Catalyst, preparation method thereof and application in preparation of unsaturated aldehyde (acid)

A catalyst, unsaturated technology, applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of catalyst heat resistance decrease, catalyst breakage, catalyst cracks, etc., to reduce the loss rate of Mo element , The effect of inhibiting deep oxidation of reaction and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

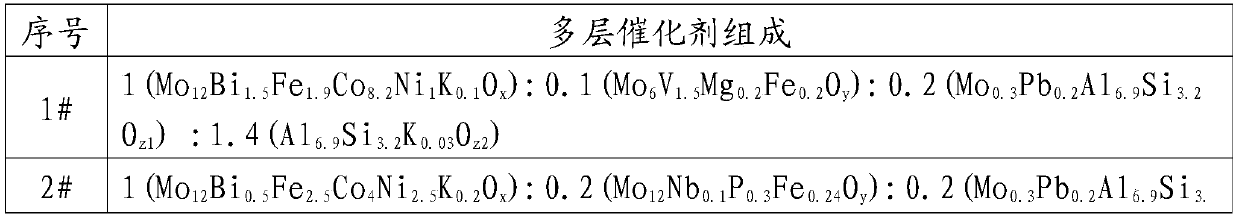

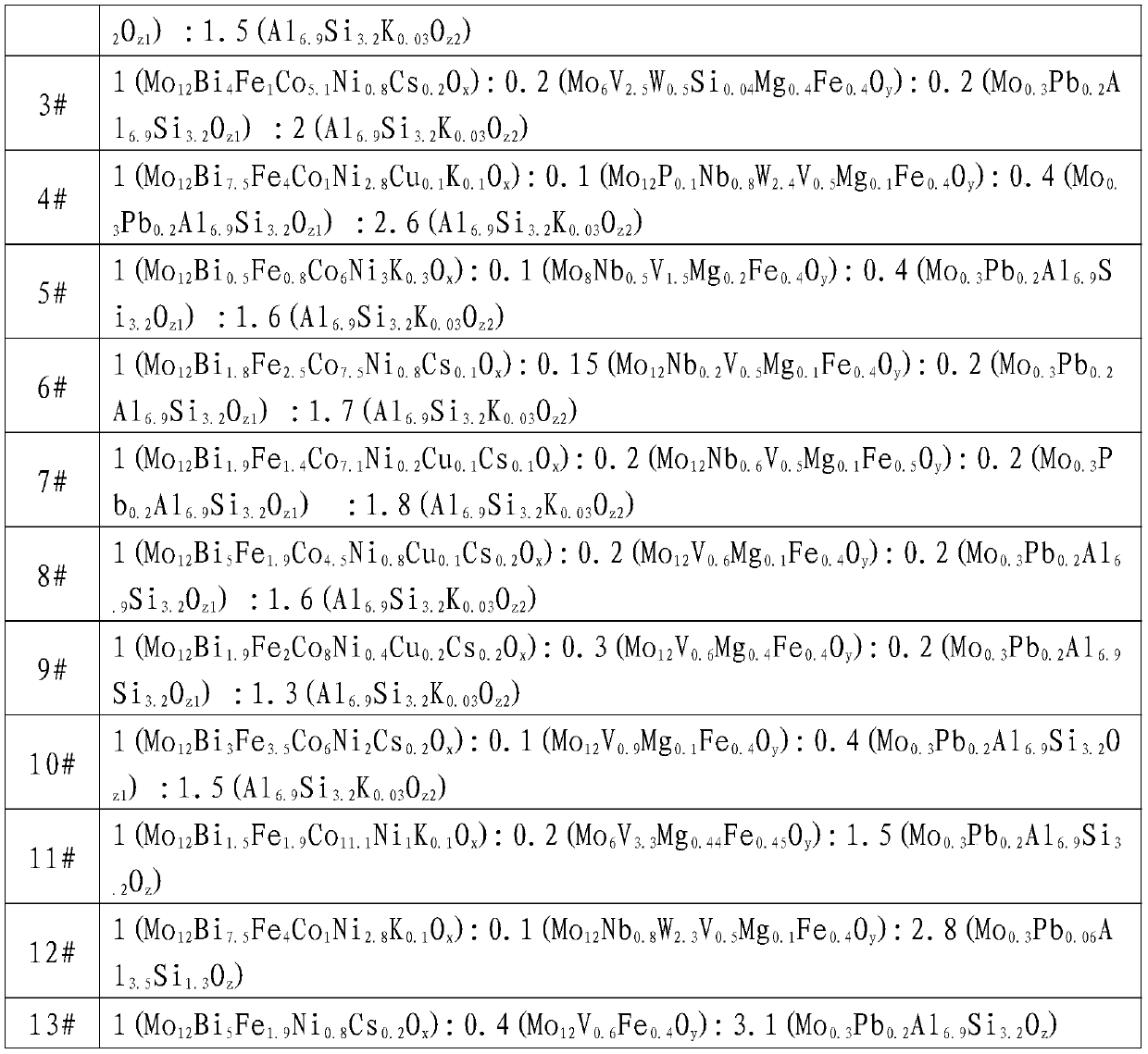

Examples

Embodiment 1

[0050] Preparation of coating catalyst 1#

[0051] (1) Preparation of outer layer catalyst powder:

[0052] Under the condition of 50° C., 4 kg of ammonium heptamolybdate (chemical formula (NH4)6Mo7O24·4H20) was dissolved in 5 L of pure water, and solution A was obtained after complete dissolution.

[0053] 1.4kg bismuth nitrate (chemical formula is Bi(NO3) 3 5H2O), 4.5kg cobalt nitrate (chemical formula is Co(NO3) 2 6H2O), 1.4kg iron nitrate (chemical formula is Fe(NO3) 3 9H2O), 19g Potassium nitrate (chemical formula is KNO3), 550g nickel nitrate (chemical formula is Ni(NO3) 6H2O) are dissolved in 4.25kg dilute nitric acid aqueous solution (15wt%), obtain solution B after dissolving completely.

[0054] Keep the solution temperature at 65°C, add solution B dropwise to solution A while stirring, adjust the pH to 3 with ammonia water during the addition process, stir and mature for 6 hours, dry at 250°C, and roast at 350°C for 4 hours to obtain the outer layer Catalyst powde...

Embodiment 2

[0070] Preparation of coating catalyst 2#

[0071] (1) Preparation of outer layer catalyst powder:

[0072] Under the condition of 50°C, 4 kg of ammonium heptamolybdate was dissolved in 5 L of pure water, and solution A was obtained after complete dissolution.

