Horizontal construction joint of rockfill dam face and construction method of horizontal construction joint

A technology of horizontal construction joints and construction methods, applied in water conservancy projects, dams, barrages, etc., can solve problems such as construction joint opening and concrete damage, and achieve the effect of reducing the number and width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

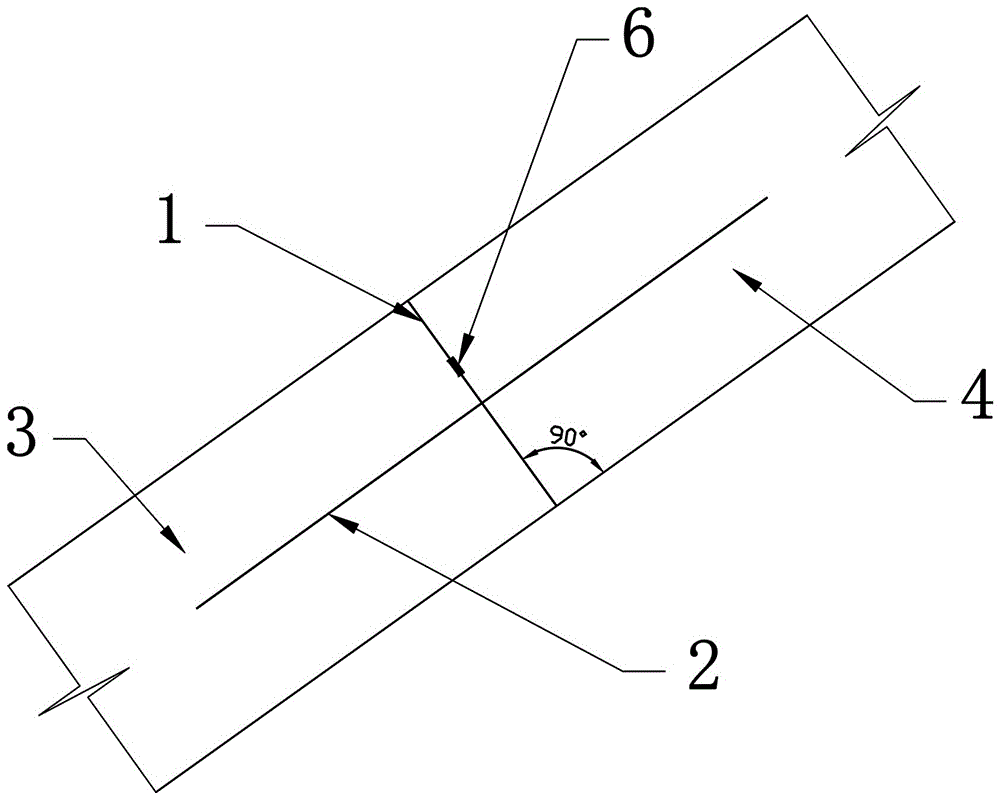

[0026] A horizontal construction joint of a rockfill dam slab, comprising a pre-cast block 3 and a post-pour block 4, a cross-joint reinforcement bar 2 is arranged between the pre-pour block 3 and a post-pour block 4, and the two ends of the cross-joint reinforcement bar 2 are respectively arranged on the pre-pour Among the block 3 and the post-cast block 4, and the joint reinforcement 2 is perpendicular to the construction joint 1 formed by the pre-cast block 3 and the post-cast block 4.

