Ni3Al-based alloy and additive manufacturing method thereof

A technology of additive manufacturing and base alloy, which is applied in the direction of additive manufacturing and additive processing, and can solve problems such as poor mechanical properties at high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

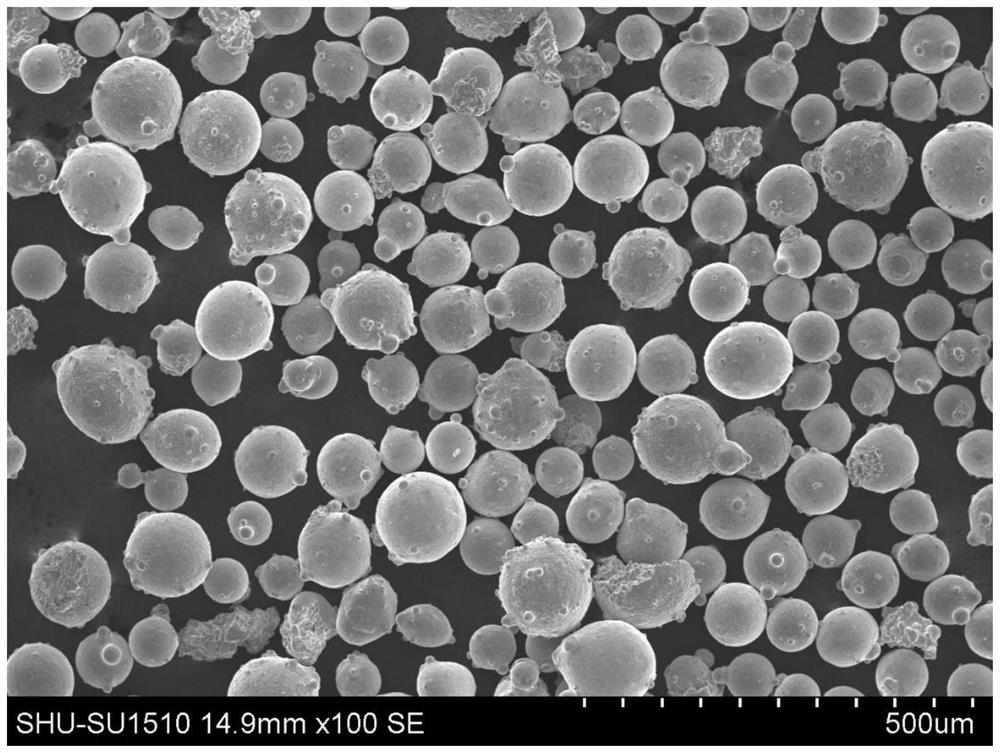

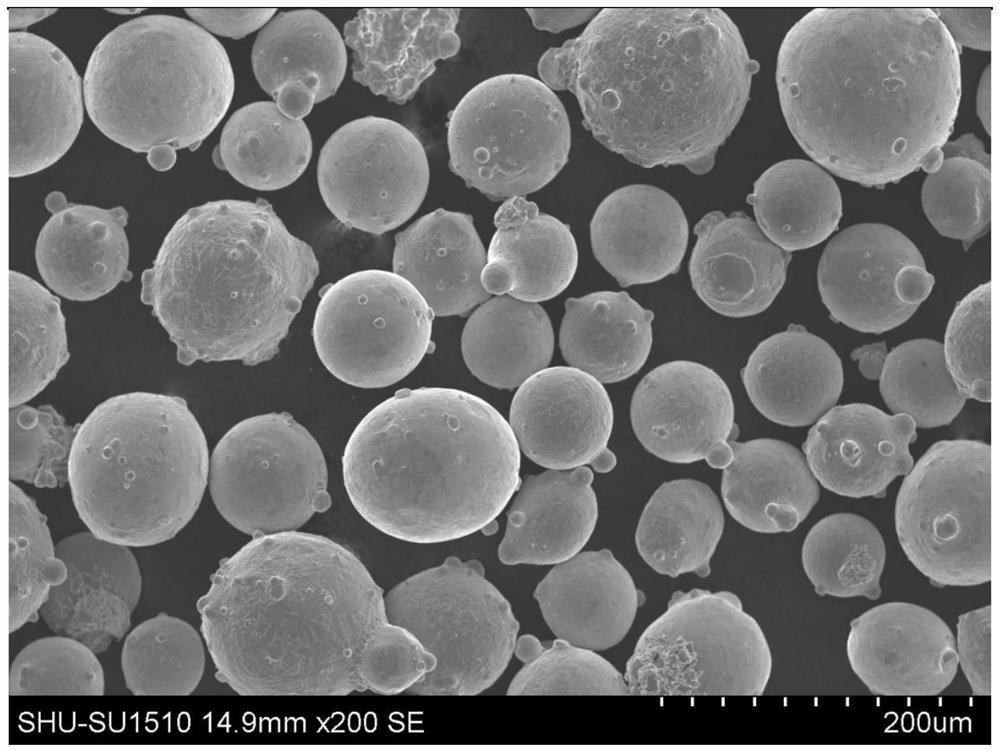

[0047] Prealloyed Ni 3 The Al powder and the pure Al powder were placed in a constant temperature vacuum drying oven for 8 hours at 120°C, and then the dried pre-alloyed Ni 3 Al powder and pure Al powder are mixed by mechanical mixing method, and then ball milled by ball mill to obtain Al-Ni rich powder with excellent sphericity and powder particle size range of 15-53 μm 3 Al alloy powder; among them, pre-alloyed Ni 3 The