Low-heat-value sludge bubbling type internal circulating fluidized bed incinerator capable of achieving self-sustaining burning

A self-sustaining incineration and incinerator technology, which is applied in fluidized bed combustion equipment, incinerators, combustion methods, etc., can solve problems such as difficult to achieve self-sustaining combustion, and achieve the effects of easy temperature stability, small supply, and uniform air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

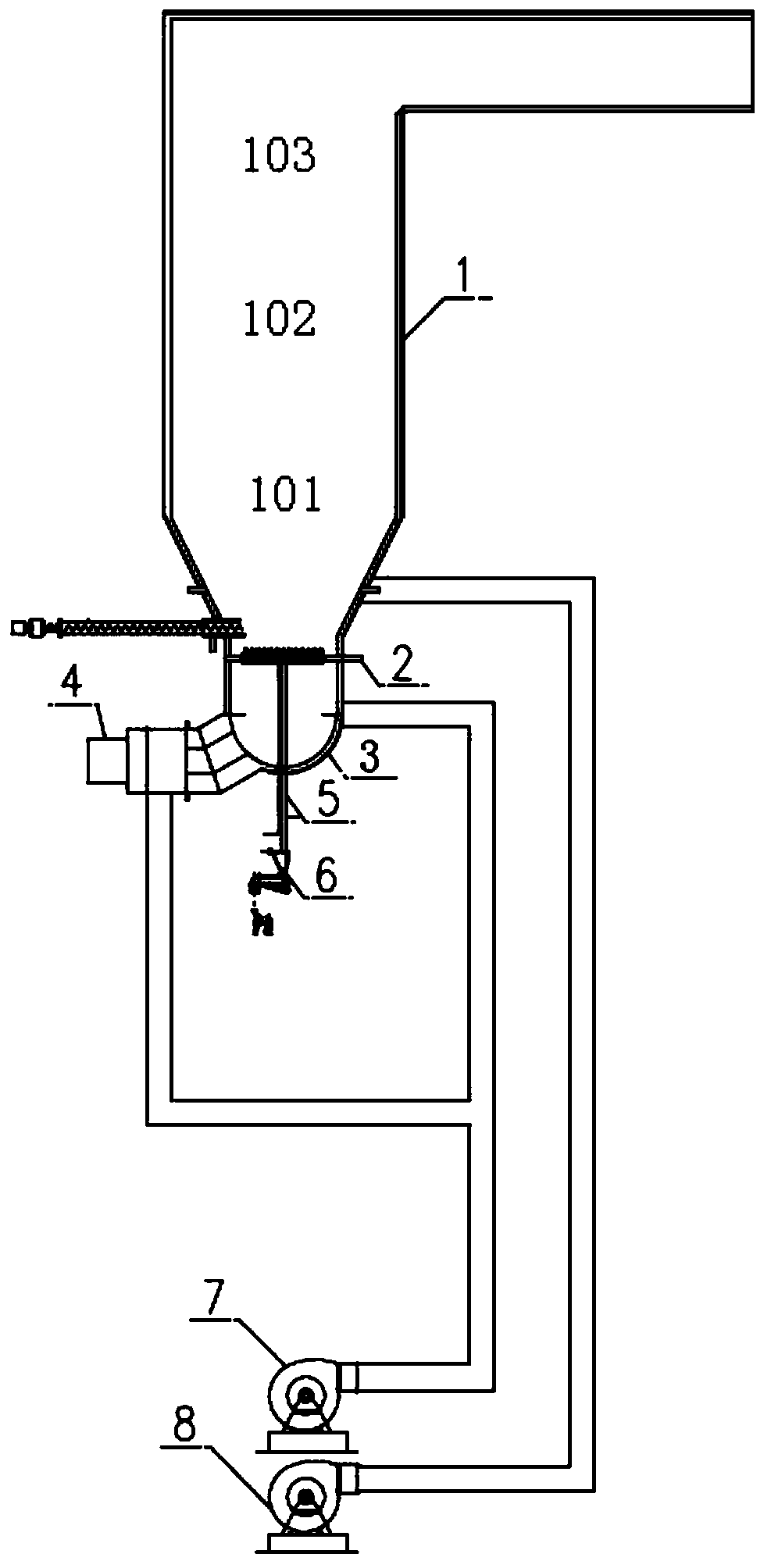

[0032] A bubbling internal circulating fluidized bed incinerator capable of self-sustaining incineration of low calorific value sludge, such as figure 1 As shown, the bottom of the furnace hall is equipped with a water-cooled air distribution plate 2, and an air chamber 3 is provided under the water-cooled air distribution plate 2. The air chamber 3 is connected with the igniter 4, and the slag discharge pipe 5 passes through the air chamber from the water-cooled air distribution plate 2. 3 is connected to the vibrating slag discharger 6 outside the furnace hall. The furnace hall is arranged vertically and is divided into dense phase area 101, dilute phase area 102 and transition area 103 from bottom to top. The air chamber 3 has a primary air duct connected to the primary fan 7, and the dense phase area of the furnace hall has a secondary air The pipe is connected with the secondary blower 8.

