A tailpipe hanger

A liner hanger and suspension mechanism technology, which is applied in wellbore/well components, earthwork drilling and production, etc., can solve the problems of easy aging of rubber seals, seal failure of sitting and hanging drive mechanisms, and affecting the durability of wellbore seals, etc., to achieve Improve safety and reliability, improve the effect of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

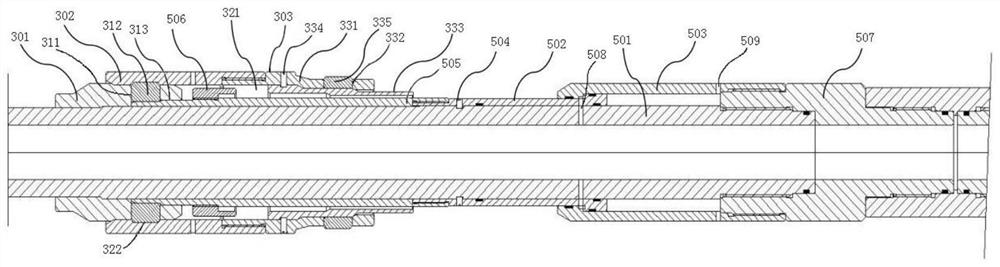

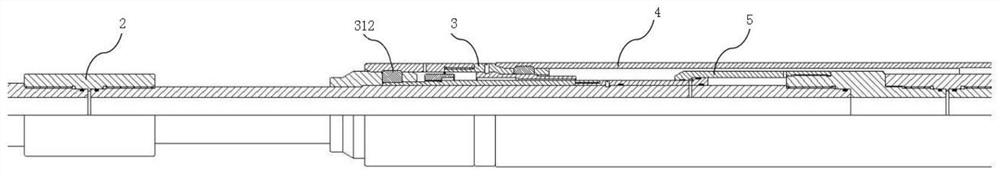

[0042] In order to make the technical solutions and advantages of the present invention clearer, the exemplary embodiments of the present invention will be described in further detail below with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than an exhaustive list of all the embodiments. Also, the embodiments of the present invention and the features of the embodiments may be combined with each other without conflict.

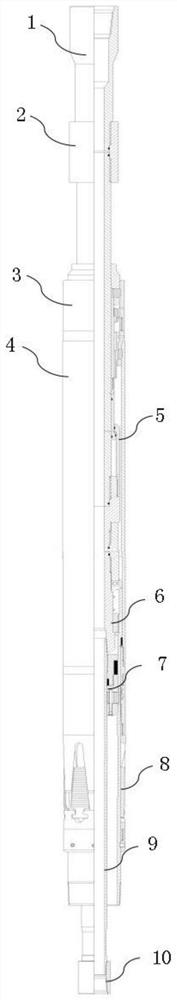

[0043] figure 1A tailpipe hanger according to one embodiment of the invention is shown schematically. According to the liner hanger of the present invention, the potential risk point and weak point of long-term stay in the well of the sitting and hanging driving mechanism are eliminated, and the pressure resistance of the liner hanger and the longevity of the pipe string sealing are greatly improved. In addition, the plug cap can effectively prevent the suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com