Device for nuclear power station pipeline crevasse sealing and strength protection

A technology for nuclear power plants and pipelines, which is applied to display devices, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problem that the welding method cannot fully meet the temporary sealing treatment of pipeline breaks, etc., achieves bright colors, enhances the sealing effect, and is convenient effect made

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

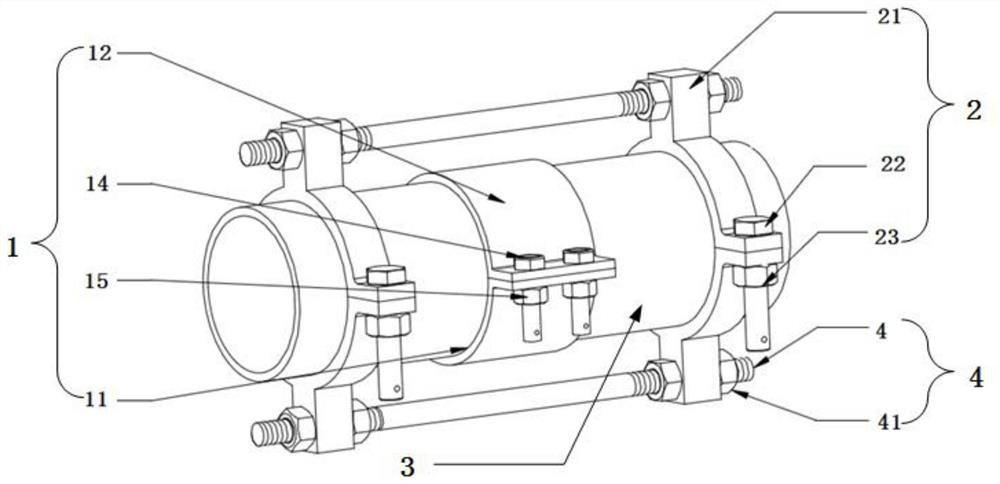

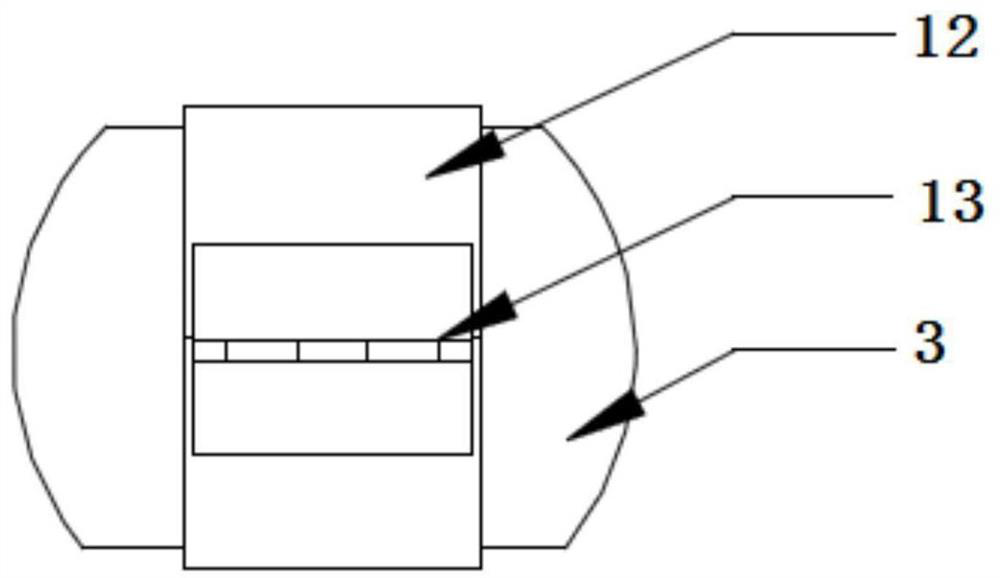

[0042] In order to better understand the present application, the technical solutions in the present application embodiment will be described in conjunction with the drawings in the present application. Obviously, the embodiments described below are only part of the present application embodiment, not all. Based on the embodiments described in the present application, those skilled in the art without paying creative labor, all of the present application protected within the scope of the present application.

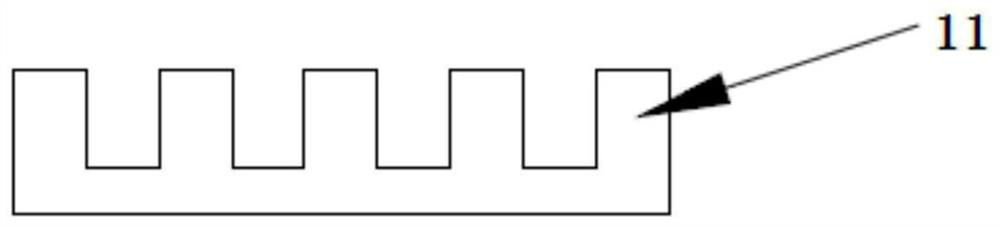

[0043] In the study, it was found that the current nuclear power plant temporary pipe sealing fixture is generally two semi-circular hugs plus sealing rubber, using sealing rubber contacts, two clamps are connected to bolts on both sides. . Since there is a tension in both sides, the strip produces a shape under the effect of the clamp friction, resulting in a small tape in the bolt, the leak is pulled, and the strip has become weak and sensitive. Since the surface of the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com