Embodiment 2

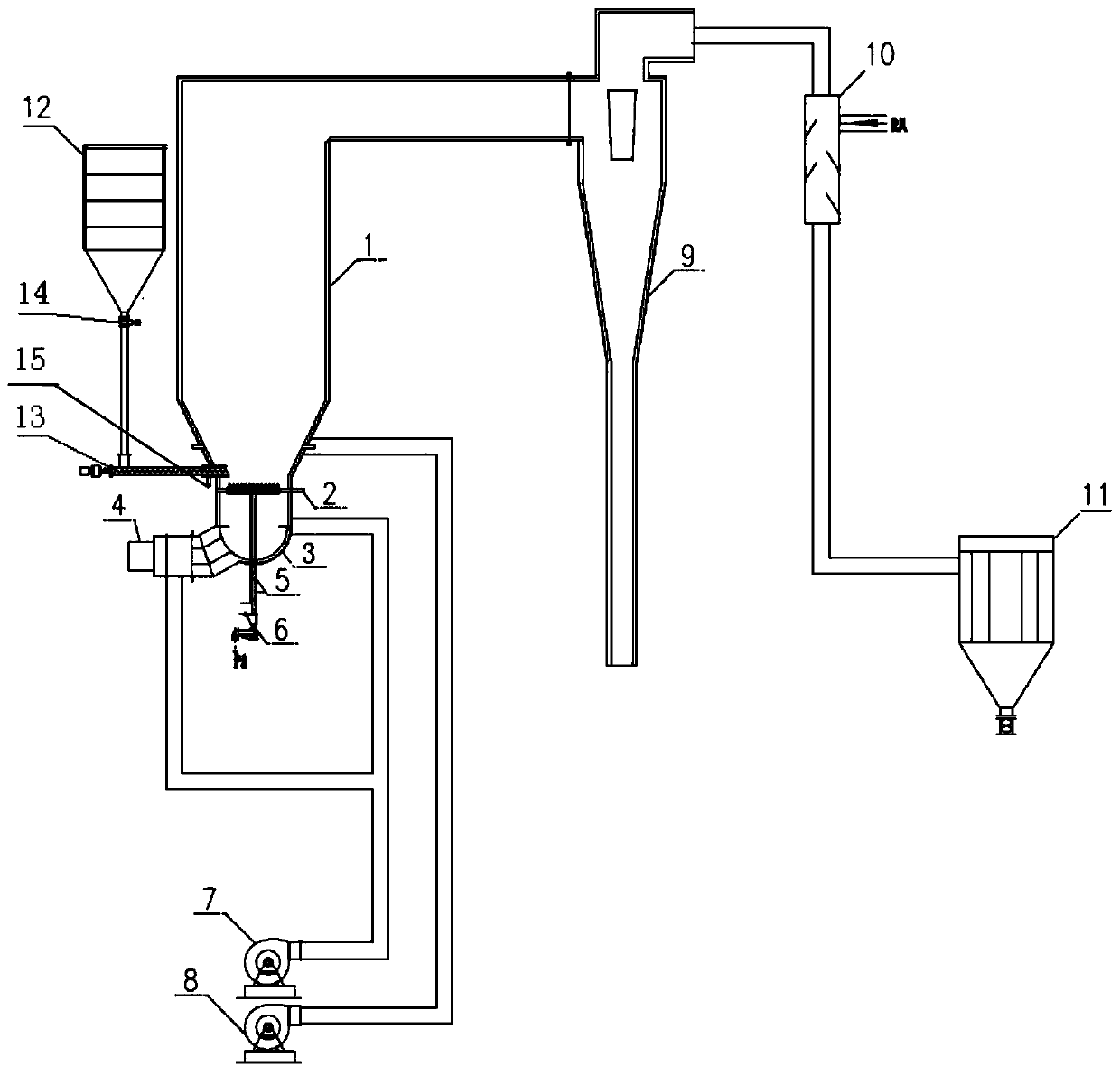

[0034] incinerator such as figure 2 As shown, on the basis of Example 1, the top opening of the furnace body is connected to the cyclone dust collector 9, and the outlet flue of the cyclone dust collector is provided with an air distribution chamber 10 and a gas-solid separator 11 for secondary purification of smoke and dust. The bubbling internal circulating fluidized bed incinerator for self-sustained incineration of low calorific value sludge also includes a dry sludge storage bin 12 connected to the furnace body. The dry sludge storage bin 12 is a cylindrical container with a cone at the bottom. At the discharge port of the cone, there is a feeder 14 that can adjust the amount of dry sludge. The front end of the feeder has a sowing wind. When adding fuel to the furnace body, the feeder blows the sowing air into the furnace at the same time. The feeder is a frequency conversion screw feeder 13 with a sowing wind. Dosing.

