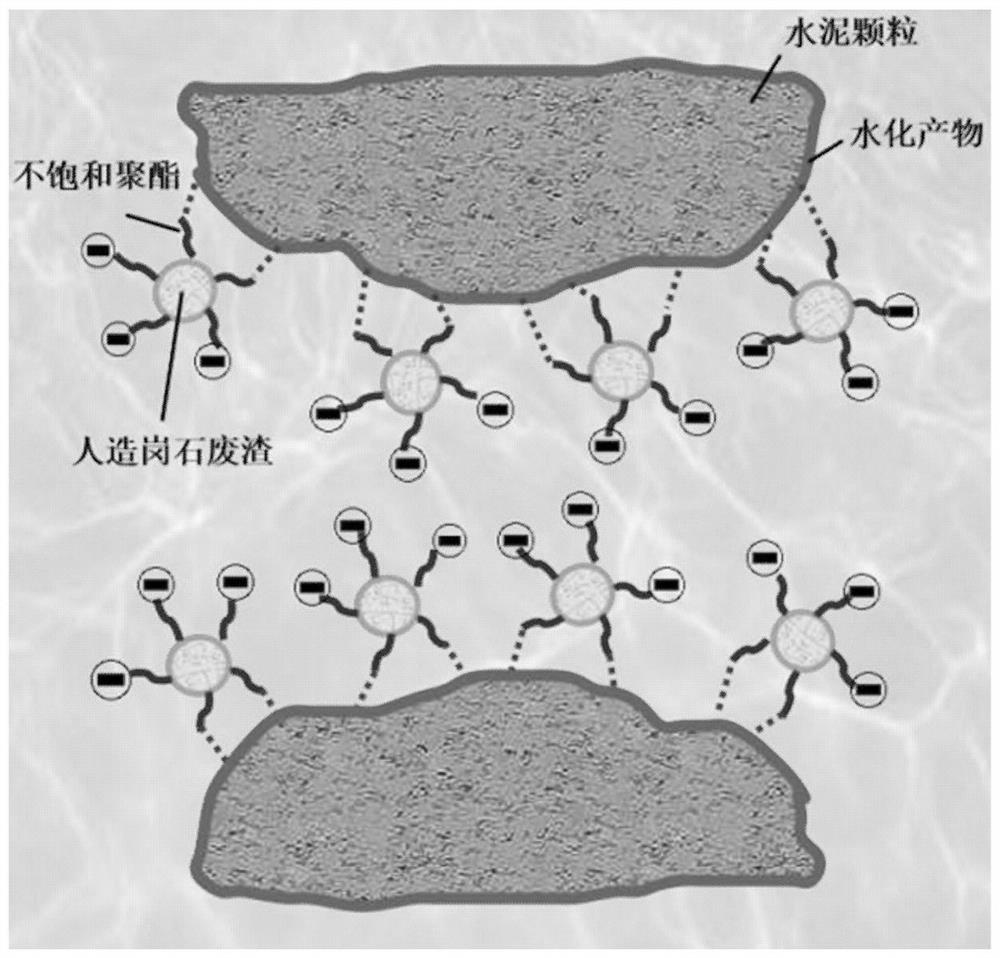

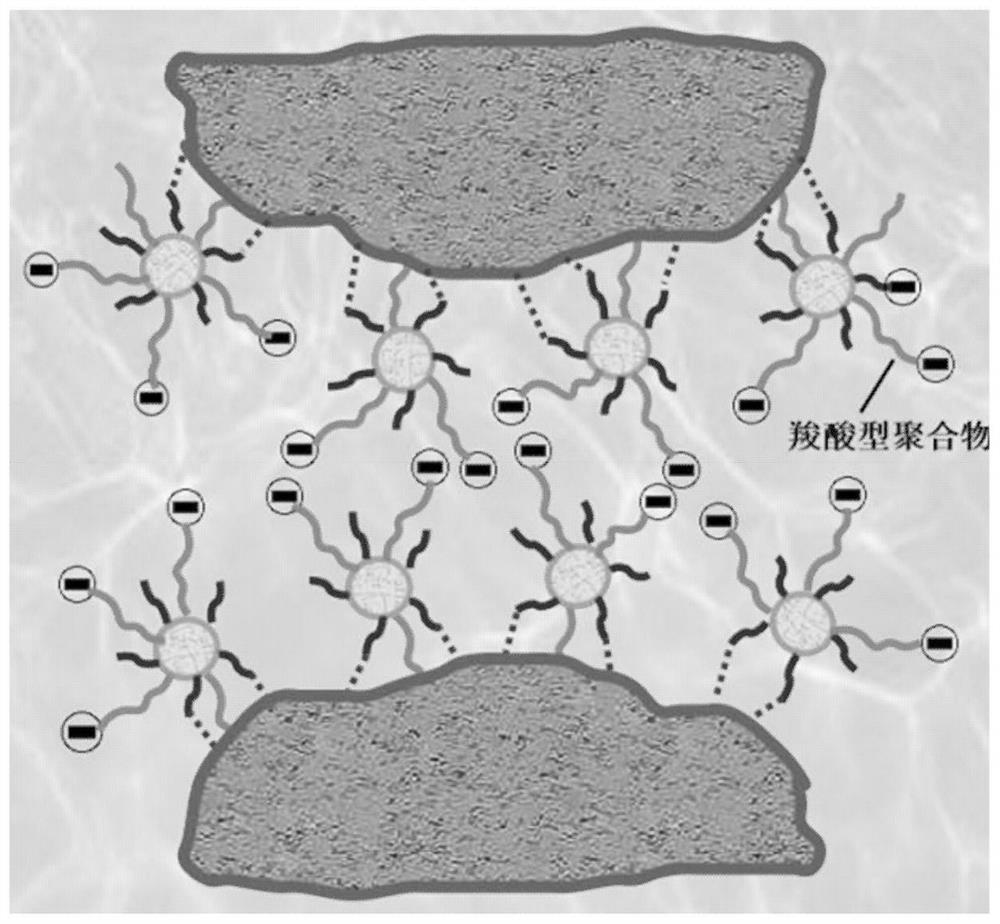

Artificial agglomerated stone waste residue-based cement mortar reinforcing agent and preparation method thereof

A technology of artificial granite and cement mortar, which is applied in the field of building materials, can solve the problems of low compressive and bending strength, limit the application of cement mortar, and high brittleness, and achieve low cost, broad market application prospects, and reduce water reduction. The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

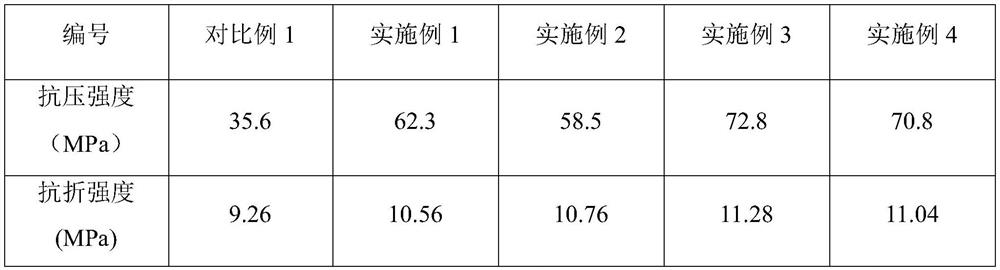

Embodiment 1

[0029] Put 630 parts of cement, 1080 parts of river sand, and 120 parts of artificial rock waste slag powder into the cement mortar mixer, stir at low speed for 2 minutes, take 1.5 parts of carboxylic acid type high-performance water reducer, and mix 283.5 parts of water (keep water The gray ratio is 0.45), mixed and made into a water reducer solution, added to the mixer, stirred rapidly for 2 minutes, poured the obtained cement mortar into the mold and vibrated it, and left it for 2 days. 95±5%, and the temperature is 20±2℃ in saturated lime water for 28 days. According to the national standard GB / T 17671-1999, the flexural strength and compressive strength of the cured cement mortar specimens were tested.

Embodiment 2

