Regenerative thermal oxidation device and process for processing electroplating sludge sintering waste gas

A technology of thermal oxidation and electroplating sludge, which is applied in heat storage equipment, incinerators, combustion methods, etc., can solve problems such as low heat recovery efficiency, large fluctuations in calorific value of combustible components, and difficult cleaning of bed blockages. Low, ensure long-term safe operation, increase the effect of process unit life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

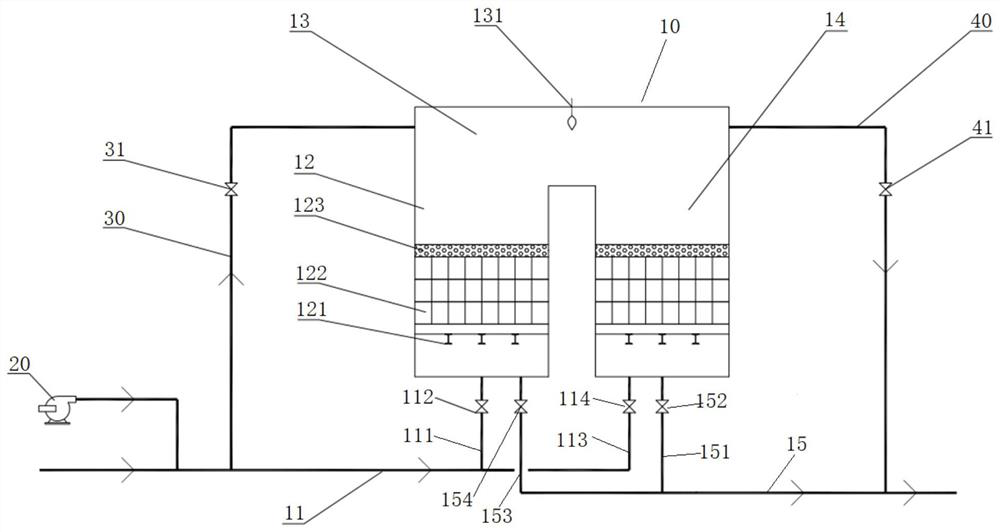

[0039] Such as figure 1 As shown, the regenerative thermal oxidation device for treating electroplating sludge sintering waste gas provided by the present invention includes a regenerative thermal oxidation furnace 10 and a frequency conversion fresh air fan 20 . The regenerative thermal oxidation furnace 10 is a two-chamber RTO, including an inlet pipe 11 , a first regenerator 12 , a combustion chamber 13 , a second regenerator 14 , and an outlet pipe 15 . The inlet pipeline 11 is divided into a first inlet pipeline 111 connected with the first regenerator 12 and a second inlet pipeline 113 connected with the second regenerator 14, and a first inlet switching valve 112 is arranged on the first inlet pipeline 111. A se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com