Air cooler for finned flat tube integrated structure

A technology of finned flat tubes and air coolers, applied in the field of refrigeration and refrigeration, which can solve the problems of performance degradation of the refrigeration system, incomplete cleaning of defrosting water, and reduction of heat transfer coefficient, so as to reduce heat transfer temperature difference and eliminate contact thermal resistance , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the drawings and specific embodiments.

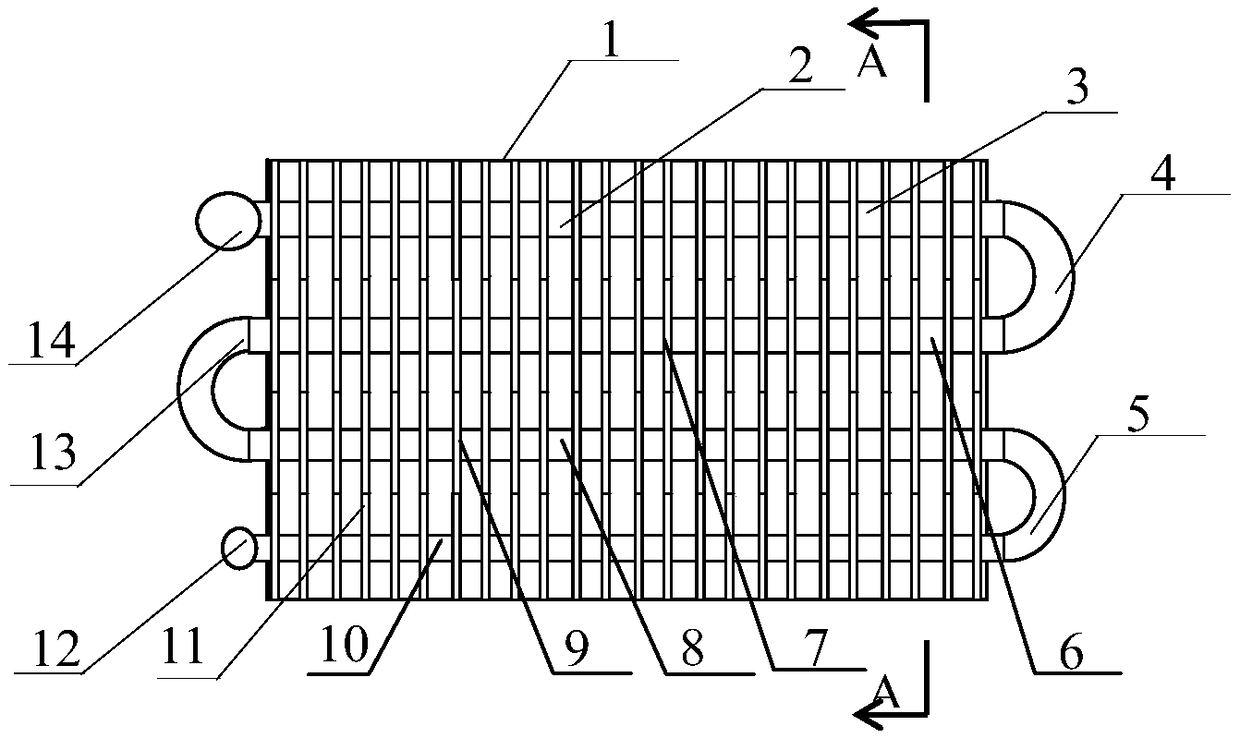

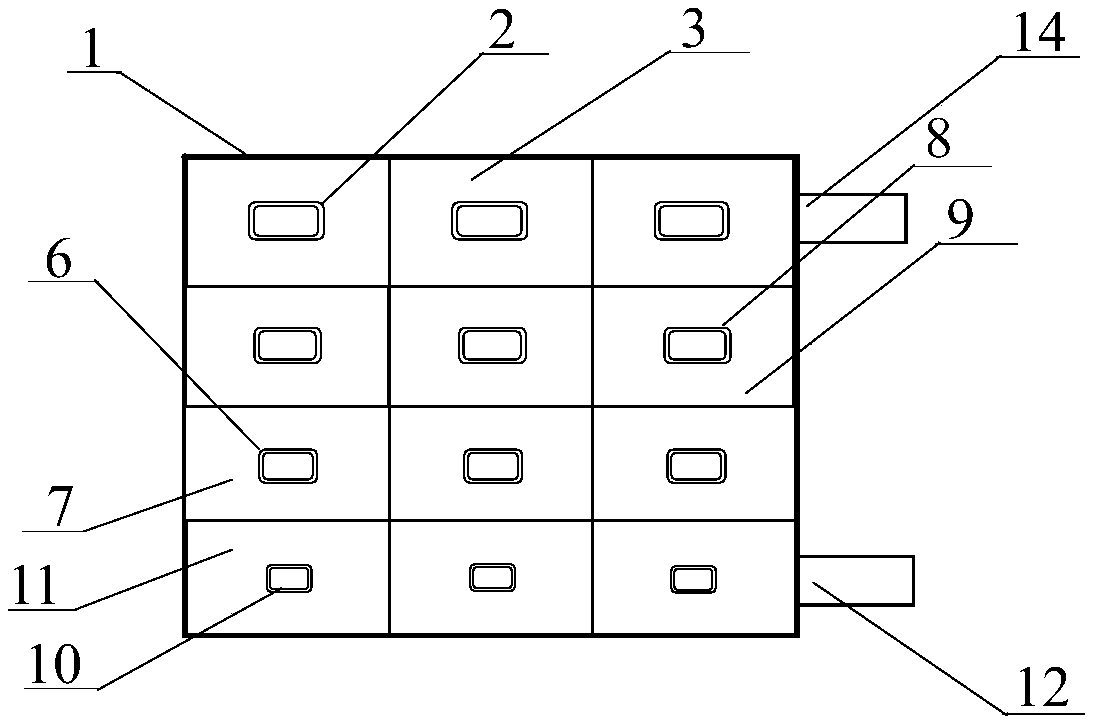

[0014] Such as Figure 1 to Figure 2 As shown, the air cooler with integrated finned tube structure includes:

[0015] Frame 1, first flat tube 2, first flat tube fin 3, third elbow 4, first elbow 5, second flat tube 6, second flat tube fin 7, third flat tube 8, first Three flat tube fins 9, a fourth flat tube 10, a first flat tube fin 11, a liquid supply tube 12, a second elbow 13, and a gas collection tube 14.

[0016] The first flat tube 2 and the first flat tube fin 3 outside the tube, the second flat tube 6 and the second flat tube fin 7 outside the tube, the third flat tube 8 and the third flat tube fin outside the tube The fin 9, the fourth flat tube 10 and the first flat tube fin 11 outside the tube are all formed by a single integral cold-worked structure. The first flat tube 2, the second flat tube 6, the third flat tube 8, the fourth flat tube The int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com