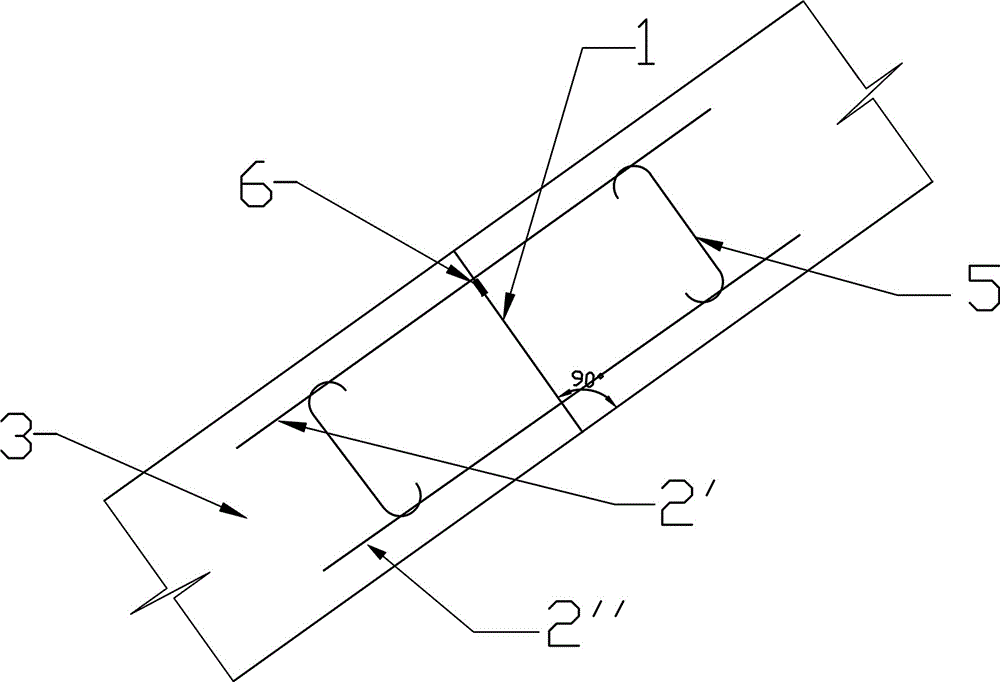

[0027] In a preferred solution, the double-layer seam reinforcement 2 includes an upper layer seam reinforcement 2' and a lower layer seam reinforcement 2'', and the upper layer seam reinforcement 2' and the lower layer seam reinforcement 2'' are respectively combined to form an upper reinforcement mesh and the lower layer of steel mesh, the upper and lower layer of steel mesh are connected by connecting bars 5.

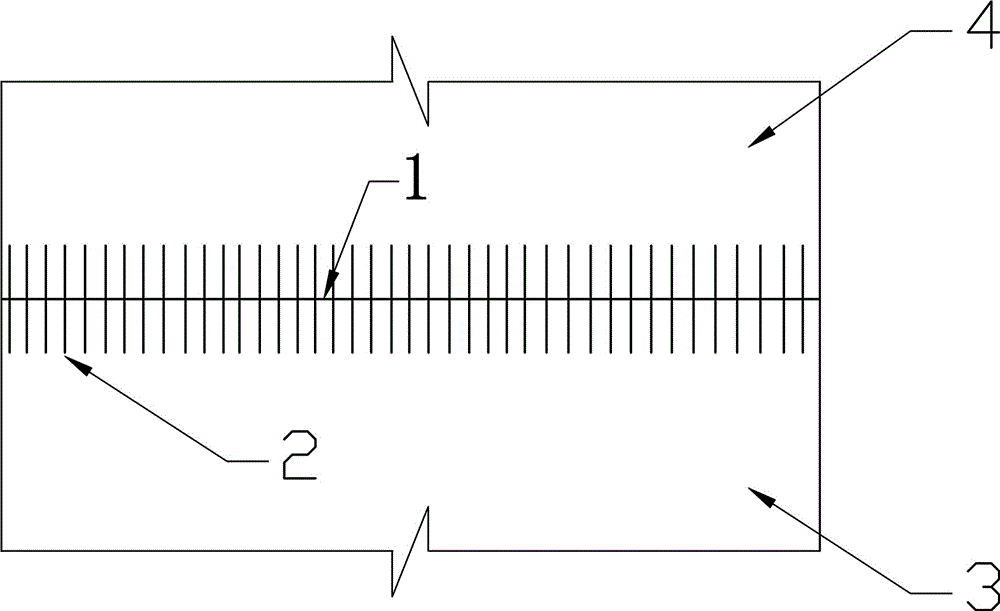

[0028] In the preferred scheme, the single-layer joint reinforcement 2 is loc...

Embodiment 2

[0030] On the basis of Example 1, the following methods are used to construct the horizontal construction joints of the face of the rockfill dam:

[0031] 1) 1) Calculate and determine the size and position of the construction joint between the first pouring block 3 and the subsequent pouring block 4, and the size of the mortar strip on the underlying layer of the panel;

[0032] 2) Lay the mortar, and set the PVC gasket on the laid mortar, and erect the side form at the horizontal construction joint of the first pouring block 3;

[0033] 3) Preset the cross-joint reinforcement 2 in the side formwork of the erected horizontal construction joint and use the slip form for concrete pouring. After the concrete pouring of block 3 is completed, remove the side formwork of the horizontal construction joint, and press Standardize chiseling treatment, and uninterrupted maintenance of the first pouring block 3;

[0034] 4) At least 20 days after the first pouring block 3 is poured, mos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com