[0031] Put 630 parts of cement, 1080 parts of river sand, and 120 parts of artificial rock waste slag powder into the cement mortar mixer, stir at low speed for 2 minutes, take 1 part of carboxylic acid type high-performance water reducer, and mix 283.5 parts of water (keep water The gray ratio is 0.45), mixed and made into a water reducer solution, added to the mixer, stirred rapidly for 2 minutes, poured the obtained cement mortar into the mold and vibrated it, and left it for 2 days. 95±5%, and the temperature is 20±2℃ in saturated lime water for 28 days. According to the national standard GB / T 17671-1999, the flexural strength and compressive strength of the cured cement mortar specimens were tested.

Embodiment 3

[0033] Get 120 parts of artificial stone waste slag powder, 10 parts of polyacrylate emulsion, mix and stir for 10 minutes in proportion to obtain the artificial stone waste slag powder modified by polyacrylate emulsion, and mix it with 630 parts of cement and 1080 parts of river sand , add it to the cement mortar mixer, stir at low speed for 2 minutes, take 1.5 parts of carboxylic acid type high-performance water reducer, mix with 283.5 parts of water (keep the water-cement ratio at 0.45), mix it into a water reducer solution, and add it to the mixer In the process, stir quickly for 2 minutes, pour the obtained cement mortar into the mold and vibrate it, and place it for 2 days. Finally, the cement mortar specimen is cured in saturated lime water with a humidity of 95±5% and a temperature of 20±2°C for 28 days. That's it. According to the national standard GB / T 17671-1999, the flexural strength and compressive strength of the cured cement mortar specimens were tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com