[0073] 460g of bismuth nitrate, 2.2kg of cobalt nitrate, 1.9kg of iron nitrate, 1.4kg of nickel nitrate, and 38g of potassium nitrate were dissolved in 4.25kg of dilute nitric acid aqueous solution (15wt%) to obtain solution B after completely dissolving.

[0074] Keep the solution temperature at 65°C, add solution B to solution A while stirring, and then adjust the pH to 0.8 with ammonia water. After adjustment, stir and mature for 6 hours, dry at 80°C, and roast at 350°C for 4 hours to obtain outer layer catalyst powder with a thermal expansion coefficient of 7.1*10 -6 m / m.K.

[0075] (2) Preparation of middle layer catalyst powder:

[0076] Under the condition of 90°C, 3.1kg ammonium heptamolybdate, 1.1kg molybd...

Embodiment 3

[0084] Preparation of coated catalyst 3#

[0085] (1) Preparation of outer layer catalyst powder:

[0086] Under the condition of 60°C, 4 kg of ammonium heptamolybdate was dissolved in 5 L of water, and solution A was obtained after complete dissolution.

[0087] With 3.6kg bismuth nitrate, 2.8kg cobalt nitrate, 760g iron nitrate, 440g nickel nitrate, 62g cesium carbonate (chemical formula is Cs 2 CO 3 ) into 5kg dilute nitric acid aqueous solution (15wt%), and obtain solution B after dissolving completely. Keep the solution temperature at 80°C, add solution B to solution A while stirring, and then adjust the pH to 6.5 with ammonia water. After adjustment, stir and mature for 6 hours, dry at 160°C, and roast at 350°C for 4 hours to obtain outer layer catalyst powder with a thermal expansion coefficient of 7.5*10 -6 m / m.K.

[0088] (2) Preparation of middle layer catalyst powder:

[0089] At 60°C, 4kg ammonium heptamolybdate, 1.1kg ammonium metavanadate, 523.2g silicotung...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com