Device and method for reducing thermal fatigue in cold and thermal fluid mixing process in T-shaped pipe

A fluid mixing and thermal fatigue technology, applied in the direction of pipeline protection, pipeline damage/wear prevention, pipe/pipe joint/pipe fittings, etc. The effect of weakening thermal shock and improving energy spectrum characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

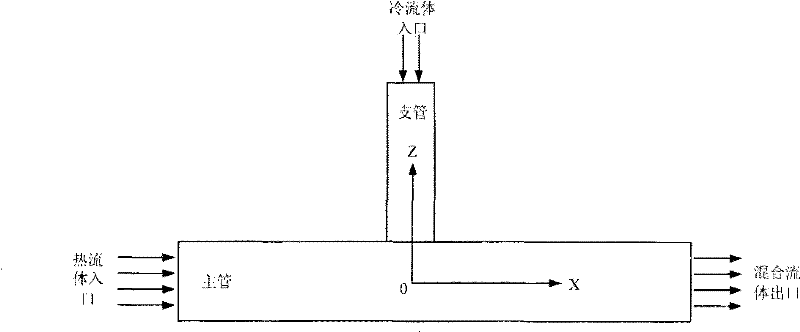

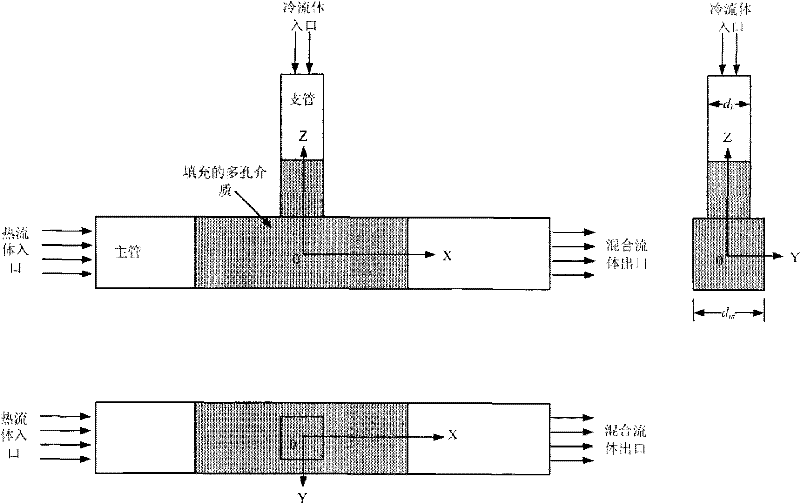

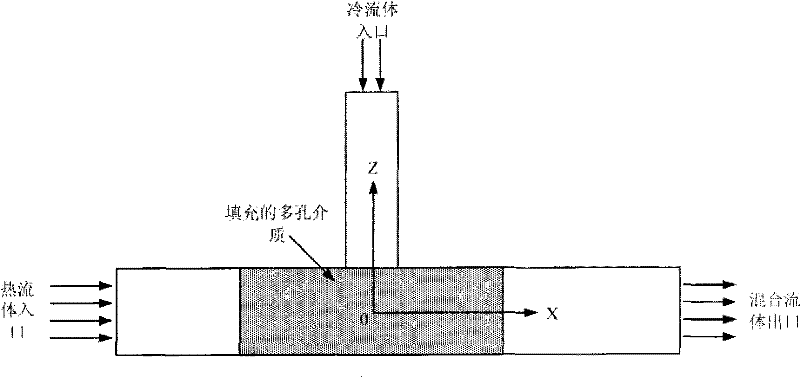

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0024] A method for reducing thermal fatigue during the mixing of hot and cold fluids in a T-shaped pipe of the present invention is as follows: reducing the thermal fatigue of the T-shaped pipe by filling the hot and cold fluid mixing zone of the T-shaped pipe with porous media. Among them, the cross-sectional shape of each branch of the T-shaped pipe can be circular, rectangular or elliptical, the angle between the axes of the two inlet branch and the outlet branch can be any angle, the cross-sectional area of each branch can be unequal, and the T-shaped pipe can be placed arbitrarily. The hot and cold fluids can be the same fluid or different fluids. The flow of the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com