chemical composition of Al powder is (mass content): Ni 81.1%, Al 8%, Cr7.7%, Mo1.43%, Zr1.7%, B 0.008% and the impurity of balance;

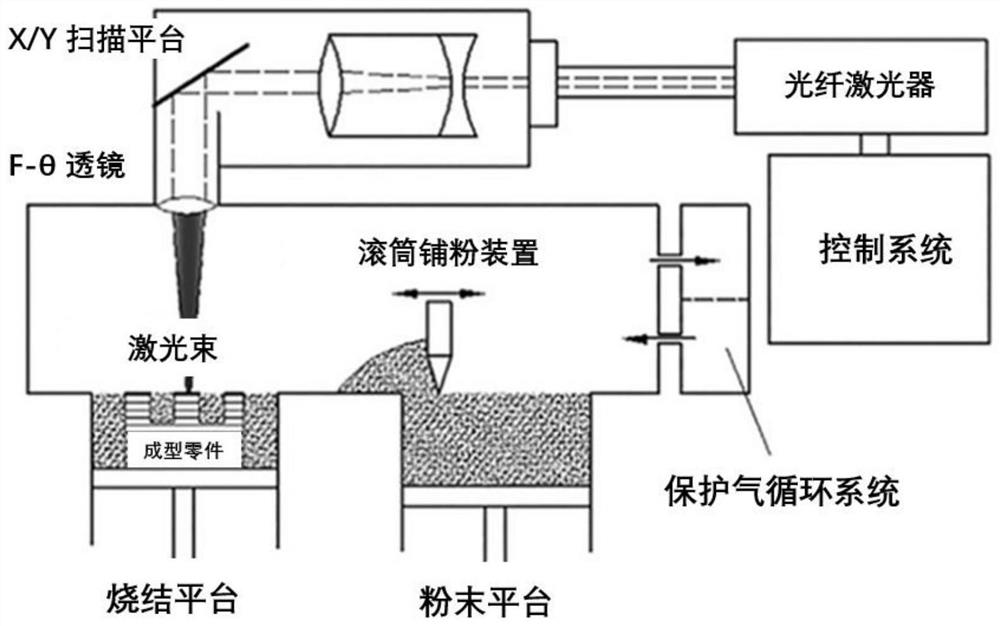

[0048] will be rich in Al-Ni 3 Al alloy powder is placed in the ProX2003D printer for selective laser melting. Hastelloy alloy substrates are used, and the surface of the substrate is polished with sandpaper. The thickness is 30 μm, and the scanning strategy is the hexagonal strategy, and the Ni 3 Al-based alloy, chemical composition (mass content): Ni 74.1%, Al 14.7%, Cr 7.7%, Mo 1.43%, Zr1.7%, B 0.008% and the balance of...

Embodiment 2

[0051] The difference from Example 1 is that the laser power is 200W.

Embodiment 3

[0053] The difference from Example 1 is that the scanning speed is 1300 mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com