A process for the production and for the winding of polyester multi-filament yarns as well as the polyester multi-filament yarns obtainable by said method and a device for the winding of one or more m

A polyester multifilament and yarn technology, applied in the direction of single-component polyester artificial filament, transportation and packaging, heat treatment of artificial filament, etc., can solve the problems of heat treatment of undisclosed yarn packages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

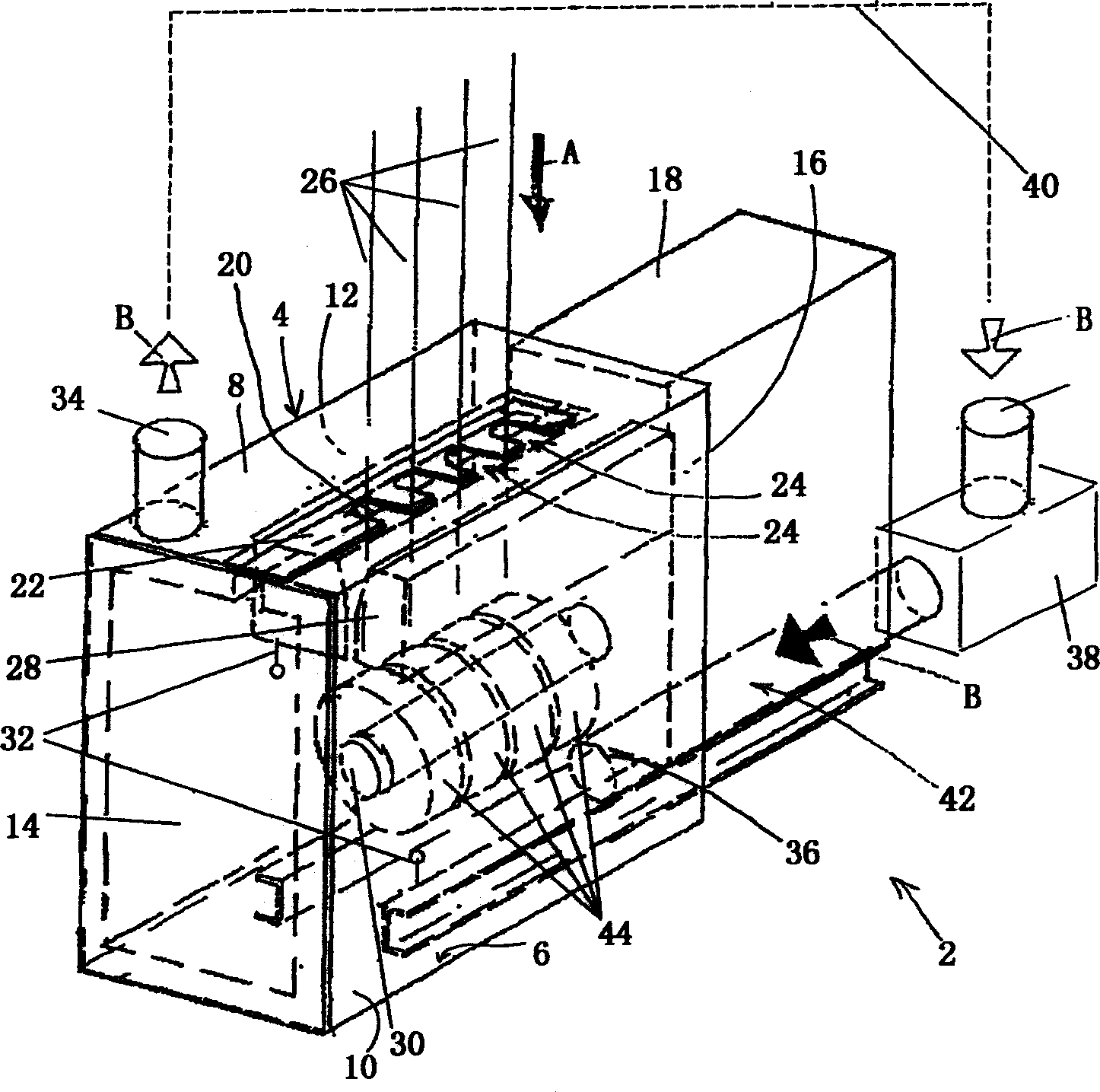

[0084] The intrinsic viscosity is 0.94dl / g, the crystallization temperature is 72 ℃, and the Corterra-type crystalline PTMT chip (Shell Oil Company (USA)) that the glass transition temperature is 45 ℃ is in a tumble drier at the temperature of 130 ℃. Dried to a moisture content of 11 ppm. The chips were melted in a 3E4 extruder produced by Barmag such that the temperature of the melt was equal to 254°C. Then the melt is transported to the spinning pump through a production line, and fed into a spinning pump, wherein the throughput of the melt to the spinning assembly is controlled to be 76.1 g / min. The melt was extruded through a spinneret with a diameter of 80 mm and 48 holes with a diameter of 0.25 mm and a length of 0.75 mm. The nozzle pressure is equal to about 120 bar.

[0085] Subsequently, the filaments were cooled in an air shaft with a cross-flow quenching system with a length of 1500 mm. The velocity of the cooling air is 0.55 m / s, the temperature is 18° C. and th...

example 2 and 3

[0097] Example 1 was repeated, except that the throughput of the melt was varied. Additionally, the heated rolls were replaced with a pair of unheated S-set godet rolls. Similar to Example 1, the multifilament yarn was wound on a winder of type SW6 (BARMAG (Germany)); wherein the bobbin carrying the yarn package fixed on the mandrel of the winder was enclosed in a housing , the housing has a slit-like opening for the multifilament yarn. The temperature in the enclosure was 63°C, which was controlled by the supply of hot air, wherein the amount of heated air supplied into the enclosure matched the amount of air exhausted. The indoor climate was set at a temperature of 24°C and a relative humidity of 60%. The exact settings for Examples 2 and 3 are listed in Table 3.

[0098] Example 2

[0099] With the method according to the invention, a package of yarn in the form of a cheese has been obtained which can be removed from the chuck without problems. A part of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com