[0035]The furnace hall is vertically arranged, a...

Embodiment 3

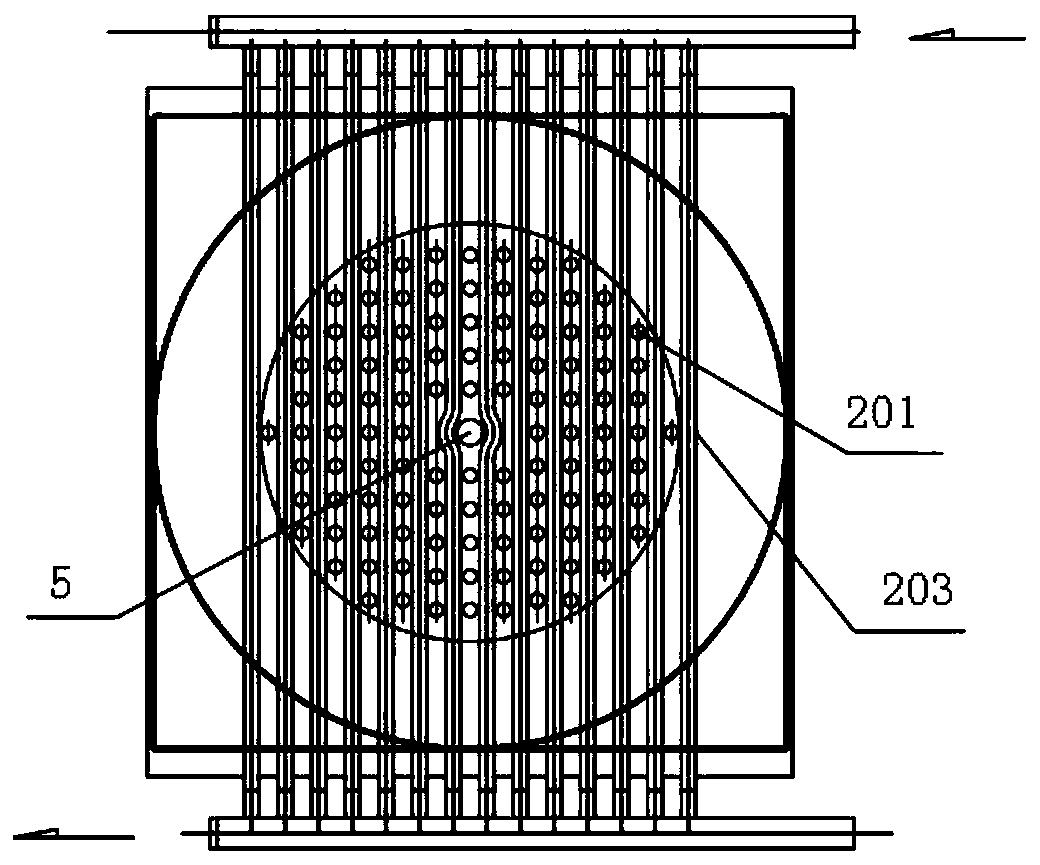

[0038] On the basis of embodiment 1 or 2, such as image 3 As shown, the upper and lower sides of the water-cooled air distribution plate 2 at the bottom of the furnace hall are covered with refractory materials to reduce the heat absorption of the water-cooled air distribution plate 2 during the ignition process. The water-cooled air distribution plate 2 consists of uniformly arranged hoods 201 ( Figure 4 ) and a plurality of water-cooling tubes 203 arranged in parallel, the air cap opening 202 is arranged in two or more layers, and the opening has a certain downward angle to ensure uniform air distribution and no backflow of bed materials; the air chamber 3 is a relatively large The large space is used to eliminate the pressure fluctuation of the primary fan 7 and ensure the stable operation of the fluidized bed.

[0039] The slag discharge pipe 5 is provided with a slag discharge port in the middle of the water-cooled air distribution plate 2. The slag discharge pipe 5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com