High-temperature plasma vitrification device for sludge and treatment method thereof

A high-temperature plasma and vitrification technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of energy consumption, high cost, difficult control, etc., and achieve low installed power. , Small footprint, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

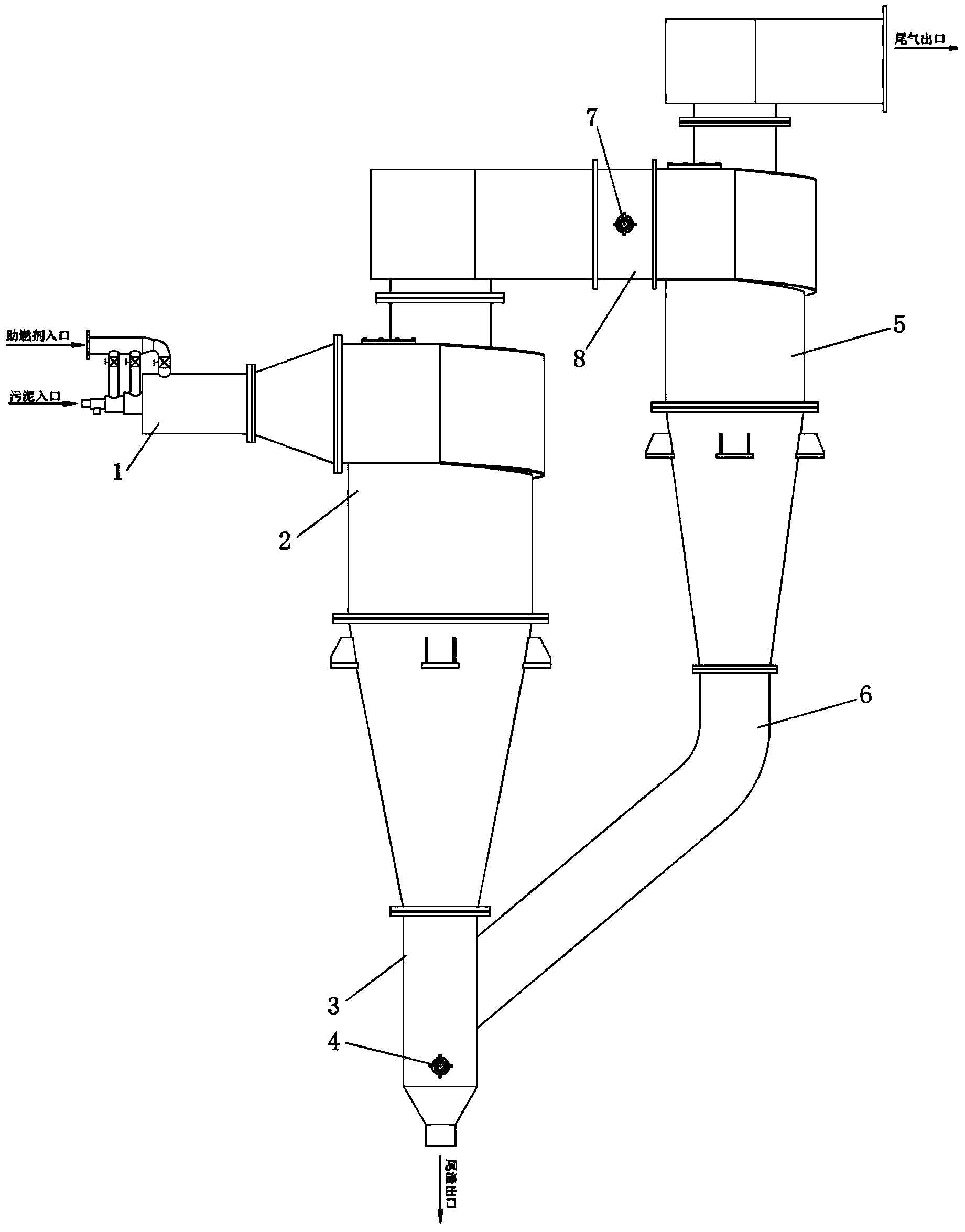

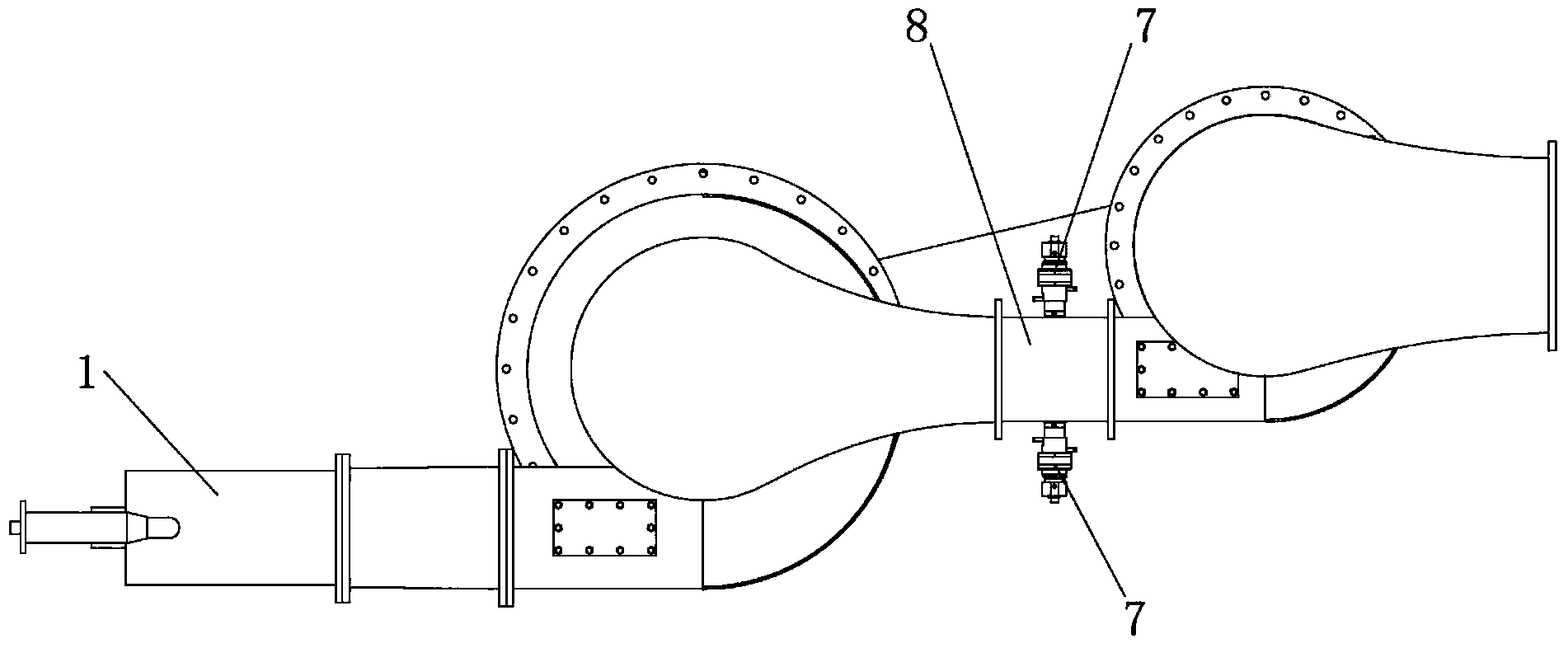

[0023] Such as figure 1 with figure 2 Shown, the present invention is realized like this, and it comprises sludge burner 1, the first catcher 2, vitrification furnace 3, the first high-temperature plasma torch 4, the second catcher 5, collection pipeline 6, the first Two high-temperature plasma torches 7, pipelines 8 and tailings outlets 9, one end of the sludge burner 1 is provided with a combustion aid inlet and a sludge feed port, and the other end of the sludge burner 1 is respectively connected to the first collecting The upper end of device 2 and one end of pipeline 8;

[0024] The lower end of the first collector 2 is connected to the upper end of the vitrification furnace 3, the lower end of the vitrification furnace 3 is provided with a tailings outlet for discharging molten sludge, and the vitrification furnace 3 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com