Modified polypropylene membrane, and preparation method thereof

A polypropylene film and polypropylene resin technology, applied in the field of modified polypropylene film and its preparation, can solve the problems of poor mechanical properties and water vapor barrier properties of the modified polypropylene film, and achieve improved mechanical strength, improved barrier properties, The effect of reducing the number and length of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

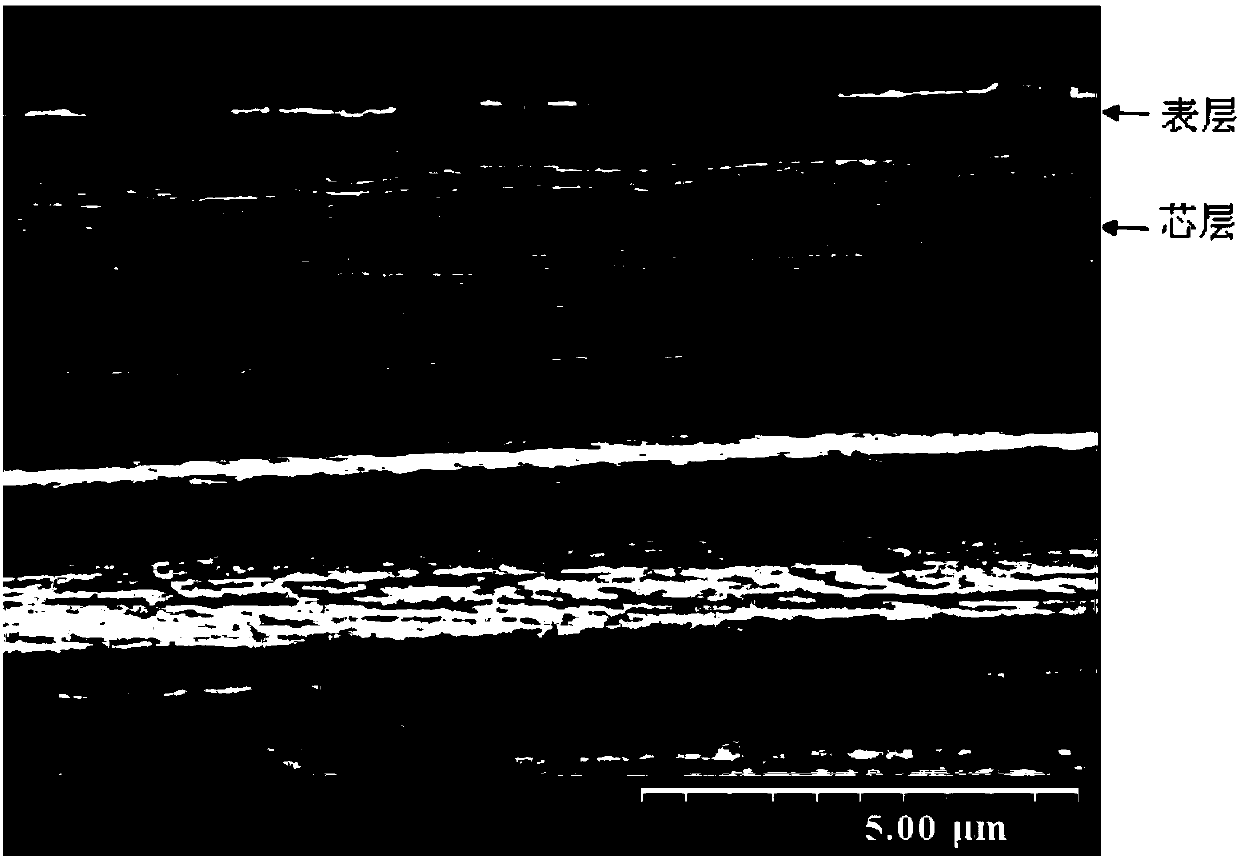

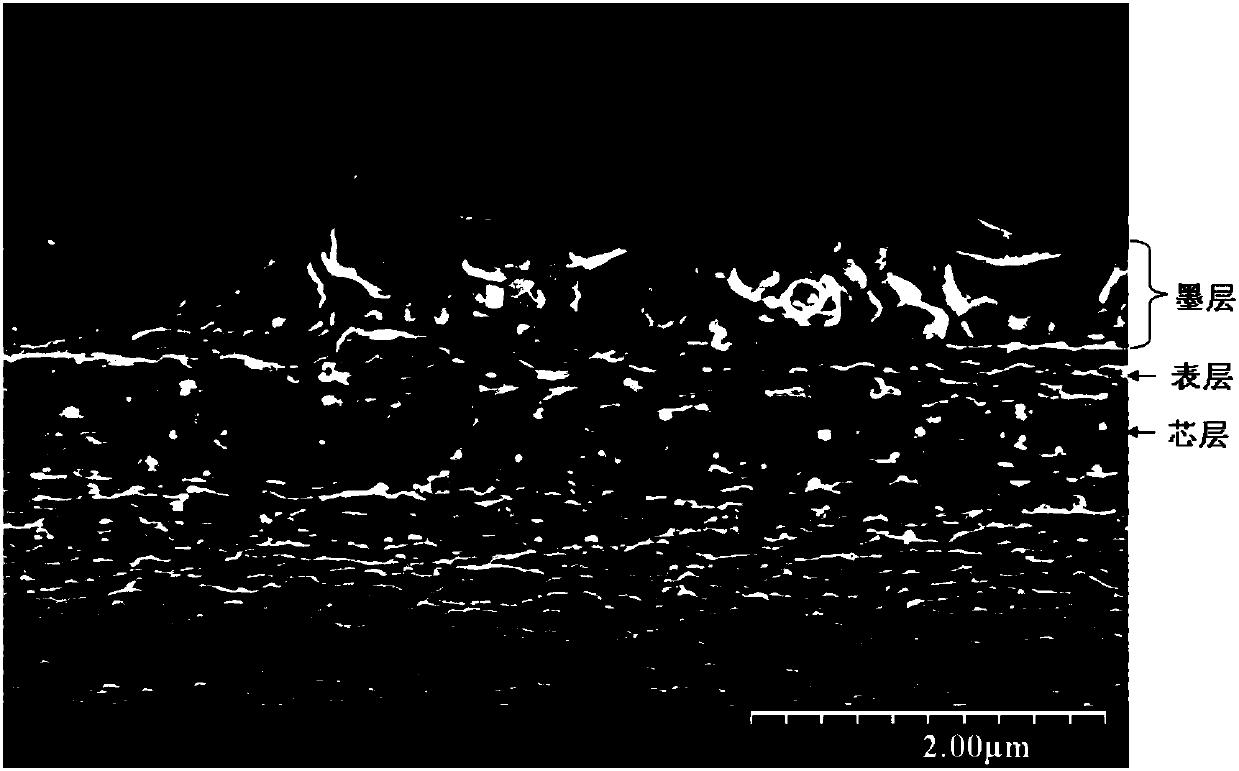

[0025] As described in the background art, the existing polypropylene film has problems of poor mechanical properties and water vapor barrier properties. In order to solve the above technical problems, the application provides a method for preparing a modified polypropylene film, the preparation method comprising: carrying out a first polymerization reaction of vinyl acetate, allyl glycidyl ether and an initiator to obtain vinyl acetate - allyl glycidyl ether copolymer; use at least part of vinyl acetate-allyl glycidyl ether copolymer to modify silica to obtain a silica modifier; and mix the first polypropylene resin with After the silicon dioxide modifier is sequentially melt-blended and biaxially stretched, a modified polypropylene film is obtained.

[0026] Both polyvinyl acetate segment and allyl glycidyl ether contain polar groups, so both have good compatibility with nano-silica. The copolymer of allyl glycidyl ether and polyvinyl acetate is used to wrap and modify nano...

Embodiment 1

[0056] Preparation of silica modifier:

[0057] Add 10 parts of AGE monomer, 200 parts of vinyl acetate monomer, and 180 parts of ethyl acetate solvent into a four-necked bottle equipped with electric stirring, condenser, and thermometer, and pass nitrogen gas for 30 minutes to remove the oxygen in the four-necked bottle. The temperature of the system was raised to 60°C, and then the ethyl acetate solution containing 0.1 part of benzoyl peroxide (containing 20 parts of ethyl acetate) was added dropwise. After 20 minutes, the dropwise addition was completed, and the temperature was raised to 70°C. Add 5 parts of distilled water into the reaction system, and then dropwise add 208 parts of ethyl orthosilicate, after 60 minutes, the dropwise addition is completed, and the temperature is kept for 3 hours to obtain the reaction product. The reaction product was vacuum-dried at 50°C to obtain a modifier (vinyl acetate-allyl glycidyl ether copolymer), wherein in the modifier, the weig...

Embodiment 2

[0062] The difference with embodiment 1 is: change the consumption of modifying agent. Specifically: 2 parts of modifying agent, 10 parts of compatibilizer and 88 parts of F280 polypropylene resin (the first polypropylene resin) are melt blended at 210-230 °C, granulated and dried to obtain modified polypropylene resin Raw materials: using an industrial biaxial stretching device, under the conditions of a longitudinal stretch ratio of 5 and a transverse stretch ratio of 10, a modified polypropylene film was obtained at a die temperature of 230° C., and the film thickness was 18 μm. The content of nano silicon dioxide in the film is 0.4wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crack length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com