Preparation method of polypropylene film layer capable of improving barrier property

A technology of polypropylene film and barrier performance, which is applied in the field of preparation of polypropylene film layer, can solve the problems of inability to enhance the barrier property of polypropylene film layer, increase gas transmission rate, and poor gas barrier property, and achieve excellent oxygen barrier performance, Good application prospects, the effect of improving barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

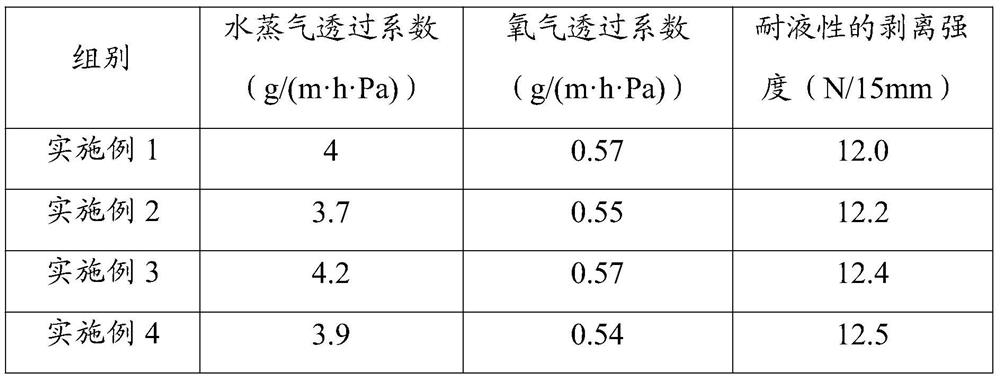

Examples

Embodiment 1

[0036] This embodiment provides a method for preparing a polypropylene film layer with improved barrier properties, which specifically includes the following steps:

[0037] (1) Preparation of isotactic polypropylene: in a dry reactor, based on the toluene solvent added every 50ml, the amount of the added reaction raw materials and catalyst is: add 25mmol alkyl aluminoxane, 15mol chain transfer agent and 0.02mmol metallocene catalyst, feed 10mmol hydrogen; feed propylene gas at a reaction temperature of 50°C, and keep the propylene reaction pressure at 1 atmosphere; obtain isotactic polypropylene after the reaction is completed; wherein, the chain transfer agent is metadiethylene Benzene, the metallocene catalyst is rac-Me 2 C(2-t-Bu-Cp) 2 ZrCl 2 , the cocatalyst is methyl aluminoxane;

[0038] (2) Preparation of silica modifier:

[0039] S1. carry out polymerization reaction with vinyl acetate, allyl glycidyl ether and initiator, obtain vinyl acetate-allyl glycidyl ether ...

Embodiment 2

[0043](1) Preparation of isotactic polypropylene: in a dry reactor, based on the toluene solvent added every 50ml, the amount of the added reaction raw materials and catalyst is: add 30mmol alkyl aluminoxane, 12mol chain transfer agent and 0.015mmol metallocene catalyst, feed 5mmol hydrogen; feed propylene gas at a reaction temperature of 15°C, keep the propylene reaction pressure at 8 atmospheres; obtain isotactic polypropylene after the reaction is completed; wherein, the chain transfer agent is p-diethylene Benzene, the metallocene catalyst is rac-Me 2 Si(2-Me-4-Naph-Ind) 2 ZrCl 2 , the cocatalyst is ethyl aluminoxane;

[0044] (2) Preparation of silica modifier:

[0045] S1. carry out polymerization reaction with vinyl acetate, allyl glycidyl ether and initiator, obtain vinyl acetate-allyl glycidyl ether copolymer;

[0046] S2. Use the vinyl acetate-allyl glycidyl ether copolymer to modify silica to obtain a silica modifier, and the weight ratio of vinyl acetate to all...

Embodiment 3

[0049] (1) Preparation of isotactic polypropylene: in a dry reactor, based on the toluene solvent added every 50ml, the amount of the added reaction raw materials and catalyst is: add 20mmol alkyl aluminoxane, 10mol chain transfer agent and 0.01mmol metallocene catalyst, feed 5mmol hydrogen; feed propylene gas at a reaction temperature of 20°C, keep the propylene reaction pressure at 2 atmospheres; obtain isotactic polypropylene after the reaction is completed; wherein, the chain transfer agent is 1,2 - Bis(4-vinylbenzene)ethane, the metallocene catalyst is rac-Me 2 Si(2-Me-4-Ph-Ind) 2 ZrCl 2 , the cocatalyst is isobutylaluminoxane;

[0050] (2) Preparation of silica modifier:

[0051] S1. carry out polymerization reaction with vinyl acetate, allyl glycidyl ether and initiator, obtain vinyl acetate-allyl glycidyl ether copolymer;

[0052] S2. Use the vinyl acetate-allyl glycidyl ether copolymer to modify silica to obtain a silica modifier, and the weight ratio of vinyl ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com